Exhaust device and engine

An exhaust device and engine technology, applied in the direction of exhaust devices, engine components, machines/engines, etc., can solve the problem of easy water ingress in the exhaust pipe, achieve huge market application potential, reasonable structural design, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

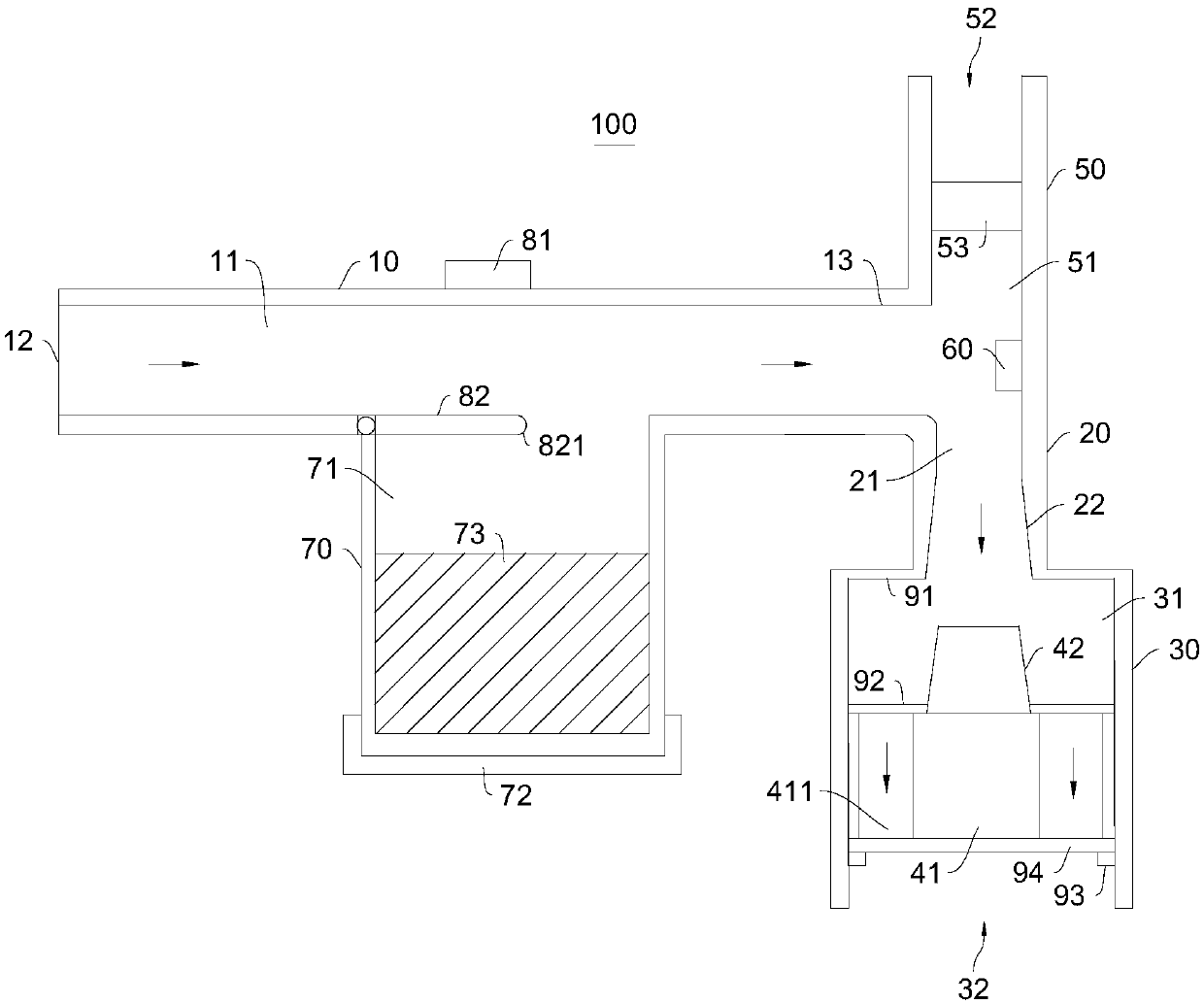

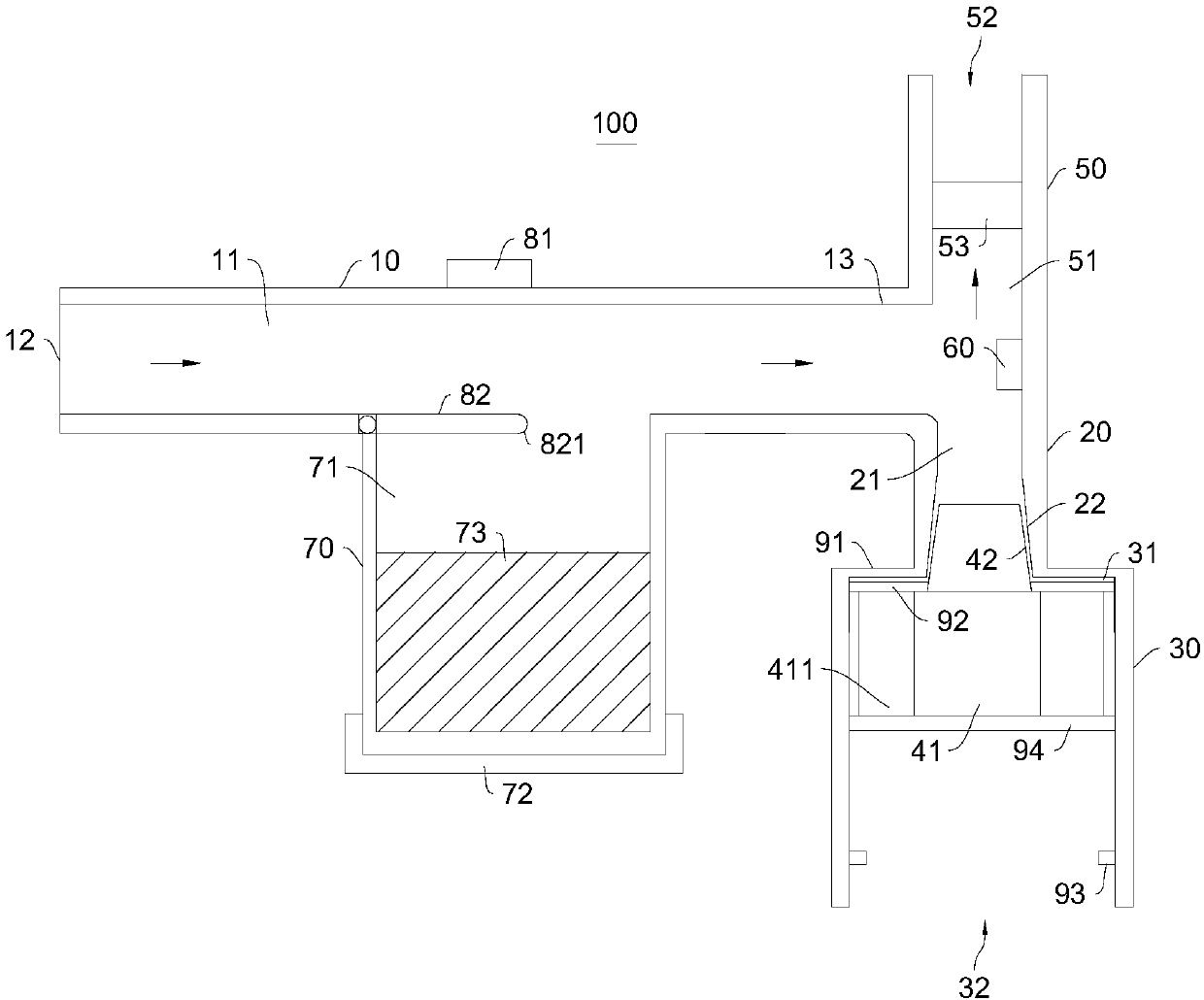

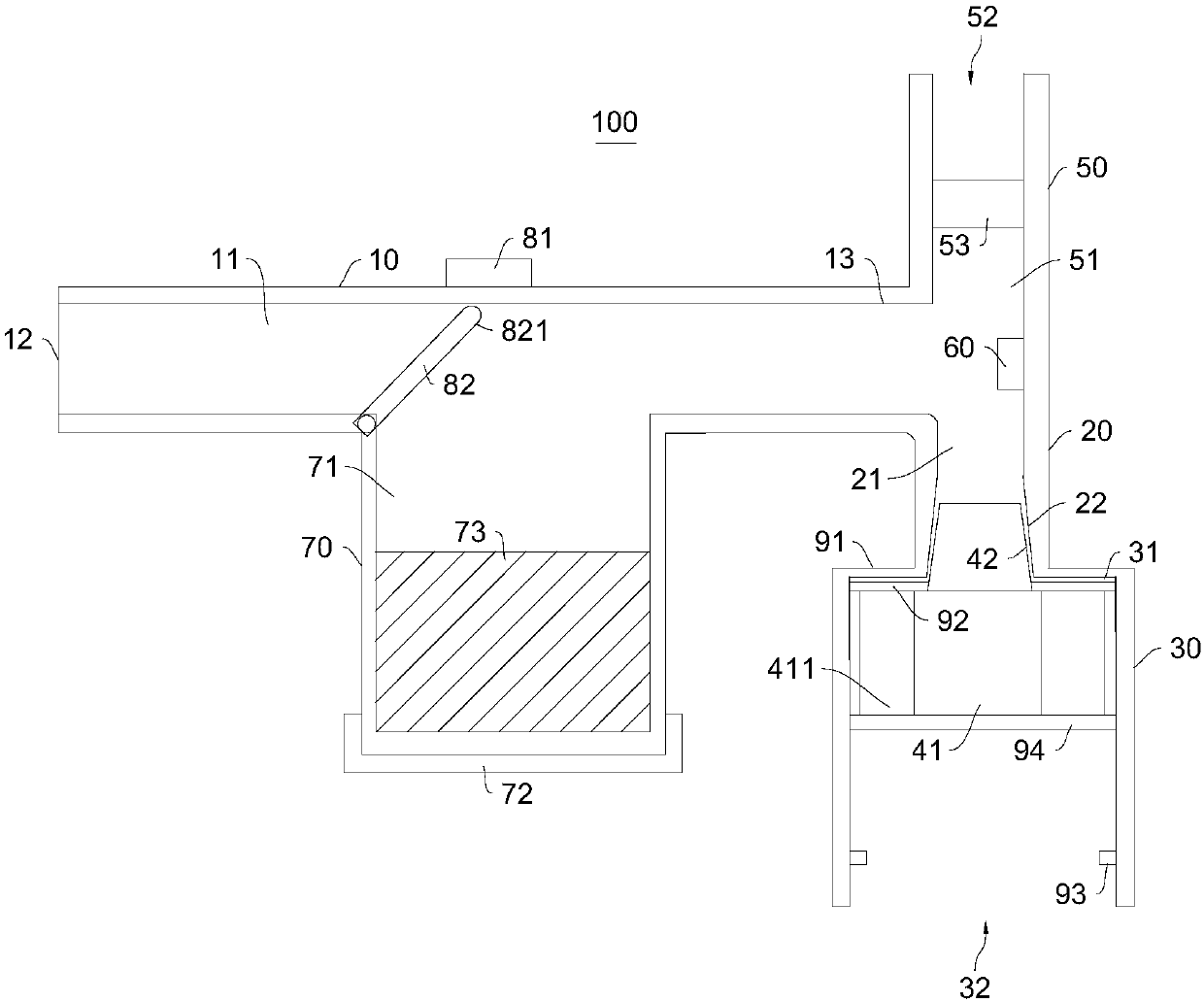

[0043] Please refer to Figure 1-Figure 4 , the present embodiment provides an exhaust device 100, which includes:

[0044] An exhaust main pipe 10, the exhaust main pipe 10 has an exhaust main channel 11, and one end of the exhaust main pipe 10 is used to communicate with the exhaust end of the engine body;

[0045] The first exhaust pipe 20, the first exhaust pipe 20 has a first exhaust passage 21, the first exhaust pipe 20 is connected to the main exhaust pipe 10 and communicates with the main exhaust passage 11 and the first exhaust passage 21;

[0046] Exhaust piece 30, the exhaust piece 30 has an exhaust chamber 31, one end of the exhaust piece 30 communicates with the first exhaust pipe 20, and the other end of the exhaust piece 30 has a first exhaust port communicated with the exhaust chamber 31 32. The opening direction of the first exhaust port 32 is vertically downward;

[0047] The floating block 40, the floating block 40 is located in the exhaust chamber 31, the f...

Embodiment 2

[0093] This embodiment also provides an engine, which includes the exhaust device 100 mentioned above, which has all the functions of the exhaust device 100 .

[0094] For the structure of the exhaust device 100, reference may be made to Embodiment 1.

[0095] The engine also includes an engine body and a silencing device. The exhaust gas produced by the engine body enters the main exhaust passage 11 after being processed by the silencing device for noise reduction.

[0096] When the above-mentioned exhaust device 100 is selected for the engine, the service life of the engine body can be effectively extended.

[0097] To sum up, the present invention provides an exhaust device 100. The exhaust device 100 adopts the design of the floating block 40. When water flows in, the floating block 40 moves up to realize sealing, preventing the exhaust pipe from entering water, thereby effectively Prevent water from flowing into the engine, effectively prolonging the service life of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com