Compensation gear pump for annular spoke springs

A technology of spring compensation and gear pump, which is applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of no effective compensation methods and measures, end face wear can not be effectively compensated, etc., to achieve market application potential Huge, easy to manufacture, innovative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure and working principle of the present invention will be further described in detail with reference to the drawings and embodiments.

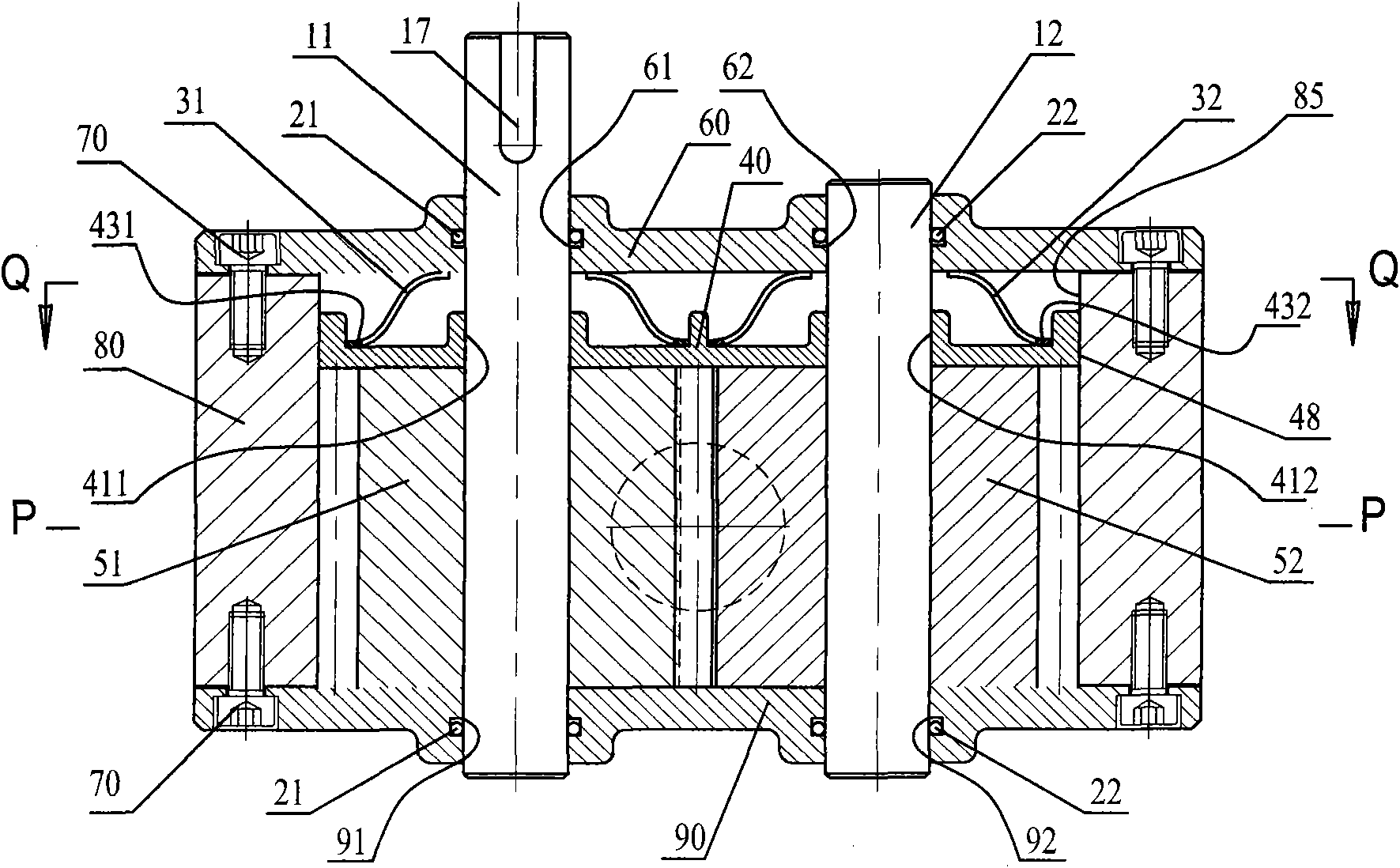

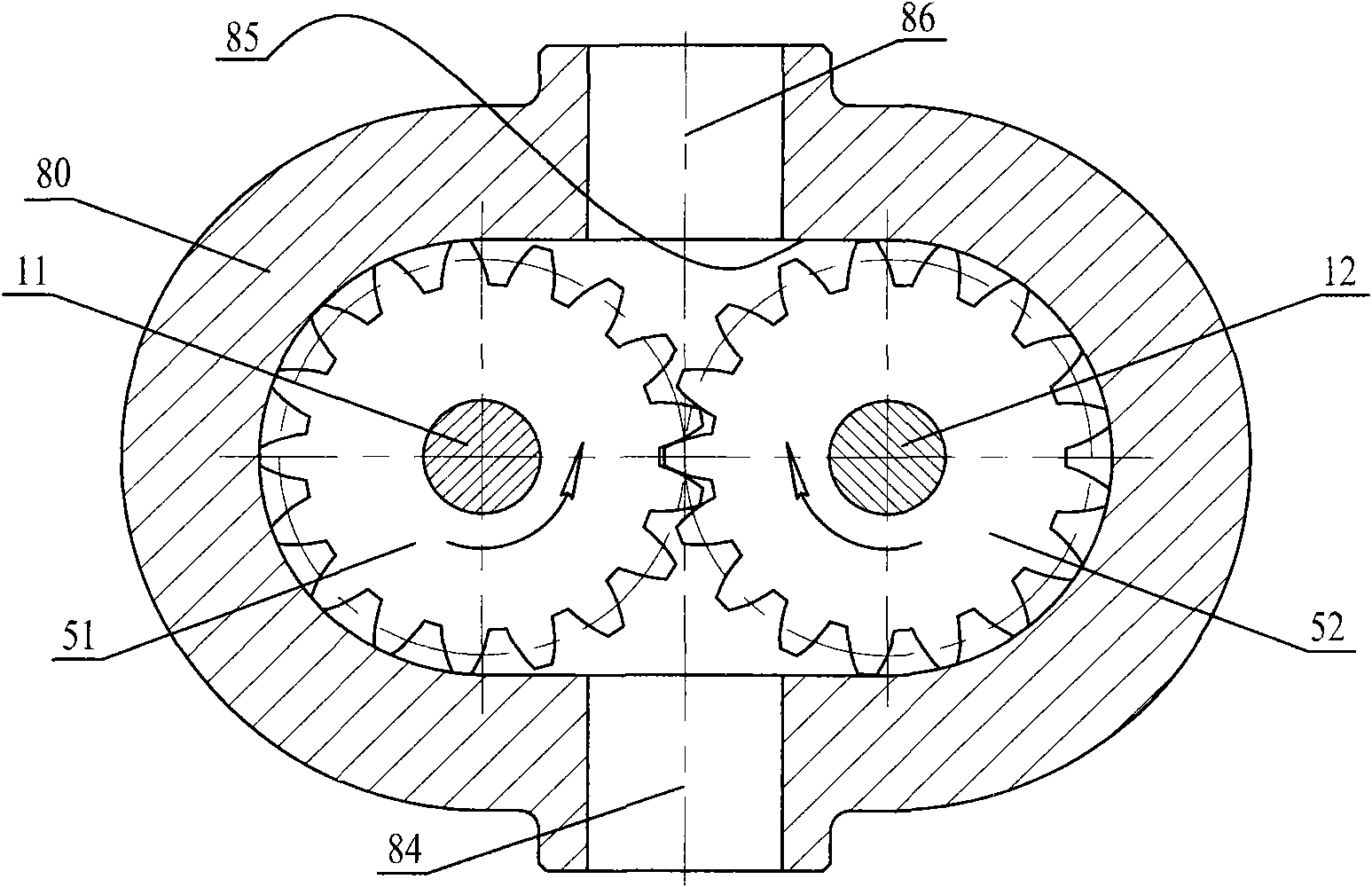

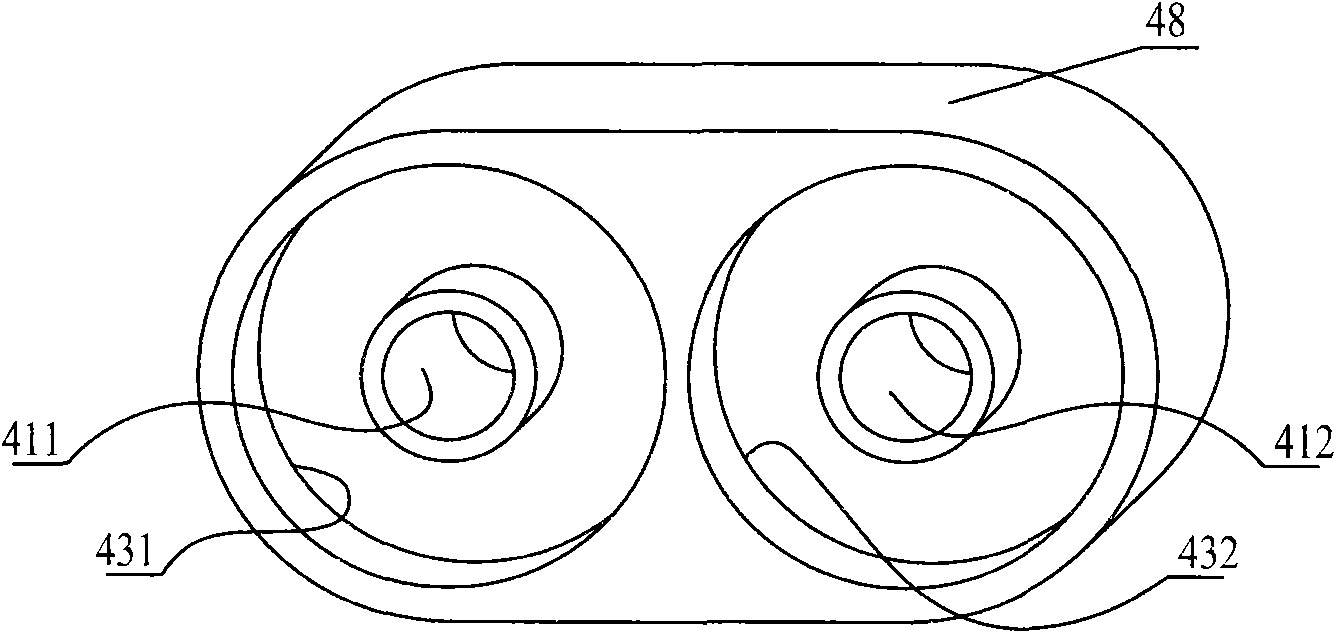

[0018] A ring spoke spring compensation gear pump, comprising a driving shaft 11, a driven shaft 12, a master gear 51, a slave gear 52, a ring spoke main spring 31, a ring spoke slave spring 32, an end surface compensation disc 40, a front outer end cover 60, End cover screw 70, pump body 80, rear outer end cover 90, the two ends of the pump body 80 are perpendicular to the double semicircular holes 85, and the front outer end cover 60 and the rear outer end cover 90 are respectively covered on the two ends. There are end cover screws 70 to fasten; the front cover driving shaft hole 61 of the front outer end cover 60 and the rear cover driving shaft hole 91 of the rear outer end cover 90 are on the same axis; the front outer end cover 60 of the The front cover driven shaft hole 62 and the rear cover driven shaft hole 92 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com