Automatic cooling device and clothing

An automatic cooling and polymer technology, applied in clothing, protective clothing, special outerwear, etc., can solve the problems of poor use effect and easy heat stroke for users, and achieve better use effect, reasonable structure design and huge market application potential. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

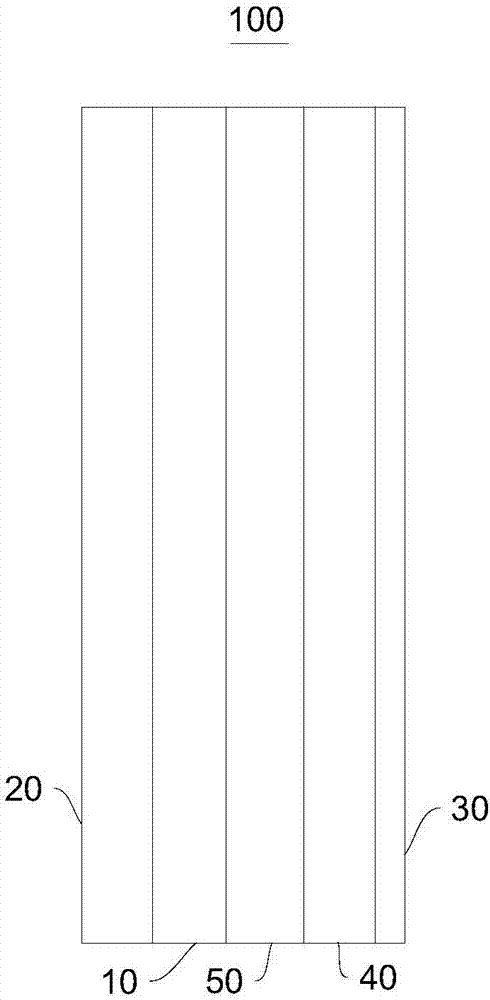

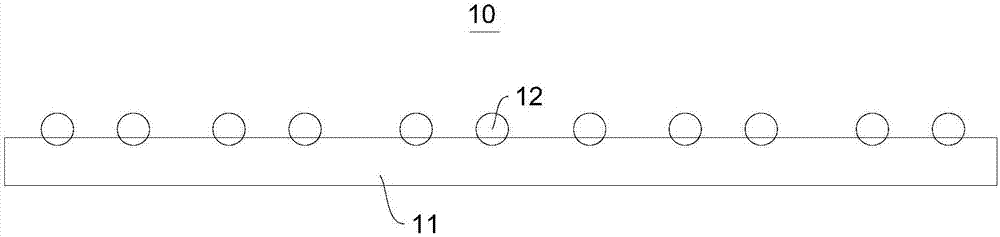

[0036] Please refer to figure 1 , the present embodiment provides an automatic cooling device 100, which includes a radiant cooling layer 10, a transparent protective layer 20, and a close-fitting layer 30 for fitting with the human body. The layer 30 is connected with the transparent protective layer 20 , the next-to-body layer 30 is located on the side of the radiative cooling layer 10 away from the transparent protective layer 20 , and the radiative cooling layer 10 is located between the transparent protective layer 20 and the next-to-body layer 30 .

[0037] Through the sandwiching effect of the transparent protective layer 20 and the close-fitting layer 30, the radiation cooling layer 10 is sandwiched inside.

[0038] The close-fitting layer 30 fits the human body, and its material can be plastic, cloth or aramid fiber. It can be made into daily clothing, underwear or decorations according to the needs of users, and can also be made into close-fitting bras, girdles, tig...

Embodiment 2

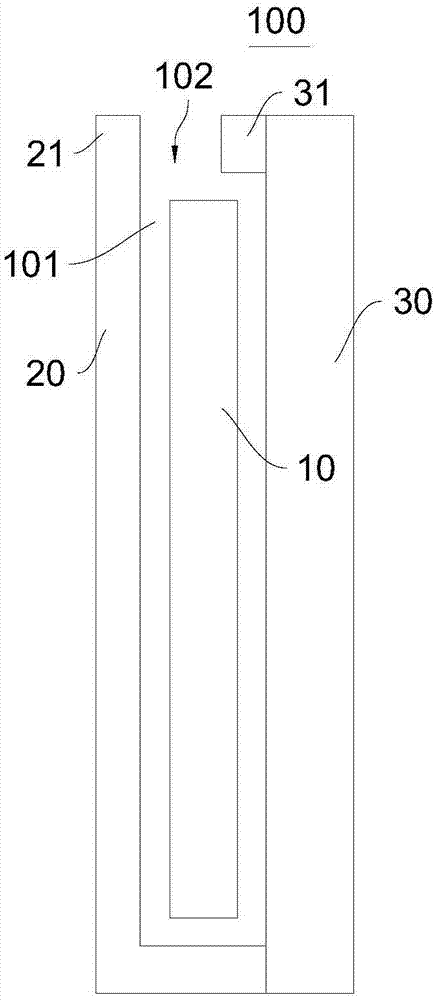

[0069] Please refer to image 3 , this embodiment also provides an automatic cooling device 100, the technical solution described in embodiment 1 is also applicable to this embodiment, and the technical solution disclosed in embodiment 1 will not be described again.

[0070] Specifically, the difference between this embodiment and Embodiment 1 is that an accommodating cavity 101 for accommodating the radiative cooling layer 10 is formed between the transparent protective layer 20 and the next-body layer 30 , and there is an accommodating chamber 101 between the transparent protective layer 20 and the next-body layer 30 . The cavity 101 communicates with the notch 102 , and the end of the transparent protective layer 20 close to the notch 102 is detachably connected with the body layer 30 and can close the accommodating cavity 101 .

[0071] The end of the transparent protective layer 20 close to the notch 102 is provided with a first connecting portion 21 , and the end of the ...

Embodiment 3

[0074] Please refer to Figure 4 , this embodiment also provides an automatic cooling device 100, the technical solution described in embodiment 1 is also applicable to this embodiment, and the technical solution disclosed in embodiment 1 will not be described again.

[0075] Specifically, the difference between this embodiment and Embodiment 1 is that the automatic cooling device 100 also includes a second heat-conducting layer 60, the next-to-body layer 30 is formed by overlapping at least two layers of base layers, and the second heat-conducting layer 60 is located on two adjacent layers of base layers. between.

[0076] The material of the second heat conduction layer 60 may be the same as that of the first heat conduction layer 40 , and its functions and effects are the same.

[0077] The next-to-body layer 30 in this embodiment is composed of a first base layer 301 and a second base layer 302 . The second heat conduction layer 60 is located between the first base layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com