Cage aviary equipment and ventilation-cooling regulation method for cage aviary

A poultry house and equipment technology, applied in the field of poultry breeding, can solve the problems of airflow short circuit and insufficient effective control ability, and achieve the effect of increasing selection, good ventilation effect and increasing wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

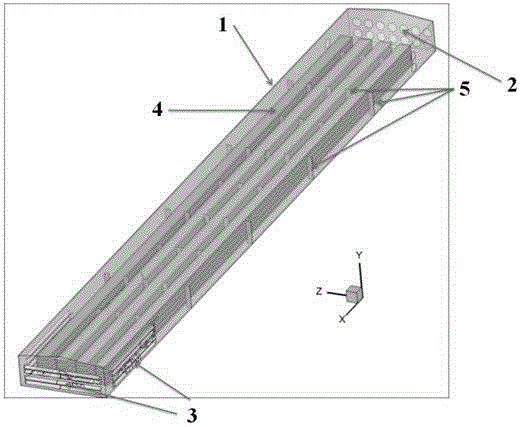

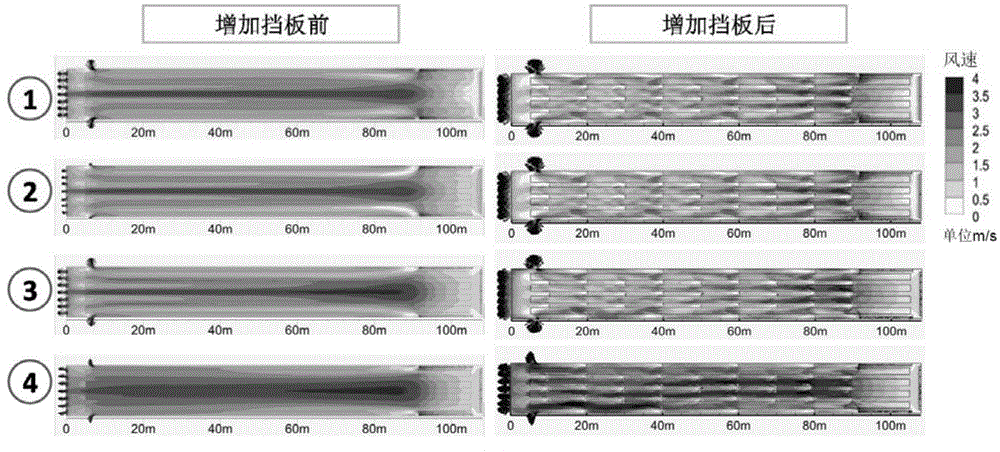

[0038] The present embodiment is caged poultry house, poultry house length 120m, there are 4 rows of poultry cage areas in the poultry house, each row of poultry cage length 100m, each row of poultry cage districts comprises 4 layers of poultry cages, and the total height of poultry cages is 5m, The channel width is 1.25m. The parameters of the windshield used are: the height of the windshield is 80% (ie, 4m) of the total height of the poultry cage, the spacing is 10m, and the width is 20% (ie, 0.25m) of the channel width. The windshields are dislocated, that is, the first row of windshields is placed on the left side of the passage, the second row of windshields is placed on the right side of the passage, the third row of windshields is placed on the left side of the passage, and so on. The windshield adopts a hinged design, and the opening angle is 10-170°.

[0039] Before adopting this design, when 9 fans are turned on, the wind speed at the channel can reach 3.5-4.0m / s, a...

Embodiment 2

[0041] The present embodiment is caged poultry house, poultry house length 120m, there are 4 rows of poultry cage areas in the poultry house, each row of poultry cage length 100m, each row of poultry cage districts comprises 4 layers of poultry cages, and the total height of poultry cages is 5m, The channel width is 1.25m. The parameters of the windshield adopted are: the height of the windshield is 80% (ie, 4m) of the total height of the poultry cage, the spacing is 10m, and the width is 60% (ie, 0.75m) of the channel width. The windshields are dislocated, that is, the first row of windshields is placed on the left side of the passage, the second row of windshields is placed on the right side of the passage, the third row of windshields is placed on the left side of the passage, and so on. The windshield adopts a hinged design, and the opening angle is 10-170°.

[0042] Before adopting this design, when 9 fans are turned on, the wind speed at the channel can reach 3.5-4.0m / s...

Embodiment 3

[0044] The present embodiment is cage poultry house, poultry house length 120m, has 4 rows of poultry cage areas in the poultry house, each row of poultry cage length 100m, each row of poultry cage districts comprises 3 layers of poultry cages, and the total height of poultry cages is 4m, The channel width is 1.5m. The parameters of the windshield used are: the height of the windshield is 90% of the total height of the poultry cage (ie, 3.6m), the spacing is 10m, and the width is 70% of the channel width (ie, 1.05m). The windshields are dislocated, that is, the first row of windshields is placed on the left side of the passage, the second row of windshields is placed on the right side of the passage, the third row of windshields is placed on the left side of the passage, and so on. The windshield adopts a louver-type design, and the area that can be blocked is 20%-100%.

[0045] Before adopting this design, when 7 fans are turned on, the wind speed at the channel can reach 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com