Composite nano waterproof heat-insulating coating for buildings and preparation method thereof

A technology of composite nanomaterials and heat-insulating coatings, which is applied in the field of composite nano-hydrophobic heat-insulating coatings for buildings and its preparation, can solve problems such as single function and poor environmental protection, and achieve enhanced heat insulation performance and good heat insulation effect , the effect of reducing the emission of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

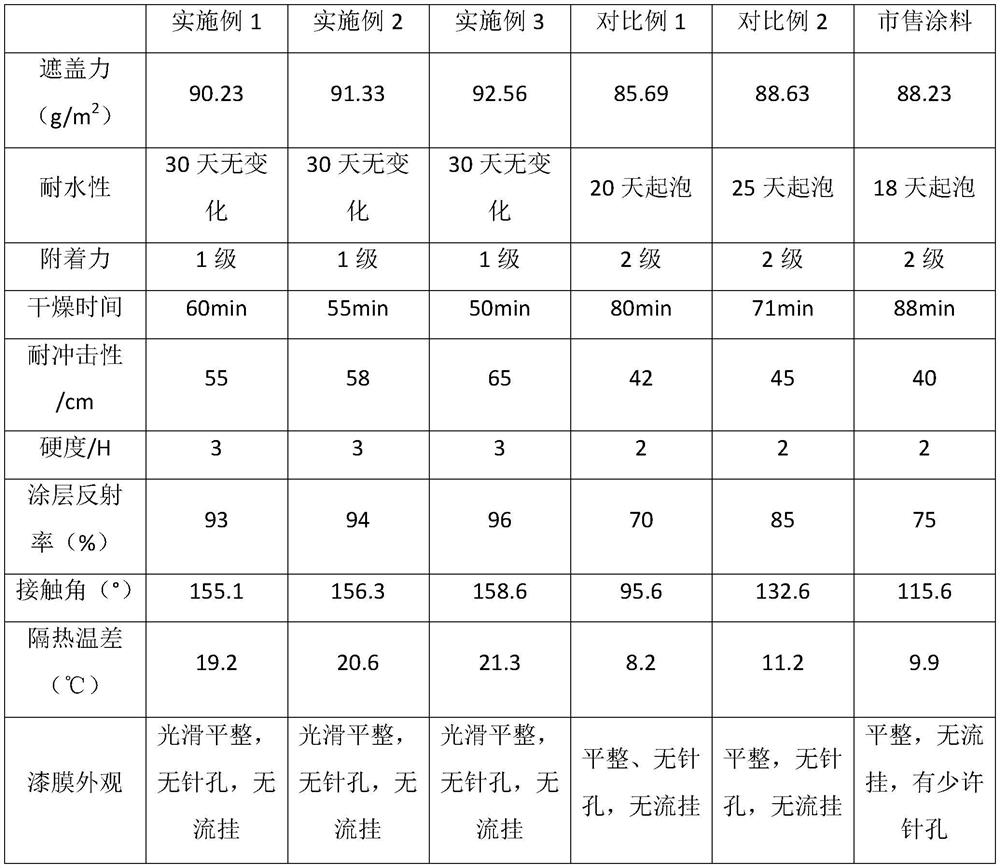

Examples

Embodiment 1

[0025] A composite nano-waterproof and heat-insulating coating for buildings, comprising the following raw materials in parts by weight: 150 parts of emulsion, 60 parts of water-based polyurethane, 60 parts of filler, 60 parts of heat-insulating composite nano-material, 30 parts of silicone hydrophobic agent, film-forming auxiliary 5 parts of agent, 3 parts of defoamer, 3 parts of synergist.

[0026] The emulsion used in this example is a polyacrylate emulsion with a solid content of 50%.

[0027] The heat-insulating composite nanomaterial is prepared by the following method: after mixing the nano-silica powder and the nano-titanium dioxide powder according to the mass ratio of 1:1, they are completely immersed in a nitric acid solution with a mass percentage of 50%. , soaked for 24 hours, then washed twice with deionized water, then soaked in a 50% methyltriethoxysilane solution for 6 hours, then placed in a muffle furnace for calcination at 450°C for 3 hours, cooled to At r...

Embodiment 2

[0040] A composite nano-waterproof and heat-insulating coating for buildings, comprising the following raw materials in parts by weight: 180 parts of emulsion, 70 parts of water-based polyurethane, 70 parts of filler, 70 parts of heat-insulating composite nano-material, 40 parts of silicone hydrophobic agent, film-forming auxiliary 8 parts of agent, 5 parts of defoamer, 4 parts of synergist.

[0041] The emulsion used in this example is a polyacrylate emulsion with a solid content of 55%.

[0042] The heat-insulating composite nanomaterial is prepared by the following method: after mixing the nano-silica powder and the nano-titanium dioxide powder according to the mass ratio of 1:1, they are completely immersed in a nitric acid solution with a mass percentage of 50%. , soaked for 24 hours, then washed 3 times with deionized water, then soaked in a 50% methyltriethoxysilane solution for 10 hours, then placed in a muffle furnace and calcined at 450 ° C for 4 hours, cooled to At...

Embodiment 3

[0055] A composite nano-waterproof and heat-insulating coating for buildings, comprising the following raw materials in parts by weight: 200 parts of emulsion, 80 parts of water-based polyurethane, 80 parts of filler, 80 parts of heat-insulating composite nano-material, 50 parts of silicone hydrophobic agent, film-forming auxiliary 10 parts of agent, 6 parts of defoamer, 6 parts of synergist.

[0056] The emulsion used in this example is a polyacrylate emulsion with a solid content of 60%.

[0057] The heat-insulating composite nanomaterial is prepared by the following method: after mixing the nano-silica powder and the nano-titanium dioxide powder according to the mass ratio of 1:1, they are completely immersed in a nitric acid solution with a mass percentage of 50%. , soaked for 24 hours, then washed 3 times with deionized water, then soaked in a 50% methyltriethoxysilane solution for 12 hours, and then placed in a muffle furnace for calcination at 450 ° C for 5 hours, coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com