Special gear pump

A gear pump, a special technology, used in pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of force and asymmetry of gear pumps that have never been seen before, and achieve great market application potential, symmetrical and uniform wear, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings and embodiments, the structure and working principle of the present invention are further described in detail:

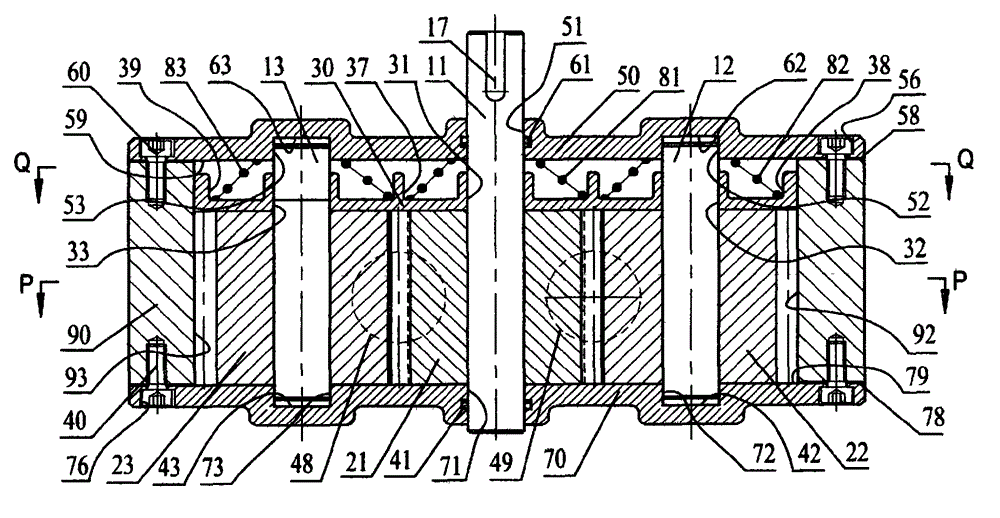

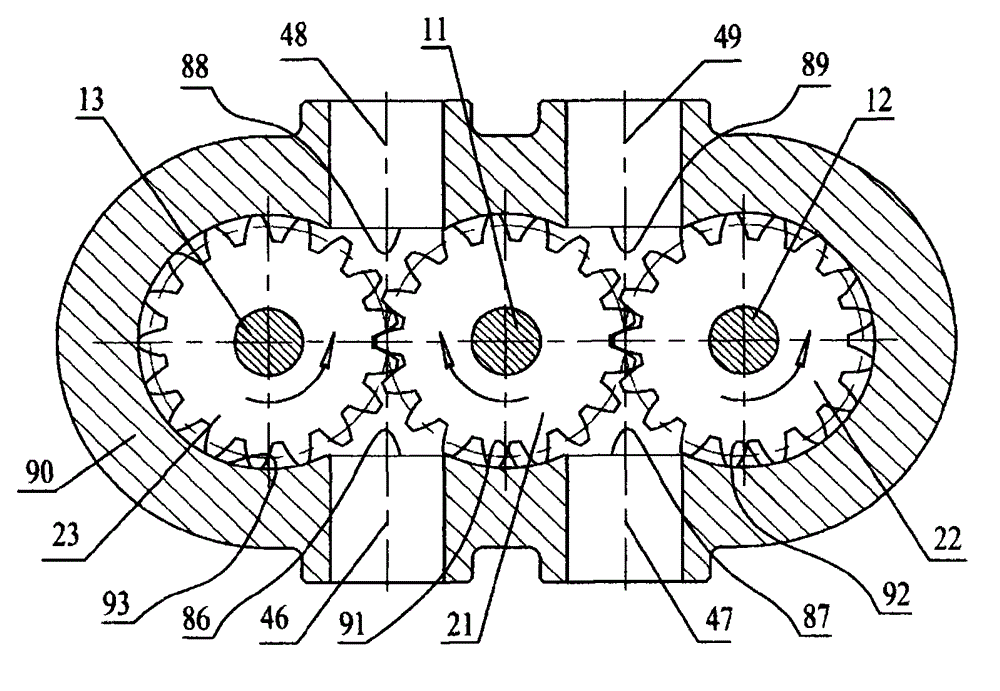

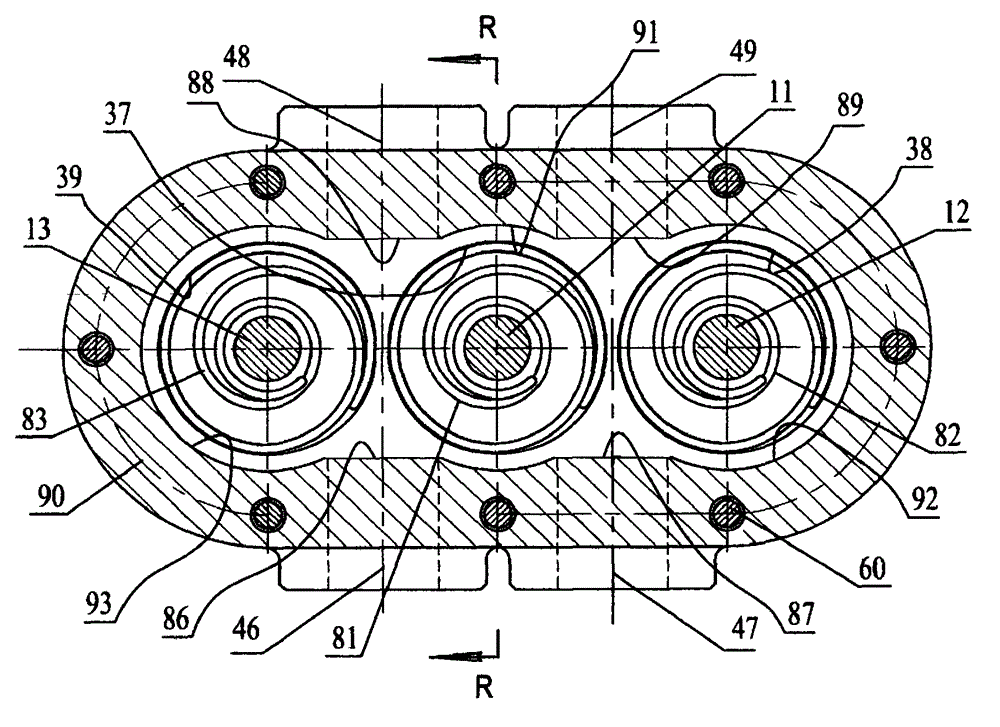

[0021] A special gear pump, including driving shaft 11, right driven shaft 12, left driven shaft 13, main gear 21, right driven gear 22, left driven gear 23, front outer end cover 50, rear outer end cover 70, middle Conical spring 81, right conical spring 82, left conical spring 83, pump body 90, as an improvement: the central two-section arc 91 on the inner cavity of the pump body 90 is slidingly fitted with the outer circle of the main gear 21; The right large half arc 92 on the cavity of the pump body 90 is slidably matched with the outer circle of the right slave gear 22; the left large semicircle 93 on the cavity of the pump body 90 is slidably matched with the left outer circle of the left slave gear 23; The drive shaft 11 at the center of the master gear 21 is parallel to the right driven shaft 12 at the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com