Preparation method of monolithic catalyst for formaldehyde purification

An integrated catalyst and formaldehyde purification technology, applied in the field of ambient air purification, can solve the problems of no catalytic effect of precious metal components, limited utilization efficiency of precious metals, uneven distribution of precious metals, etc., to improve utilization efficiency, easy operation, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 20g of pseudo-boehmite and 80g of alumina powder, add 300g of deionized water and mix, and adjust the pH to 4 with nitric acid. Take 250-mesh cordierite honeycomb ceramics with a volume of 50×50×50mm, immerse them in the above slurry, take them out, blow dry the residual liquid in the channels, dry them at 120°C, and calcinate at 550°C for 4 hours. The finally obtained cordierite honeycomb carrier whose surface is coated with an active coating. The test results are: the amount of coating on the surface of the carrier is 60g / L; the specific surface area of the coating is 87m 2 / g; after the ultrasonic vibration test, the shedding rate of the carrier surface coating is less than 3%.

Embodiment 2

[0027] Weigh 20g of pseudoboehmite and 100g of alumina powder, add 300g of deionized water and mix, and adjust the pH to 4 with nitric acid. Take a 50-mesh stainless steel honeycomb carrier with a volume of 50×50×50mm, immerse it in the above slurry, take it out, blow dry the residual liquid in the channel, dry it at 120°C, and calcinate at 550°C for 4 hours. The final product is a stainless steel honeycomb carrier coated with an active coating on the surface. The test results are: the amount of coating on the surface of the carrier is 22g / L; the specific surface area of the coating is 95m 2 / g; after the ultrasonic vibration test, the shedding rate of the carrier surface coating is less than 3%.

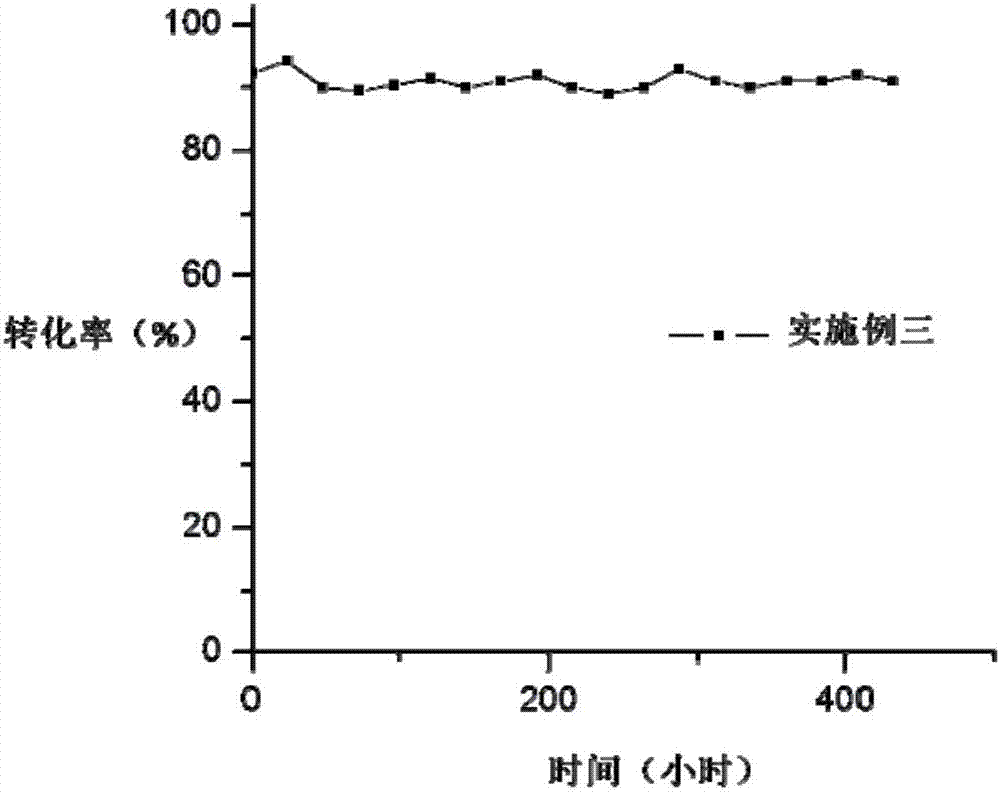

Embodiment 3

[0029] Weigh H separately 2 PtCl 6 0.0523g, Fe(NO 3 ) 3 0.0647g, Ni(NO 3 ) 2 0.0249g, use deionized water to dissolve the above-mentioned salt solution to a volume of 125mL, then add the honeycomb carrier coated with a solid active coating on the surface prepared according to Example 1, keep it for about 5 hours, and take it out. It is evenly immobilized on the surface of the active coating, and the remaining solution that does not contain active ingredients is removed. Then prepare a 0.1 mol / L sodium borohydride solution, immerse the catalyst, take it out, and dry it to obtain a formaldehyde purification catalyst with a cordierite honeycomb as a carrier. After testing, the catalyst contains 0.2g / L of Pt element, 0.12g / L of Fe element and 0.06g / L of Ni element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com