Method for electrolyzing vanadium slurry and extracting vanadium pentexide using film

A technology of vanadium pentoxide and vanadium ore, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of large investment in production equipment, large occupied site area, and long production cycle, so as to save equipment investment and improve The recovery rate and the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

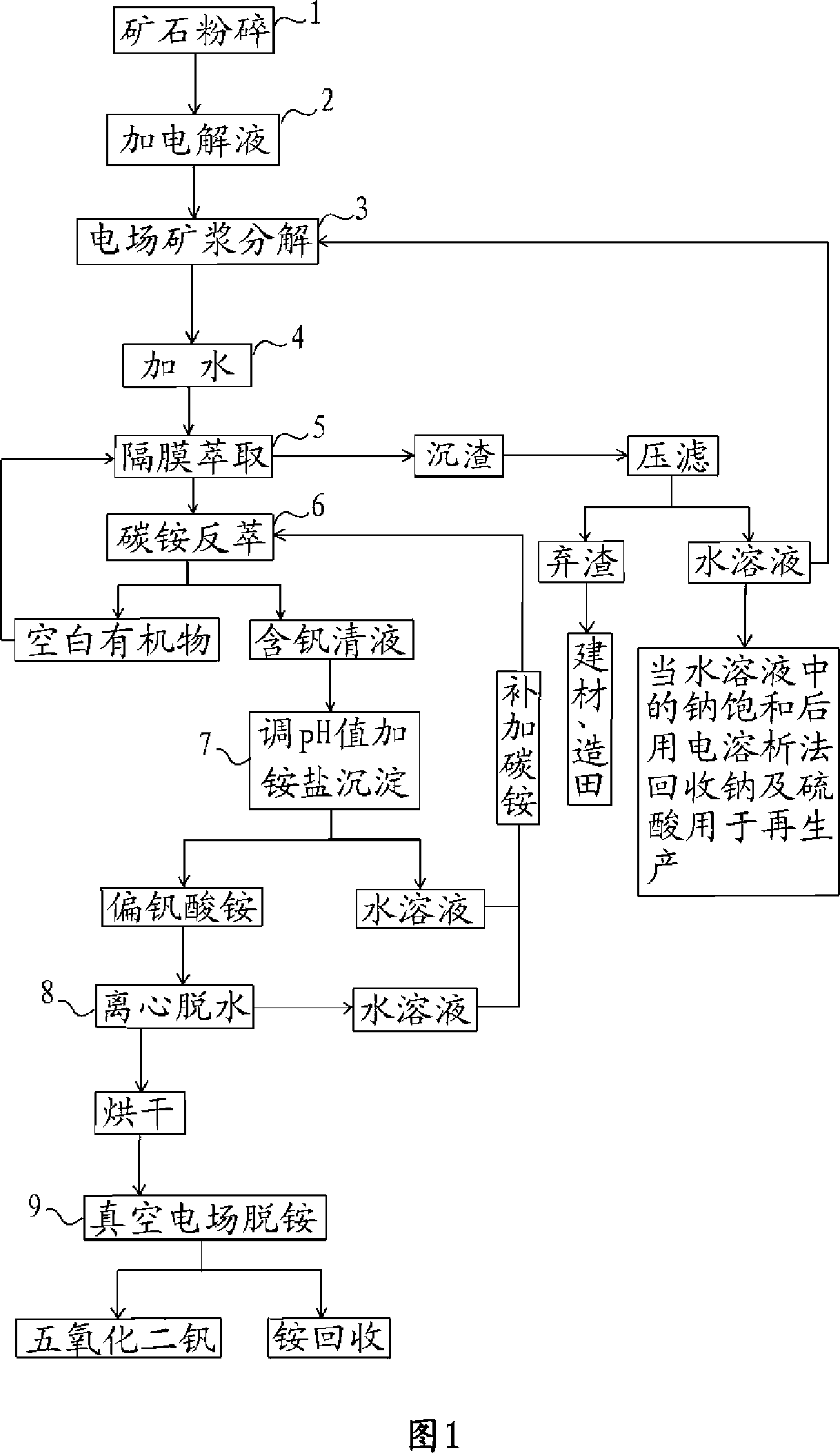

[0032] Preferred embodiment is referring to Fig. 1, and this electric field decomposes the method step of vanadium ore slurry membrane extraction production vanadium pentoxide:

[0033] Step 1, the ore is crushed, and the vanadium ore is ground to 100 to 250 meshes.

[0034] Step 2, using 2 to 4 equivalents of dilute sulfuric acid or using 10 to 15% soda ash solution to the mineral powder ratio to make the liquid to solid ratio 1: 1.5 to 2;

[0035] A), sulfuric acid system

[0036] Fe(VO 3 ) 2 +2H 2 SO 4 +XH 2 O(VO 2 ) 2 SO 4 +FeSO 4 +X+2H 2 O;

[0037] Ca(VO 3 ) 2 +2H 2 SO 4 +XH 2 O=(VO 2 ) 2 SO4+CaSO4↓+X+2H 2 O.

[0038] B), soda ash system

[0039] Ca(VO 3 ) 2 +Na 2 CO 3 +XH 2 O=2NaVO 3 +CaCO 3 ↓+XH 2 O.

[0040] Fe(VO 3 ) 2 +Na 2 CO 3 +XH 2 O=2NaVO 3 +FeO↓+CO 2 ↑+XH 2 O.

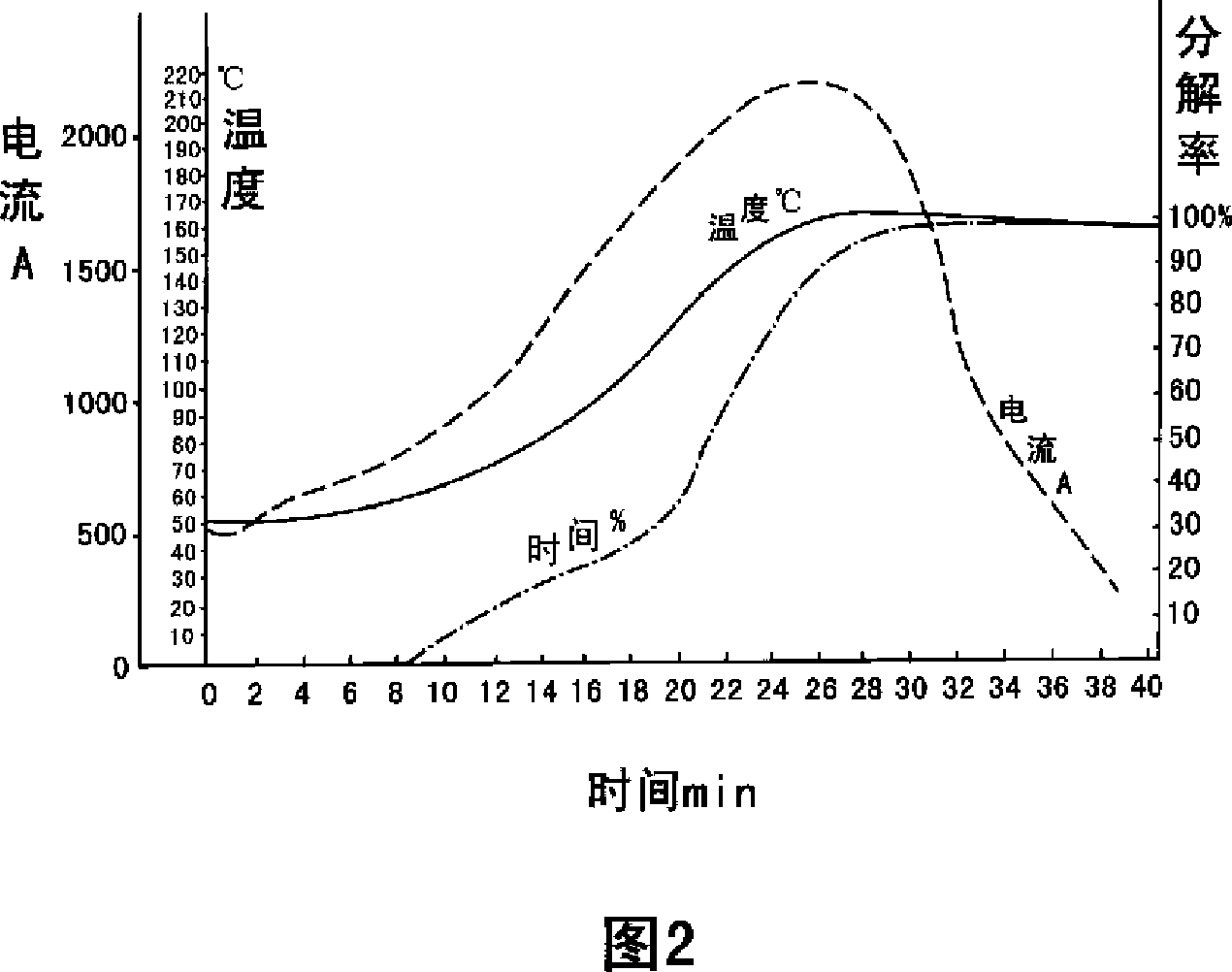

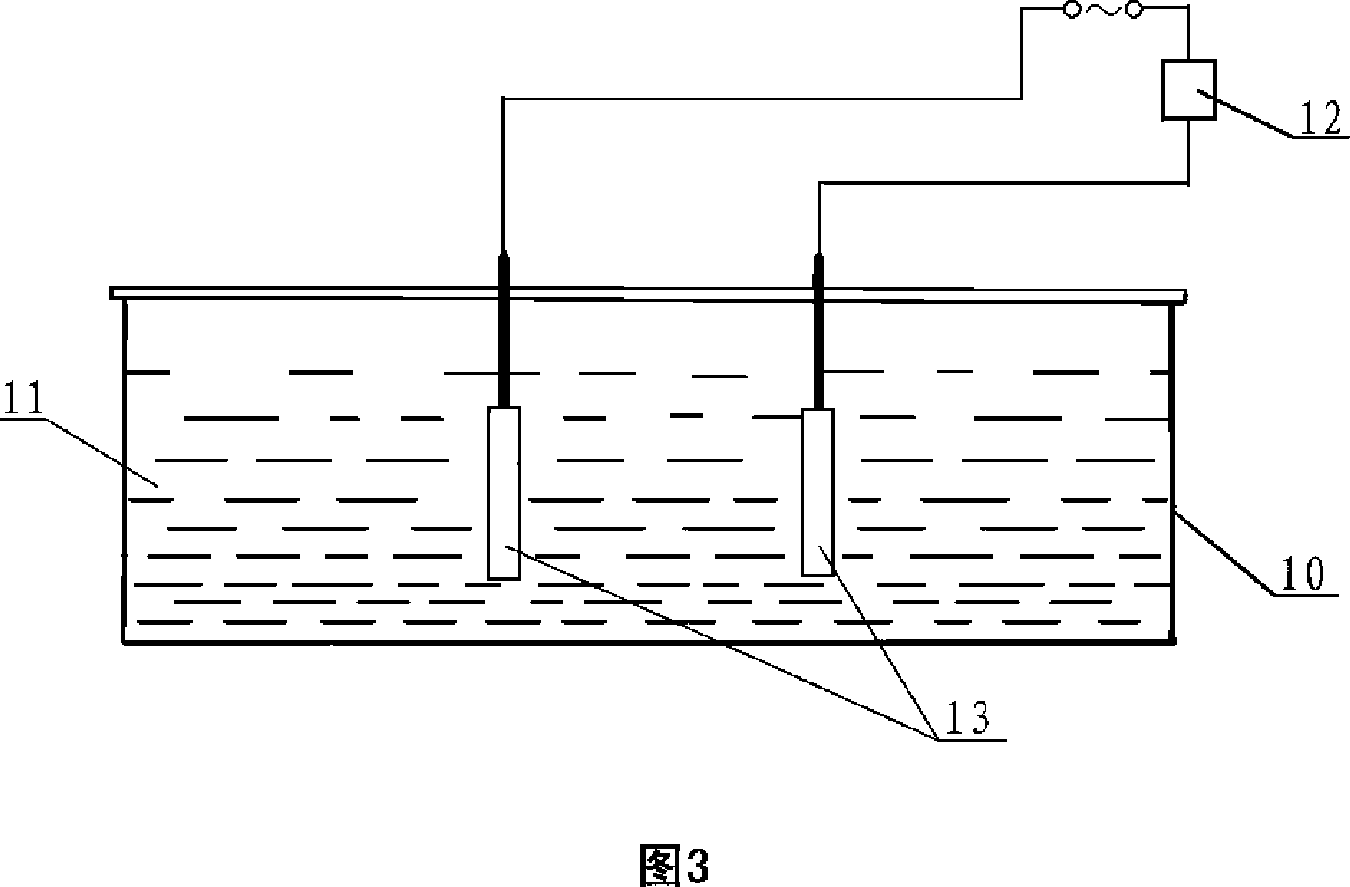

[0041] Step 3 see Fig. 2 and Fig. 3, the electric field pulp is decomposed, put the above pulp into the electric field decomposition tank 10, the power supply adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com