Method for preparing rare earth chloride from mixed rare earth concentrate or monazite concentrate

A mixed rare earth and rare earth chloride technology, applied in the direction of improving process efficiency, can solve problems such as three-waste pollution, and achieve the effects of high decomposition rate, fast decomposition speed and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

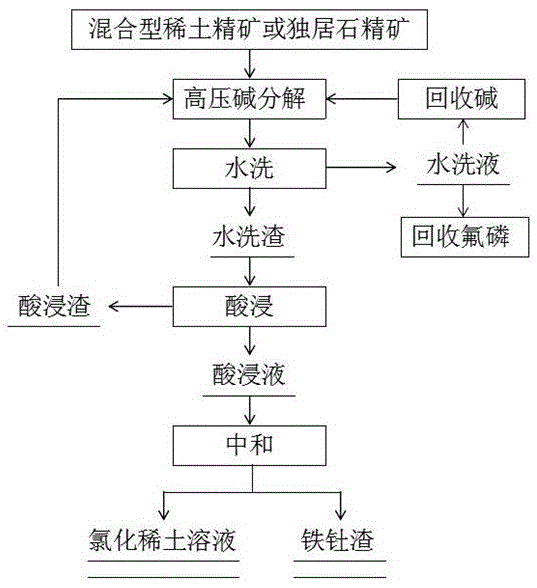

Image

Examples

Embodiment 1

[0022] (1) Add bastnaesite and monazite-based mixed rare earth concentrate with a rare earth grade of 60.85% to a sodium hydroxide solution with a mass concentration of 55% and mix evenly, with a solid-to-liquid ratio of 1:3. Alkali decomposition is carried out in the reactor, the alkali decomposition temperature is controlled at 200°C, the stirring speed is 450r / min, the reaction time is 2 hours, and the pressure in the high-pressure reactor is 2.4MPa to obtain alkali-decomposed minerals;

[0023] (2) Wash the alkali-decomposed minerals obtained in step (1) with water. The washing temperature is controlled at 70°C, and the water is washed until pH=8.0 and filtered to obtain the washing residue and washing liquid. The washing liquid is concentrated and crystallized to recover sodium hydroxide and fluoride. sodium and sodium phosphate;

[0024] (3) Leach the washed slag obtained in step (2) with hydrochloric acid. The leaching temperature is controlled at 80°C, the solid-to-liq...

Embodiment 2

[0027] (1) Add monazite rare earth concentrate with a rare earth grade of 64.27% to a certain concentration of sodium hydroxide solution and mix evenly, then add it to a high-pressure reactor for alkali decomposition. The concentration of sodium hydroxide is 65%, and the solid-to-liquid ratio is 1 : 6, the alkali decomposition temperature is controlled at 190°C, the stirring speed is 500r / min, the reaction time is 2h, and the pressure in the autoclave is 2.2MPa;

[0028] (2) Wash the alkali-decomposed minerals obtained in step (1) with water. The washing temperature is controlled at 75°C, and the water is washed until pH=8.5 and filtered to obtain the washing residue and washing liquid. The washing liquid is concentrated and crystallized to recover sodium hydroxide and fluoride. sodium and sodium phosphate;

[0029] (3) Leach the washed slag obtained in step (2) with hydrochloric acid. The leaching temperature is controlled at 70°C, the solid-to-liquid ratio is 1:6, the concen...

Embodiment 3

[0032] (1) Add bastnaesite and monazite-based mixed rare earth concentrate with a rare earth grade of 65.48% to a certain concentration of sodium hydroxide solution and mix evenly, then add it to an autoclave for alkali decomposition, and sodium hydroxide The concentration is 45%, the solid-liquid ratio is 1:3, the alkali decomposition temperature is controlled at 220°C, the stirring speed is 450r / min, the reaction time is 1.5h, and the pressure in the autoclave is 3MPa;

[0033] (2) Wash the alkali-decomposed minerals obtained in step (1) with water. The washing temperature is controlled at 50°C, and the water is washed until pH=8.5 and filtered to obtain the washing residue and washing liquid. The washing liquid is concentrated and crystallized to recover sodium hydroxide and fluoride. sodium and sodium phosphate;

[0034] (3) Leach the washed slag obtained in step (2) with hydrochloric acid. The leaching temperature is controlled at 75°C, the solid-to-liquid ratio is 1:7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com