Patents

Literature

73results about "Peroxyhydrates/peroxyacids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

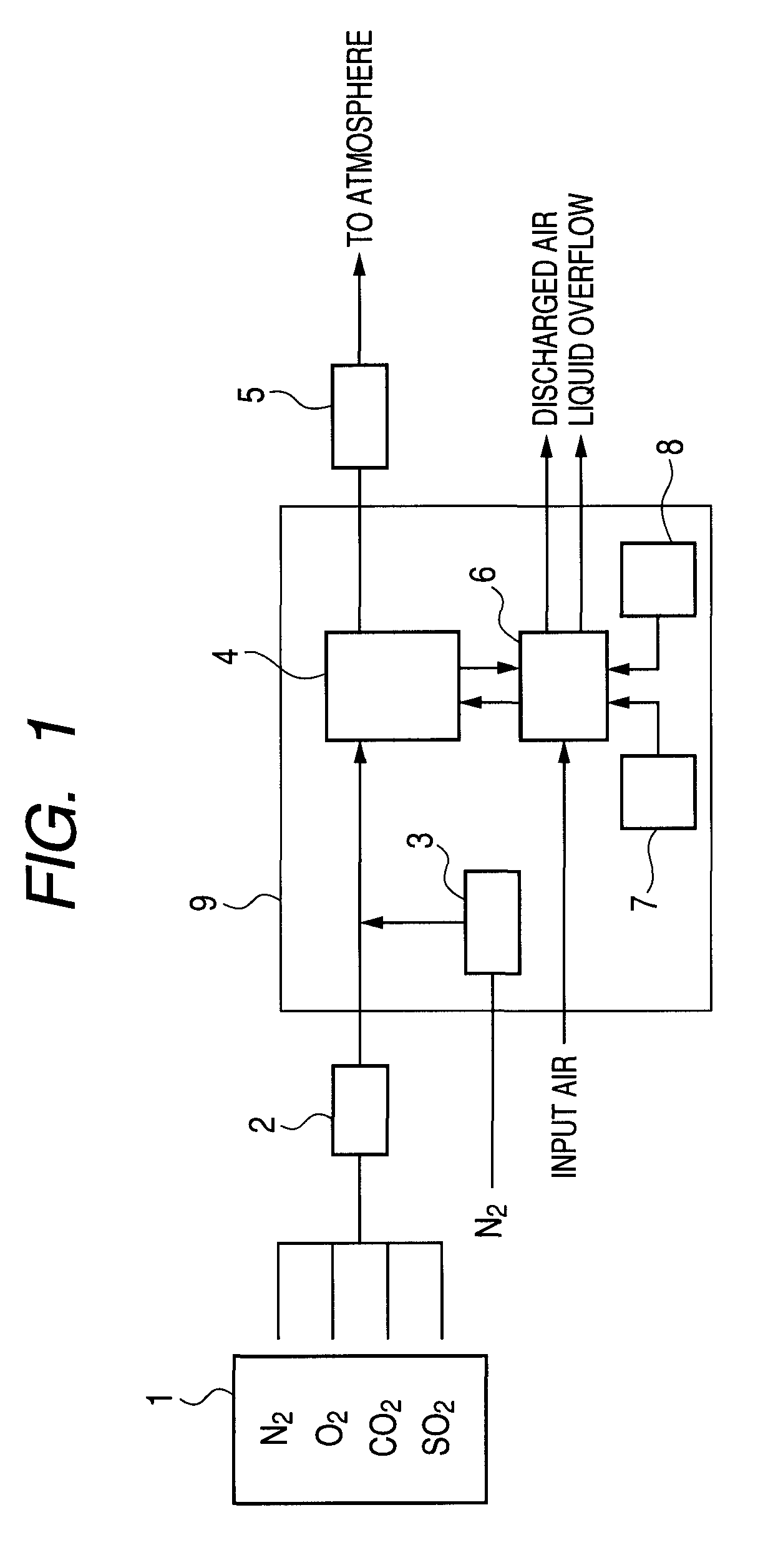

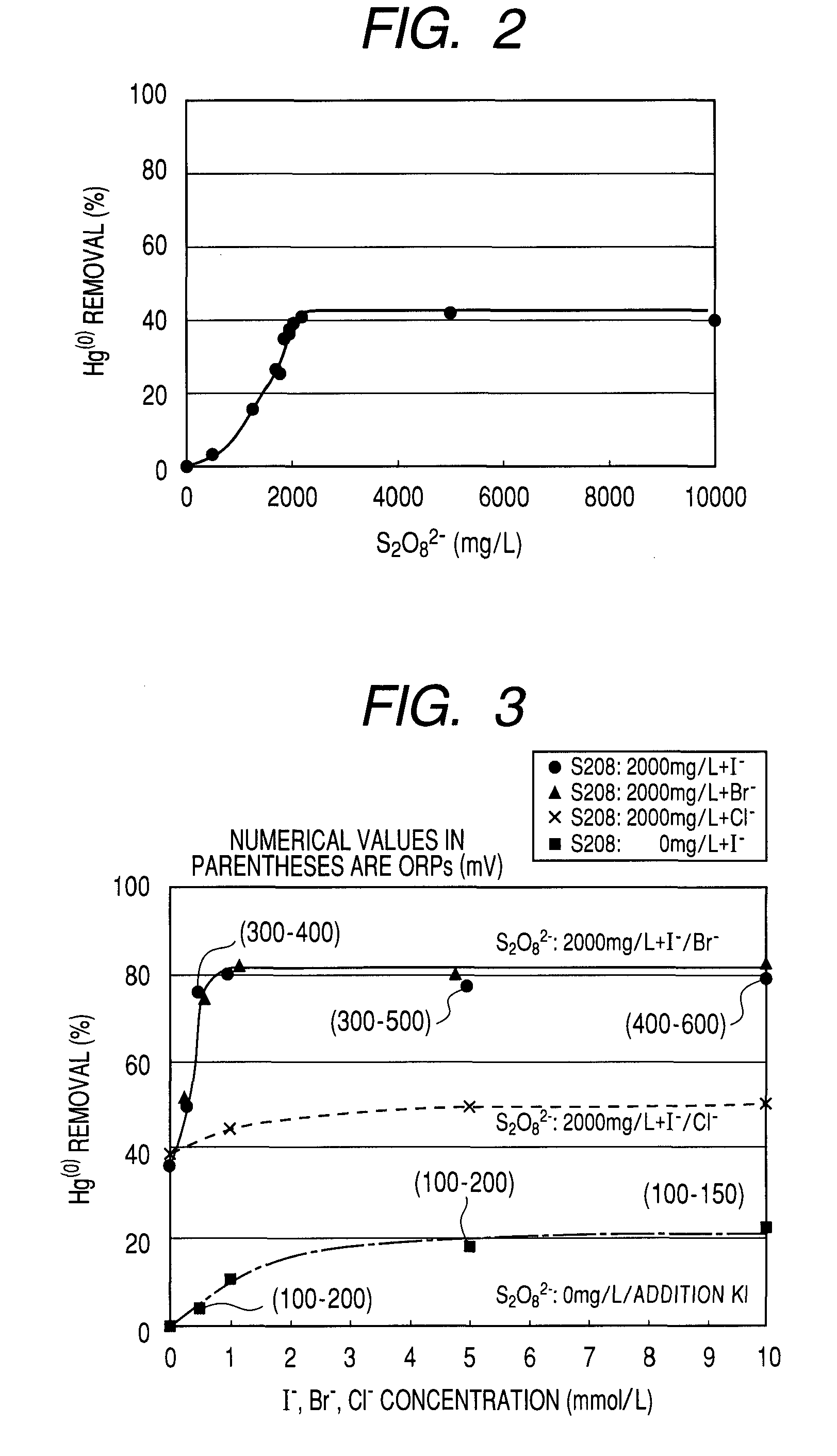

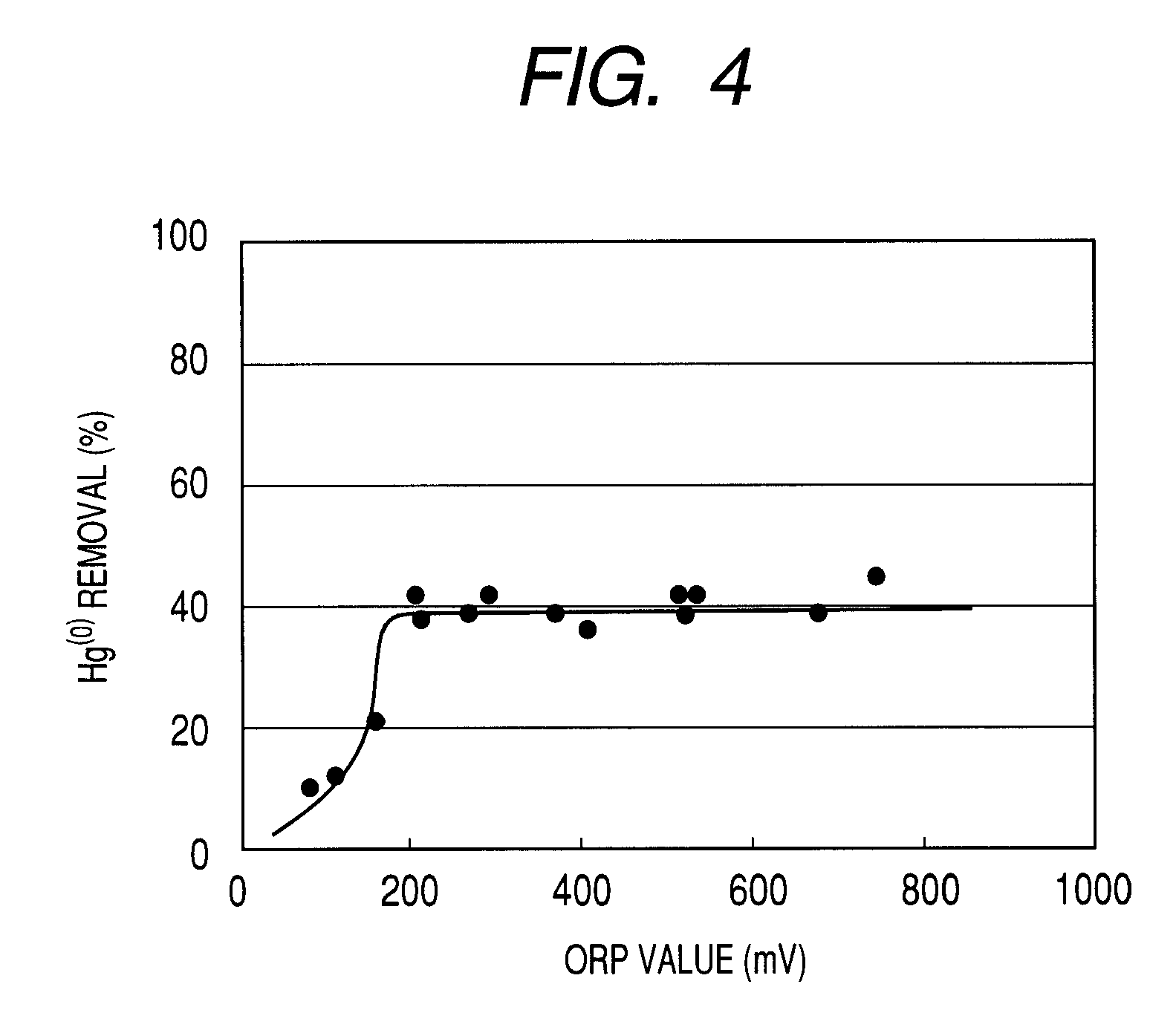

Exhaust gas treating method

ActiveUS8663594B2High removal rateEfficient use ofGas treatmentPeroxyhydrates/peroxyacidsExhaust fumesSulfur dioxide

An exhaust gas treating method removes sulfur dioxide from exhaust gas containing at least sulfur dioxide and mercury by bringing the exhaust gas into contact with absorption liquid. Persulfate is added into the absorption liquid or alternatively, iodine gas is added to the exhaust gas before the exhaust gas is brought into contact with the absorption liquid. A high removal rate for both sulfur dioxide and mercury is stably maintained if the load of power generation and the composition of exhaust gas fluctuate.

Owner:CHIYODA CORP

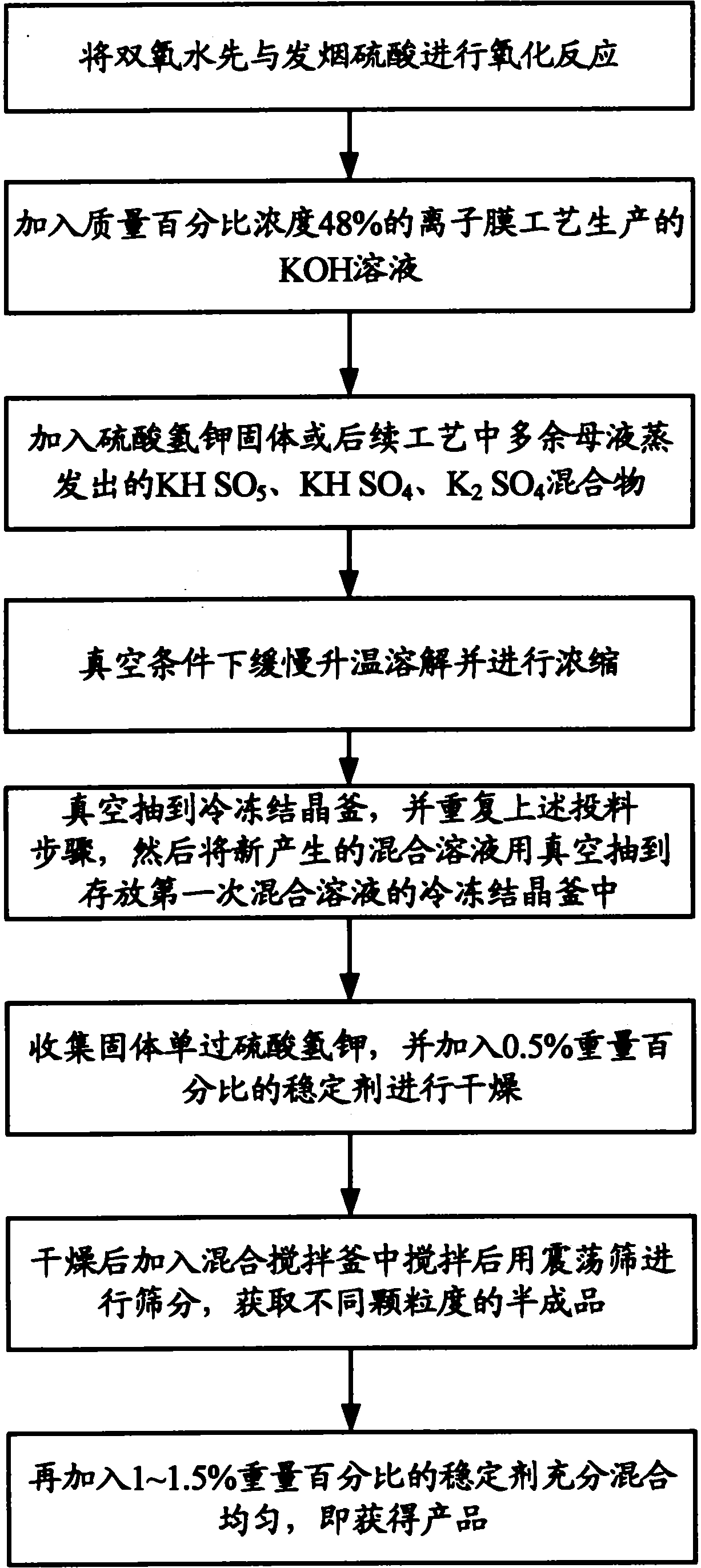

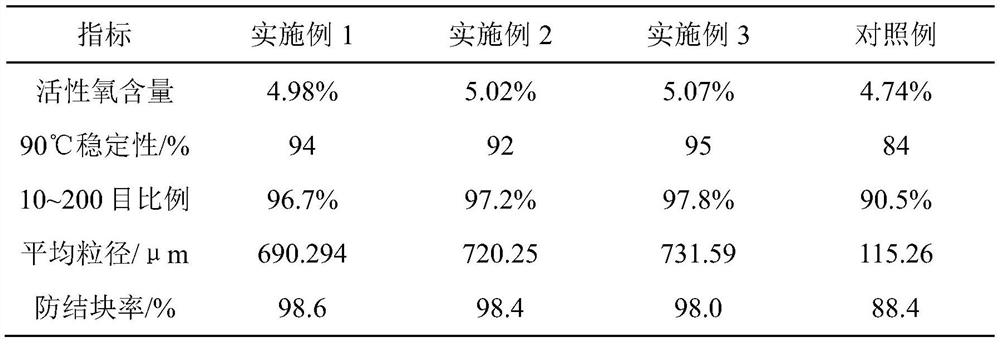

Method for preparing permonosulfuric hydrogen-pottassium compound salt

InactiveCN1528660AHigh active oxygen contentImprove stabilityPeroxyhydrates/peroxyacidsOleumPotassium hydroxide

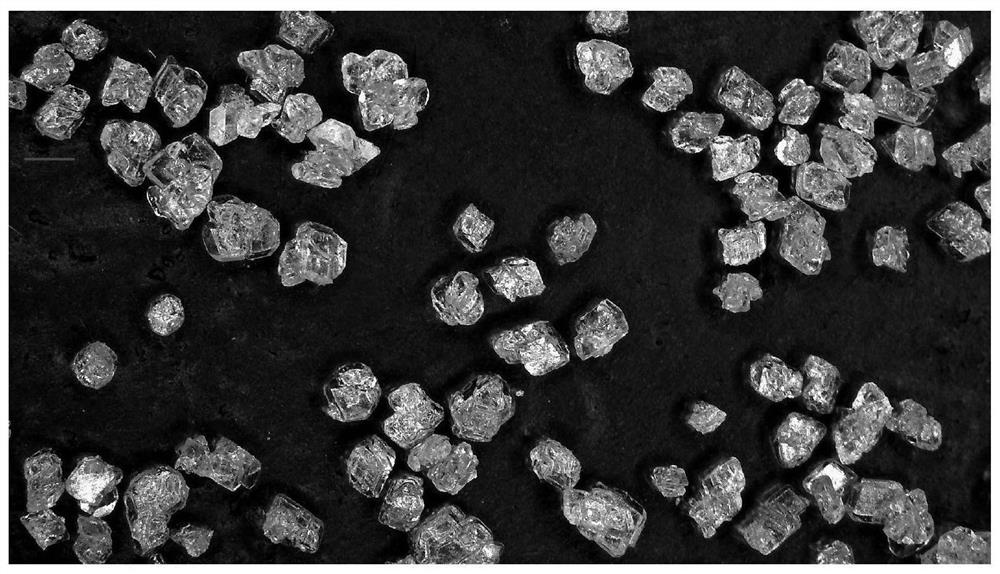

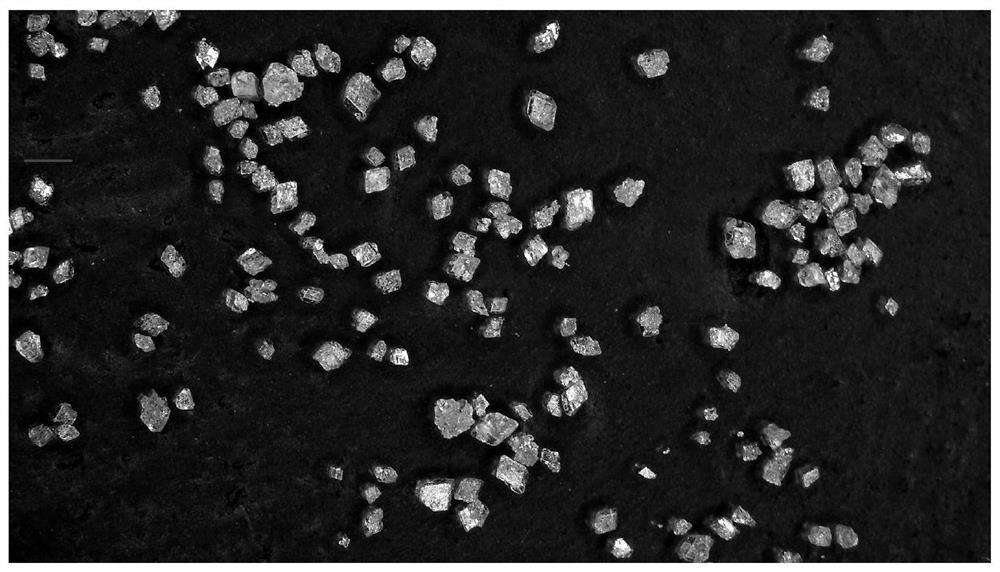

The invention is a potassium peroxy-monohydrosulfate compound salt preparing method, using oleum, perhydrol and potassium hydroxide as raw material. Firstly, adding stabilizing agent-containing perhydrol in the reactor, then dropping in the oleum to react, then dropping in potassium hydroxide solution and at the same time adding in crystal shape modifier, vacuum-condensing, cooling and crystallizing, and then drying to obtain its dried product; the perhydrol solution concentration is 45-80% and the oleum concentration 35-65%. It uses oleum to replace the vitriol oil and thick perhydrol solution to replace dilute perhydrol solution, and adds in potassium hydroxide to adjust the components. It has better stability.

Owner:陶华西

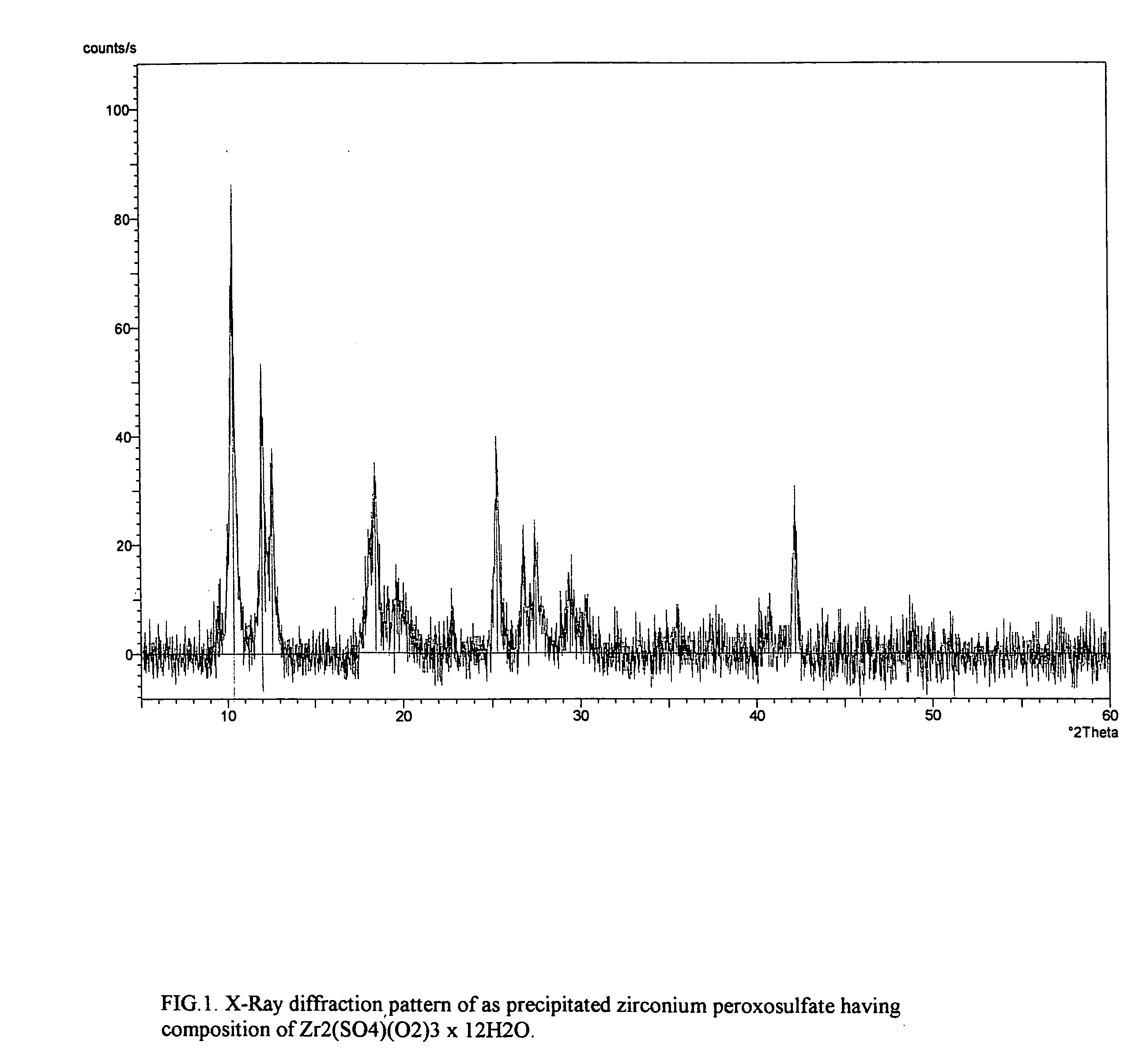

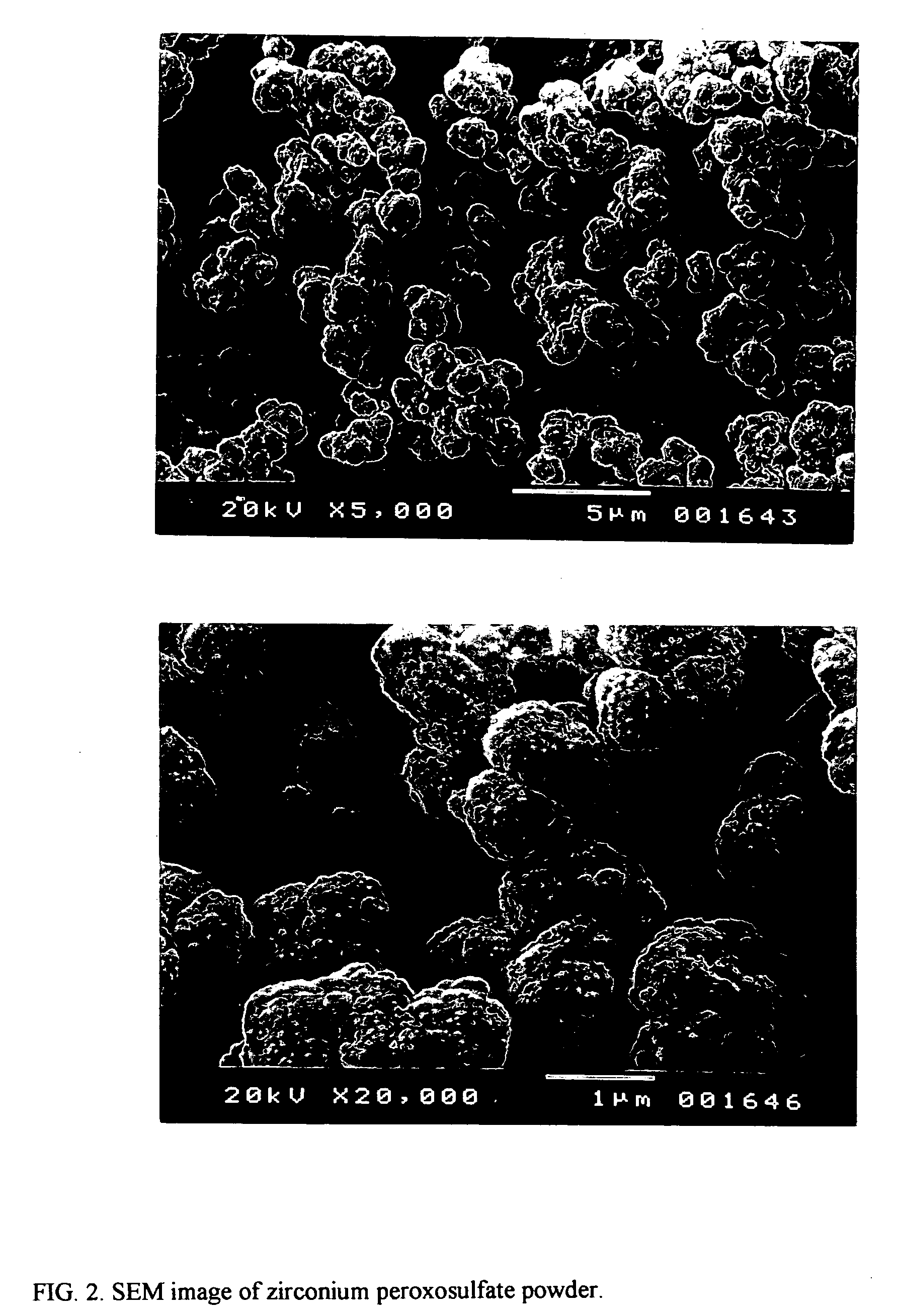

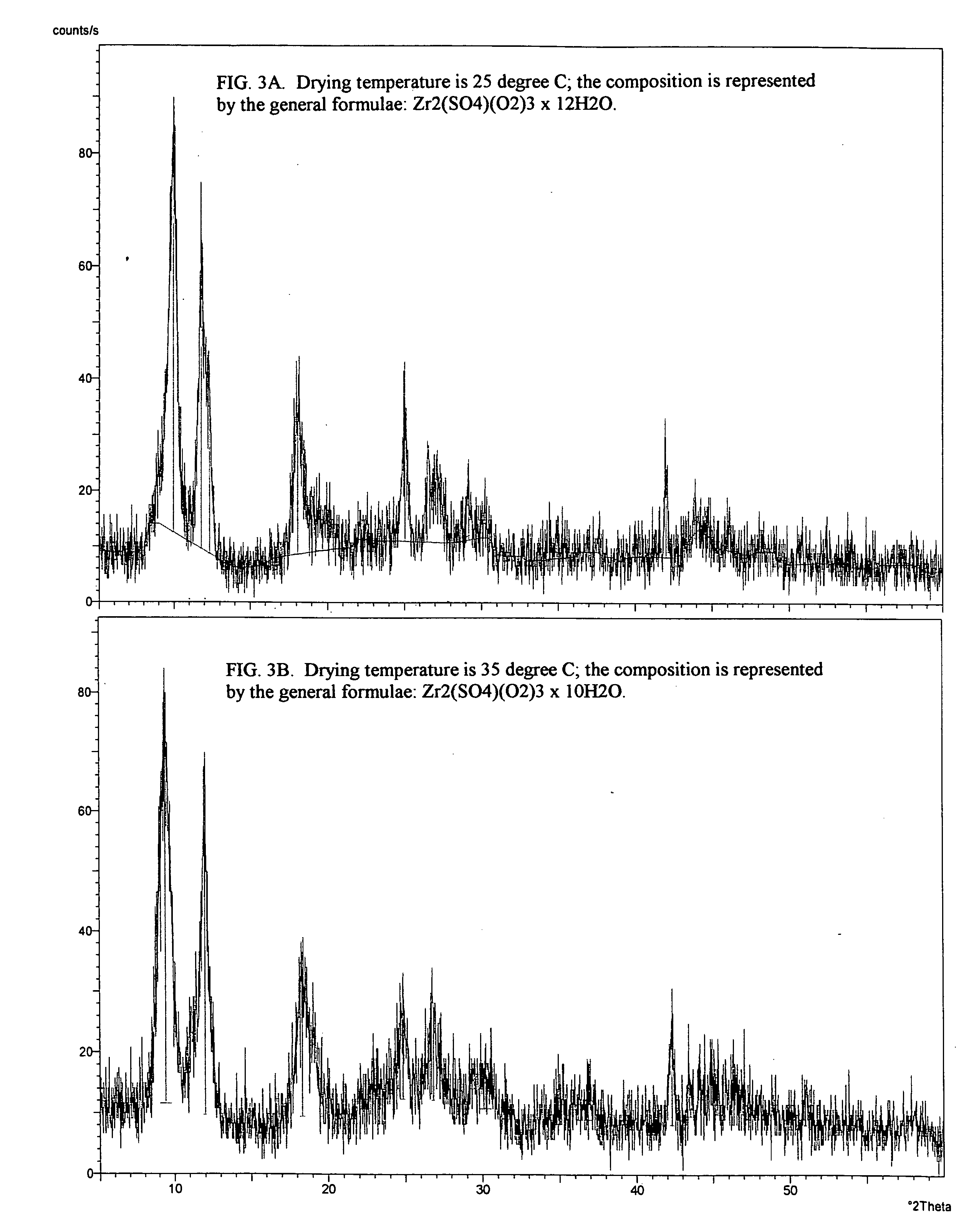

Process for the isolation and purification of zirconium peroxosulfate and uses thereof

InactiveUS20050180911A1High degreeShort processing timePeroxyhydrates/peroxyacidsSulfate preparationPurification methodsZirconium compounds

Provided is a process for isolating zirconium peroxosulfate and its use, either as is or to prepare high purity zirconium compounds including powders of zirconium dioxide and stabilized zirconia. The process is based on precipitating a peroxide compound from an acidic peroxide solution of zirconium and provides a simple, economical method for producing the zirconium peroxosulfate powder and its derivatives with degree of zirconium recovery more than 99%. This process further provides an effective method for the separation and purification of zirconium from a variety of elements and / or naturally occurring ores.

Owner:BELOV VLADIMIR +1

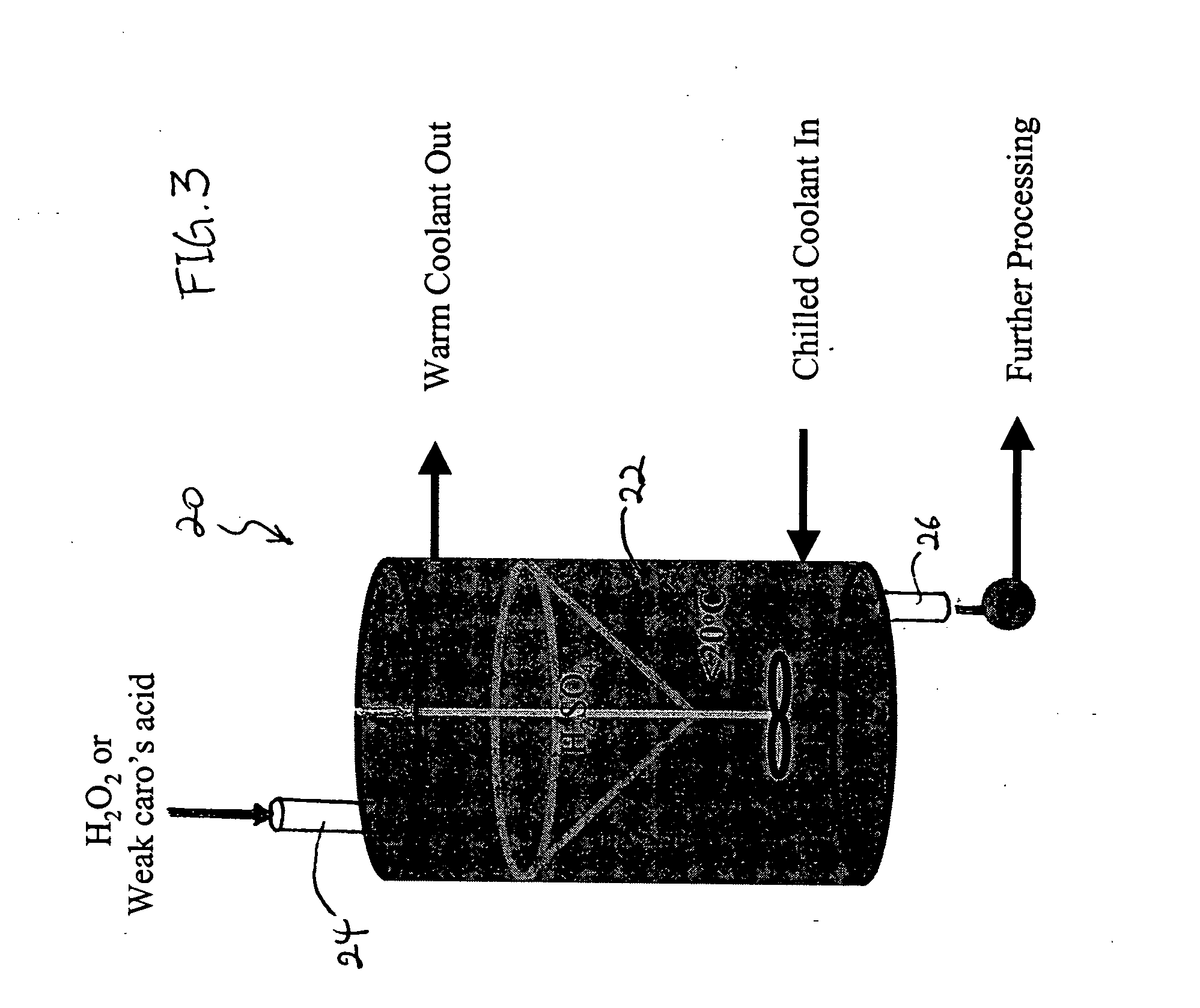

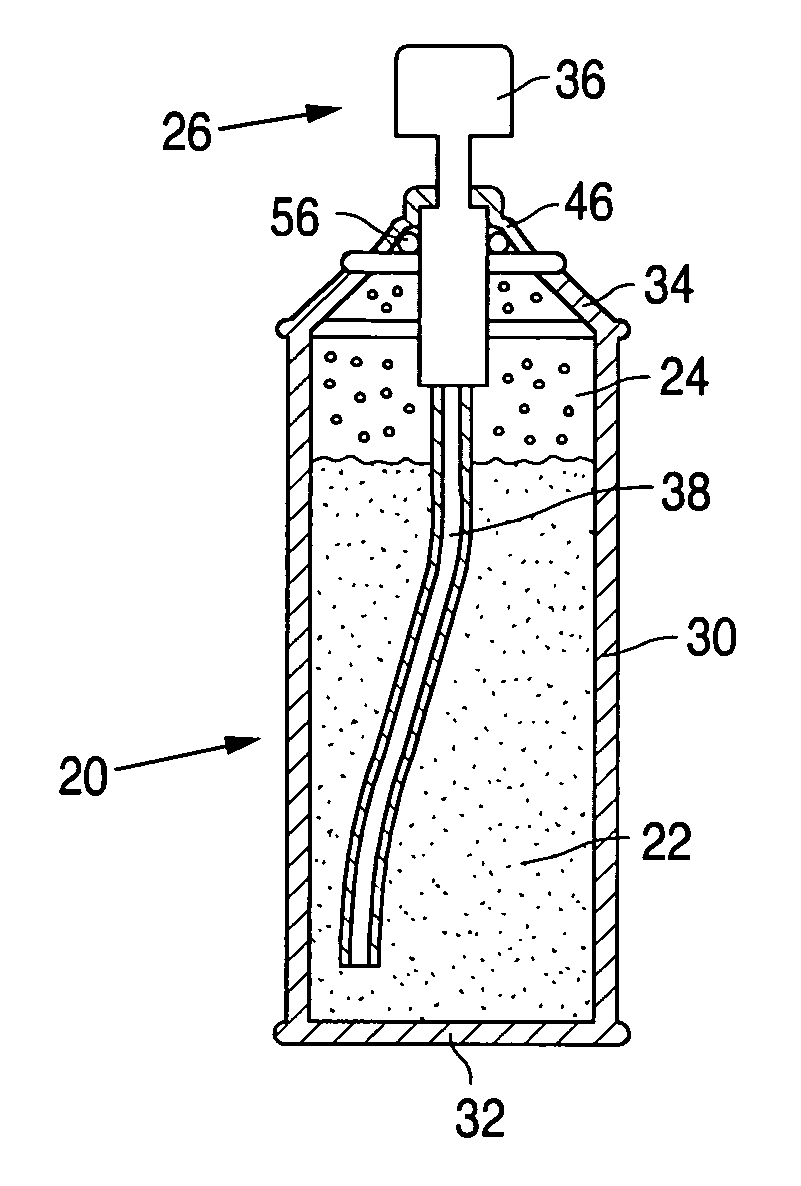

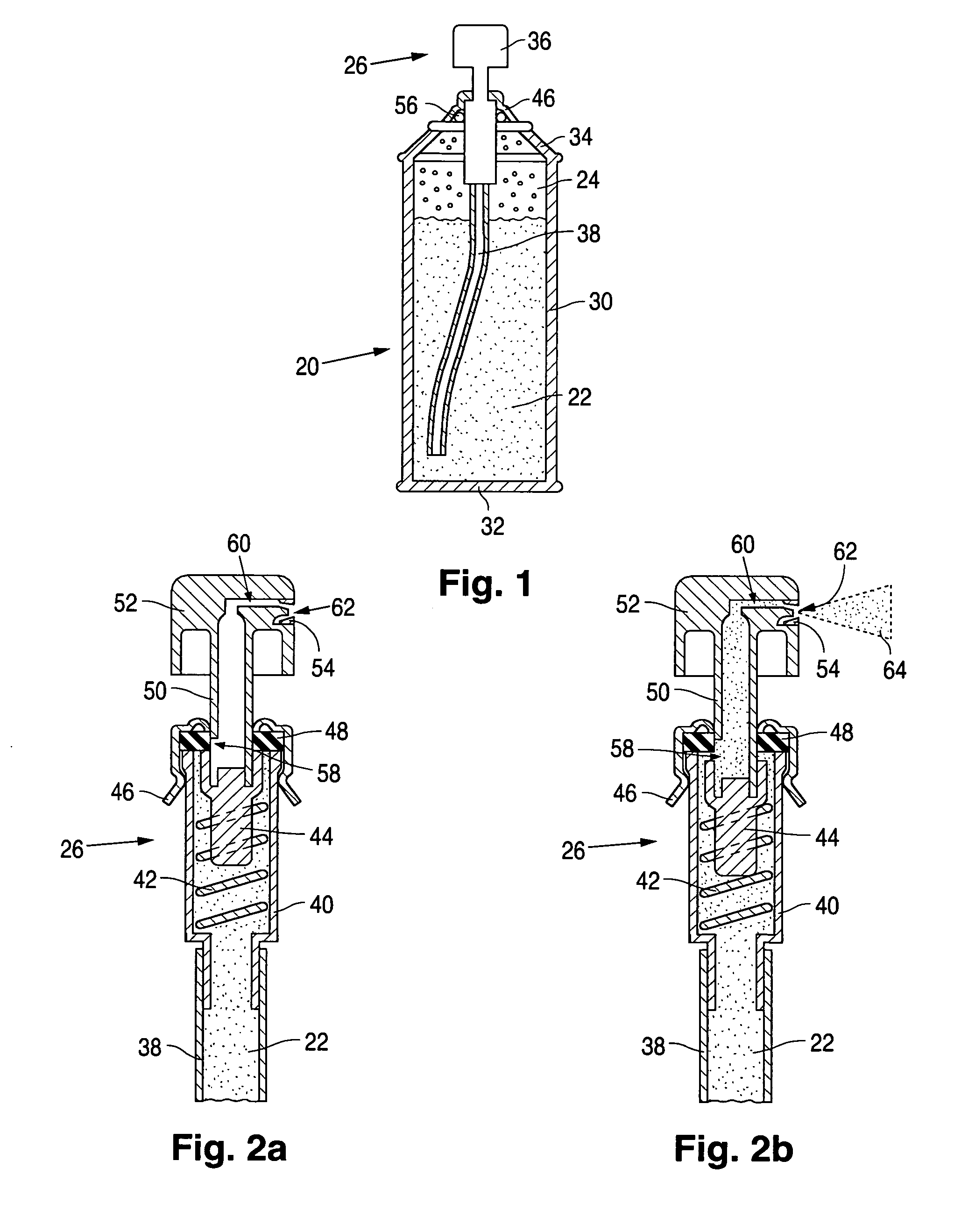

Method and apparatus for producing a peroxyacid solution

InactiveUS20050031530A1Less K2S2OHigh active oxygen contentPeroxyhydrates/peroxyacidsExhaust apparatusHigh concentrationSingle stage

A method and apparatus for production of a high-concentration H2SO5 solution is presented. This high-concentration H2SO5 solution is useful for producing a stable, non-hygroscopic triple salt. The invention includes a single-stage reactor that includes a reservoir for holding an oxyacid solution and an inlet to the reservoir for receiving a peroxide solution. The peroxide solution is added such that a gradient of peroxide concentration forms in the oxyacid solution as a function of distance from the inlet, and less than all of the oxyacid solution reacts with the peroxide solution at a given time. A stirring mechanism slowly dissipates the gradient, so that any H2SO5 formed as a result of reaction between the peroxide and the oxyacid is stirred away from the high-peroxide concentration zone, thereby preventing the decomposition of H2SO5 by an equilibrium reaction. The temperature of the reservoir is maintained at less than or equal to 20 ° C.

Owner:MARTIN PERRY L

Deammonation Method in procedure for producing sodium persulfate

ActiveCN101049913AGood desorption areaGood deamination effectPeroxyhydrates/peroxyacidsDecompositionAmmonia

This invention discloses a method for deamination during sodium persulfate production. The method comprises: pre-heating sodium persulfate solution produced from ammonium persulfate solution and NaOH solution to 30-50 deg.C, and passing through an evaporator with a surface temperature of 60-80 deg.C under (-0.090)-(-0.098) MPa. The thickness of the solution layer is 0.1-5 mm. The method can realize deamination at a high temperature within a short time, thus has an ideal deamination effect, and has reduced side reactions and decomposition rate with high purity and yield.

Owner:XILONG SCI CO LTD

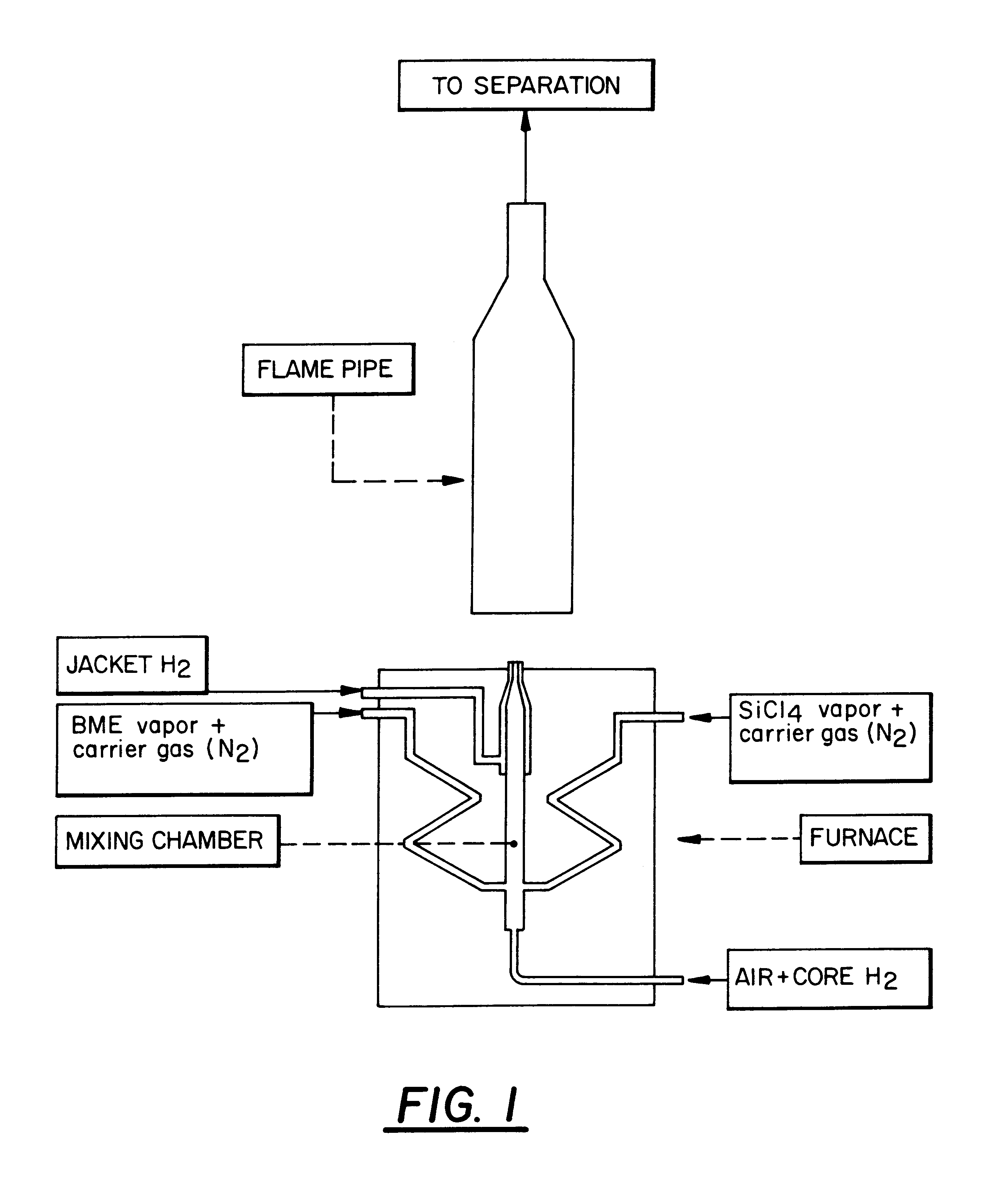

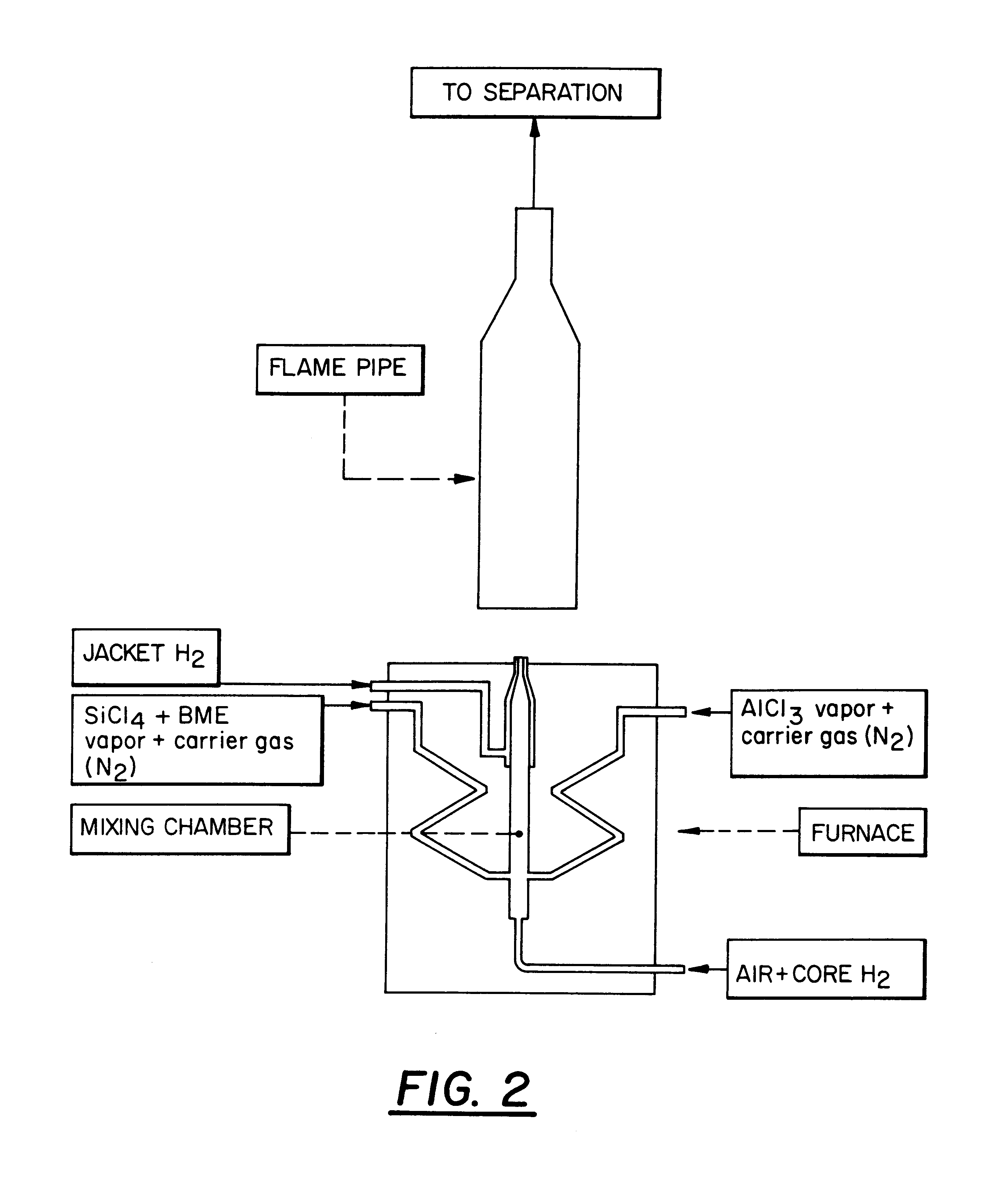

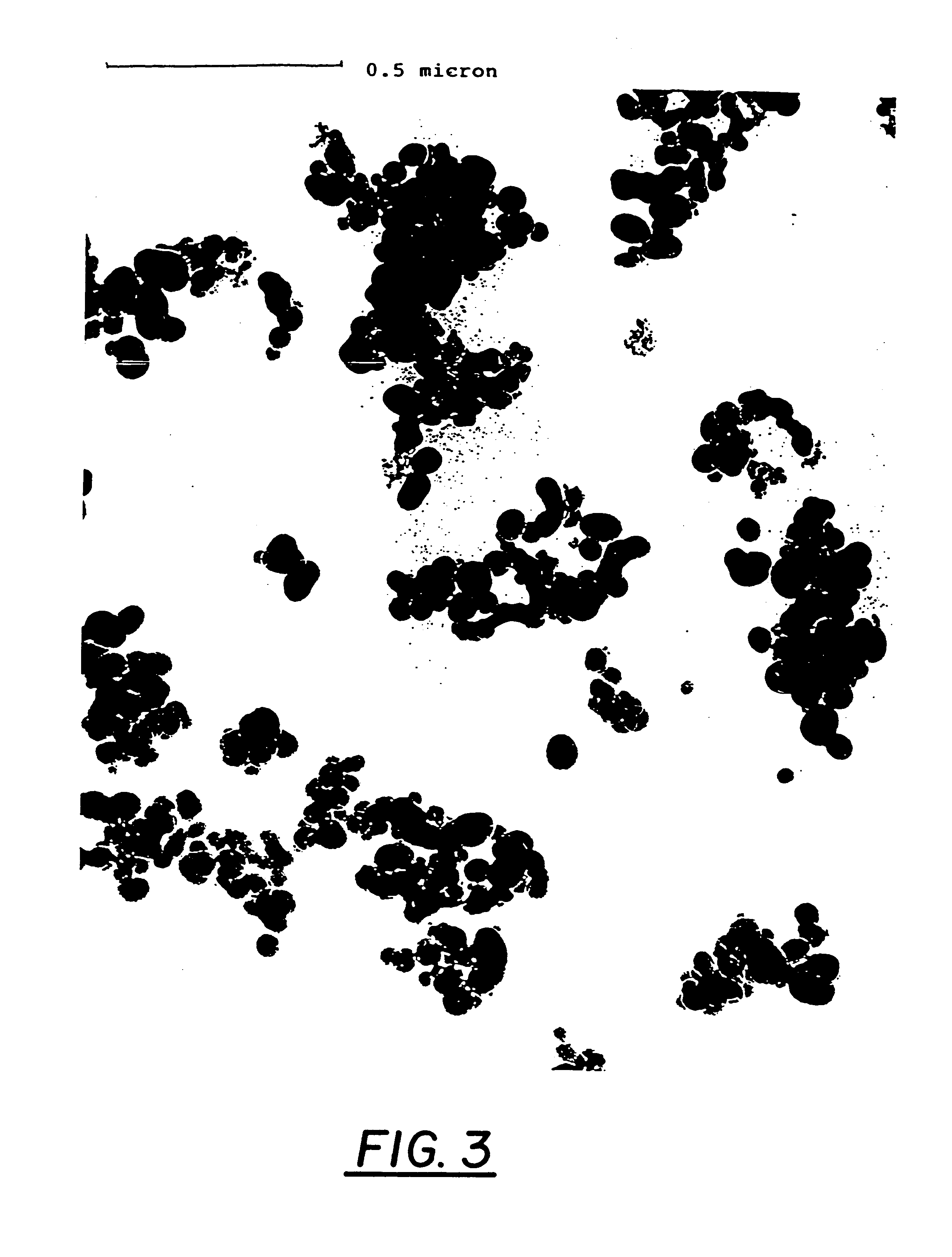

Boron oxide-silicon dioxide mixed oxide

A boron oxide-silicon dioxide mixed oxide which has a BET surface of less than 100 m2g, and optionally containing oxides of aluminium, titanium or zirconium, is prepared pyrogenically by flame hydrolysis. The mixed oxide is used in glass making.

Owner:DEGUSSA AG

Multi-oxidizer-based slurry for nickel hard disk planarization

InactiveUS20040232379A1Easy to controlSemiconductor/solid-state device manufacturingDead animal preservationPtru catalystMetallurgy

A slurry composition for planarizing nickel or nickel-alloy coating on substrates, such as a nickel coating on a memory hard disk, includes at least two oxidizers, an abrasive, water, and no metal catalyst. The composition is effective for polishing nickel (Ni) and nickel alloys coatings formed in the manufacture of memory disks.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Anti-caking processing method of potassium monopersulfate compound salt

InactiveCN101372318ADoes not reduce active oxygen contentImprove liquidityPeroxyhydrates/peroxyacidsMonoglycerideHydrogen Sulfate

The invention relates to a processing method for preventing agglomeration of potassium peroxymonosulfate, and belongs to the technical field of preparing inorganic peroxide; wet potassium peroxymonosulfate is added with a surface active agent which is taken as a anti-caking agent in a spraying way, and after drying a magnesium compound which functions as a separant is added in; the surface active agent can be any one of or the mixture of more than one of sodium dodecyl sulfate, sodium alpha-olefin sulfonate, fatty alcohol polyoxyethylene ether, polyoxyethylene polyoxypropylene ether, dodecyl trimethyl ammonium chloride, sodium carboxymethyl cellulose, fatty alcohol polyoxyethylene alkyl ether ammonium sulfate, stearic acid monoglyceride, methyl-silicone oil, nonylphenol ethoxylates, and the like, and the addition amount accounts for 0.05-1% of the weight of the wet potassium peroxymonosulfate. By properly selecting the surface active agent as the anti-caking agent and the magnesium compound as the separant, the processing method has the advantages of simple production technique and easy operation and is suitable for large-scale industrial production.

Owner:陶华西

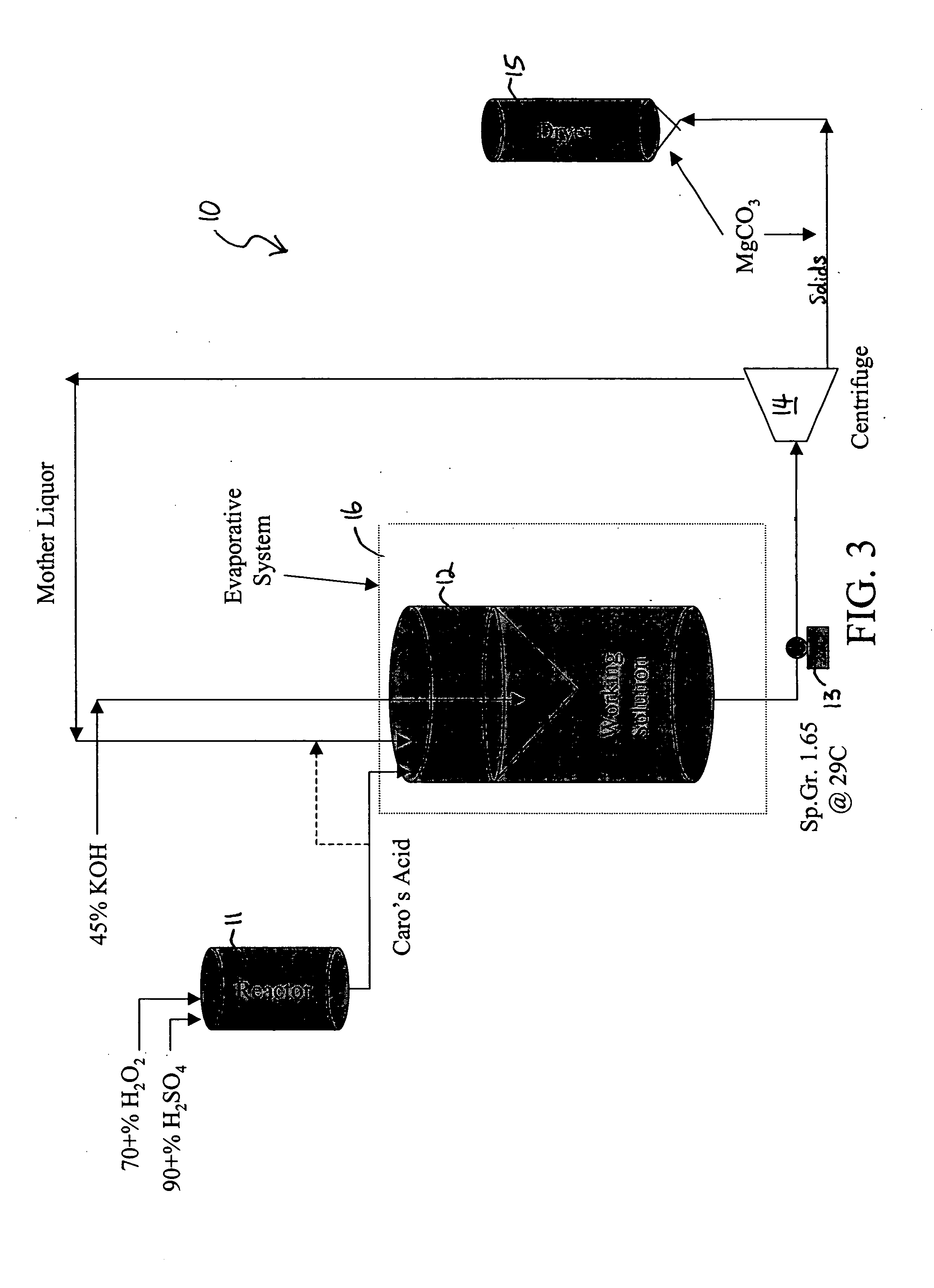

Method for treating tailing slurries with Caro's acid

InactiveUS6090297AMinimize decomposition and hydrolysisEfficient dilutionPeroxyhydrates/peroxyacidsSulfur compoundsCyanideSlurry

A process for treating precious metal tailing slurries with Caro's acid, in which the Caro's acid is accompanied by reduced amounts of Caro's acid mist, is disclosed. The hot Caro's acid-containing mixture, formed by reaction of concentrated sulfuric acid and hydrogen peroxide, is quenched with water to reduce or eliminate the Caro's acid mist. The resulting cooled and diluted mixture is introduced into a precious metal tailings slurry to reduce the amount of cyanide values in the slurry.

Owner:FMC CORP

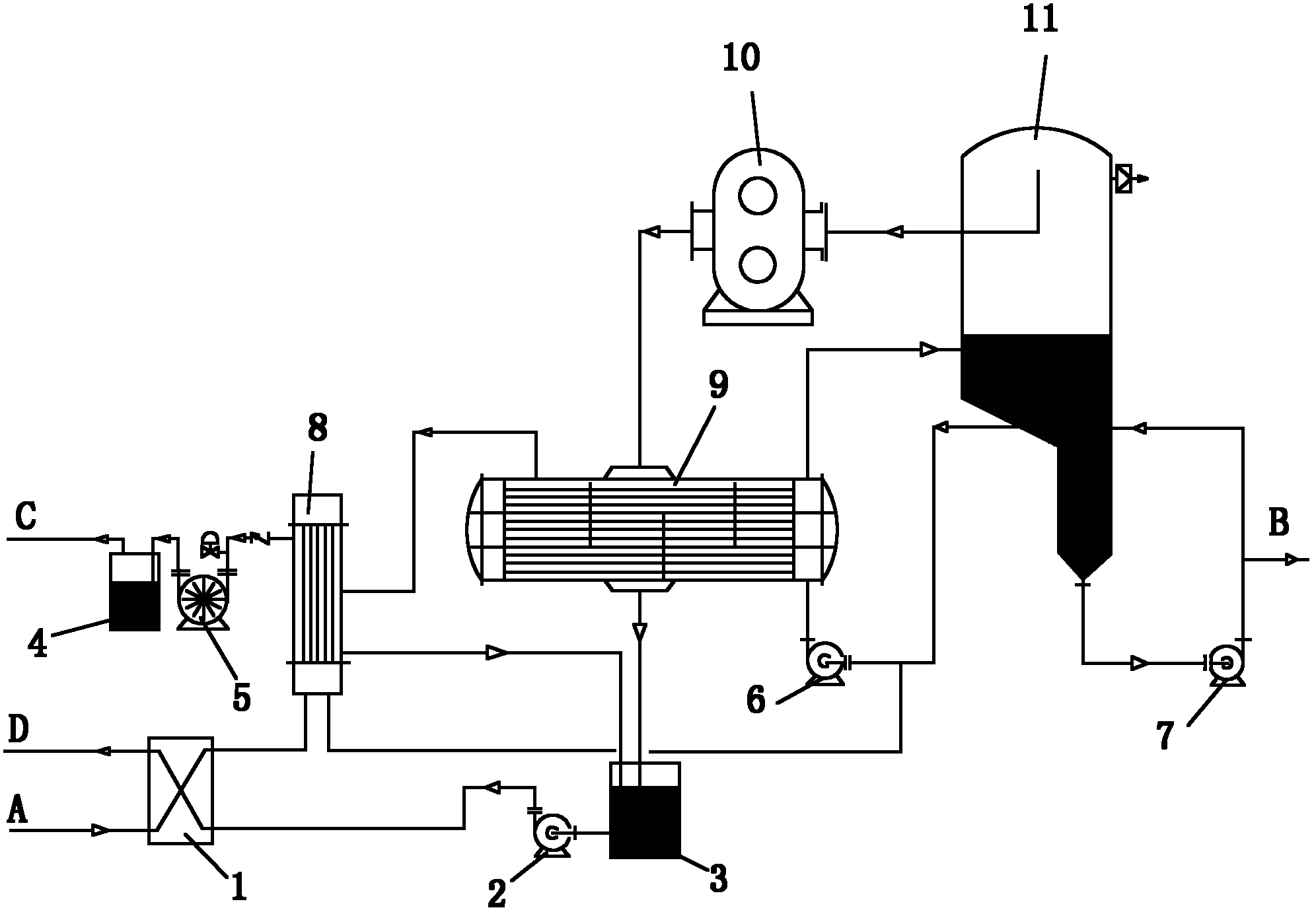

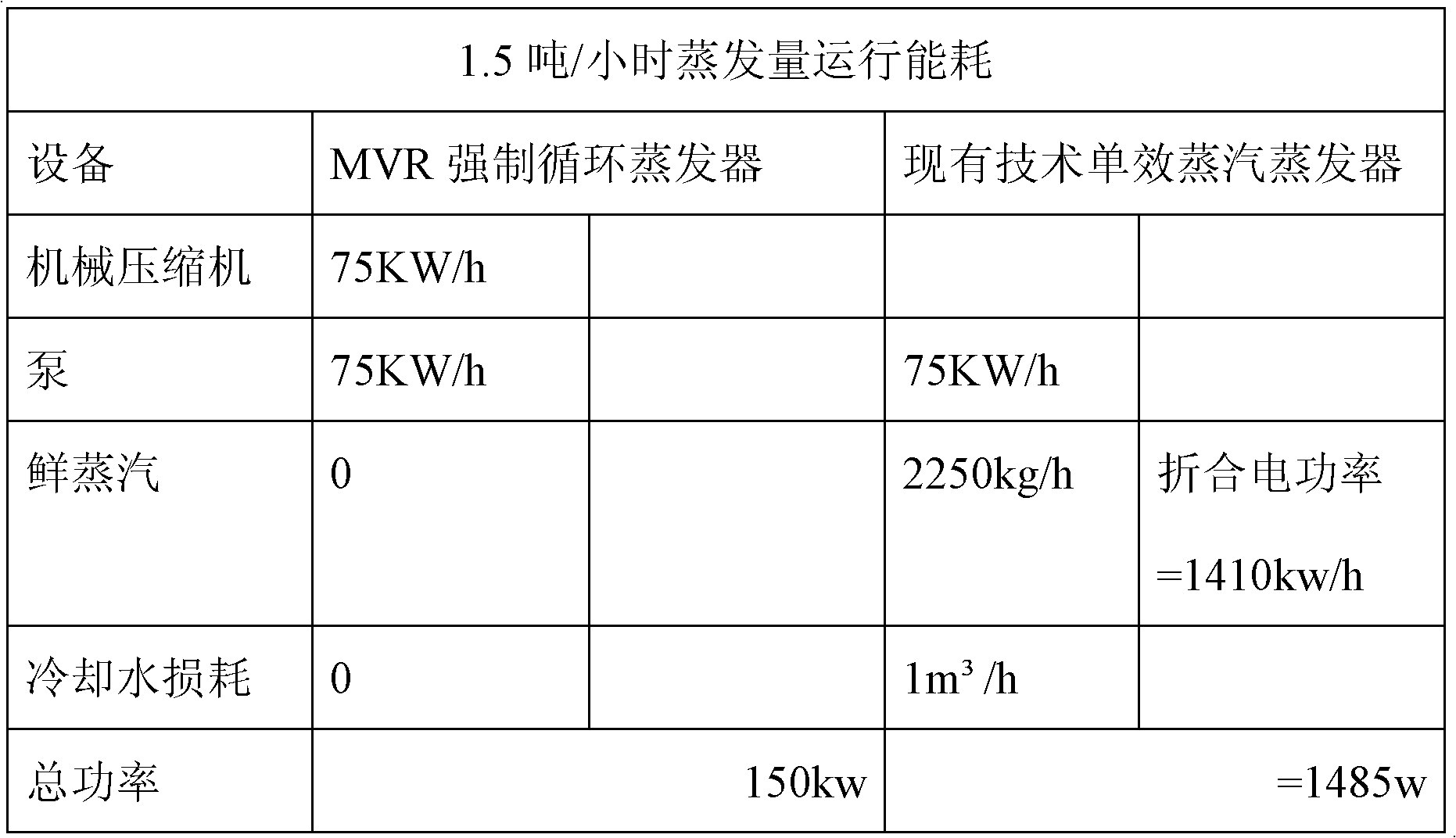

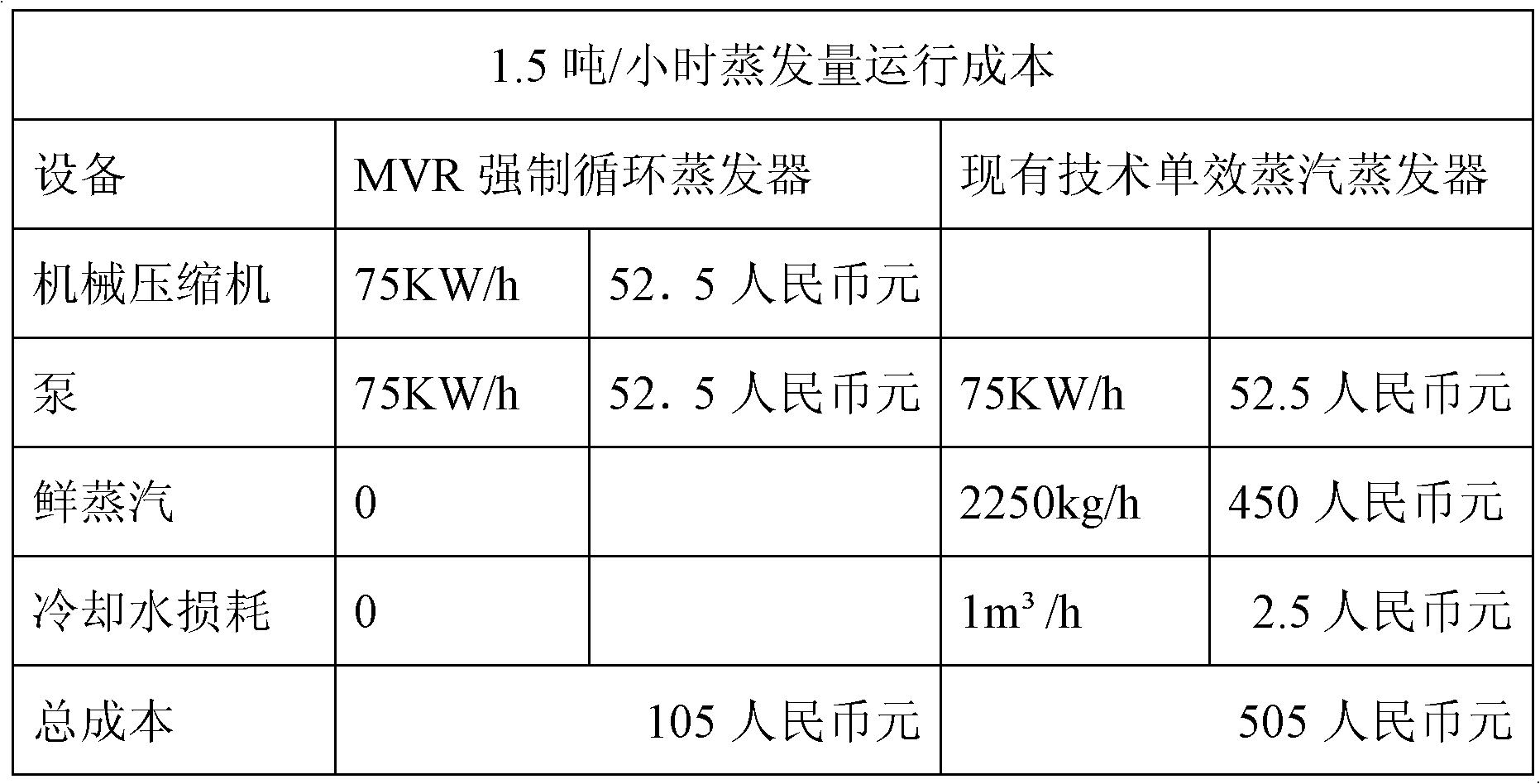

Method for evaporating sodium persulfate at low temperature

ActiveCN102320575ALower evaporation temperatureGet rid of dependencePeroxyhydrates/peroxyacidsChemical industryElectricityFully automatic

The invention discloses a method for evaporating sodium persulfate at a low temperature, and the technical problem needs to be solved, and the cost for evaporating the sodium persulfate needs to be lowered. The method disclosed by the invention comprises the following steps of: feeding and preheating, forcibly and circularly heating and evaporating, crystallizing and separating through a separator, extracting, and centrifuging to obtain sodium-persulfate crystal grains and a mother solution. Compared with the prior art, the sodium persulfate is evaporated by using a mechanical-type steam-recompression evaporator, so that the evaporating temperature of the sodium persulfate is decreased, energy is saved, and the environment is protected; the energy consumption for evaporating 1 ton of water is about 1 / 6 to 1 / 5 of that of a traditional evaporator, so that the method completely gets rid of the dependence on a steam boiler and can be used as along as electricity exists; and the method hasa high automation degree and fully-automatic working flows and does not need to be manually monitored.

Owner:SHENZHEN SUNEVAP TECH

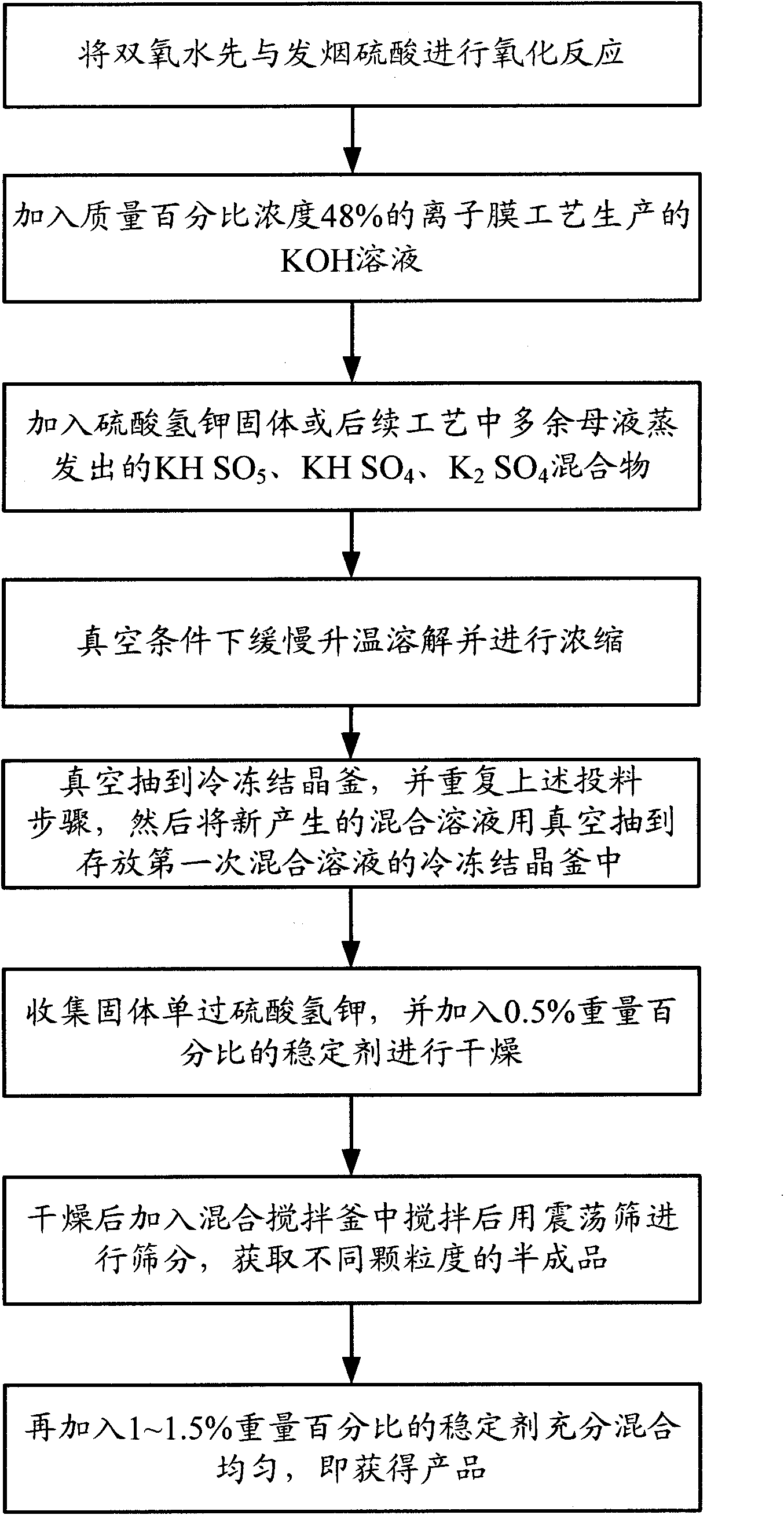

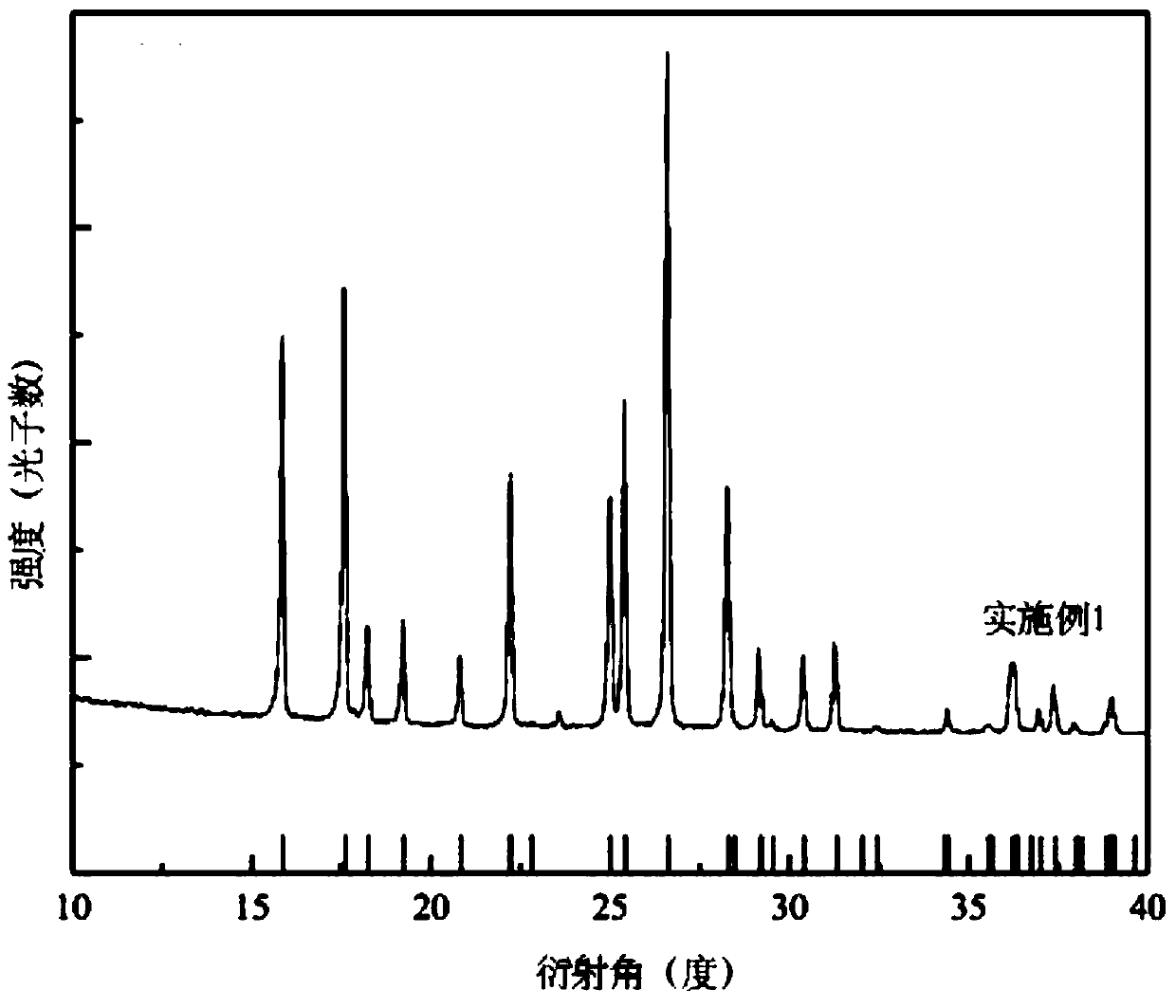

Method for preparing potassium hydrogen peroxymonosulfate composite salt

ActiveCN102311100AEasy to operateEase of industrial productionPeroxyhydrates/peroxyacidsIonHydrogen peroxide

The invention relates to a method for preparing potassium hydrogen peroxymonosulfate composite salt. The method comprises the following steps: (1) firstly carrying out oxidation reaction on hydrogen peroxide and fuming sulfuric acid; (2) adding potassium hydrogen sulfate aqueous solution with the ratio of K to S being 0.8 to 1 or a mixed solution of potassium hydrogen sulfate and sulfuric acid or mother liquor after crystallization and centrifugation processes to the product obtained in the step (1), mixing and reacting to obtain the target product mixed solution of relatively stable H2SO5, KHSO5, KHSO4, H2SO4 and the like; (3) adding a 48wt% KOH solution produced by an ionic membrane process into the mixed solution produced in the step (2), and reacting under the vacuum condition; (4) adding potassium hydrogen sulfate solid or the mixture of KHSO5, KHSO4 and K2SO4 evaporated in the redundant mother liquor in the subsequent process into the mixed solution produced in the step (3), slowly heating for dissolving in vacuum, and concentrating; and (5) cooling and crystallizing, then collecting solid potassium hydrogen peroxymonosulfate by adopting a conventional method, and drying to obtain the product.

Owner:宋海鹏

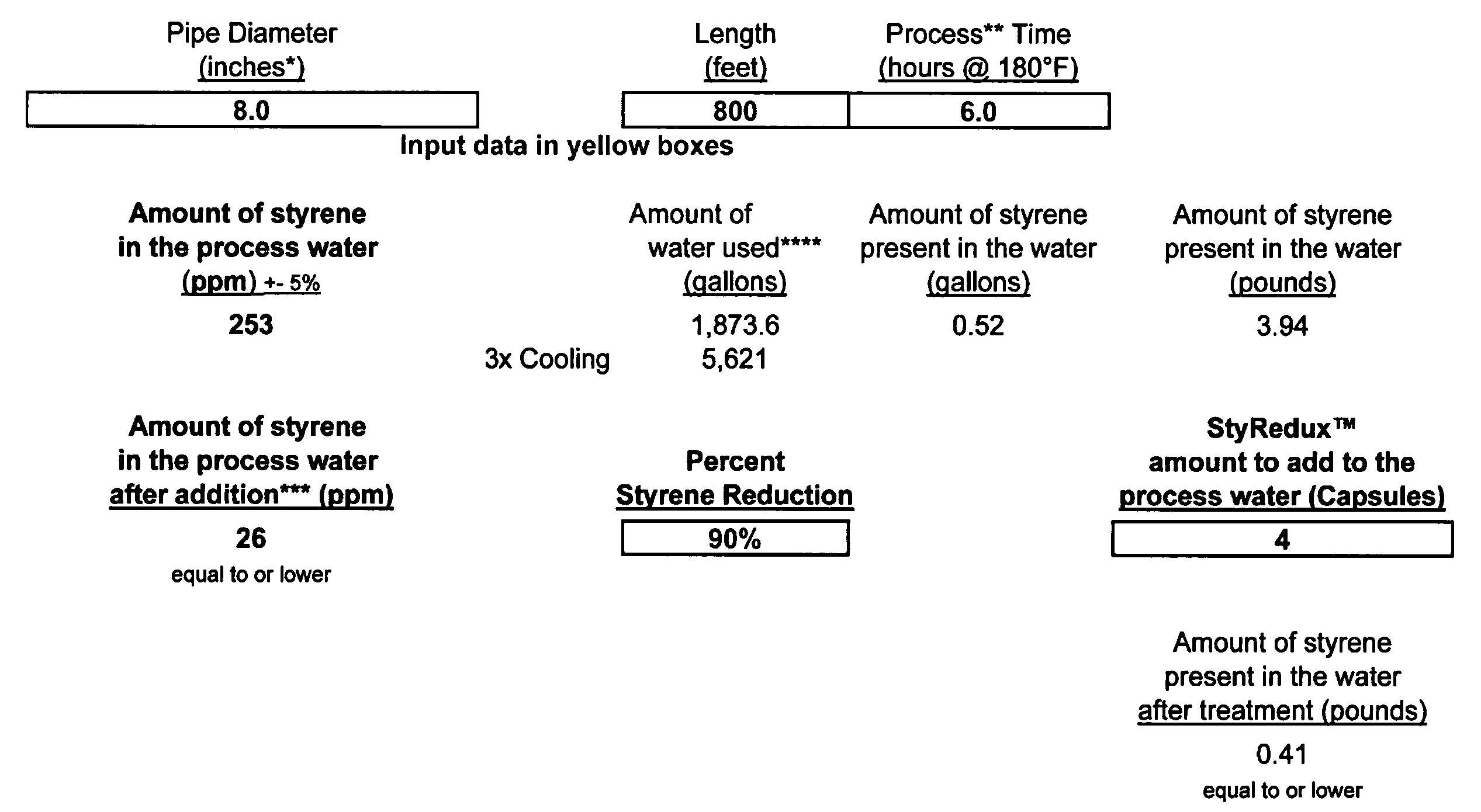

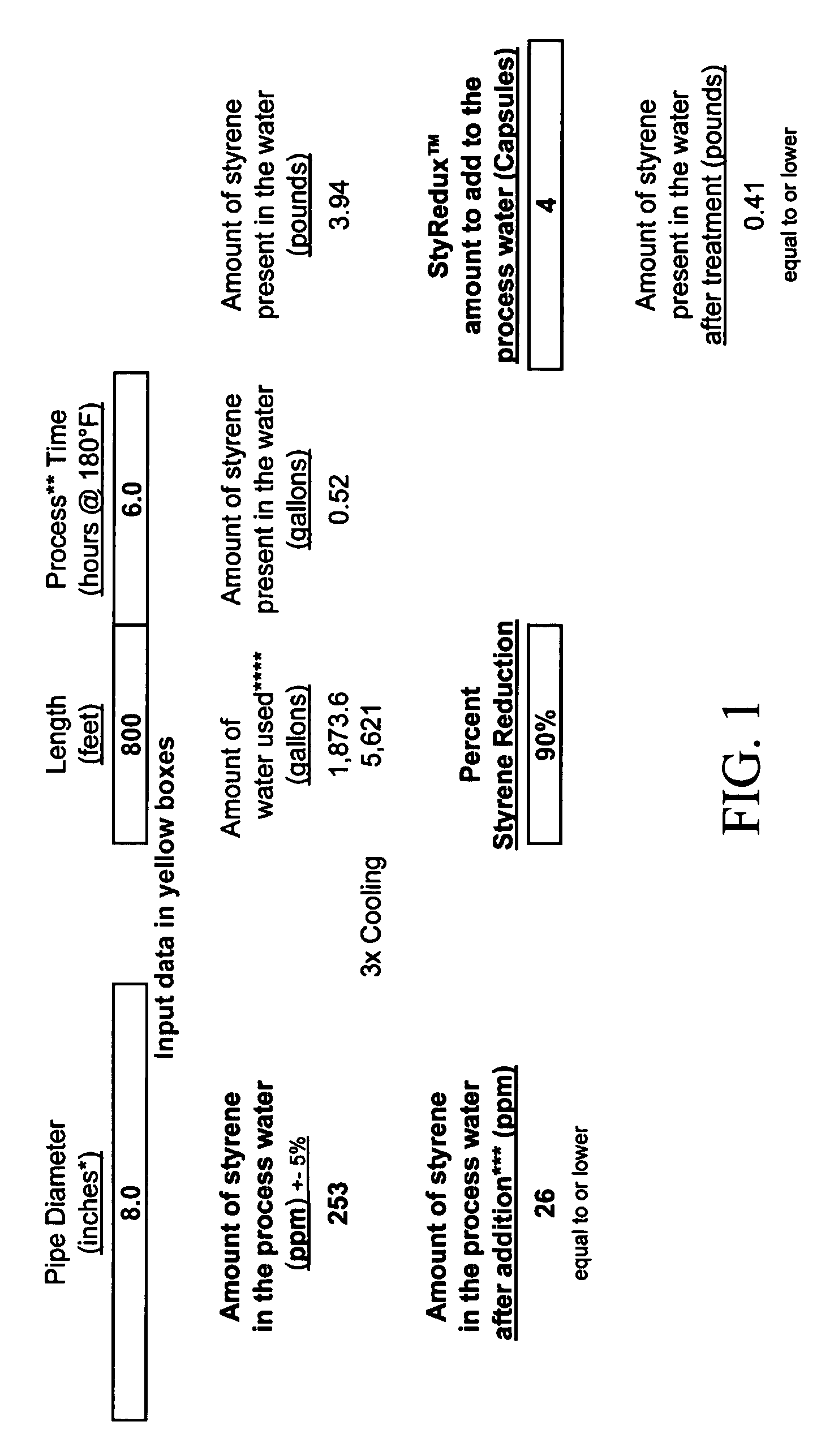

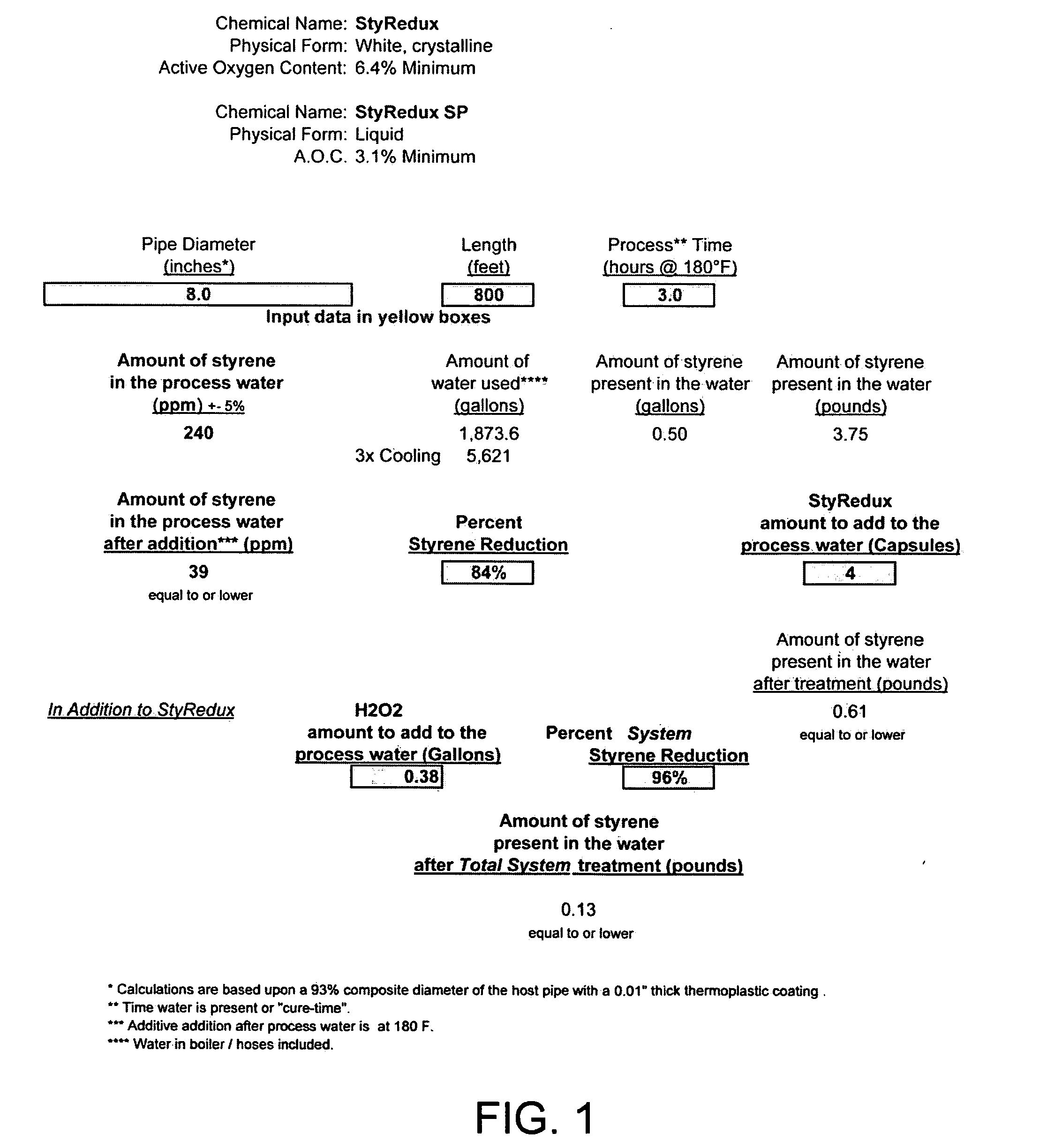

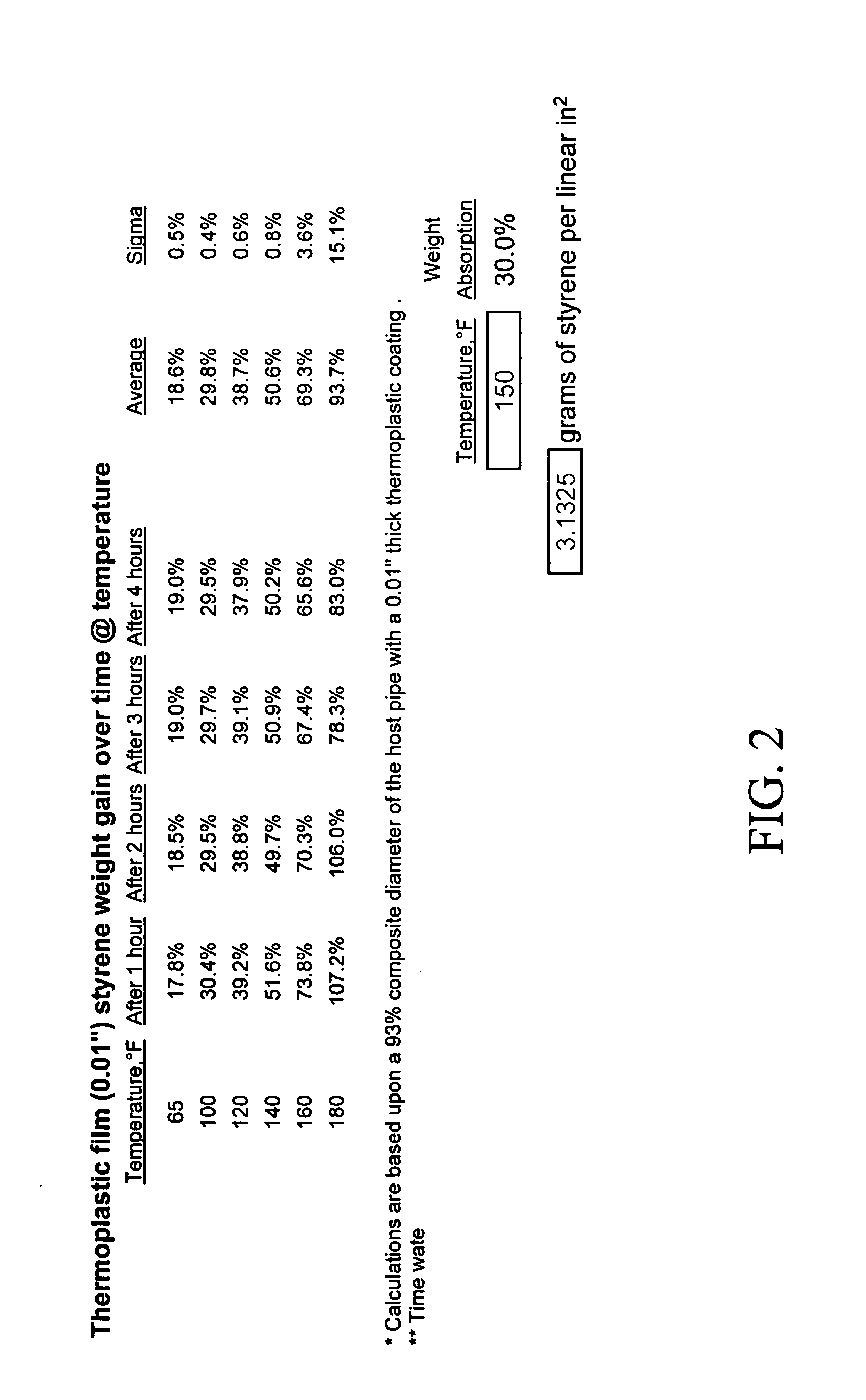

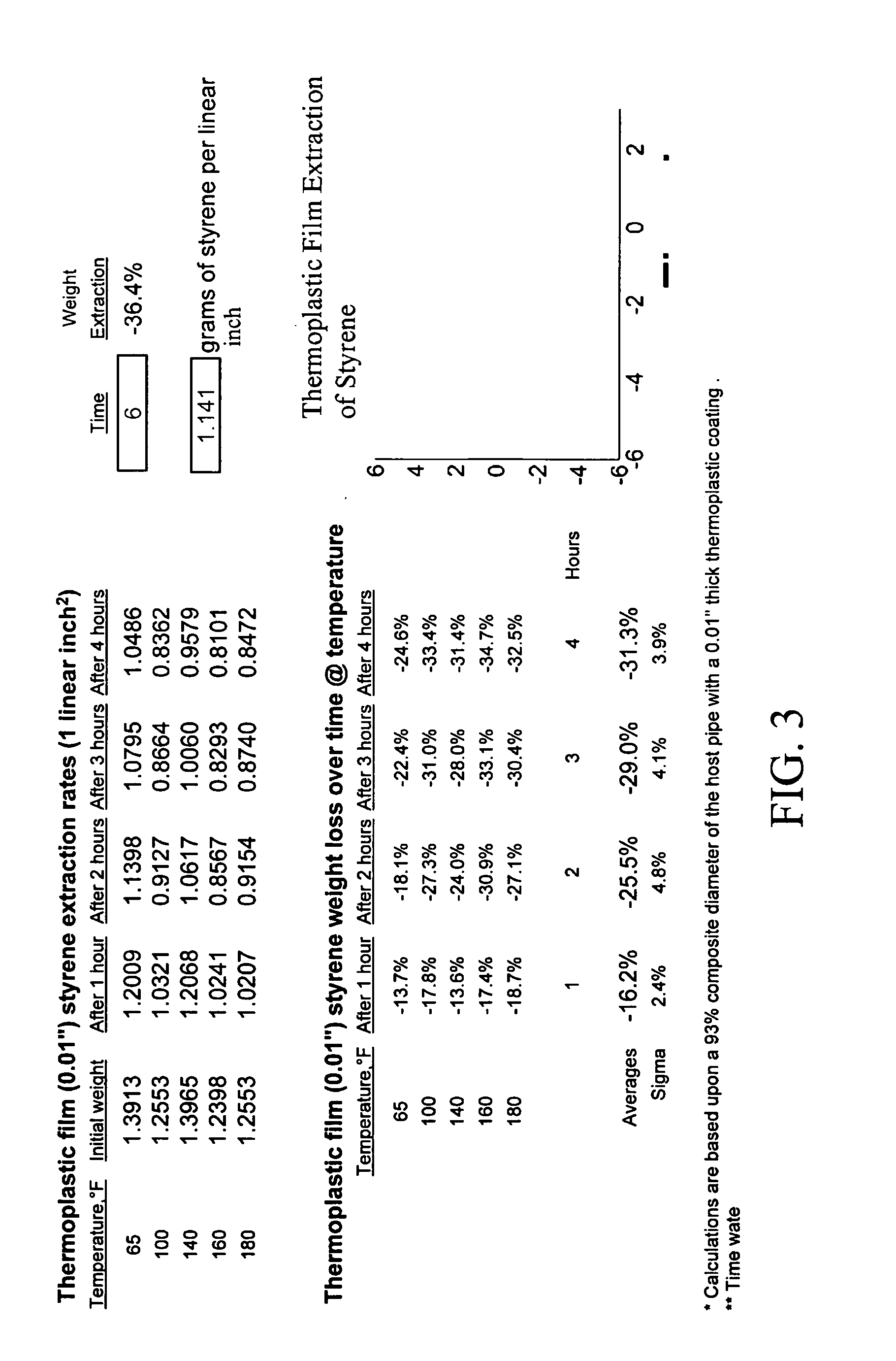

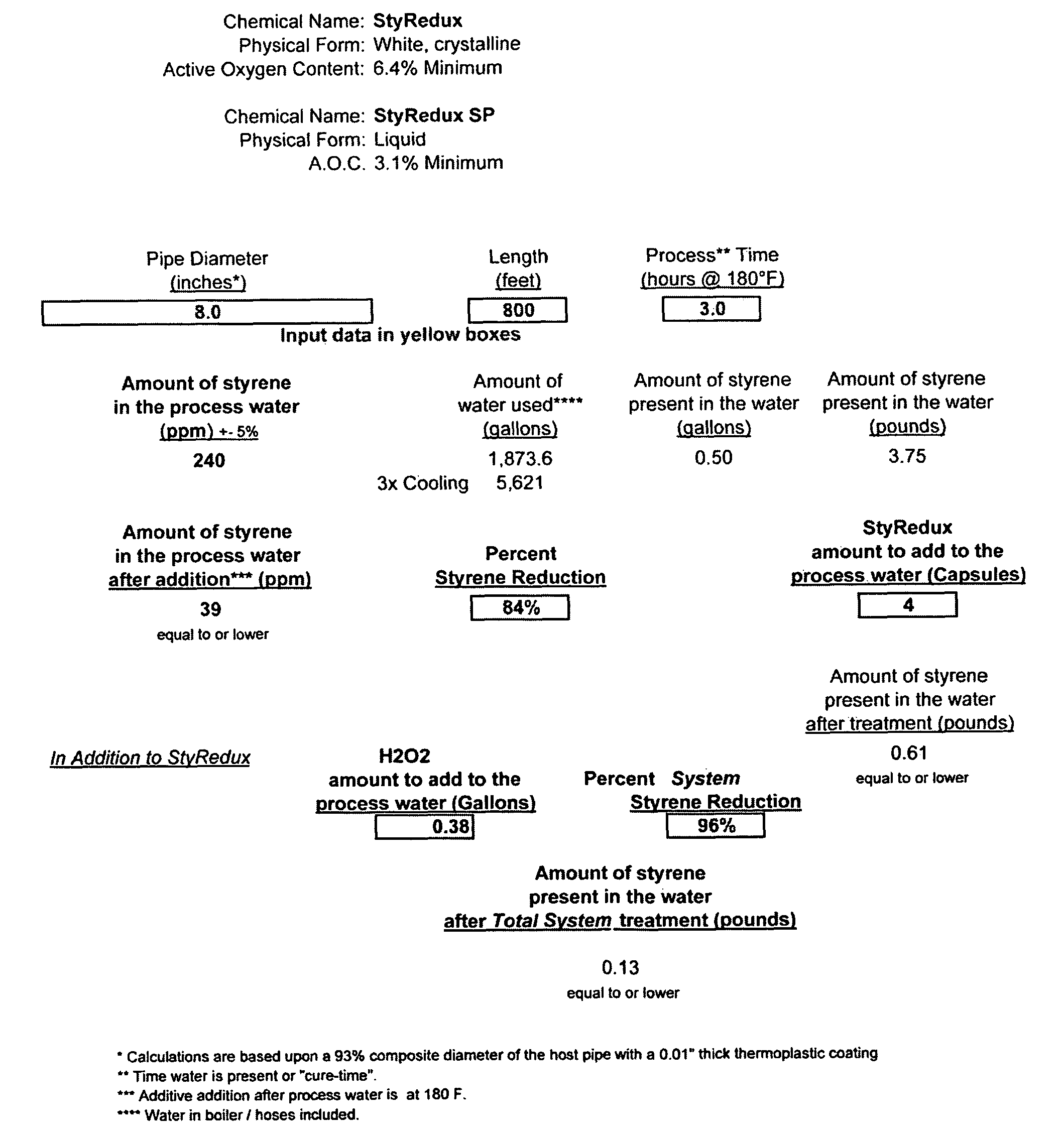

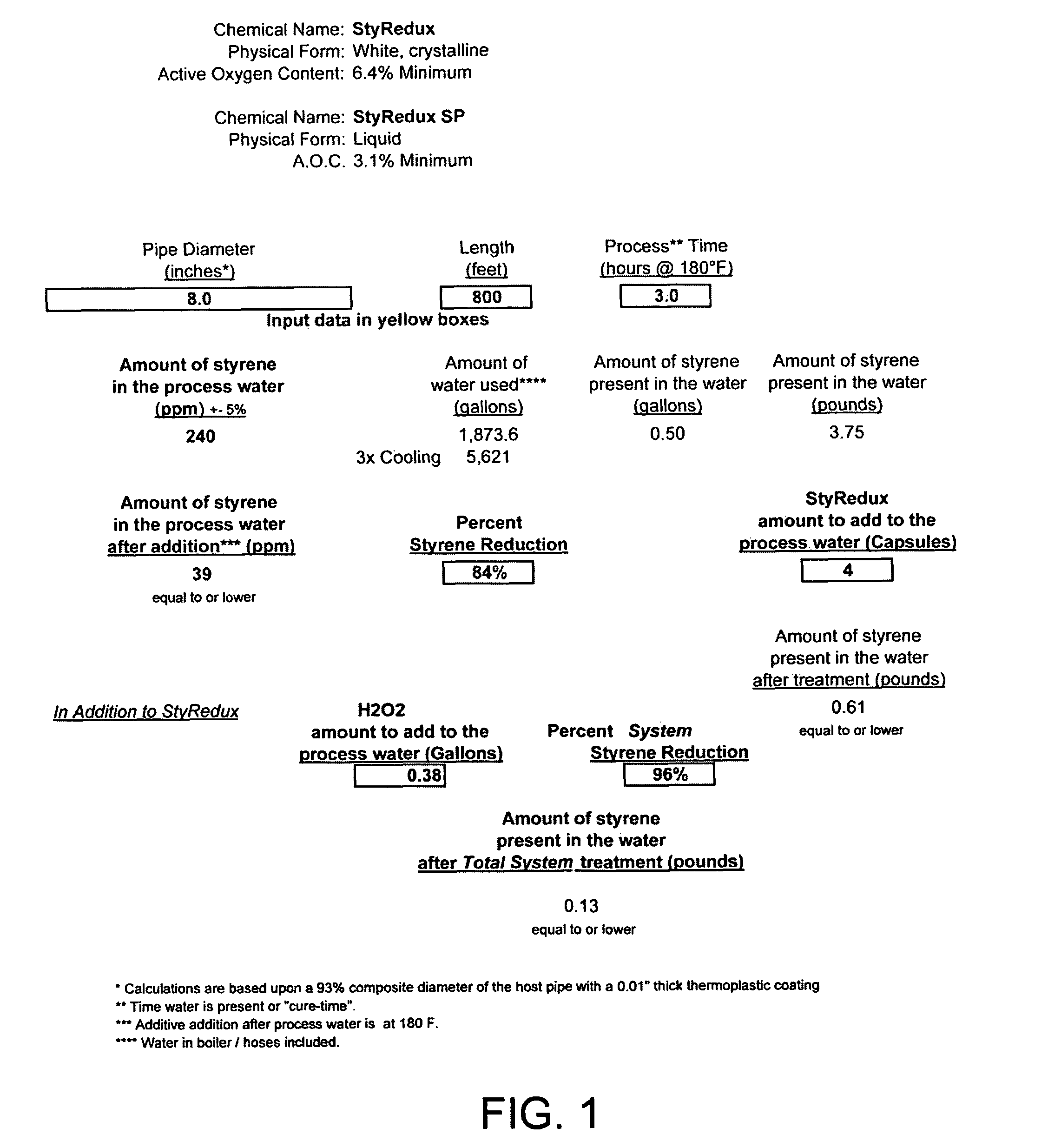

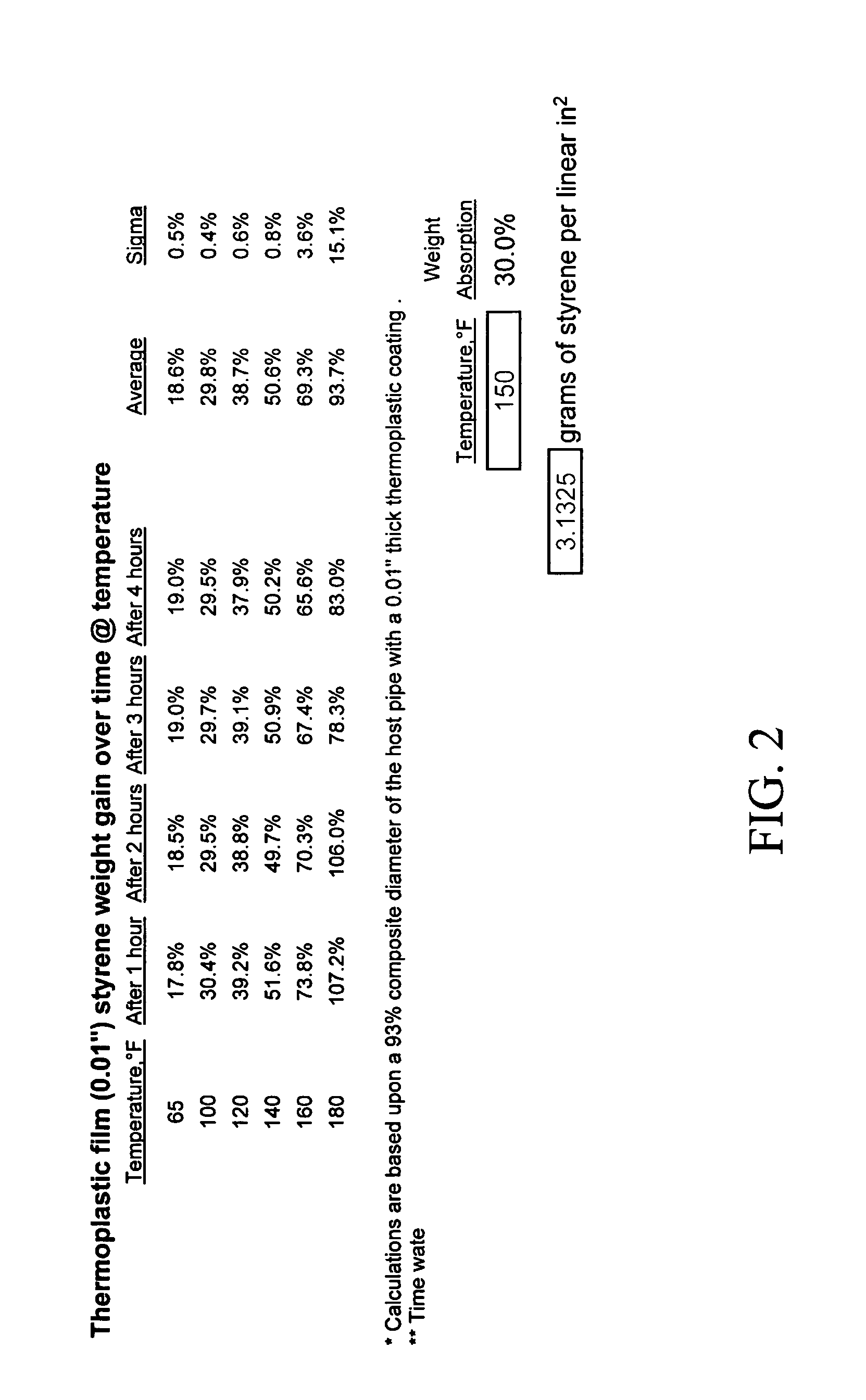

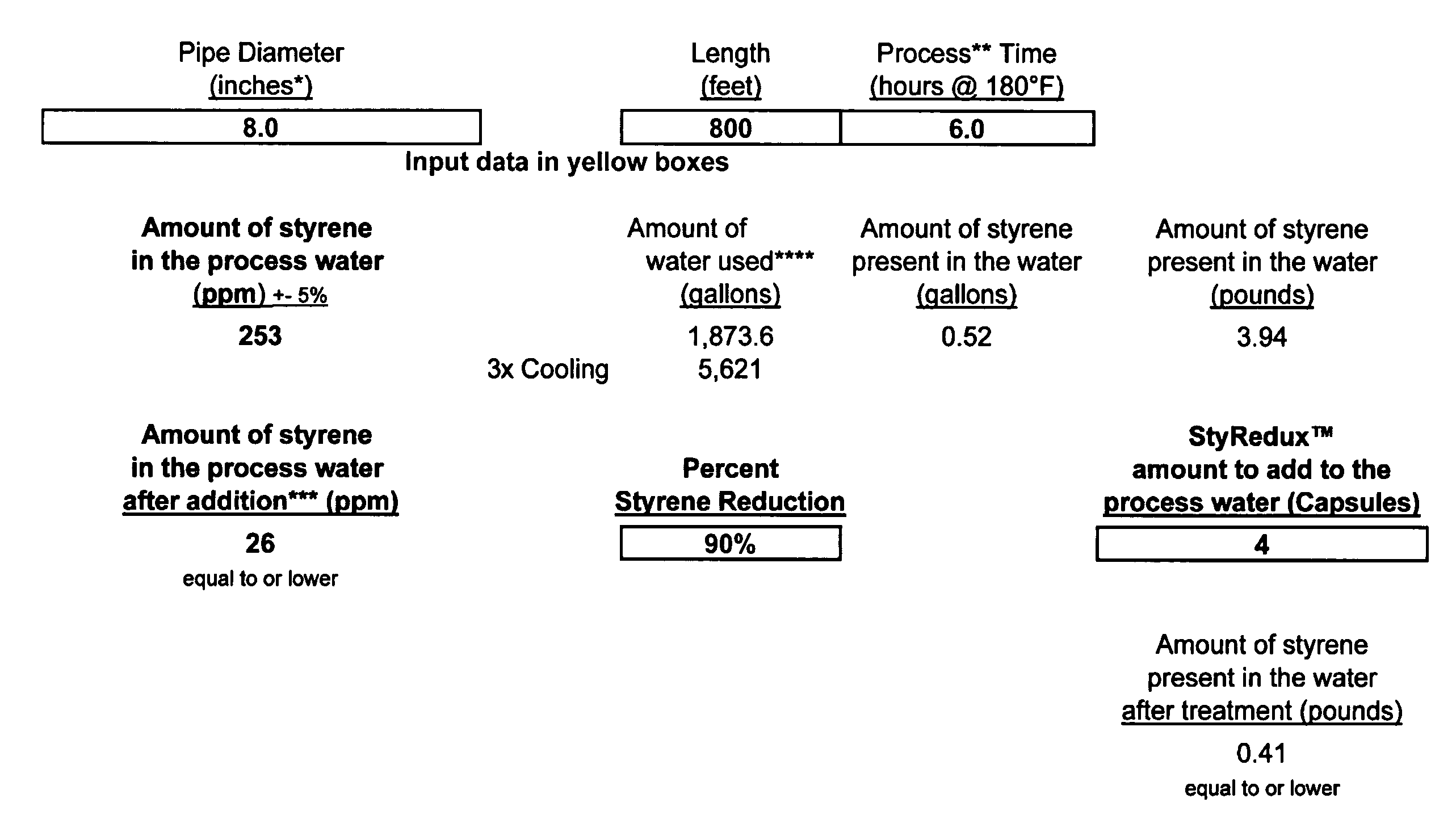

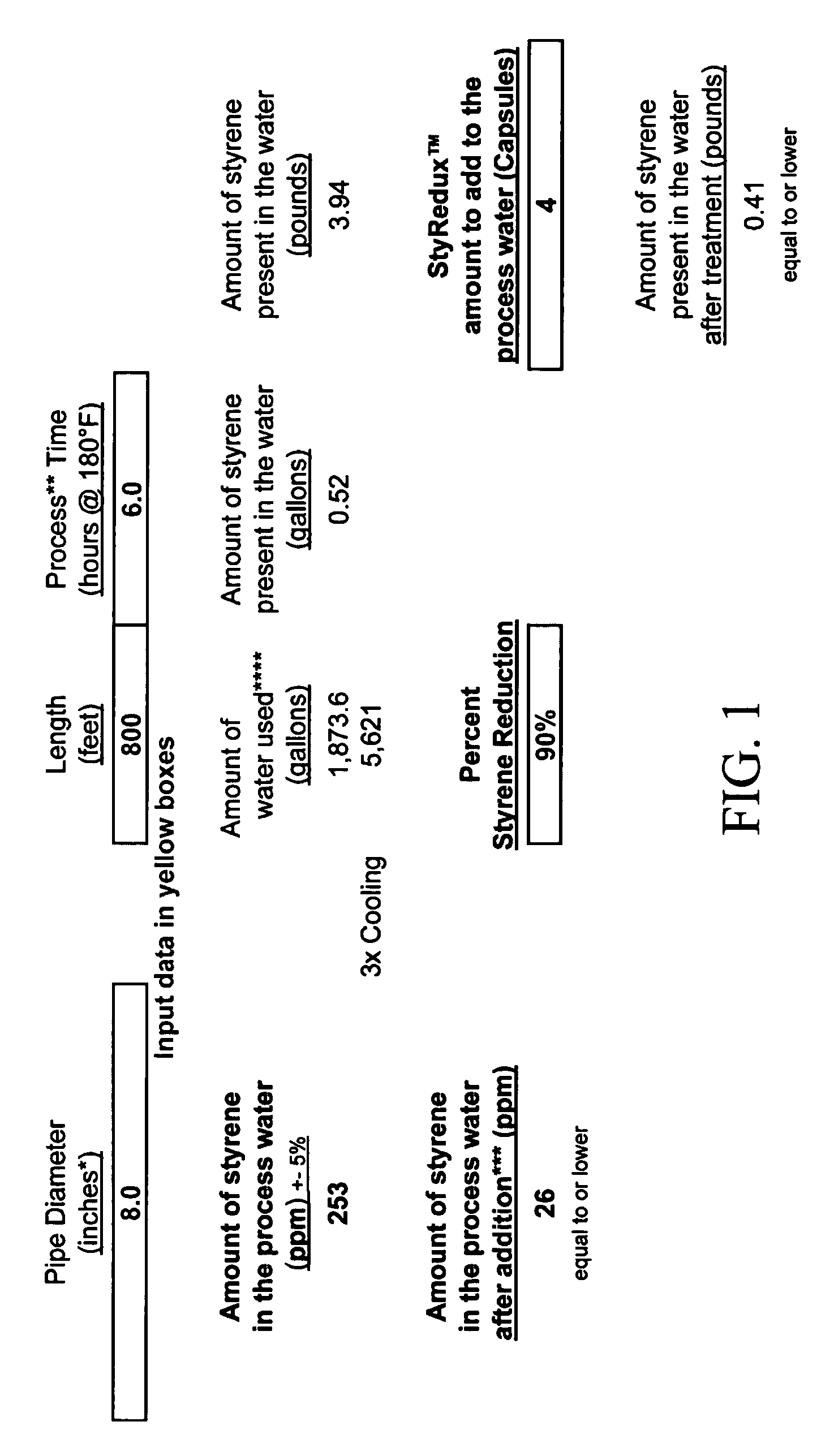

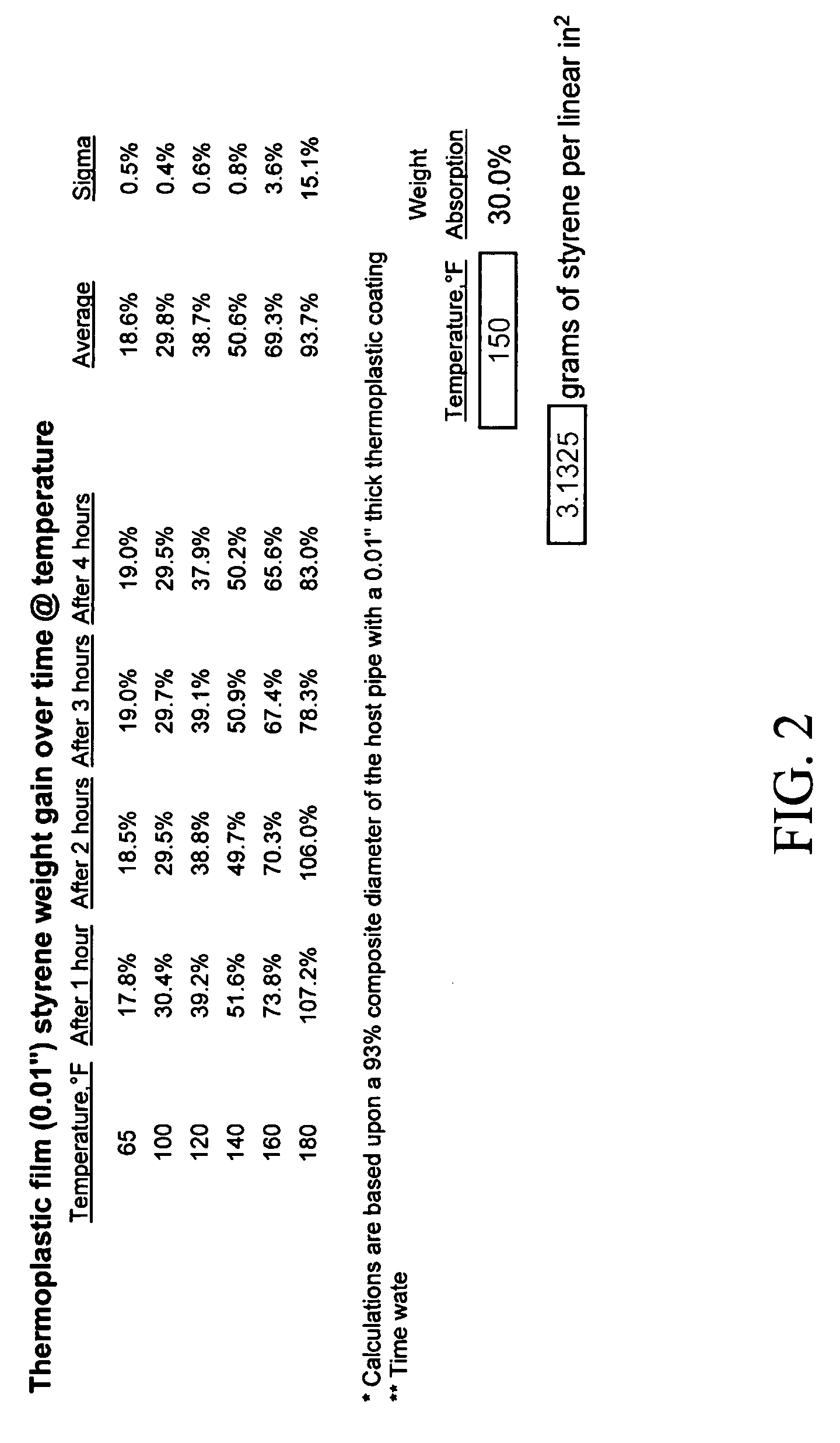

Styrene reduction agent

InactiveUS20060270761A1Reduce decreaseFacilitate quickHydrogen peroxidePeroxyhydrates/peroxyacidsCured-in-place pipeResidual monomer

A styrene reduction agent that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. Capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHEL

Preparation of single potassium persulfate

InactiveCN1778669AEasy to operateEase of industrial productionPeroxyhydrates/peroxyacidsSodium/potassium compoundsPotassium persulfatePotassium bisulfate

Production of monoper-potassium bisulfate includes oxidation reacting for hydrogen peroxide sulfuric acid to obtain reaction product, reacting the product with potassium hydrate to obtain monoper-potassium bisulfate solution, cooling, crystallizing, collecting solid monoper-potassium bisulfate, drying and obtaining end product. It is simple and convenient for industrial production.

Owner:JIAYUAN IND SHANGHAI

Preparation method of potassium peroxymonosulfate

InactiveCN108821242AHigh degree of directional hydrolysisMild responsePeroxyhydrates/peroxyacidsHigh concentrationPeroxydisulfate

The invention discloses a preparation method of potassium peroxymonosulfate. The preparation method comprises following steps: adding a potassium peroxydisulfate solution into a hydrolysis reactor, carrying out hydrolysis under the action of a catalyst to generate potassium peroxymonosulfate and potassium hydrogen sulfate; after the hydrolysis degree reaches the requirement, removing the catalystfrom the solution by a filter, adding the solution into a neutralization reactor, adding a stabilizing agent into the neutralization reactor, then adding potassium hydrogen sulfate solids, stirring, mixing; then adding potassium hydroxide into the neutralization reactor to carry out neutralization reactions; carrying out vacuum concentration, cooling, crystallizing, performing centrifugal separation, and baking to obtain a dry product of potassium peroxymonosulfate. Potassium peroxydisulfate is used to replace high concentration hydrogen peroxide, reacts with fuming sulfuric acid, and is hydrolyzed to generate potassium peroxymonosulfate and potassium hydrogen sulfate under the action of a catalyst; the reactions are mild, the reaction heat is little, the danger of reactions is reduced effectively; under the action of the catalyst, the degree of directional hydrolysis is high, the active oxygen content of products is qualified, and the product quality is stable.

Owner:SHANGYU JIEHUA CHEM

Catalytic oxidation of peroxy salts

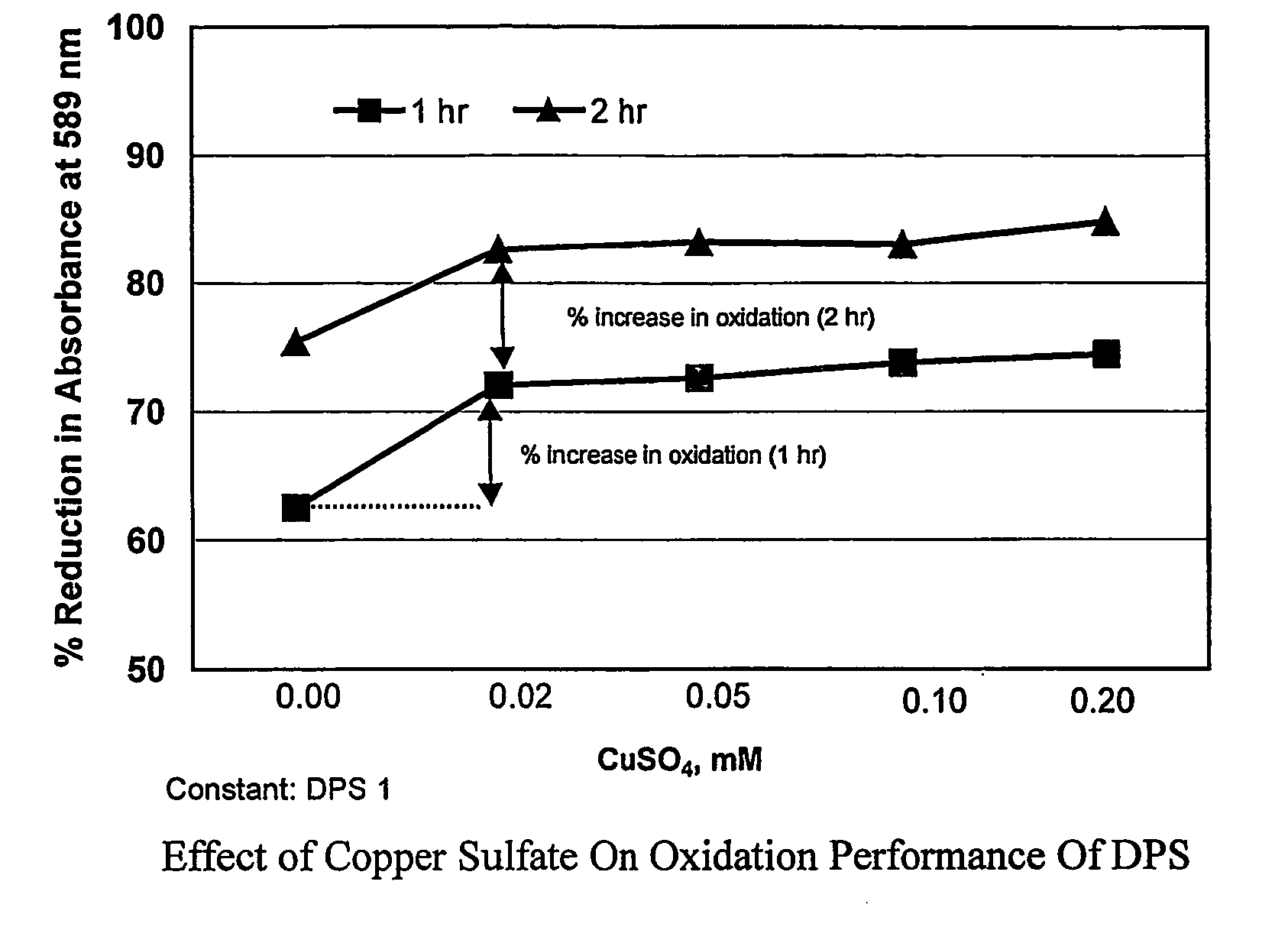

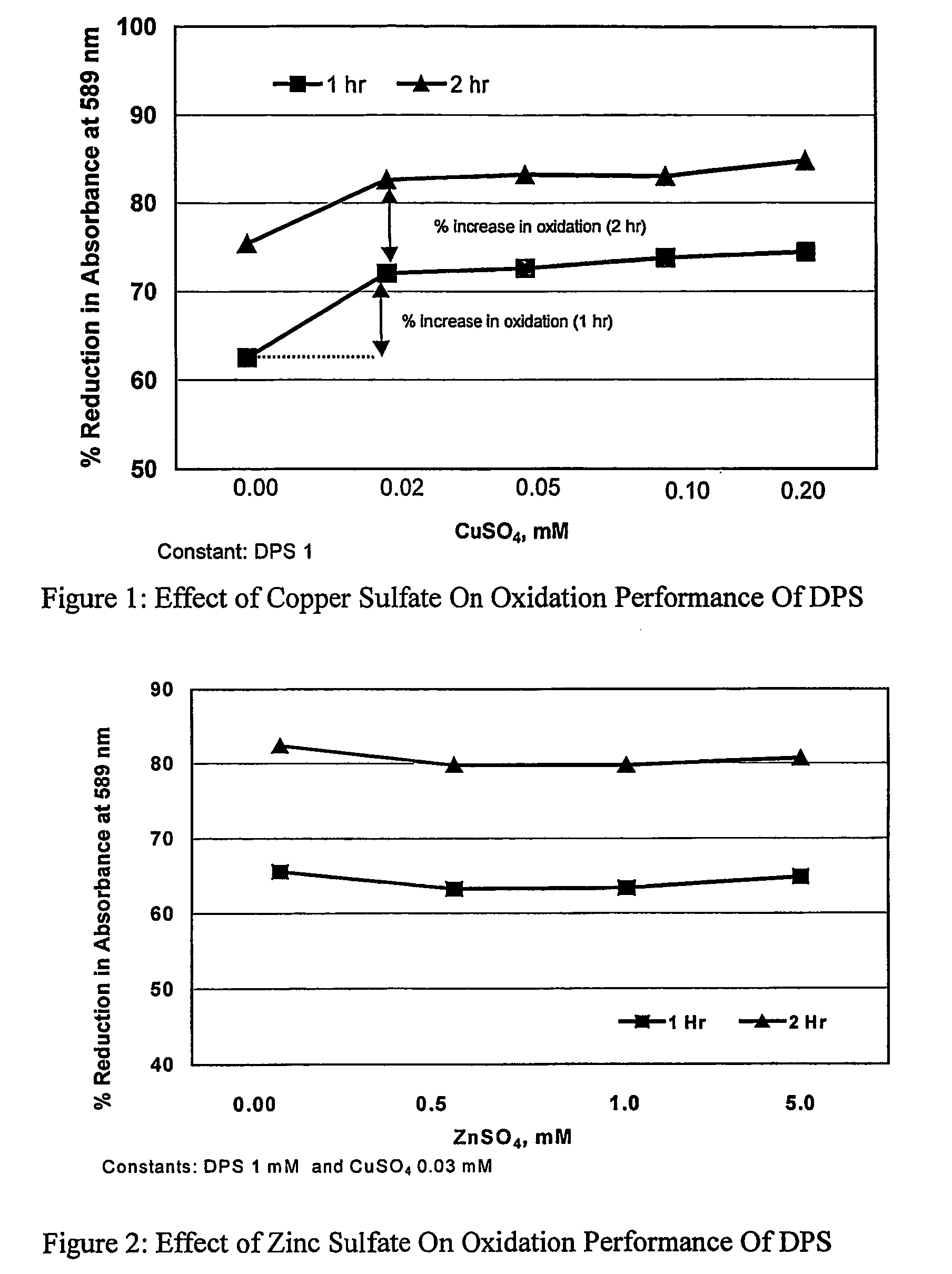

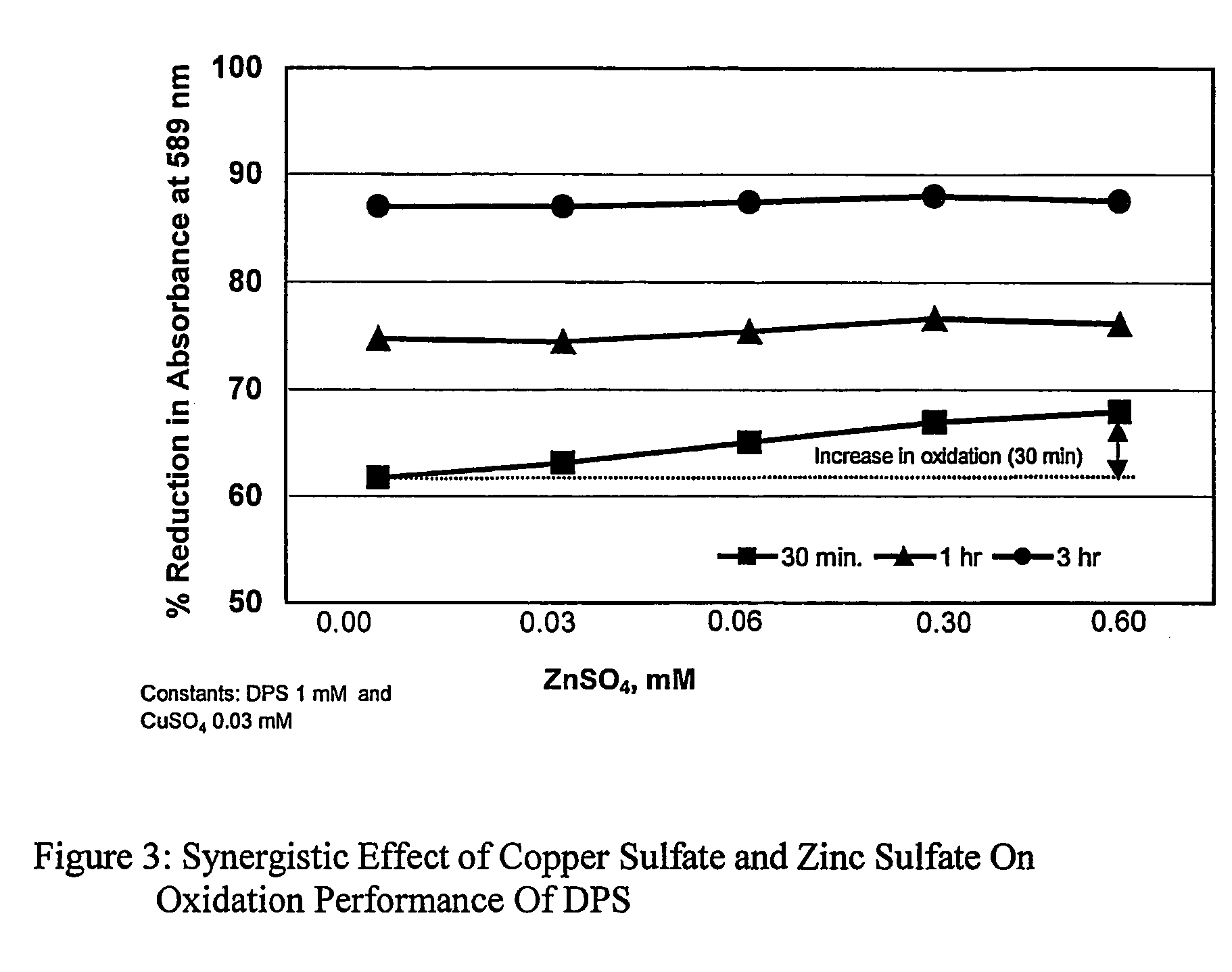

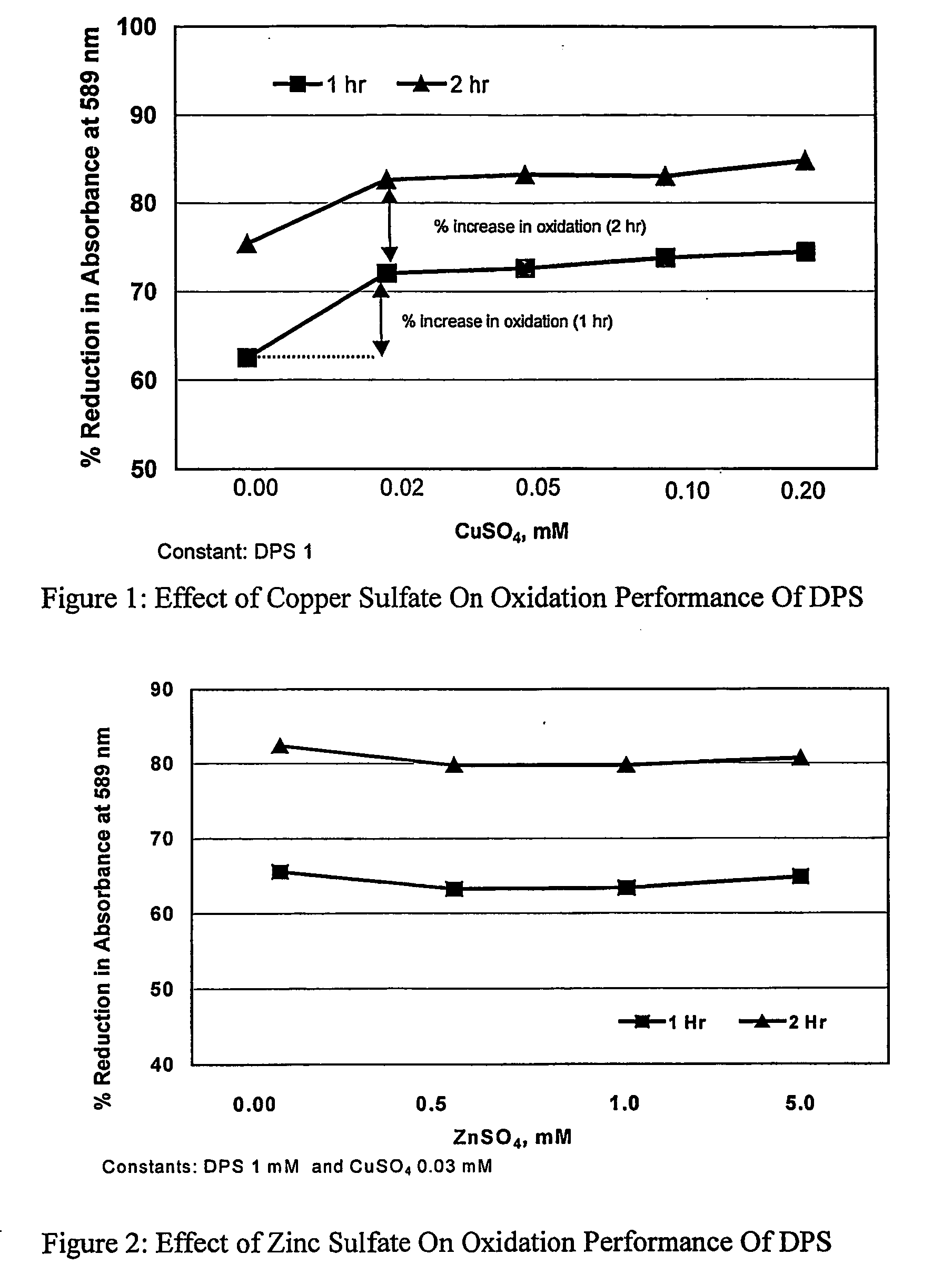

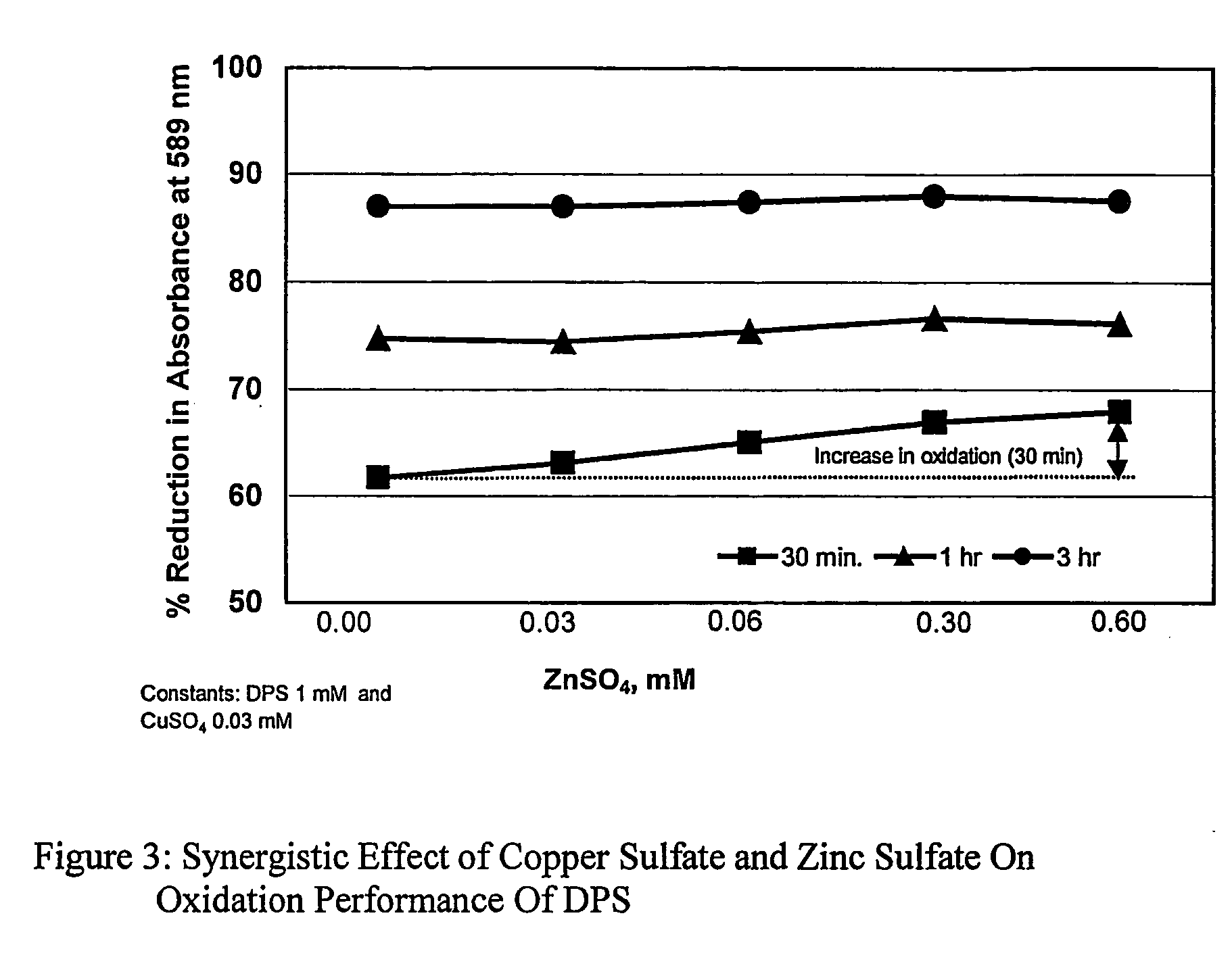

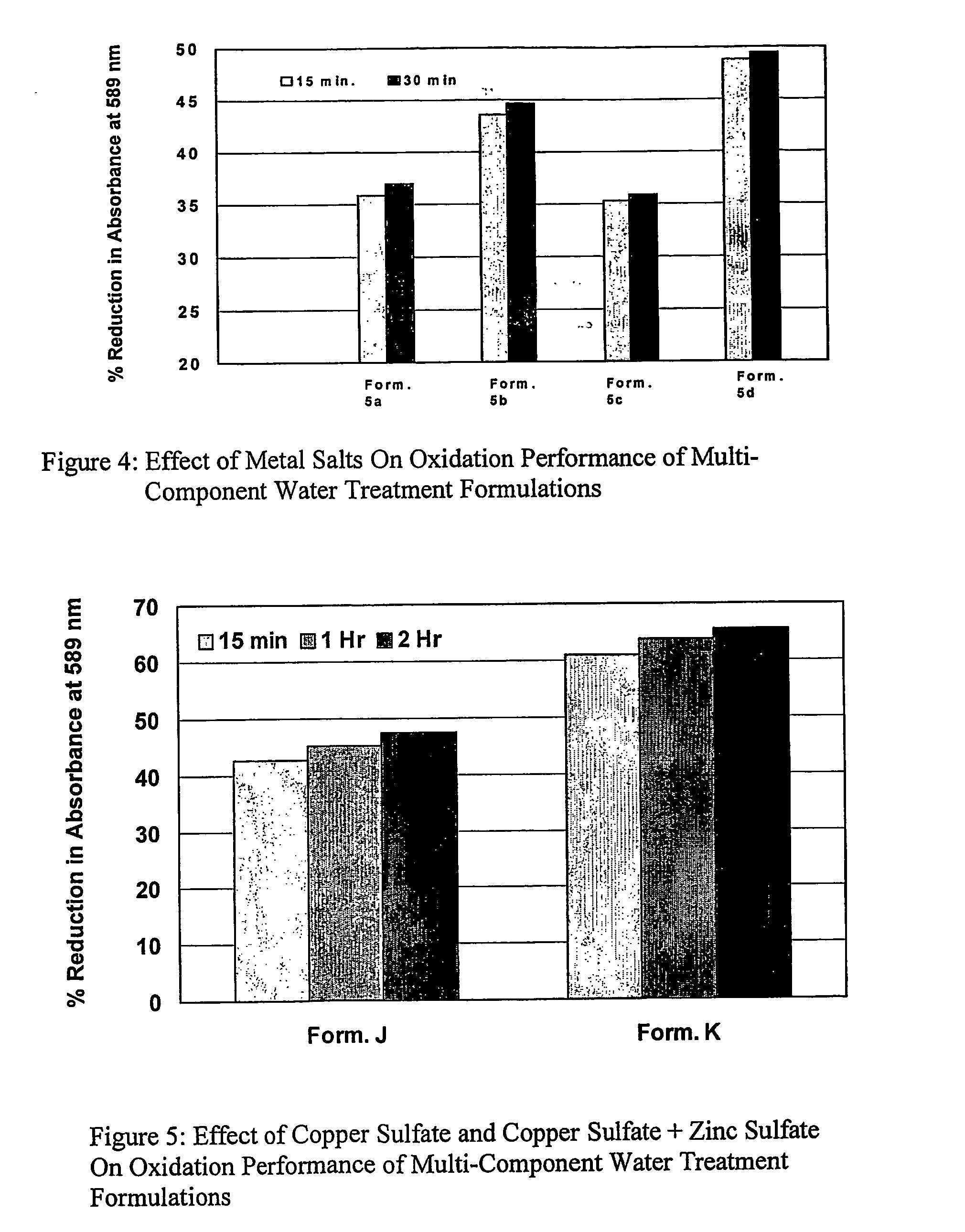

InactiveUS7238290B2Better allow oxidizing sanitizersImprove oxidation capacityOrganic/inorganic per-compounds compounding agentsDetergent bleaching agentsPersulfateCatalytic oxidation

Transition metal ions have the ability to increase the oxidation performance of the inorganic peroxy salts at room temperature by possibly lowering their activation energy or by producing more reactive free radicals. When two transition metal salts are used together to decompose dipersulfate, it provides synergistic oxidation activity, better than obtained by dipersulfate or dipersulfate with either copper or zinc alone. The transition metals mentioned are the water soluble salts of copper and zinc. Oxidation performance of sodium dipersulface in presence of catalytic amount of copper and zinc salts was determined by measuring the destruction of crystal violet dye at a wavelength of 589 nm.

Owner:BIOLAB INC

Multi oxidant based sizing material for nickel hard disk flattening

A slurry composition for planarizing nickel or nickel-alloy coating on substrates, such as a nickel coating on a memory hard disk, includes at least two oxidizers, an abrasive, water, and no metal catalyst. The composition is effective for polishing nickel (Ni) and nickel alloys coatings formed in the manufacture of memory disks.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Catalytic oxidation of peroxy salts

InactiveUS20050147691A1Improve oxidation capacityBetter allow oxidizing sanitizersBiocideInorganic active ingredientsCatalytic oxidationOxidation Activity

Transition metal ions have the ability to increase the oxidation performance of the inorganic peroxy salts at room temperature by possibly lowering their activation energy or by producing more reactive free radicals. When two transition metal salts are used together to decompose dipersulfate, it provides synergistic oxidation activity, better than obtained by dipersulfate or dipersulfate with either copper or zinc alone. The transition metals mentioned are the water soluble salts of copper and zinc. Oxidation performance of sodium dipersulfate in presence of catalytic amount of copper and zinc salts was determined by measuring the destruction of crystal violet dye at a wavelength of 589 nm.

Owner:BIOLAB INC

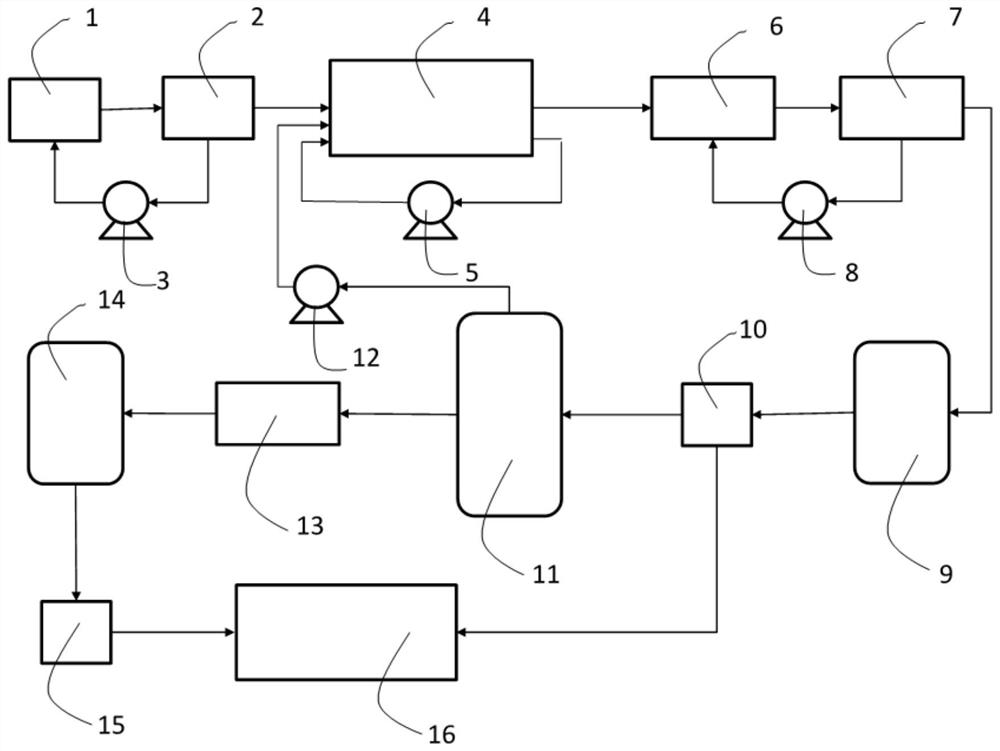

Method and apparatus for controlling contamination from pipe coatings

InactiveUS20100029879A1Reduce decreaseImprove responseHydrogen peroxidePeroxyhydrates/peroxyacidsPersulfateAdditive ingredient

A combination of a styrene reduction agent and a catalyst that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. The catalyst is hydrogen peroxide (H2O2). A calibrated amount of the styrene reduction agent capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process, and this is followed by a calibrated amount of the H2O2 catalyst in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHAEL

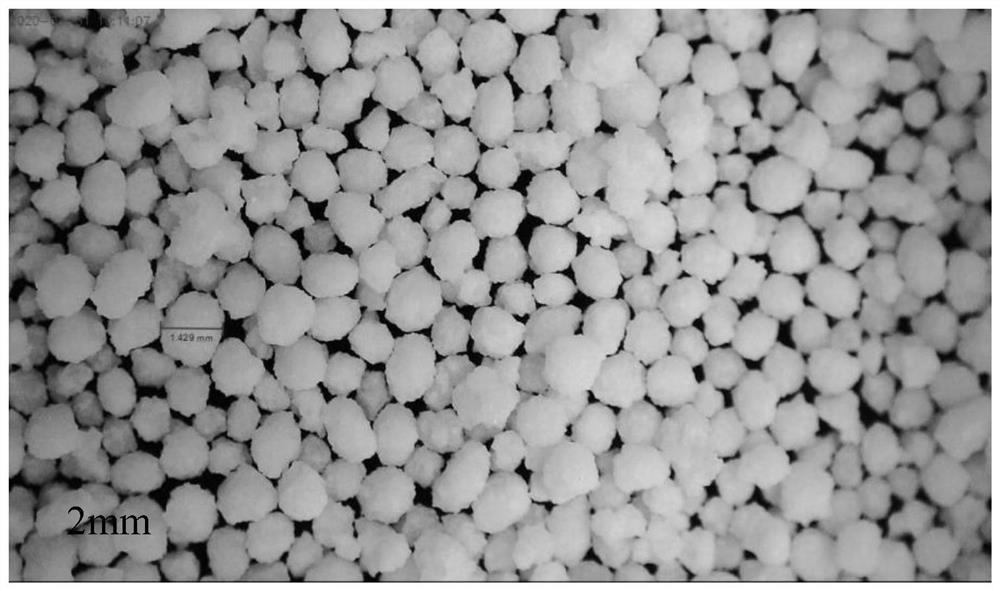

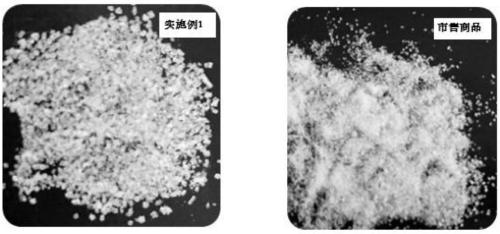

Method for controlling crystallization growth of potassium peroxymonosulfate composite salt

PendingCN112357890APromote formationSuppression of explosive spontaneous nucleationPeroxyhydrates/peroxyacidsOleumMoisture absorption

The invention discloses a method for controlling crystallization growth of potassium peroxymonosulfate composite salt. The method comprises the following steps: (1) adding 1-hydroxyethylidene-1,1-diphosphonic acid into a hydrogen peroxide solution, and adding fuming sulfuric acid into the hydrogen peroxide solution to obtain an oxidation solution of peroxymonosulfate; (2) adding the oxidation liquid prepared in the step (1) and potassium carbonate into a neutralization kettle of water or centrifugal mother liquor, and carrying out a neutralization reaction; (3) transferring the reaction solution neutralized in the step (2) into a crystallization kettle, adding a crystal modifier and seed crystal slurry containing potassium peroxymonosulfate composite salt, stirring, cooling and crystallizing; and (4) carrying out solid-liquid separation on the cooled and crystallized material in the step (3), and drying and screening the solid to obtain the potassium peroxymonosulfate composite salt with the particle size of more than 200 meshes. The potassium peroxymonosulfate composite salt prepared by the crystallization method disclosed by the invention is relatively large in particle size andhigh in yield, and has natural moisture absorption resistance and anti-caking property, so that the stability of active oxygen of the product is higher.

Owner:ZHEJIANG JINKE CHEM

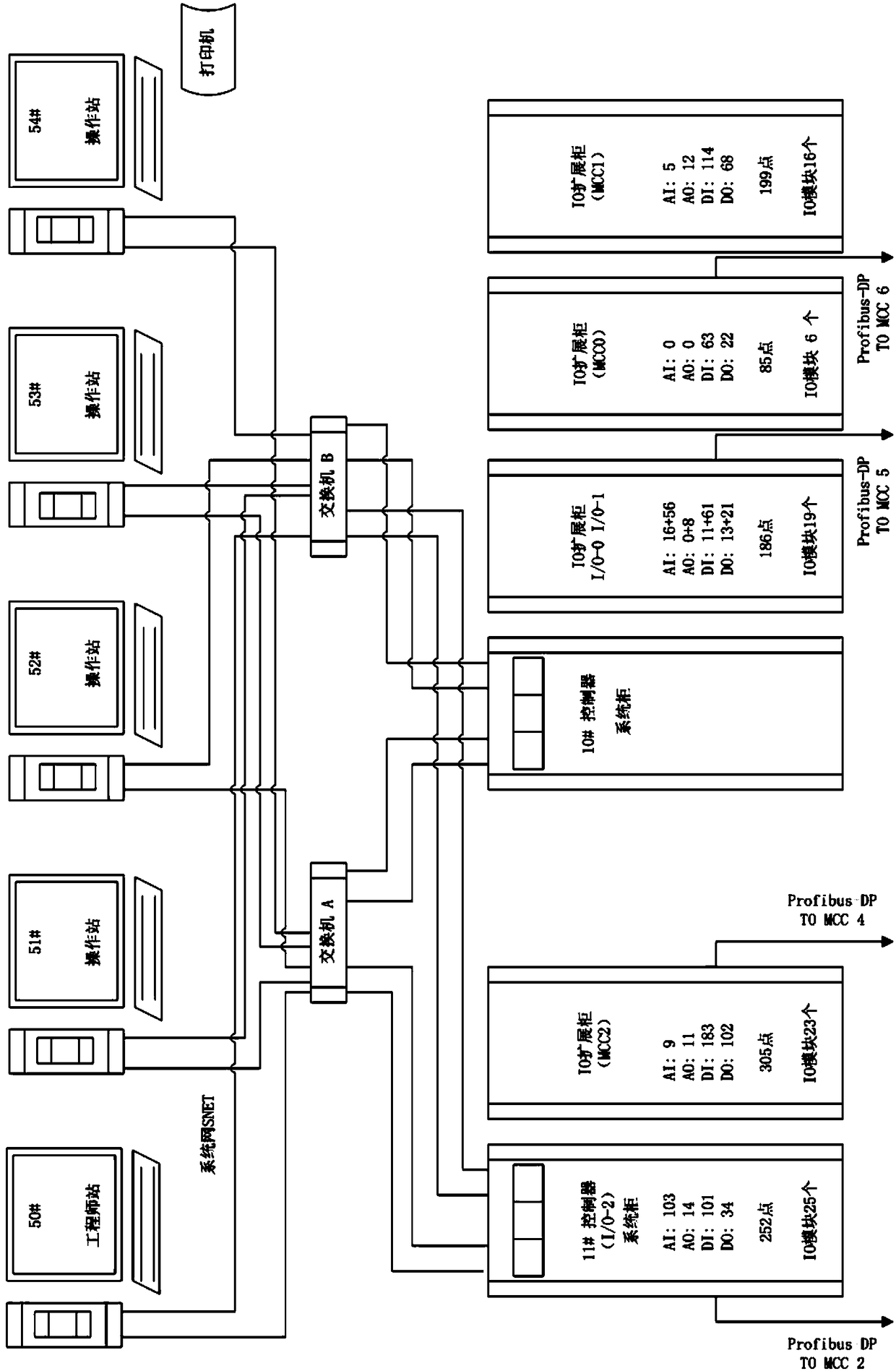

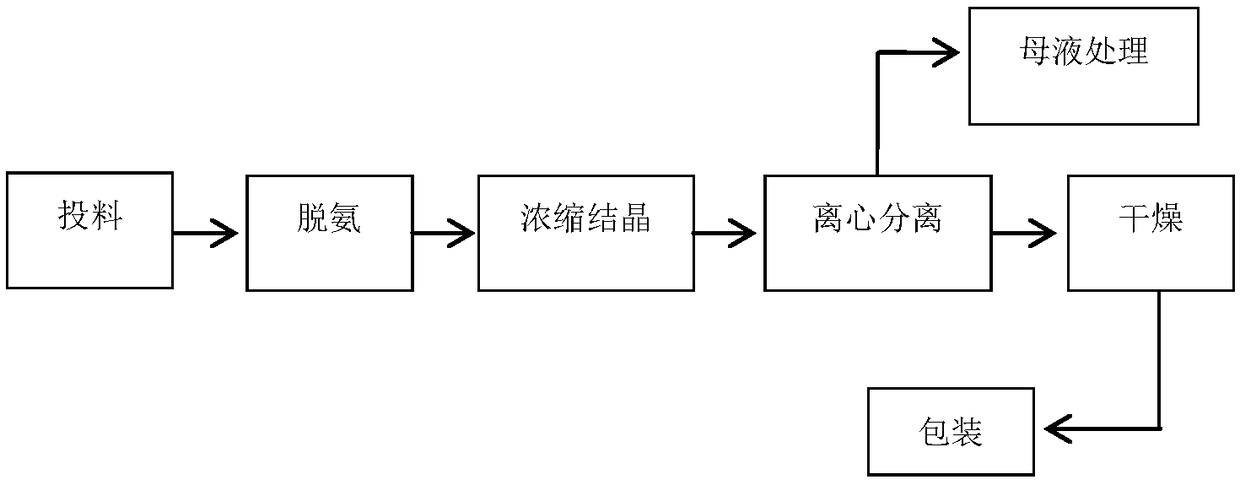

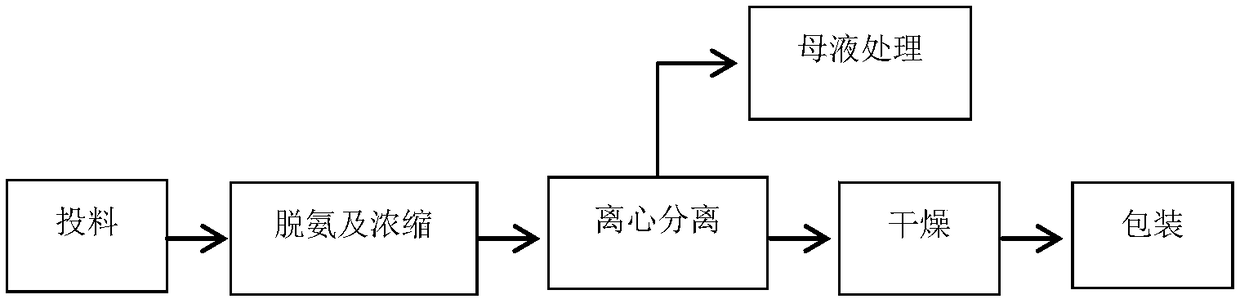

DCS (distributed control system) and control method for sodium persulfate and potassium persulfate production apparatuses

PendingCN108227668AIncrease profitImprove labor productivityPeroxyhydrates/peroxyacidsTotal factory controlPotassium persulfatePersulfate

The invention discloses a DCS (distributed control system) and control method for sodium persulfate and potassium persulfate production apparatuses. The DCS, a sodium persulfate production apparatus and a potassium persulfate production apparatus are involved; the DCS control system comprises a master controller, an exchanger and an operating station; the master controller is used for controllingthe sodium persulfate and potassium persulfate production apparatuses in real time; the sodium persulfate and potassium persulfate production apparatuses are provided with field I / O stations; all PLCs(programmable logic controllers) of field devices are connected with the field I / O stations; the field I / O stations are connected with the master controller of the DCS through a DP (decentralized periphery) bus. Through the application of the DCS, it is fully possible to use various large-sized evaporation and crystallization apparatuses and achieve stable production during sodium persulfate andpotassium persulfate production; therefore, high automation, large size and modernization are achieved for the sodium persulfate and potassium persulfate production apparatuses.

Owner:SHANGHAI TIANTAN AUX

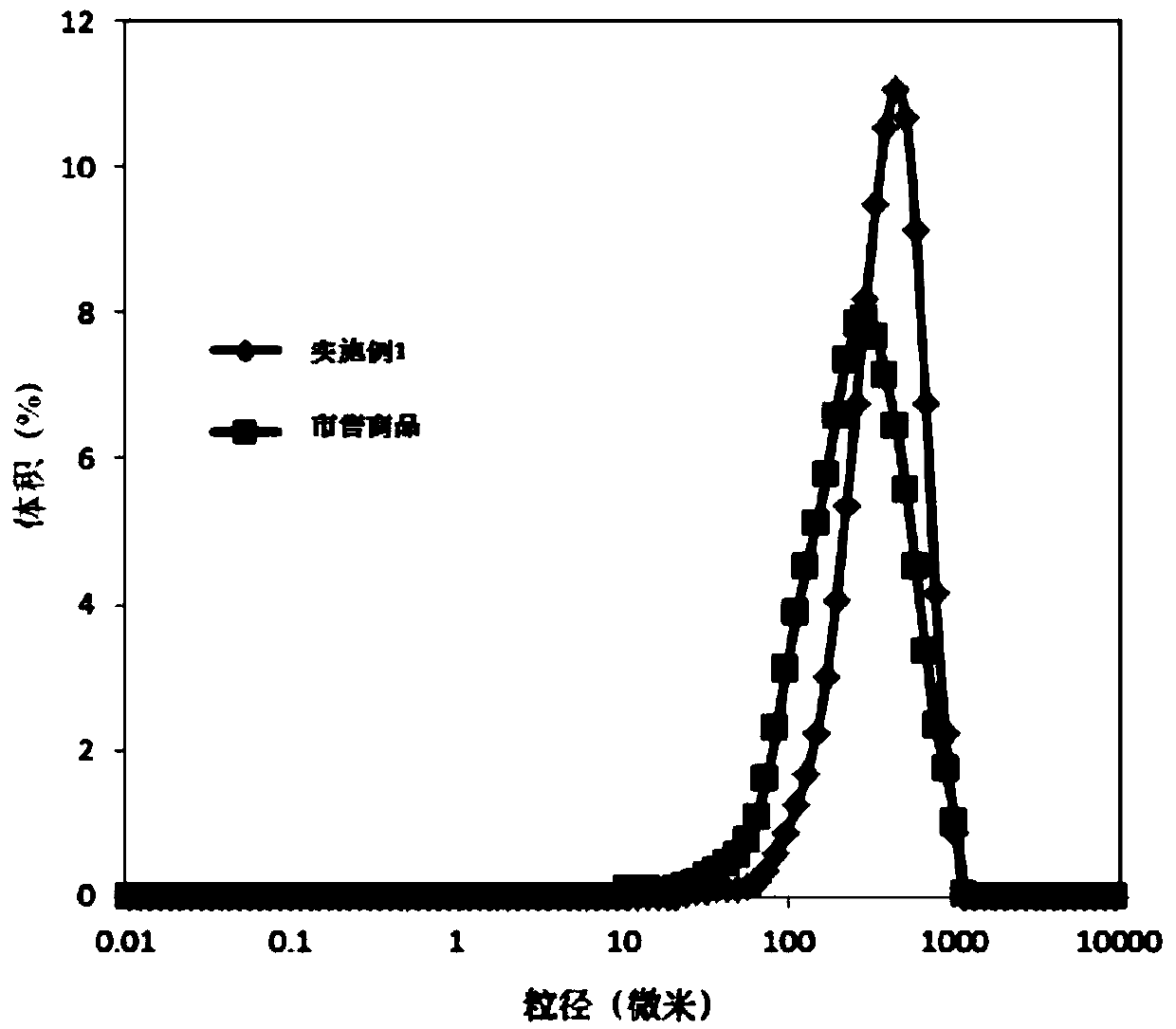

Preparation method of ammonium persulfate crystal

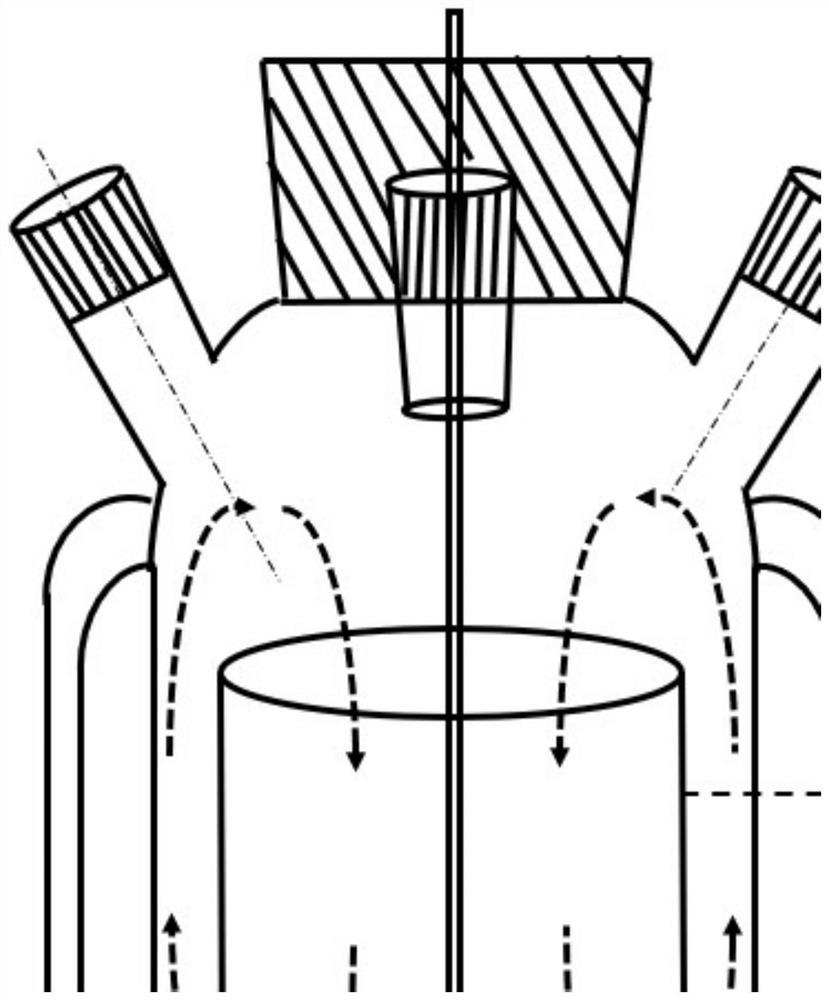

ActiveCN112678779AEasy to controlHigh purityPeroxyhydrates/peroxyacidsPhysical chemistrySeed crystal

The invention provides a preparation method of an ammonium persulfate crystal. The preparation method comprises the following steps of: adding an ammonium persulfate seed crystal into a mixed solution of ammonium persulfate and ammonium sulfate at 25-35 DEG C under the stirring action of a push-type stirrer with a guide cylinder to carrying out seeding; slowly heating to 0.5-1 DEG C; and cooling to -3 to -10 DEG C at a cooling rate of 3-18 DEG C / h, and carrying out cooling crystallization to obtain the ammonium persulfate crystal. The average particle size of the ammonium persulfate crystal is greater than 800 microns. According to the preparation method of the ammonium persulfate crystal of the present invention, the push-type stirrer with the guide cylinder is used, the micro-amplitude 0.5-1 DEG C heating process is performed, and a cooling range is extended; and the growth and crystallization process of the crystal can be well controlled through the synergistic effect of a plurality of factors, and therefore, the purity, the uniformity and the average particle size of the crystal can be increased, the anti-caking performance of the ammonium persulfate crystal can be improved, and the application range of the product is greatly extended.

Owner:TIANJIN UNIV

Potassium hydrogen peroxymonosulfate solutions

ActiveCN1768005AInsulating substrate metal adhesion improvementPeroxyhydrates/peroxyacidsHigh concentrationHydrogen

The invention discloses a solution comprising potassium peroxymonosulfate with a high concentration of KHSO5 and a weight ratio of SO5 / SO4 greater than 1.0:1, and its use in microetching metal substrates.

Owner:EI DU PONT DE NEMOURS & CO

Product typically based on salt of peroxymonosulfuric acid and suitable for medicinal usage, and associated product fabrication

InactiveUS20120074014A1Facilitate chemical reactionsImprove performancePowder deliveryBiocideDiseaseProduct base

Products based on salt of peroxymonosulfuric acid are suitable for treating or / and preventing diseases and other debilitating medical conditions caused by bacterial, eukaryotic, prion, and viral pathogens and by non-pathogenic inflammation. The products may alternatively be based on inorganic halide and an oxidizing agent reactable in water with the inorganic halide to generate hypohalite ions. In addition, the products can be employed in other applications such as commercial and industrial applications.

Owner:LUTRAN INDS

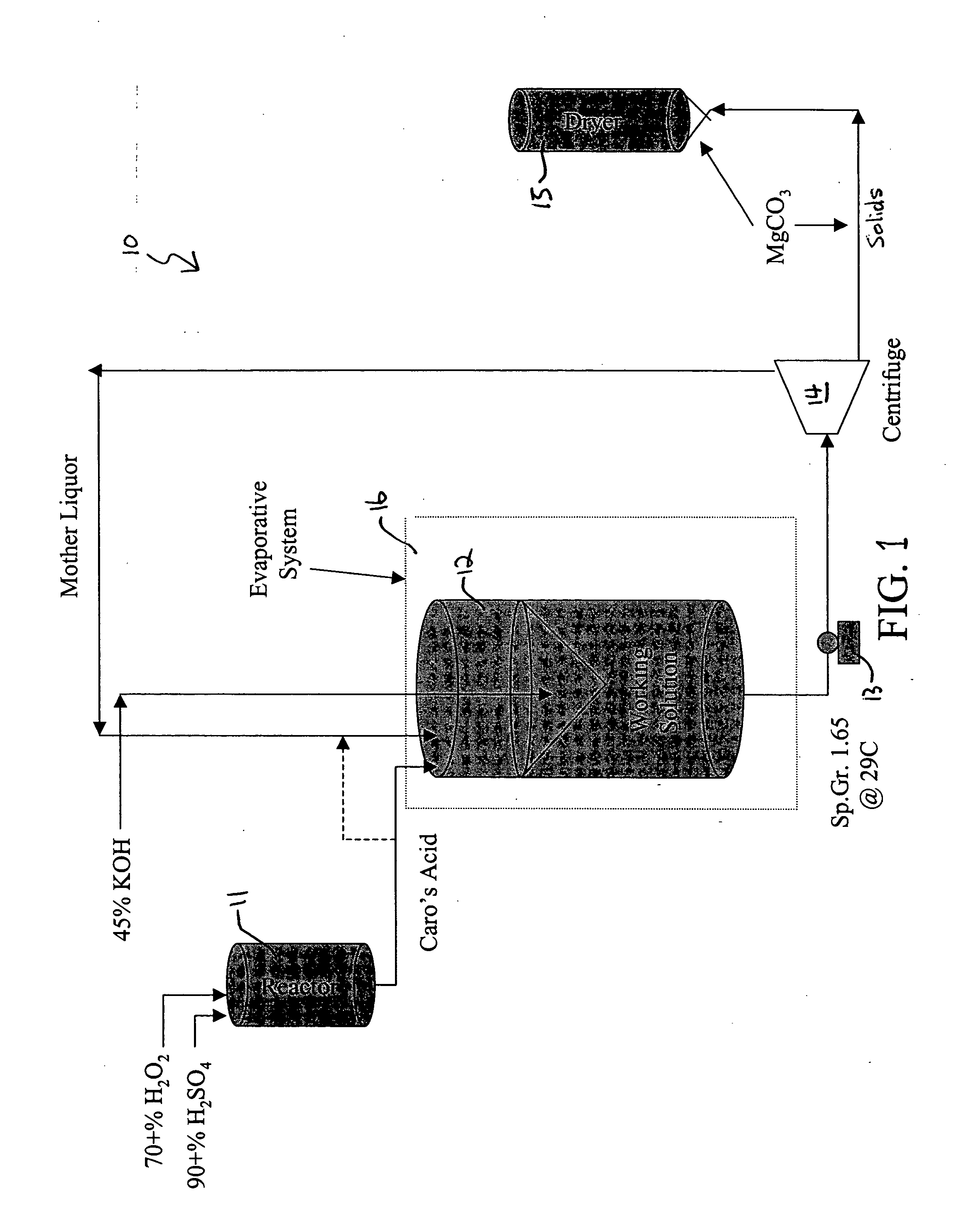

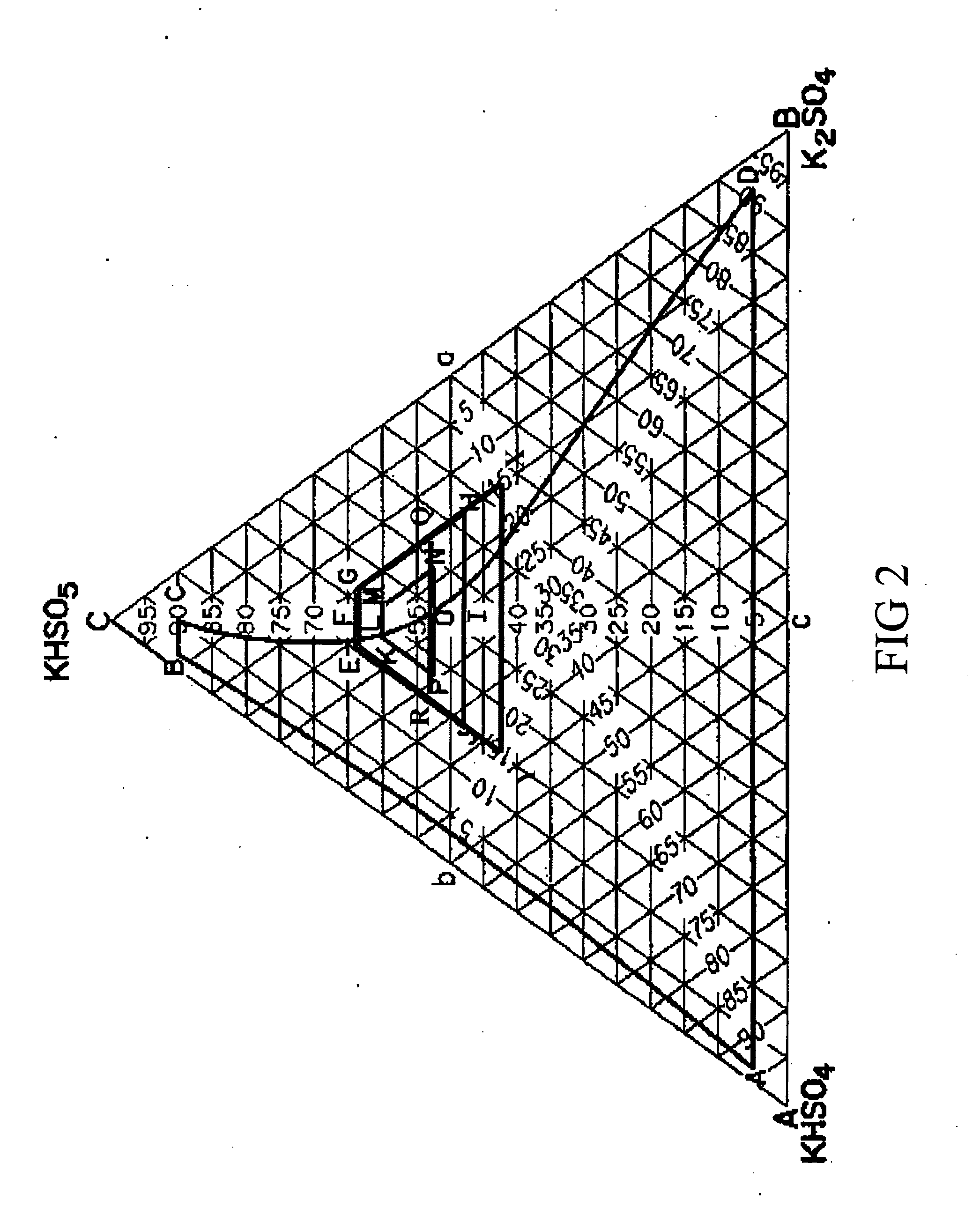

Production of potassium monopersulfate triple salt using oleum

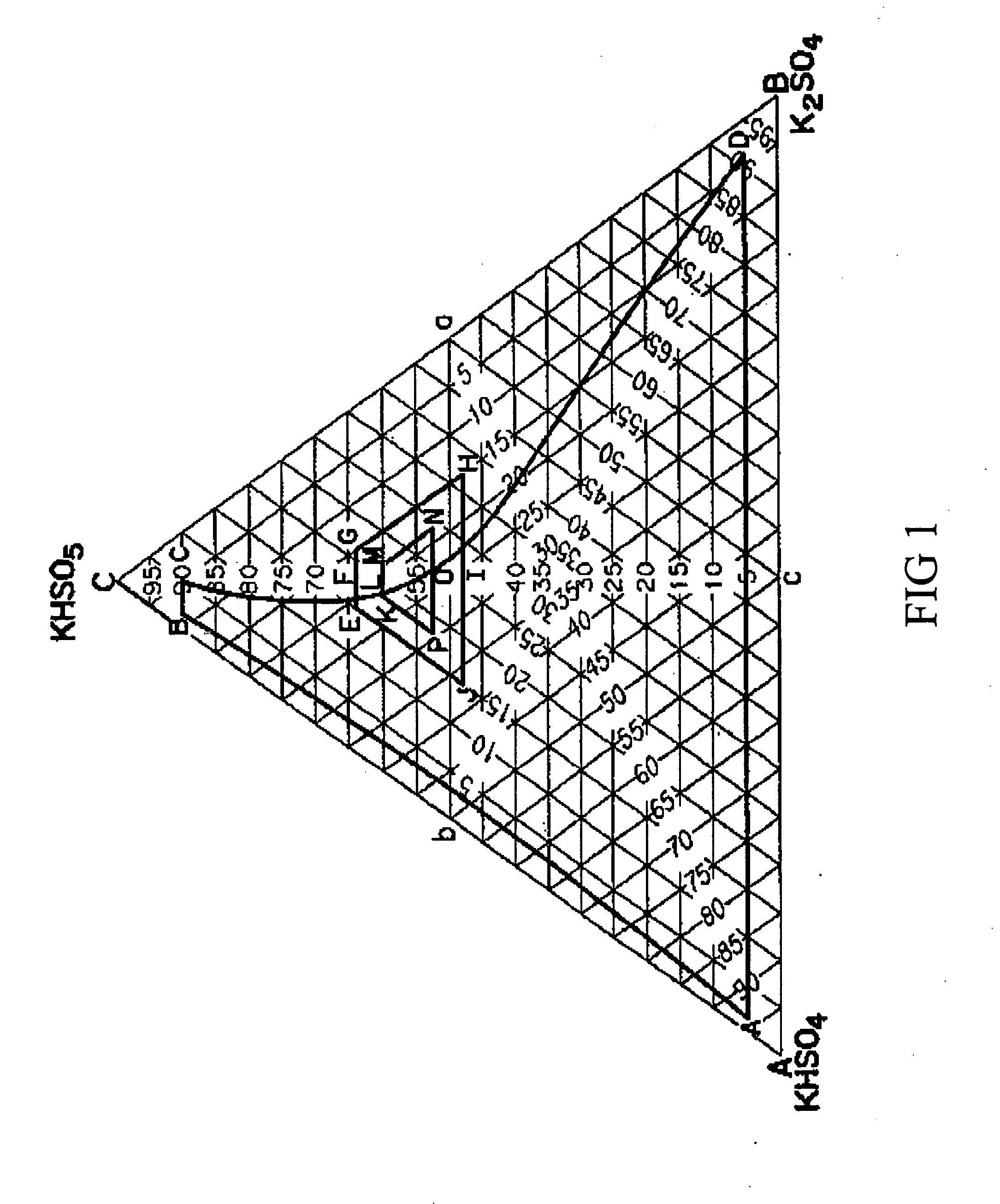

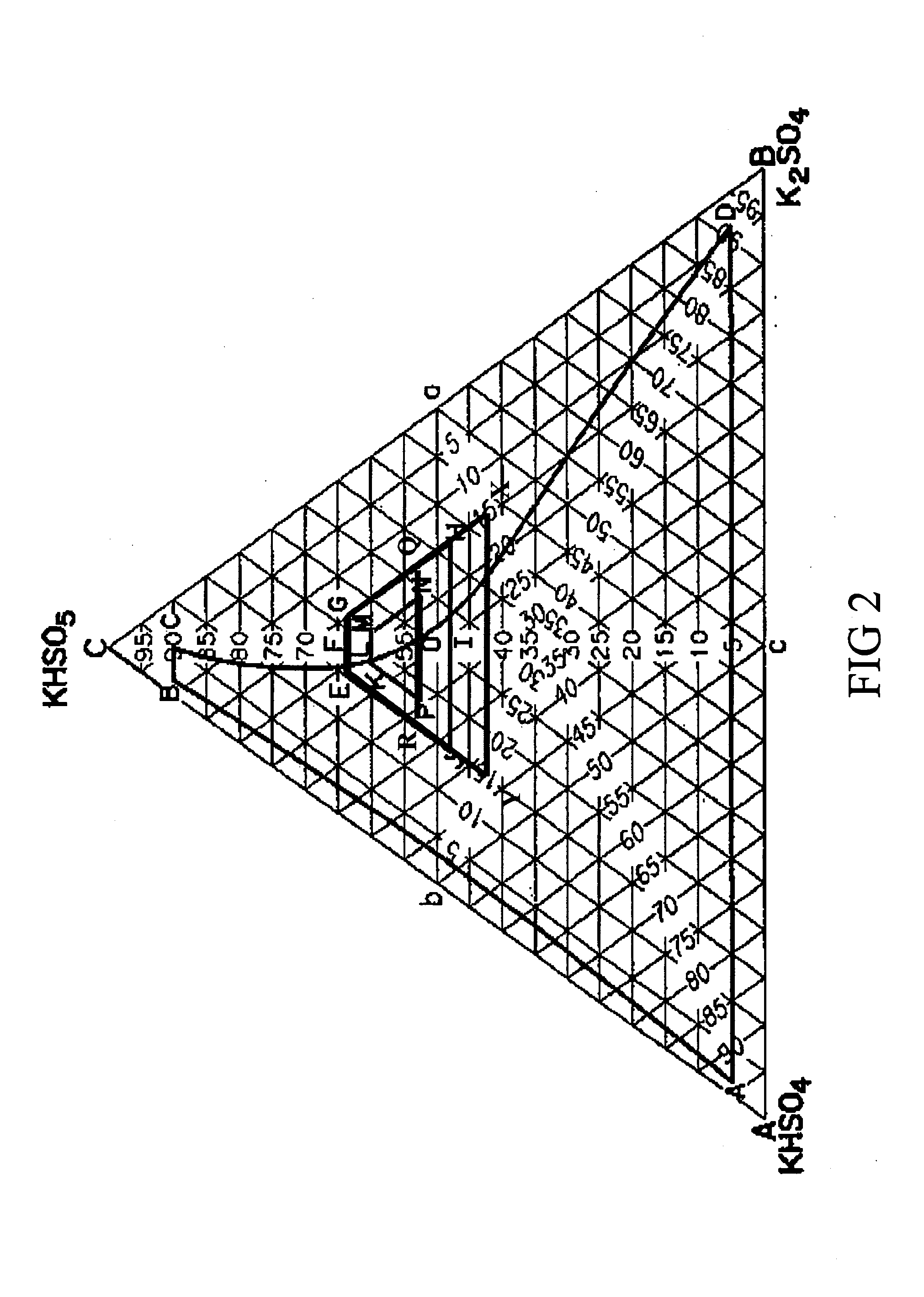

A method of preparing a potassium monopersulfate composition is presented, wherein the potassium monopersulfate composition has the formula (KHSO5)x(KHSO4)y(K2 SO4)z, where x+y+z=1 and x=0.46−0.64, y=0.15−0.37, and z=0.15−0.37, said potassium monopersulfate composition having an active oxygen content greater than or equal to 4.9 wt. % and K2S2O8 at a concentration of <0.5 wt. % of the potassium monopersulfate composition. The method includes reacting an H2O2 solution containing at least 70 wt. % H2O2 with oleum at a substoichiometric ratio of oleum to H2O2 to generate a weak Caro's acid solution, then combining the weak Caro's acid solution with an H2SO4 solution to produce a rich Caro's acid solution. The rich Caro's acid solution may be combined with an alkali potassium compound to produce the potassium monopersulfate composition. The temperature is preferably maintained at below 30° C. during the process.

Owner:TRUOX

Preparation method of ammonium persulfate crystal

ActiveCN109665498AEasy to operateLow equipment requirementsPeroxyhydrates/peroxyacidsInorganic saltsCrystallinity

The invention relates to the technical field of inorganic salt crystallization, in particular to a preparation method of an ammonium persulfate crystal. Since cooling rate and temperature of ammoniumpersulfate seed crystal added are controlled, the growth rate of ammonium persulfate crystal is much higher than the nucleation rate, the obtained ammonium persulfate crystal has large grain, uniformgrain size, high crystallinity and good fluidity, has good compatibility with other materials in practical application, and is not easy to be affected by caking during storage and transport in use. The preparation method has the advantages of high operational simplicity, low requirements to equipment and the like, and can save processing cost.

Owner:河北中科同创科技发展有限公司 +1

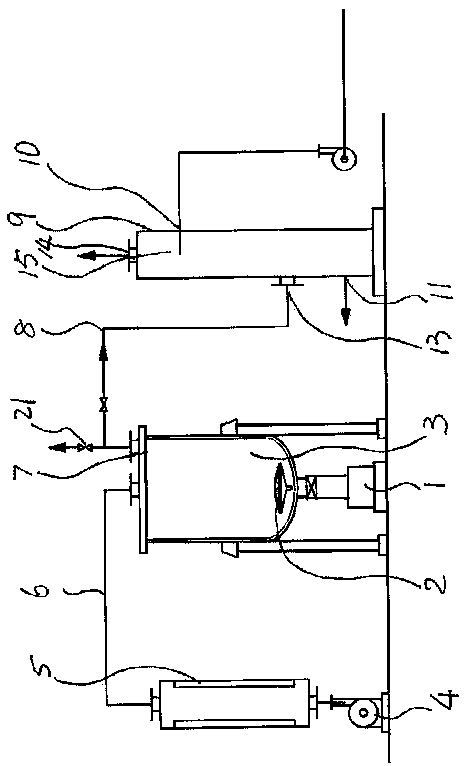

Deaminizing and dewatering technology and special device for sodium persulfate (salt) synthetic fluid

InactiveCN103432974AIncrease productionReduced potential for pyrolysisPeroxyhydrates/peroxyacidsChemical/physical/physico-chemical processesElectrolysisDecomposition

The invention belongs to the technical field of sodium persulfate (salt) preparation, and particularly discloses a deaminizing and dewatering technology and a special device for sodium persulfate (salt) synthetic fluid. According to main technical schemes, air heated to 80-200 DEG C by an air heater passes through an air distributor arranged in a reaction still, then heat is uniformly and quickly transferred to reaction liquid, so that ammonia and moisture in the reaction liquid are quickly evaporated, separated ammonia gas enters an ammonia recovery tower through a gas pipeline, is circularly absorbed by mother liquid containing dilute sulphuric acid to become ammonium sulfate mother liquid and then the ammonium sulfate mother liquid enters a sodium persulfate electrolysis system. The special device has the characteristics of simple structure and convenience for operation; side reactions can be reduced through deaminizing and dewatering by utilizing the device, so that the high temperature decomposition possibility of a sodium persulfate target product is greatly reduced, the yield of sodium persulfate is increased, and the economic benefit is increased.

Owner:河北冀衡集团有限公司

Method and apparatus for controlling contamination from pipe coatings

InactiveUS7820069B2Improve responseQuicker more complete reductionHydrogen peroxidePeroxyhydrates/peroxyacidsPersulfateWaste stream

A combination of a styrene reduction agent and a catalyst that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. The catalyst is hydrogen peroxide (H2O2). A calibrated amount of the styrene reduction agent capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process, and this is followed by a calibrated amount of the H2O2 catalyst in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHAEL

Continuous production system and method for potassium peroxymonosulfate composite salt

ActiveCN112645290AEasy to controlGuaranteed concentrationPeroxyhydrates/peroxyacidsInorganic saltsOleum

The invention relates to the technical field of inorganic salt production, and in particular relates to a continuous production system and method for potassium peroxymonosulfate composite salt. The production method comprises the steps of S1 continuously adding hydrogen peroxide and fuming sulfuric acid into a first reactor and a second reactor respectively, starting a reaction liquid circulating pump, enabling the hydrogen peroxide and the fuming sulfuric acid to be in contact with each other, circulating in an oxidation reaction device and then flowing into a dilution device; S2 allowing oxidation liquid to flow into a neutralization reactor through the dilution device, continuously adding potassium carbonate, cooling the obtained neutralization liquid through a cooler, and allowing the cooled neutralization liquid to flow into a continuous crystallization device; and S3 enabling the crystallized neutralization liquid to flow into a first solid-liquid separation device, enabling the liquid as a mother solution to flow into a mother solution circulating tank, opening a mother solution circulating pump to enable the mother solution in the mother solution circulating tank to flow into the dilution device to dilute the oxidation liquid, further processing the solid, and outputting, thereby realizing automatic production and continuous product output.

Owner:河北纳泰化工有限公司

Styrene reduction agent

InactiveUS7892448B2Effectively and economically reduces styrene, or reactiveSimple taskHydrogen peroxidePeroxyhydrates/peroxyacidsWaste streamPersulfate

A styrene reduction agent that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. Capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHEL

Preparation method of high-purity low-nitrogen potassium persulfate

InactiveCN105565278AReduce the chance of decompositionFast concentrationPeroxyhydrates/peroxyacidsPotassium persulfateIce water

The invention relates to a preparation method of high-purity low-nitrogen potassium persulfate. The method includes the steps of: (1) adding distilled water into a pressure vessel, conducting heating to 20-50DEG C, adding 2-5Kg of potassium persulfate, mounting a decompression device and a stirring device, conducting decompression distillation under stirring, controlling the pressure at 10-20mmHg, the temperature at 20-50DEG C and the stirring speed at 100-160rpm, distilling off about 1 / 7-1 / 5 of water, and stopping heating; (2) pouring the solution into a crystallization tank, conducting ice water cooling externally, precipitating crystals, filtering the crystals, and performing washing with cold ethanol 1-2 times; and (3) carrying out dissolution, washing and crystallization again, and finally performing drying in a vacuum drying box at 60DEG C so as to obtain low-nitrogen potassium persulfate. The method provided by the invention adopts low temperature and decompression operation, accelerates the concentration speed, reduces the decomposition opportunity of potassium persulfate, and increases the yield.

Owner:TIANJIN GUANGFU TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com