DCS (distributed control system) and control method for sodium persulfate and potassium persulfate production apparatuses

A technology of sodium persulfate and potassium persulfate, which is applied in general control systems, control/regulation systems, program control, etc., can solve problems such as low labor productivity, instability, and low product quality, and improve labor efficiency and utilization efficiency and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

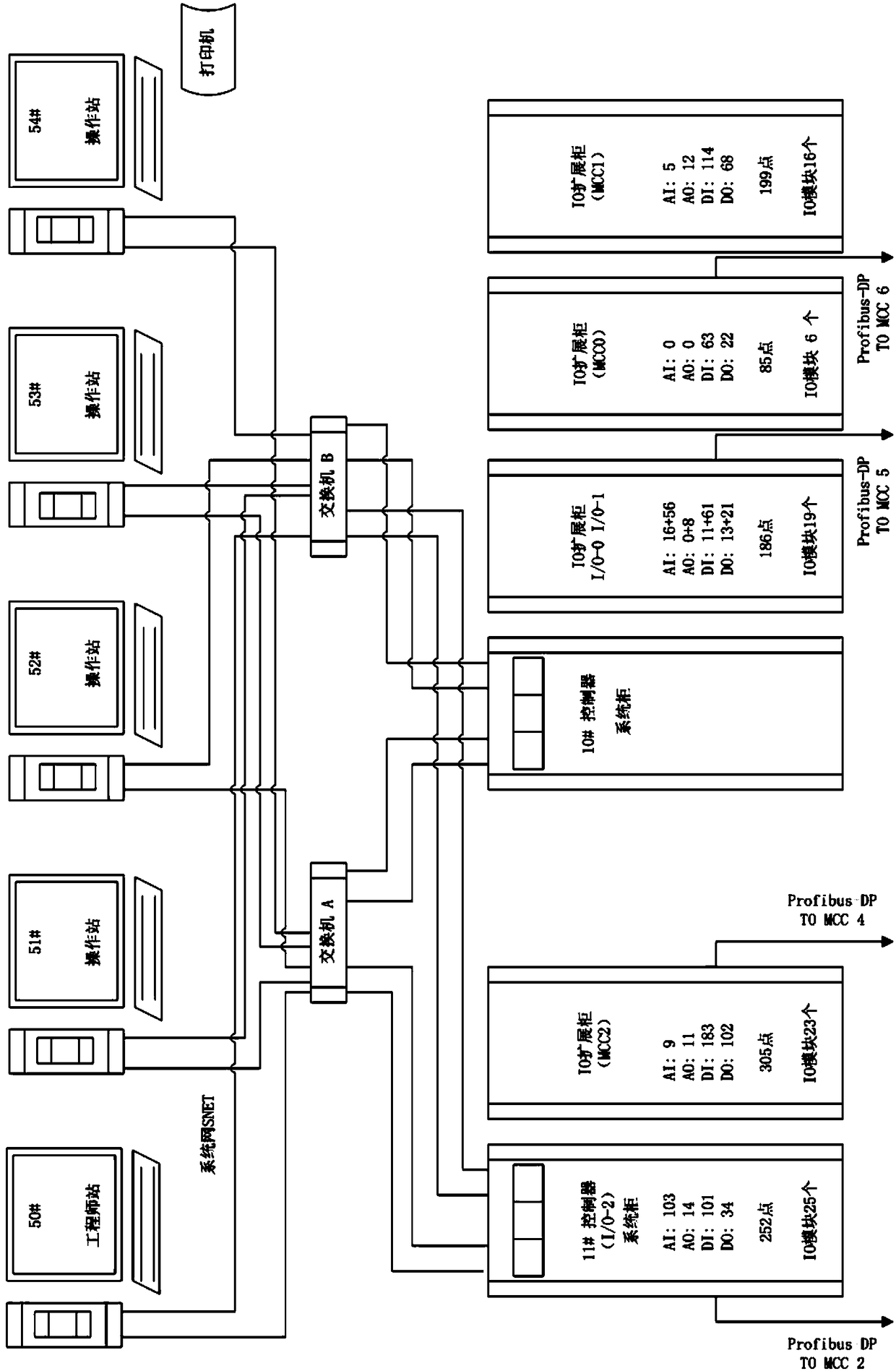

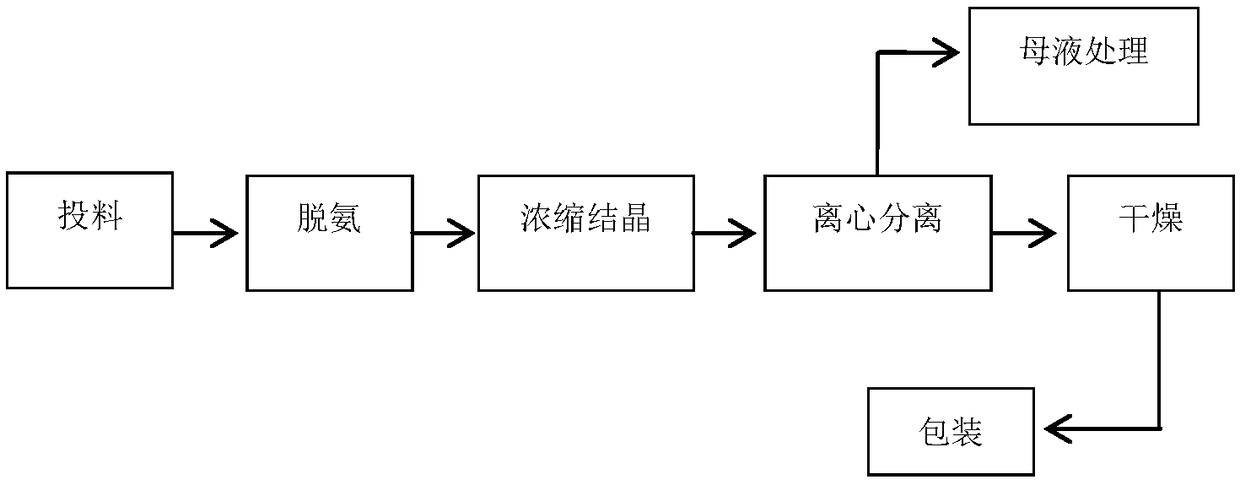

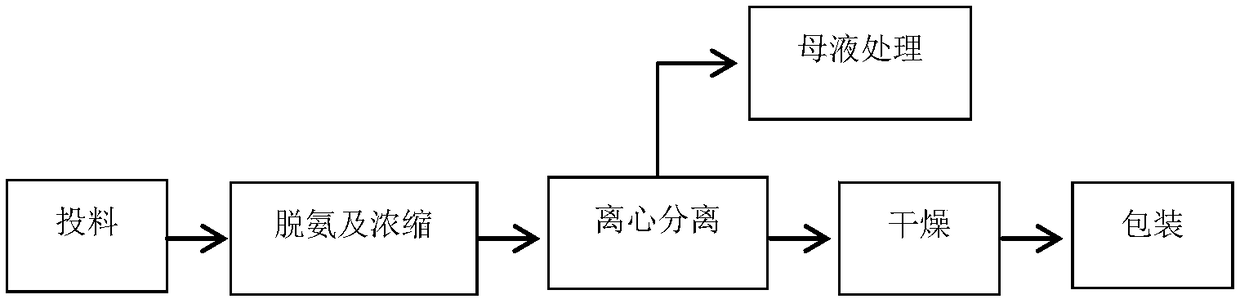

[0049] Such as figure 1 , figure 2 , image 3 Shown, a kind of sodium persulfate and potassium persulfate production unit DCS control system of the present invention, it comprises DCS control system, sodium persulfate production unit and potassium persulfate production unit.

[0050] The block diagram of the DCS control system of the present invention is shown in figure 1 , the entire DCS control system, including two system cabinets located in the central control room (each system cabinet has a main controller), and three I / O control cabinets located on the site of the ammonium persulfate production plant, and Two I / O control cabinets installed at the site of sodium persulfate and potassium persulfate production plant.

[0051] figure 1 The central control room is equipped with two main controllers (10# main controller, 11# main controller), two switches (switch A, switch B), two printers, four operating stations (51 #operation station, 52# operation station, 53# oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com