Deaminizing and dewatering technology and special device for sodium persulfate (salt) synthetic fluid

A technology of sodium persulfate and special equipment, applied in the direction of peroxyhydrate/peroxyacid, chemical/physical process, chemical/physical/physicochemical process, etc., can solve the problem of increased operating cost, high steam cost, waste of materials, etc. problems, to achieve the effect of fast heating speed, improving economic benefits and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment, the structure of sodium persulfate (salt) synthetic liquid deamination, dehydration process special device and its utilization of the special device to carry out sodium persulfate (salt) synthetic liquid deamination, dehydration process of the present invention To elaborate further:

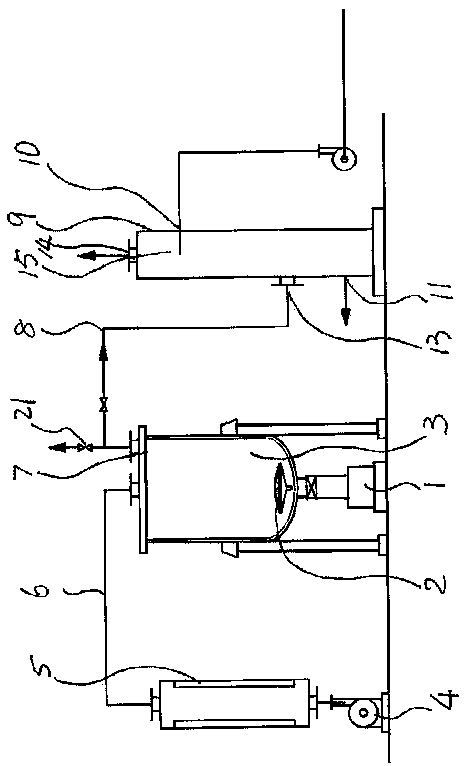

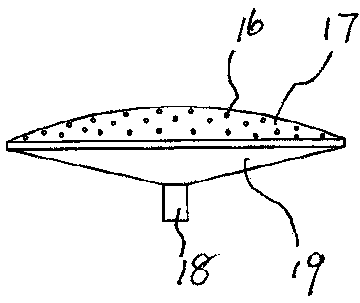

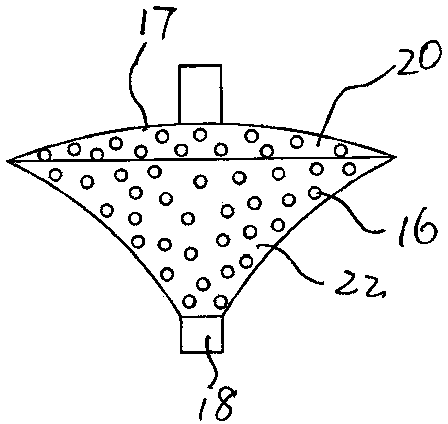

[0020] Such as figure 1 Shown is a structural schematic diagram of a special device constituting the deammonization and dehydration process of sodium persulfate (salt) synthetic liquid provided by the present invention. The structure constituting the device includes a reaction kettle 3 equipped with a material separator 1 and an air distribution mechanism 2 inside, a blower mechanism 4 and an air heater 5 with a heating function. The air distribution mechanism in the reactor is connected, and the exhaust port 7 arranged on the upper end of the reaction kettle is connected with the absorption mechanism 9 containing dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com