Continuous production system and method for potassium peroxymonosulfate composite salt

A potassium hydrogen persulfate compound salt and production system technology, which is applied in the continuous production system field of potassium hydrogen persulfate compound salt, can solve problems such as low efficiency, high energy consumption, unstable product quality, etc., and achieve an increase in production The effect of high efficiency, fast material flow rate, and improvement of equipment utilization and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

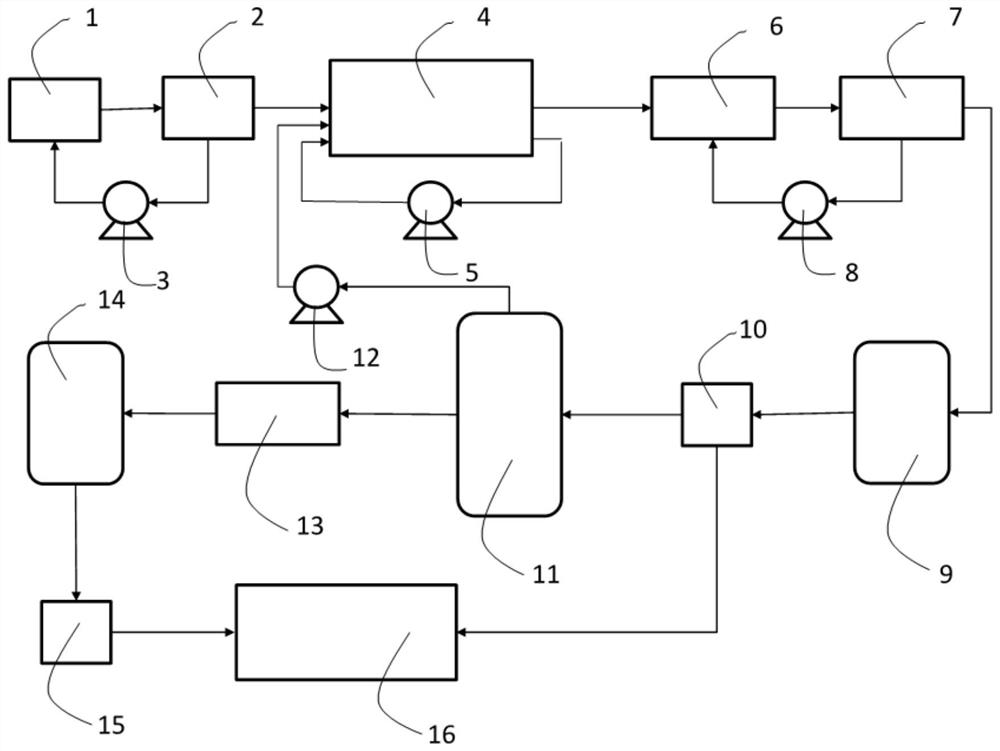

[0036] see figure 1 , the continuous production system of potassium hydrogen persulfate compound salt provided by the present invention is now described, and the continuous production system includes: an oxidation reaction device, a dilution device, a neutralization device, and a continuous crystallization device connected in sequence according to the flow direction of the feed liquid 8 , the first solid-liquid separation device 9, the mother liquor circulation device, the mother liquor crystallization system and the second solid-liquid separation device 14;

[0037] The oxidation reaction device includes a first reactor 1, a second reactor 2 and a reaction liquid circulation pump 3 connected in sequence, and the first reactor 1 is provided with a hydrogen peroxide feed port, a circulating oxidation liquid inlet and a first feed liquid outlet , the second reactor 2 is provided with a sulfuric acid feed port, a first feed liquid inlet, a circulating oxidation liquid outlet and ...

specific Embodiment approach

[0044] A specific embodiment provided as the continuous production system of potassium hydrogen persulfate compound salt of the present invention: the first solid-liquid separation device 10 is a centrifuge; the second solid-liquid separation device 15 is a centrifuge; The dilution device 4 itself is provided with a dilution liquid circulation pump 5; 7 between the neutralization reactor 6 and the neutralization cooler is provided with a neutralization liquid circulation pump 8; the addition of the circulation pump contributes to the solution in the reaction system Further cooling and dilution can improve the stability and safety of the reaction system.

[0045] As a specific embodiment provided by the continuous production system of potassium hydrogen persulfate compound salt of the present invention: the mother liquor crystallization system includes a low-temperature evaporator and a crystallization device connected in sequence to further recycle the products in the mother li...

Embodiment 2

[0048] Present embodiment provides a kind of continuous production method of potassium monopersulfate compound salt, produces with the continuous production system of potassium monopersulfate compound salt in embodiment 1. Specifically include the following steps:

[0049] S1: Continuously add hydrogen peroxide with a mass concentration of 70% to the first reactor 1, the mass flow rate of the hydrogen peroxide is 60kg / h, and continuously add SO to the second reactor 2 3 Content is the oleum of 65%, the mass flow rate of described oleum is 110kg / h, starts described oxidizing liquid circulation pump 3, makes hydrogen peroxide and oleum contact and circulates in described oxidation device, obtains oxidation liquid, control the temperature in the first reactor 1 to 1°C, and the temperature in the second reactor 2 to 5°C. When the detection sampling point at the outlet of the second reactor 2 measures When the mass concentration reaches 55% to 58%, control the oxidation liquid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com