Preparation method of ammonium persulfate crystal

A technology of ammonium persulfate and ammonium sulfate, applied in the direction of peroxyhydrate/peroxyacid, etc., can solve the problems such as the average particle size of ammonium persulfate crystals and the anti-caking performance to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a kind of crystallization method of ammonium persulfate crystal, comprises the steps:

[0050] (1) Ammonium persulfate and ammonium sulfate are dissolved in distilled water according to the mass ratio of 1:1.25 to make a mixture liquid, and the concentration of ammonium persulfate is 0.4g / mL;

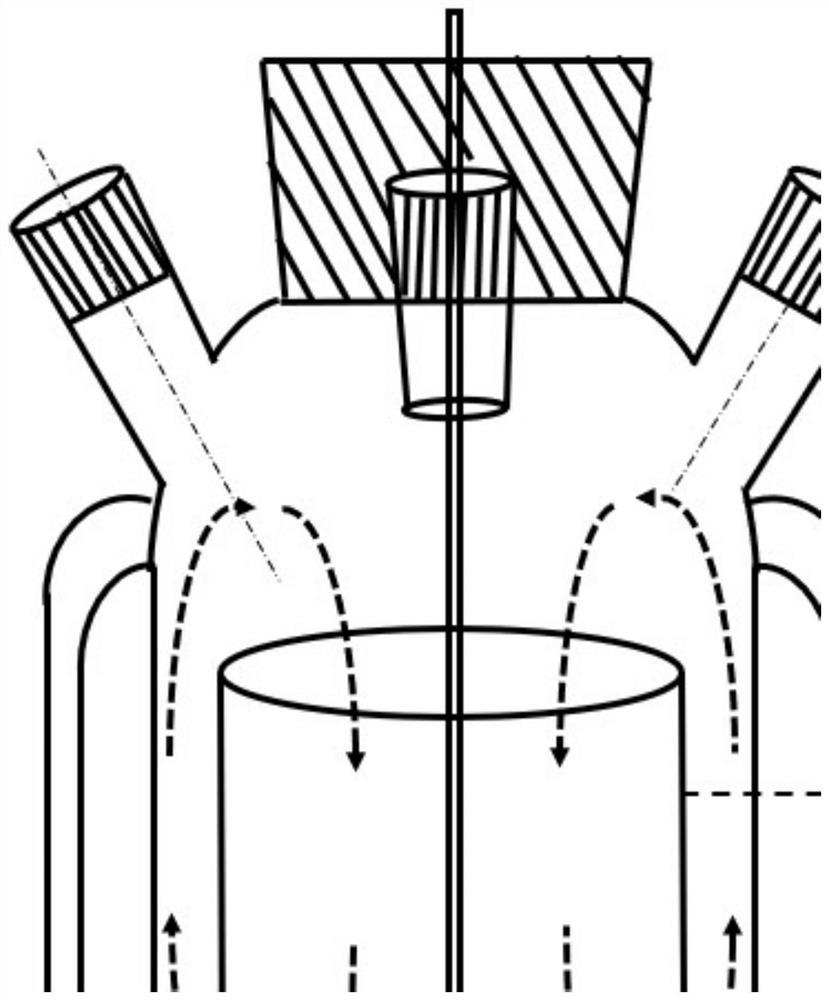

[0051] (2) Place the mixed material liquid obtained in step (1) in a crystallizer with a draft tube, turn on the propeller stirrer, control the stirring rate to 230rpm, and control the temperature of the mixed material liquid at 30°C to add particle size Ammonium persulfate seed crystals of 80-100 mesh, the concentration of the seed crystals in the mixed material liquid is 6mg / mL, and then the temperature is slowly raised to 0.5°C, and then cooled to -5°C at a cooling rate of 10°C / h for cooling and crystallization to obtain crystalline mixture;

[0052] (3) Filter the crystallization mixture obtained in step (2) to obtain a solid, then wash and dr...

Embodiment 2

[0067] The only difference from Example 1 is that the concentration of ammonium sulfate is 0.8g / mL, and the rest of the preparation methods are the same as in Example 1.

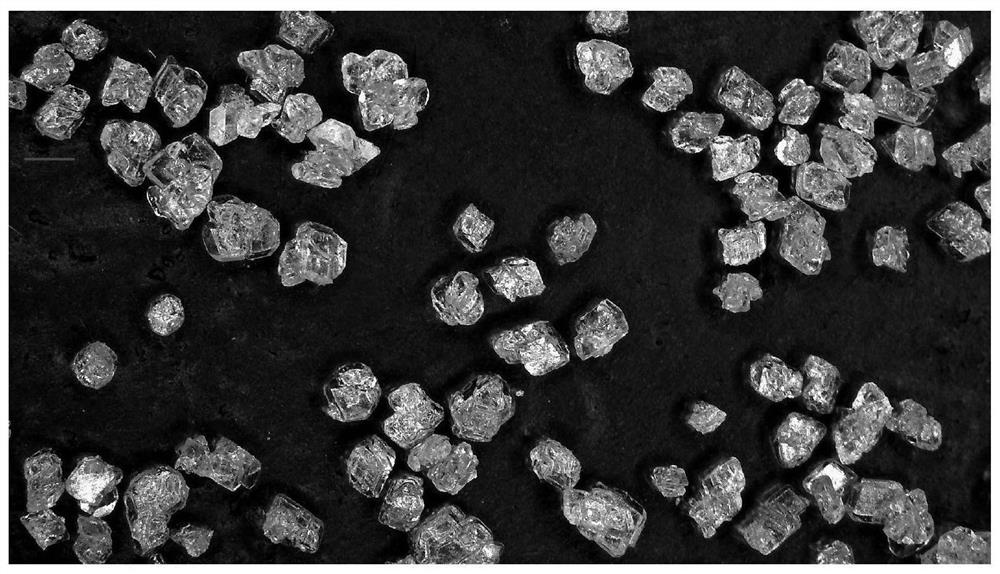

[0068] The ammonium persulfate crystal obtained in the present embodiment adopts the same test method as in Example 1, and it can be known that the purity of the ammonium persulfate crystal obtained is 98%, and the average particle diameter is 822 μm.

Embodiment 3

[0070] The only difference from Example 1 is that the concentration of ammonium persulfate is 0.5g / mL, the concentration of ammonium sulfate is 0.625g / mL, and the rest of the preparation methods are the same as in Example 1.

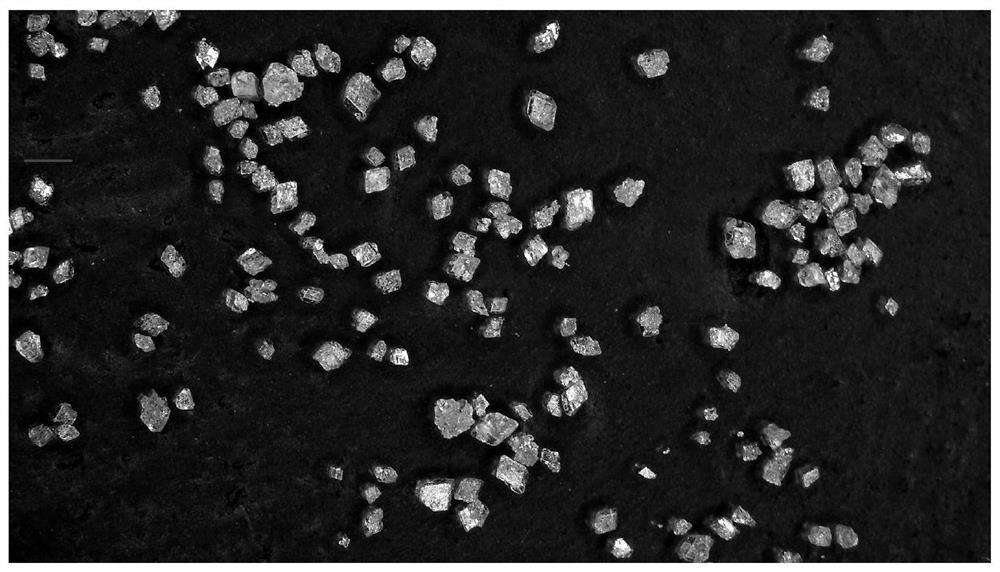

[0071] The ammonium persulfate crystal obtained in the present embodiment adopts the same test method as in Example 1, and it can be known that the purity of the ammonium persulfate crystal obtained is 99%, and the average particle diameter is 831 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com