Method for controlling crystallization growth of potassium peroxymonosulfate composite salt

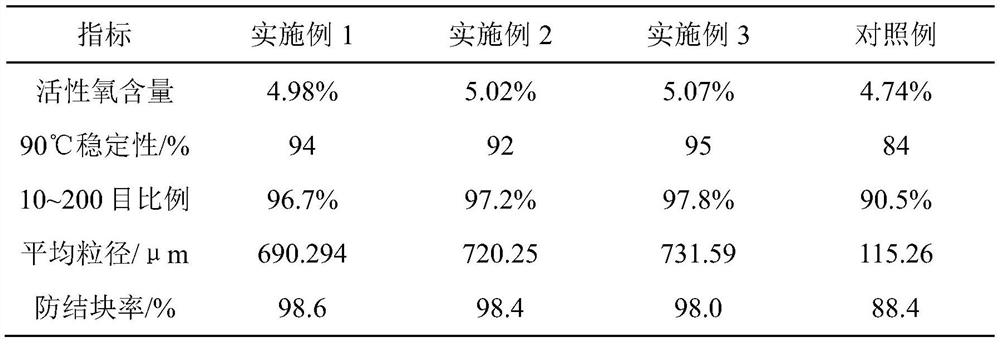

A potassium hydrogen peroxymonosulfate complex salt, crystallization technology, used in chemical instruments and methods, peroxyhydrate/peroxyacid, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, etc. It can solve the problems of reducing product purity, product particle size description, increasing equipment requirements and production links, etc., to achieve the effect of good anti-caking performance, high product active oxygen stability and large particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of potassium hydrogen persulfate compound salt crystallization growth control method, comprises the steps:

[0036] (1) 0.5kg stabilizer HEDP is added into 97kg, and mass fraction is 70% in the hydrogen peroxide solution and mixes evenly, then 213kg mass fraction is that 65% oleum is added dropwise in the hydrogen peroxide solution, control reaction system temperature At 5°C, an oxidizing solution was prepared.

[0037] (2) 600kg centrifuged mother liquor (containing KHSO obtained after centrifugation process) 5 、KHSO 4 , K 2 solution of SO4 and other substances) into the neutralization tank, slowly add the oxidizing solution prepared in step (1) and 170kg of potassium carbonate particles into the neutralization tank at the same time, control the reaction temperature at 5°C, and carry out the neutralization reaction under normal pressure .

[0038] (3) After the feeding is completed, the reaction solution after neutralization is transferred to the crystalliza...

Embodiment 2

[0040] Example 2 is basically the same as Example 1, except that 17.5 kg of the crystallization agent sodium tripolyphosphate and 24 kg of seed crystal slurry with a solid content of 40% are added in step (3). Stir, cool and crystallize, the crystallization temperature is -10°C, the cooling rate is 3.5°C / h, and the crystallization time is 5h, to obtain potassium monopersulfate compound salt crystals.

Embodiment 3

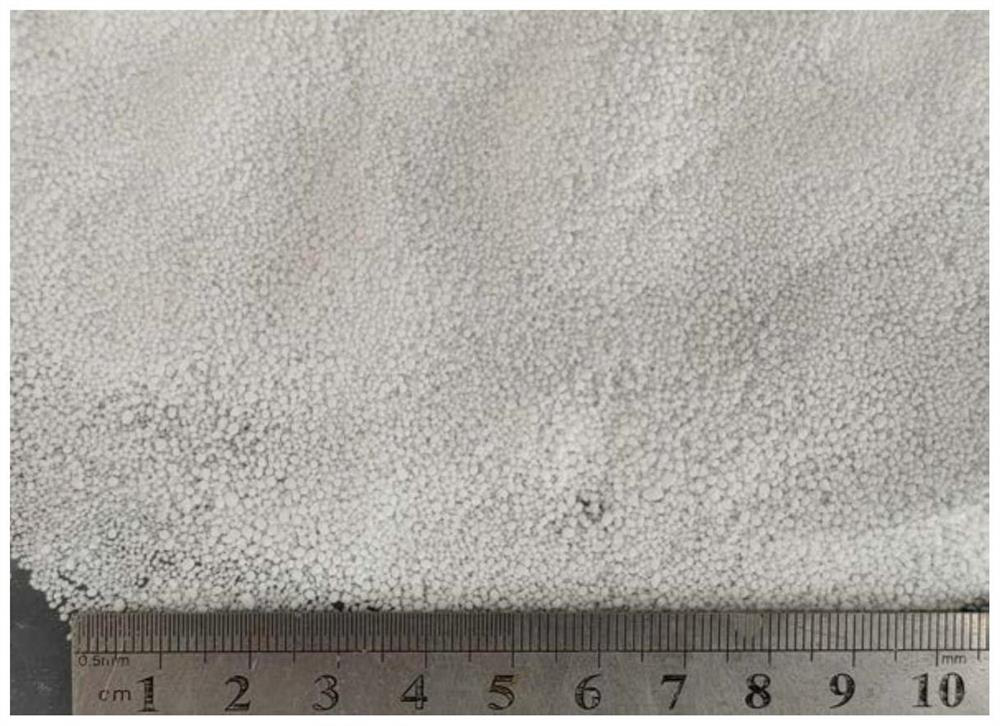

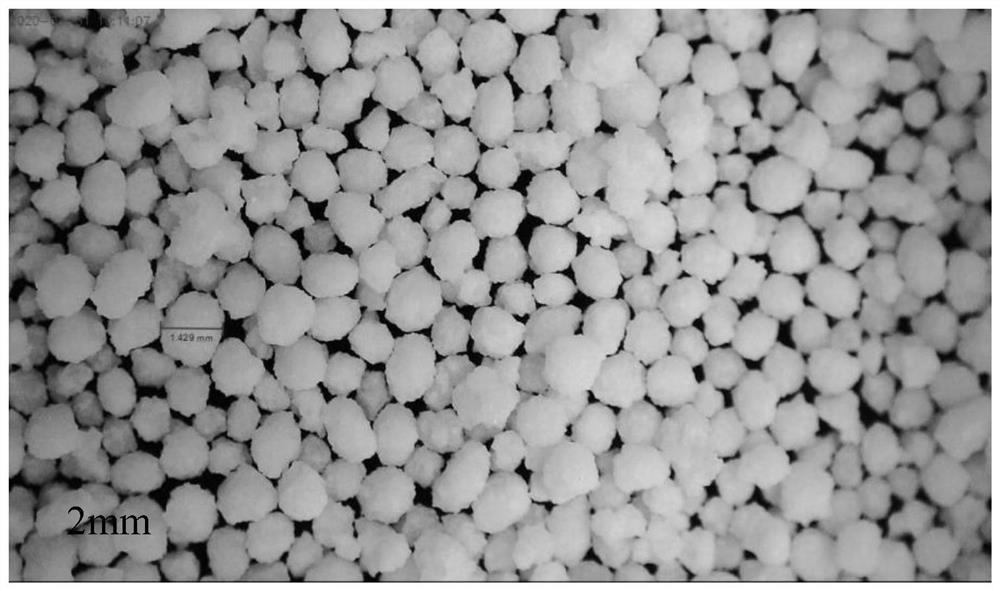

[0042] Example 3 is basically the same as Example 1, except that 15 kg of the crystallization agent sodium hexametaphosphate and 25 kg of seed crystal slurry with a solid content of 50% are added in step (3). Stir, cool and crystallize, the crystallization temperature is -15°C, the cooling rate is 5°C / h, and the crystallization time is 8h, to obtain potassium monopersulfate compound salt crystals. Carry out solid-liquid separation of the potassium monopersulfate compound salt crystal, dry the solid, and sieve the potassium monopersulfate compound salt with a particle size of 10 to 200 meshes. The obtained optical diagram of the potassium monopersulfate compound salt is as follows figure 1 As shown, the SEM image is shown in figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com