Patents

Literature

253 results about "Zirconium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium: compounds information This section lists some binary compounds with halogens (known as halides), oxygen (known as oxides), hydrogen (known as hydrides), and some other compounds of zirconium.

Well treatment composition crosslinkers and uses thereof

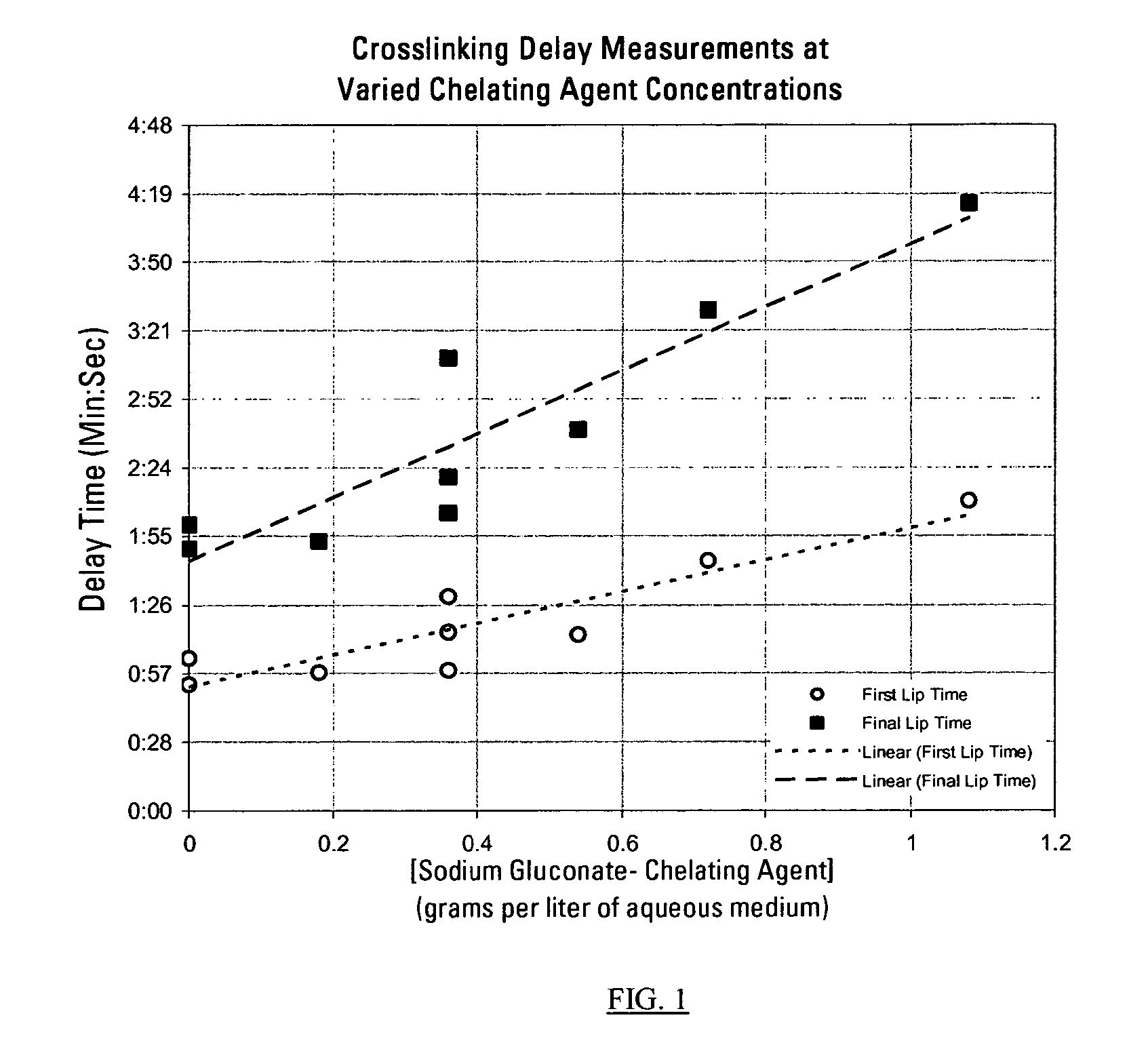

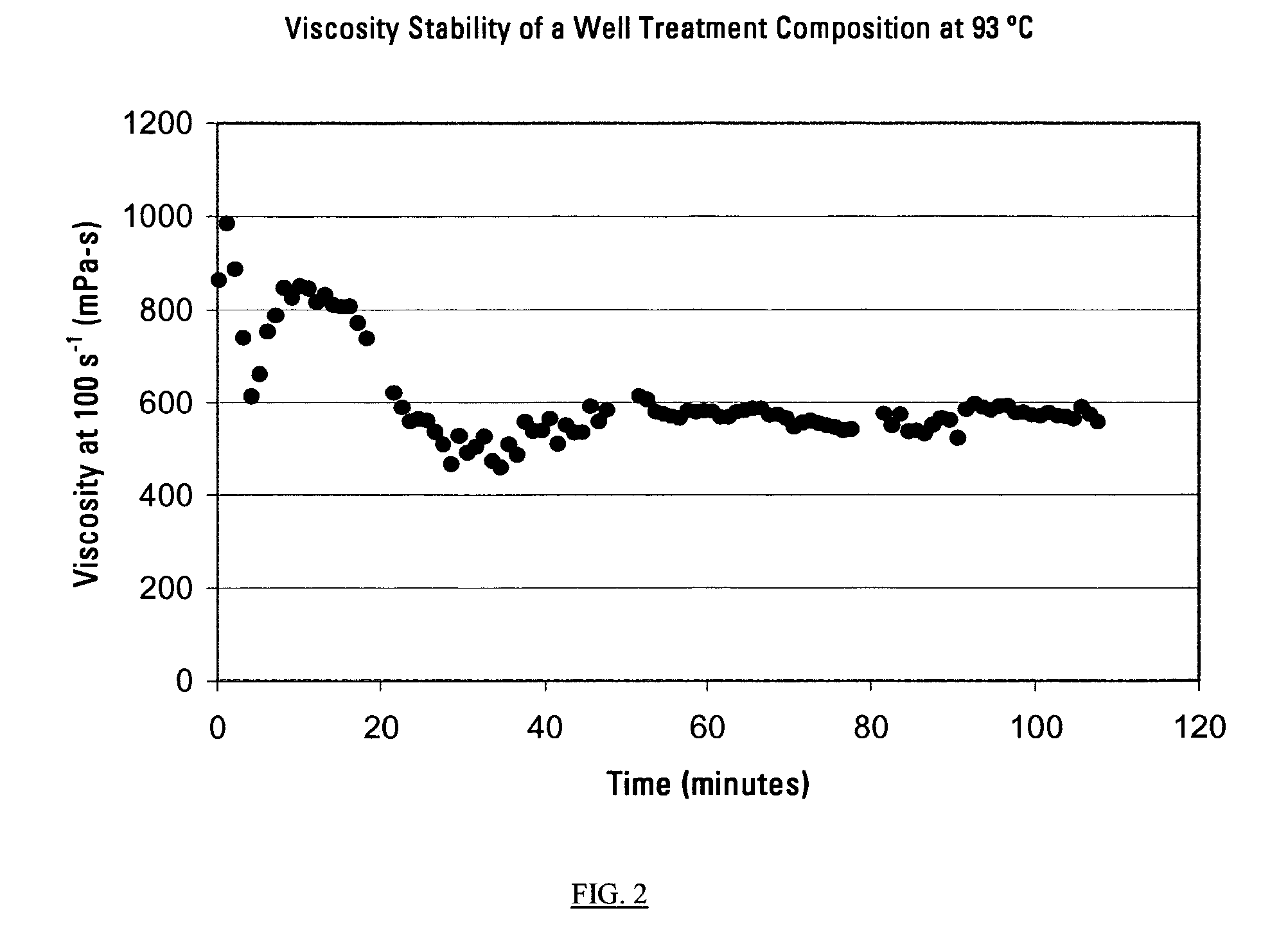

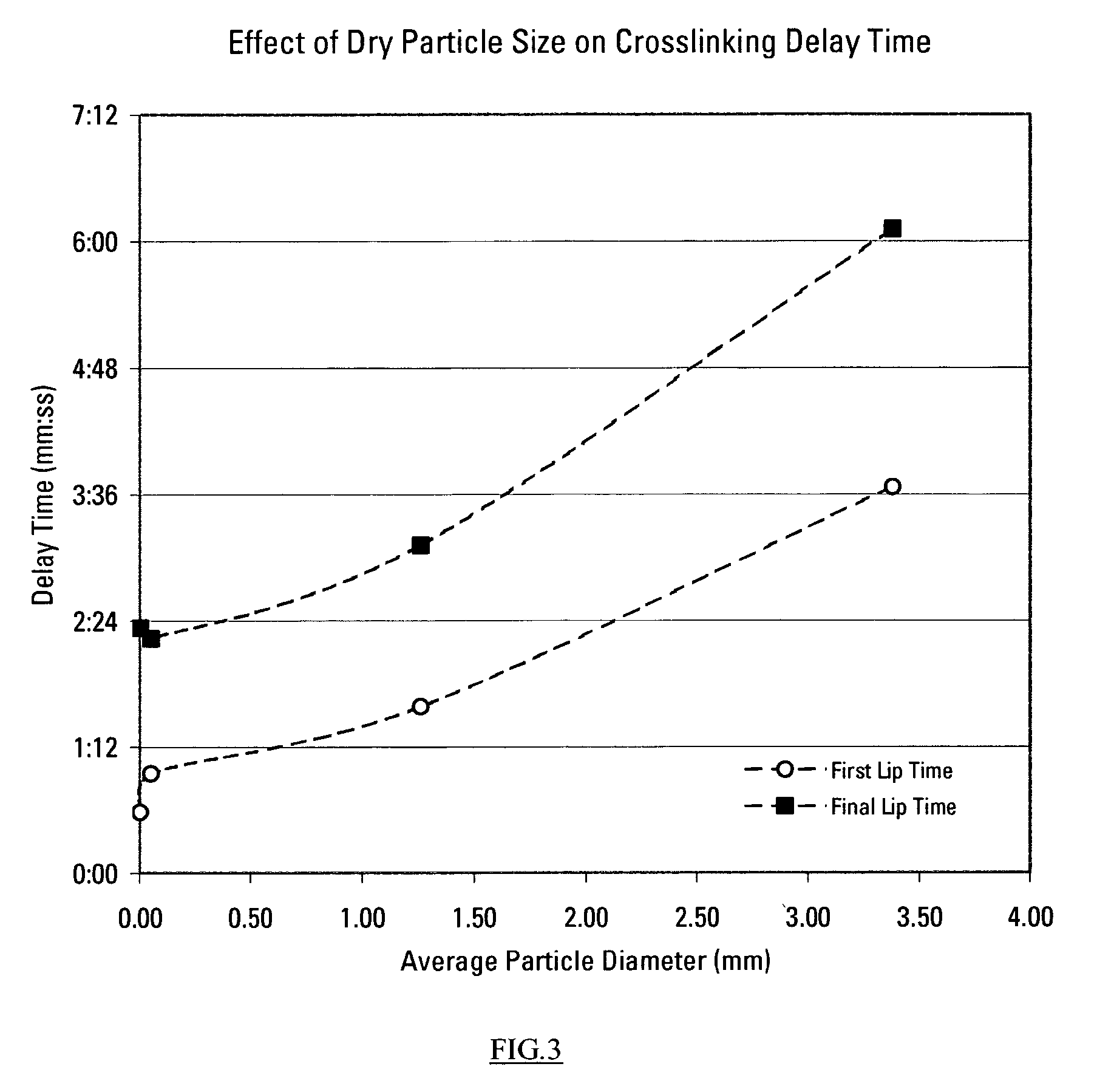

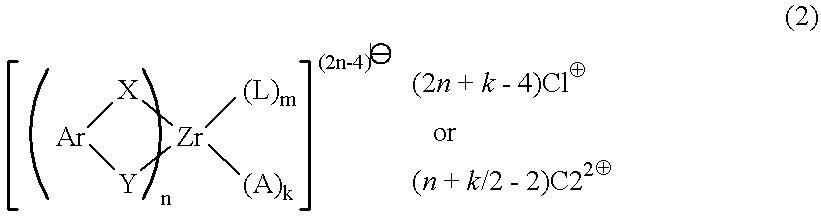

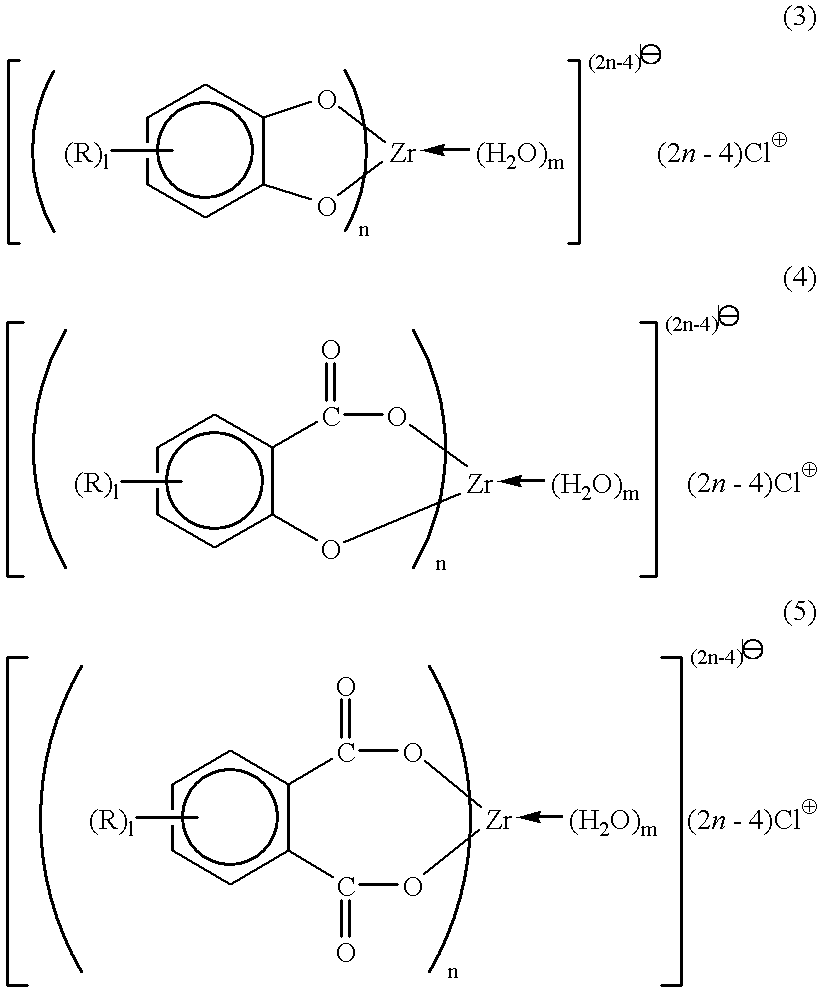

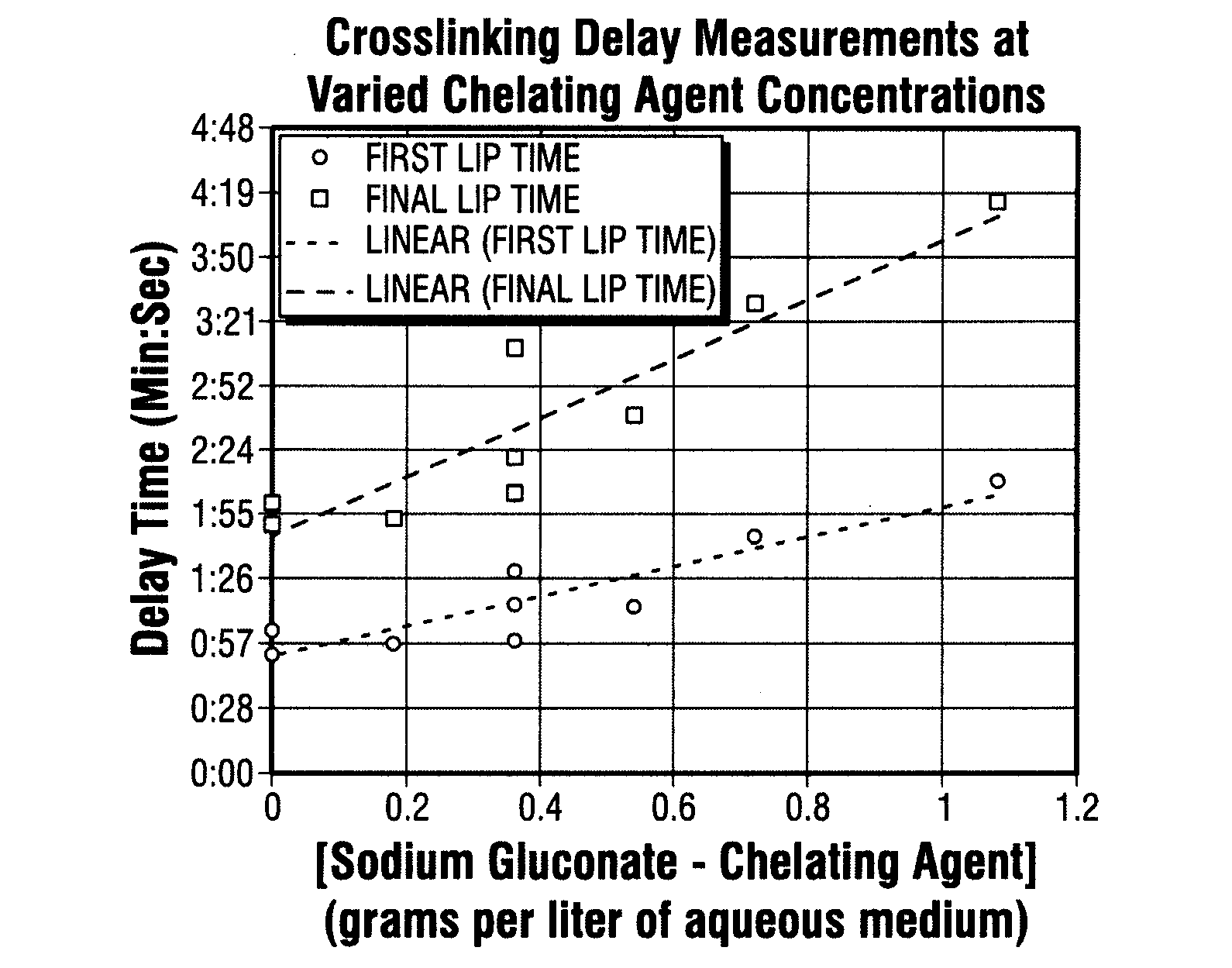

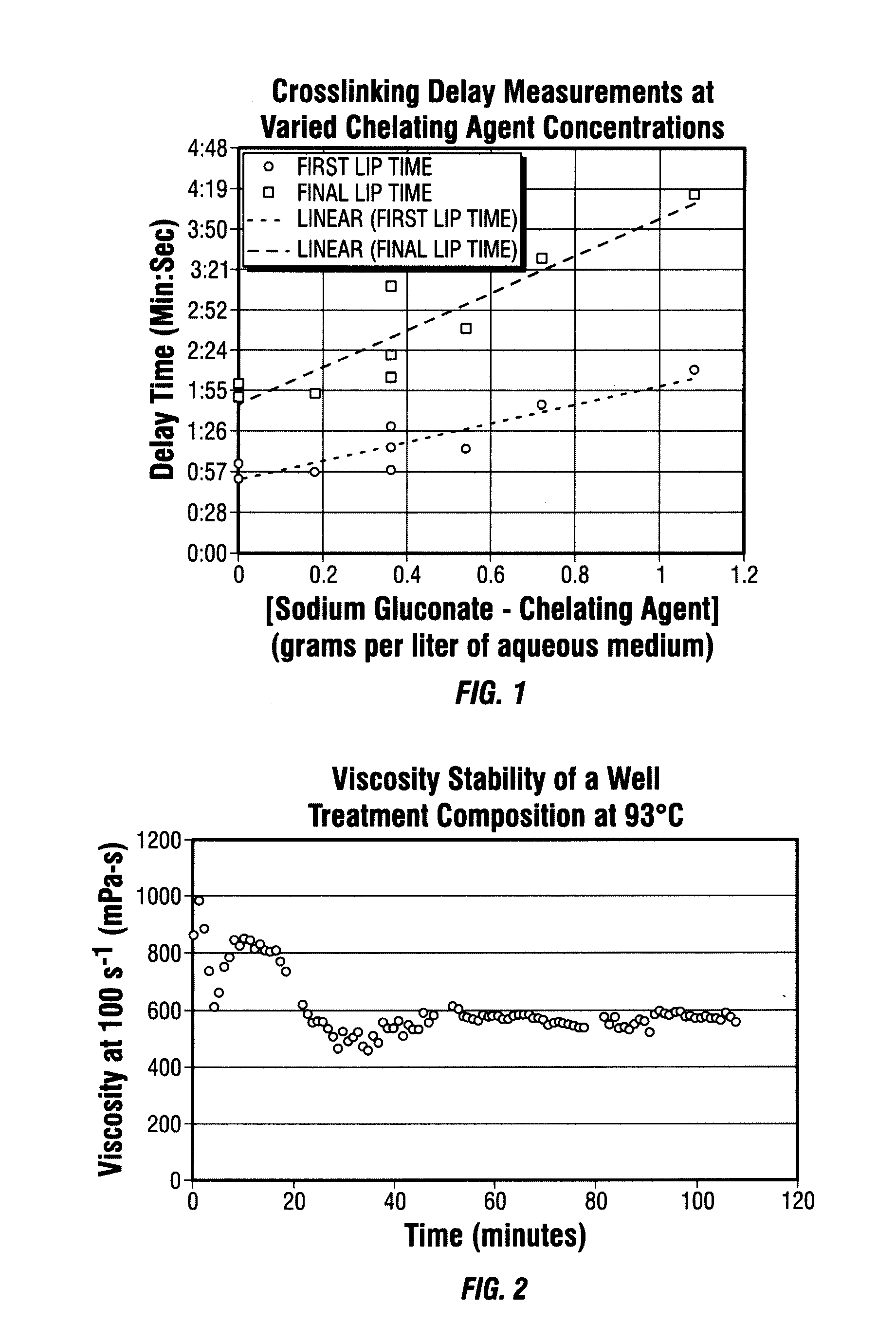

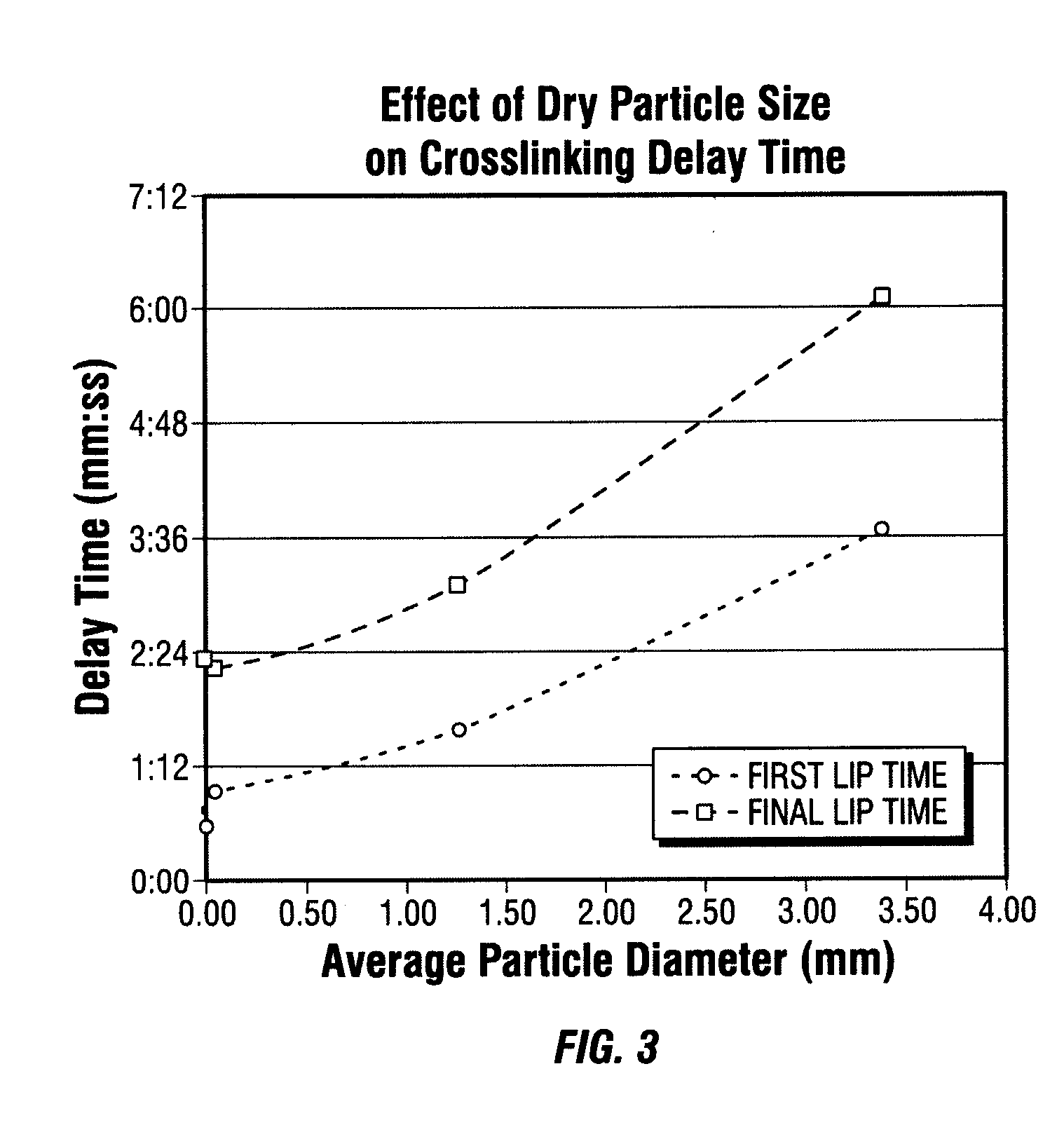

This invention relates to compositions used in treating subterranean formations, which include a hydrated polymer, and a dry blended multi-functional component. The hydrated polymer and dry blended multi-functional component are mixed at the ground surface of a wellsite, and subsequently injected into the formation providing controlled delay in crosslinking to achieve targeted fluid viscosity properties. The hydrated polymer may be a guar, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, synthetic polymers, and guar-containing compounds. The dry blended multi-functional component may include a crosslinker and a chelating agent, and the well treatment fluid may further include an activator mixed with the hydratable polymer. The chelating agent may be a polyols, gluconate, sorbitol, mannitol, carbonate, or any mixtures thereof. The crosslinker may be any source of boron, alkaline earth metal borates, alkali metal borates, zirconium compounds, titanium compounds, or any combination thereof, while the activator may be a caustic soda or magnesium oxide compound. The invention further provides methods for producing a well treatment composition including providing a hydrated polymer, and providing a dry blended multi-functional component. Also, methods of hydraulically fracturing a subterranean formation, as well as cleanup operations and gravel packing a wellbore are provided as well.

Owner:SCHLUMBERGER TECH CORP

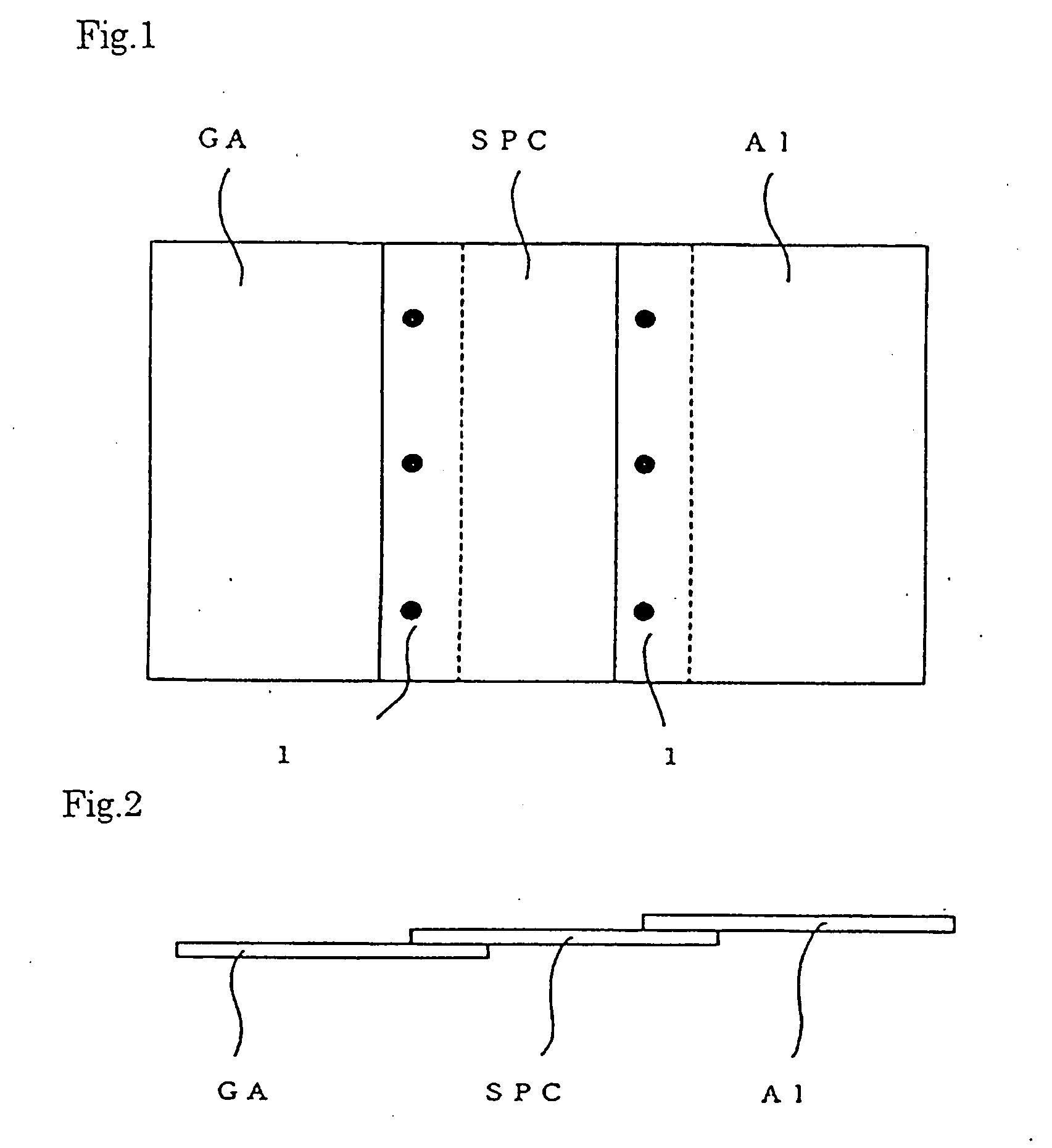

Treating solution for surface treatment of metal and a method for surface treatment

InactiveUS20060185769A1Improve corrosion resistanceAnodisationElectrolytic inorganic material coatingSurface-active agentsOxygen

Treating solution for surface treatment of metal to treat one metal material selected from the group consisting of ferriferous material, zinciferous material, aluminiferous material and magnesiferous material or to treat two or more metal materials selected from the group consisting of ferriferous material, zinciferous material, aluminiferous material and magnesiferous material at the same time, wherein the aqueous surface treating solution contains from 5 to 5000 ppm of at least one compound selected from the group consisting of zirconium compound and titanium compound by the metal element, and from 0.1 to 100 ppm of free fluorine ion, further the pH of the treating solution is from 2 to 6. To the treating solution, calcium compound, magnesium compound, strontium compound, nitric acid group, oxygen acid and / or salt of oxygen acid, polymer compound and surface active agent can be added.

Owner:NIHON PARKERIZING +2

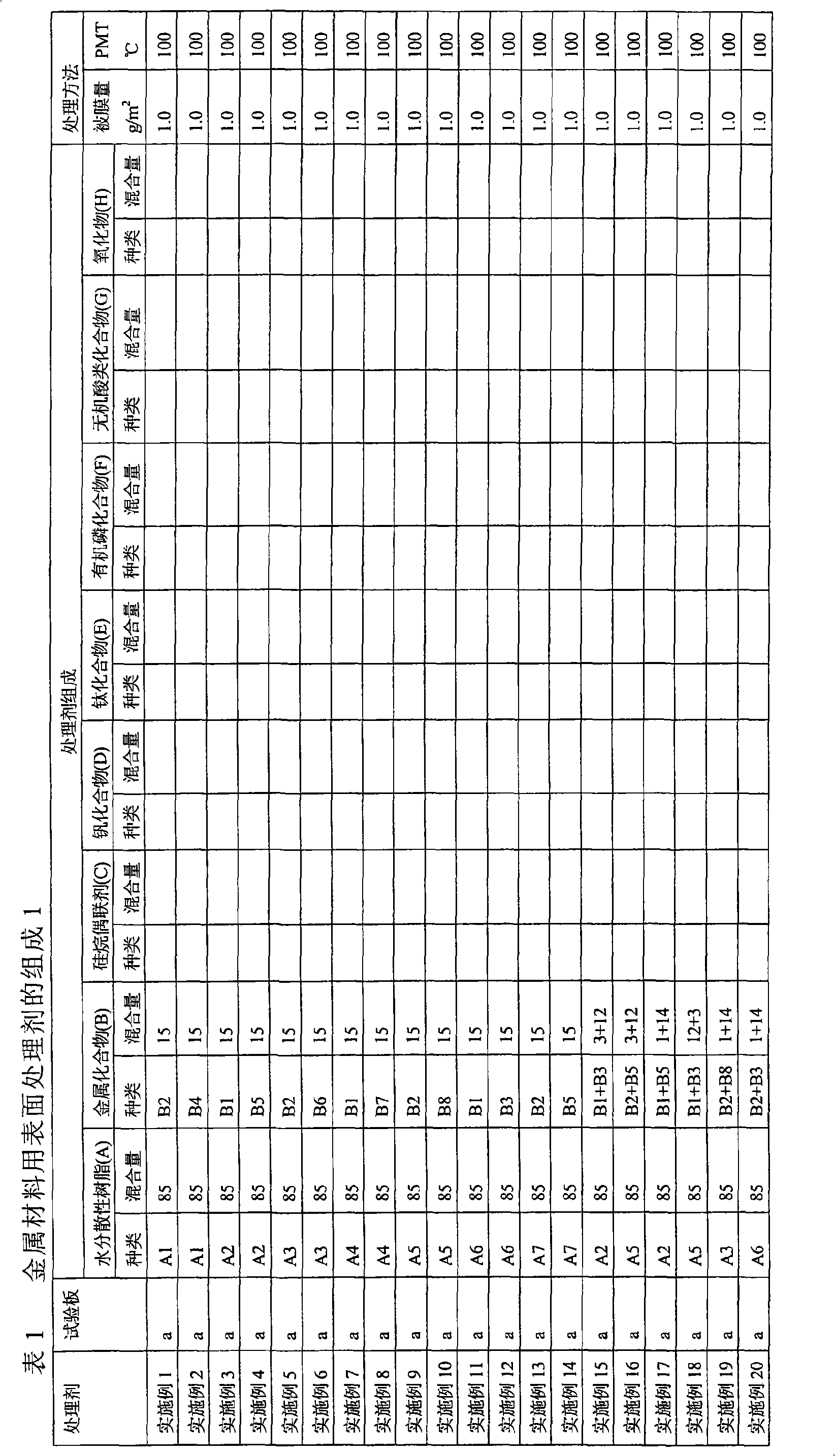

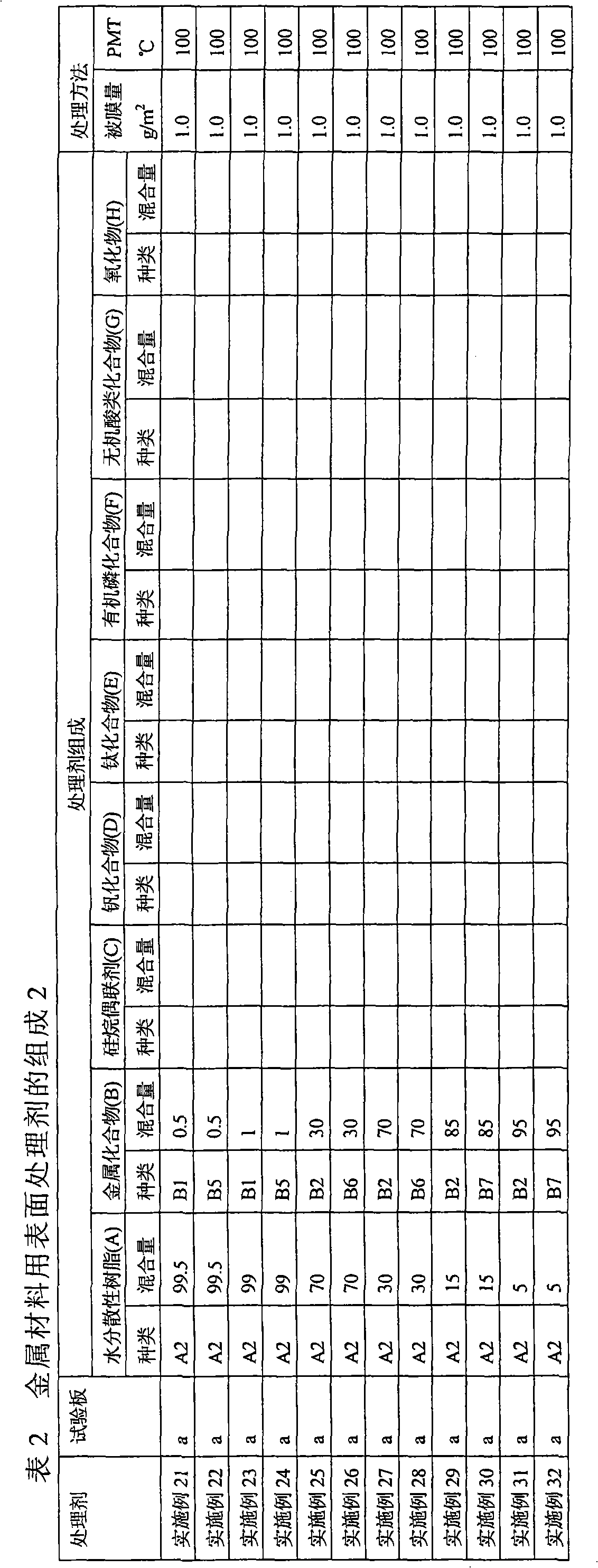

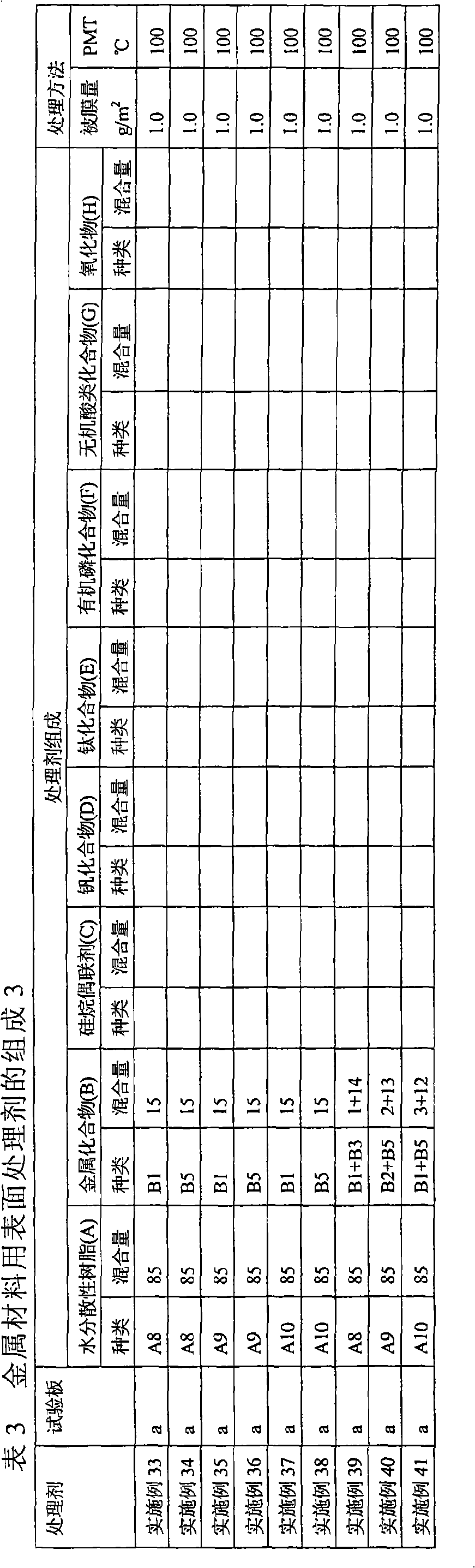

Surface treatment for metal materials, surface treatment process, and surface- treated metal materials

InactiveCN101326308AImprove use valueImprove corrosion resistanceLiquid surface applicatorsMetallic material coating processesChromium freeWater dispersible

A surface treatment for metal materials obtained by incorporating an anionic water-dispersible resin (A) having a glass transition temperature of 0 DEG C or above and at least one member (B) selected from the group consisting of alkali metal silicates and basic zirconium compounds in water, wherein the alkali metal silicates have M2O / SiO2 mass ratios of 1 / 1000 to 6 / 10 with M being at least one element selected from the group consisting of lithium, sodium and potassium; a surface treatment process; and surface-treated metal materials. The invention provides a chromium-free surface treatment for metal materials which is useful for imparting excellent corrosion resistance, chemical resistance, thermal discoloration resistance and weather resistance to metal materials. Additional incorporation of one or more members selected from among silane coupling agents, vanadium compounds, titanium compounds, organophosphonic acids, polyhydric alcohol phosphates, inorganic acids, salts thereof, metal fluorides, and metal oxides brings about further improvement in the performance of the treatment.

Owner:NIHON PARKERIZING

Method for treating metallic surfaces

InactiveUS6572983B2Improve corrosion resistanceEasy to processPretreated surfacesEfficient propulsion technologiesWater dispersiblePhosphate ion

A method of treating a metallic surface which comprises treating a metal-coated steel panel with a nonchromate metallic surface treating agent containing, in each liter thereof, (a-1) a silane coupling agent and / or a hydrolytic condensation product thereof, (a-2) water-dispersible silica in a proportion, and (a-3) a zirconium compound and / or a titanium compound, drying the treated steel panel and coating it with an anticorrosion coating agent containing, in each liter of an aqueous resin solution or dispersion, (b-1) a silane coupling agent and / or a hydrolytic condensation product thereof, (b-2) water-dispersible silica and (b-3) at least one phosphorus-containing ion selected from among phosphate ion, phosphite ion and hypophosphite ion.

Owner:NIPPON PAINT CO LTD

Low-hardness glue-dispensing shaping shielding conductive adhesive as well as preparation method and application thereof

ActiveCN102516929ALower impedanceReduce connectivityElectrically-conducting adhesivesAdhesiveChemistry

The invention relates to a low-hardness glue-dispensing shaping shielding conductive adhesive as well as a preparation method and application thereof. The conductive adhesive comprises the following components in parts by weight: (A) 100 parts of organic polysiloxane of which each molecule comprises at least two alkenyl; (B) 2-10 parts of the organic polysiloxane of which each molecule comprises at least two silicon-hydrogen bonds and a hydrolysable group; (C) 100-350 parts of metal base conductive fillers; (D) 0.001-0.005 parts of Pt-based catalyst; and (E) 0.1-2.0 parts of aluminum compounds or zirconium compounds or titanium compounds. Compared with the prior art, the conductive adhesive provided by the invention has the advantages of low hardness, high conductivity, high shielding performance, strong shaping ability, excellent adhesiveness and the like.

Owner:SHANGHAI RELAND PHOTOVOLTAIC MATERIAL

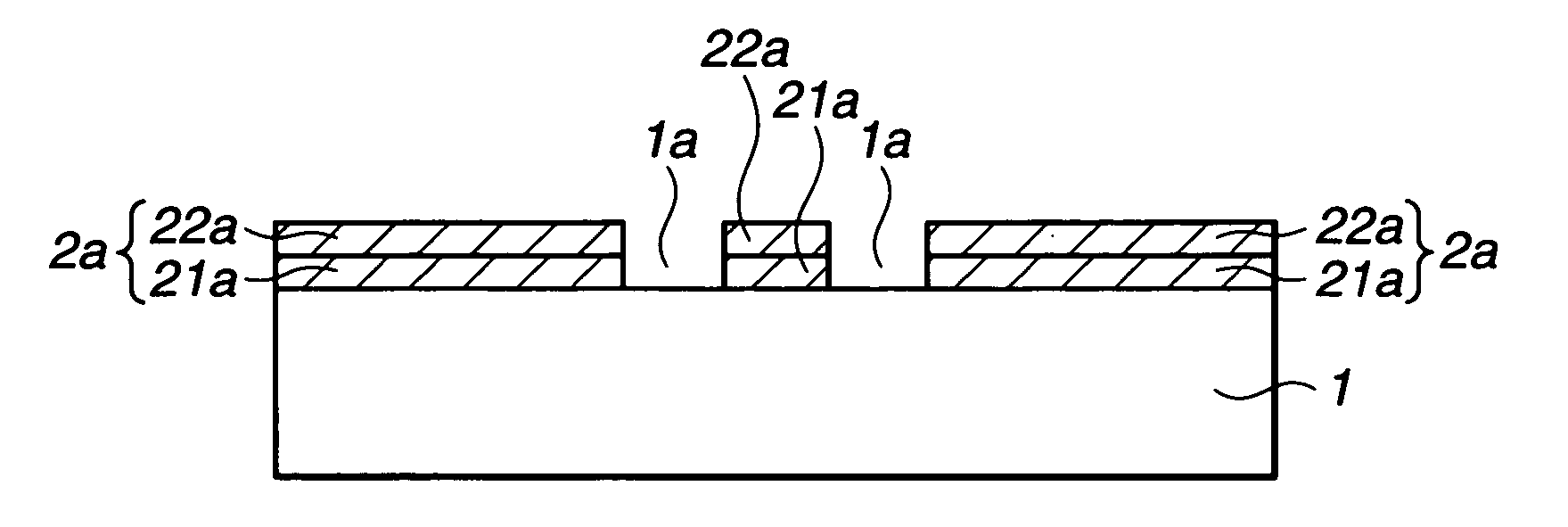

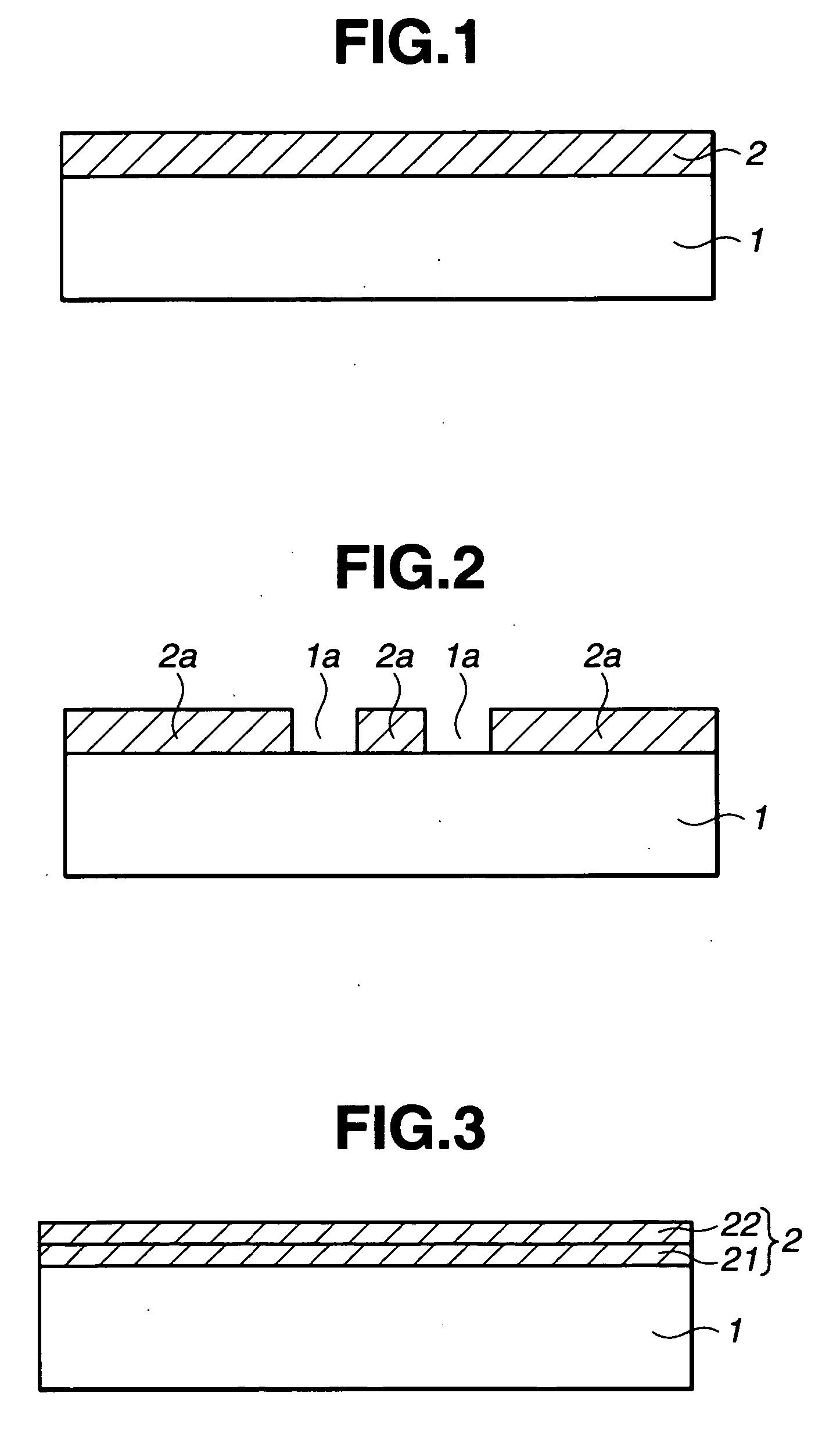

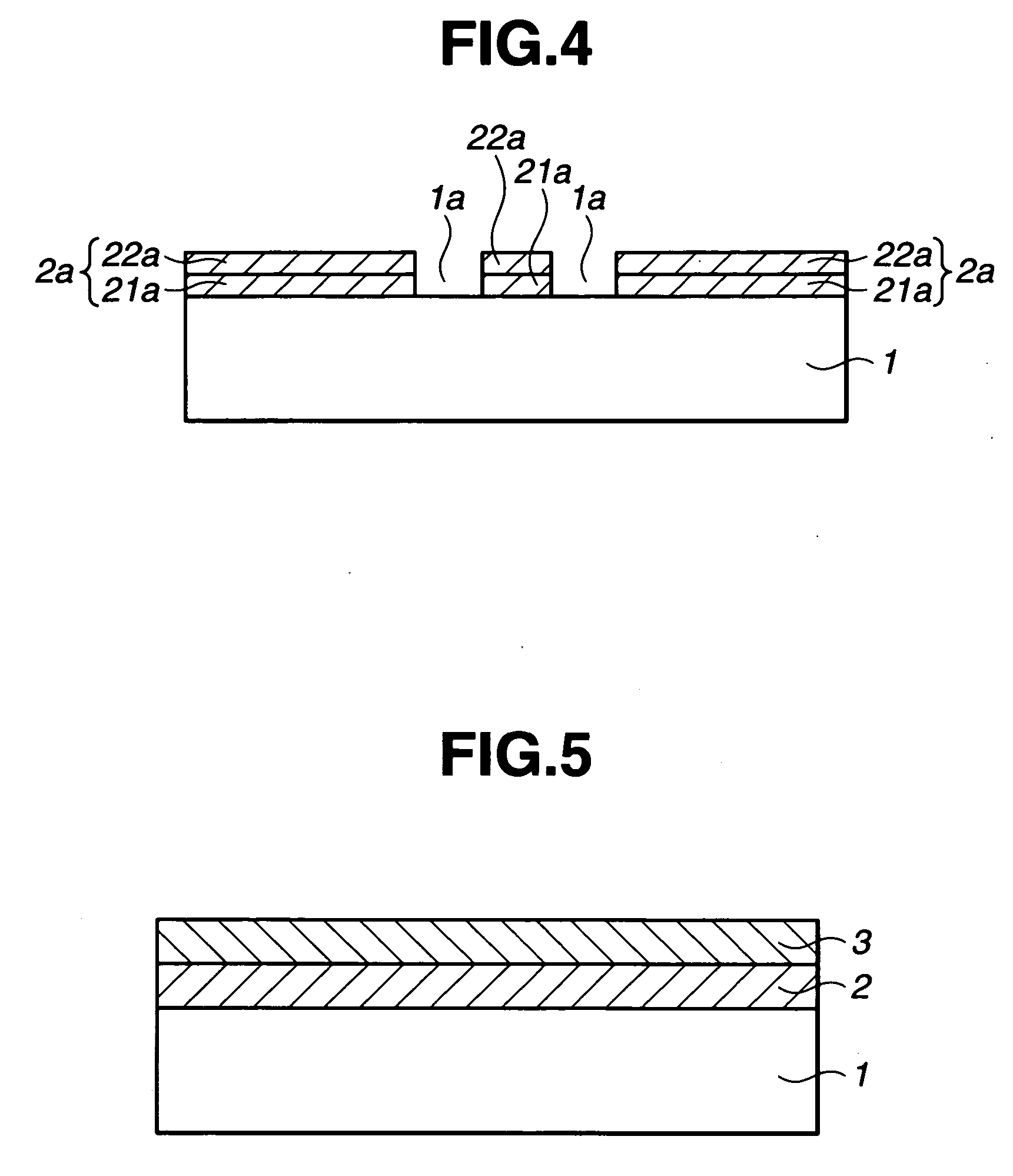

Photomask blank, photomask, and method of manufacture

A photomask blank comprising a multilayer film including at least four layers of different compositions, wherein the interface between the layers is moderately graded in composition; a phase shift mask blank comprising a phase shift film of at least two layers including a surface layer of a composition based on a zirconium silicide compound and a substrate adjacent layer of a composition based on a molybdenum silicide compound, and a further layer between one layer and another layer of a different composition, the further layer having a composition moderately graded from that of the one layer to that of the other layer; a phase shift mask blank comprising a phase shift film including a plurality of layers containing a metal and silicon in different compositional ratios which are stacked in such order that a layer having a higher etching rate is on the substrate side and a layer having a lower etching rate is on the surface side. The invention provides a photomask blank, typically a phase shift mask blank, which satisfies optical properties such as transmittance, reflectance and refractive index at an exposure wavelength of interest, and has an etched pattern with a minimal line edge roughness, and a photomask, typically a phase shift mask obtained therefrom.

Owner:SHIN ETSU CHEM IND CO LTD

Toner having negative triboelectric chargeability and image forming method

InactiveUS6232027B1Improve image qualityNot causing image defectDevelopersCarboxylic acidOrganic compound

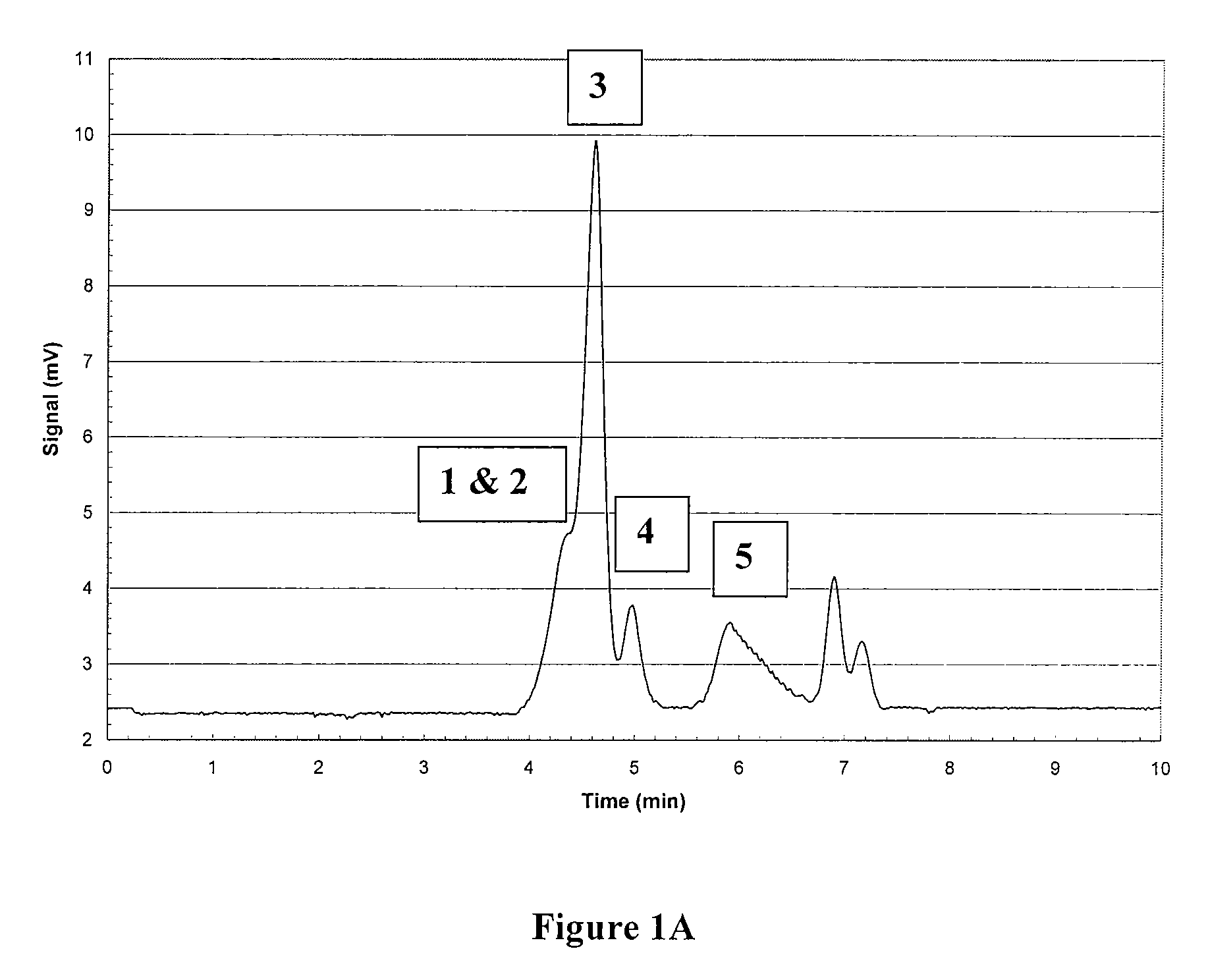

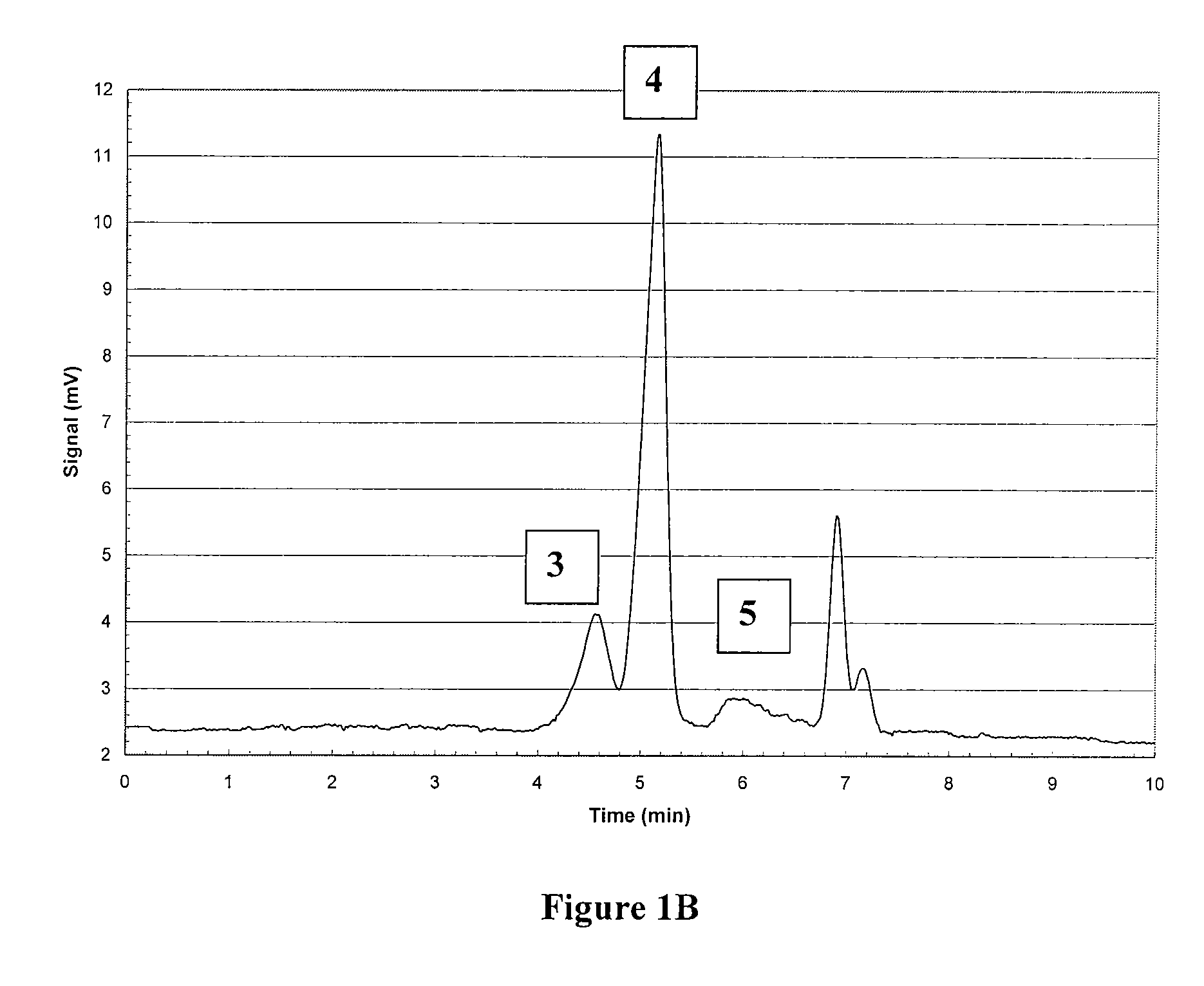

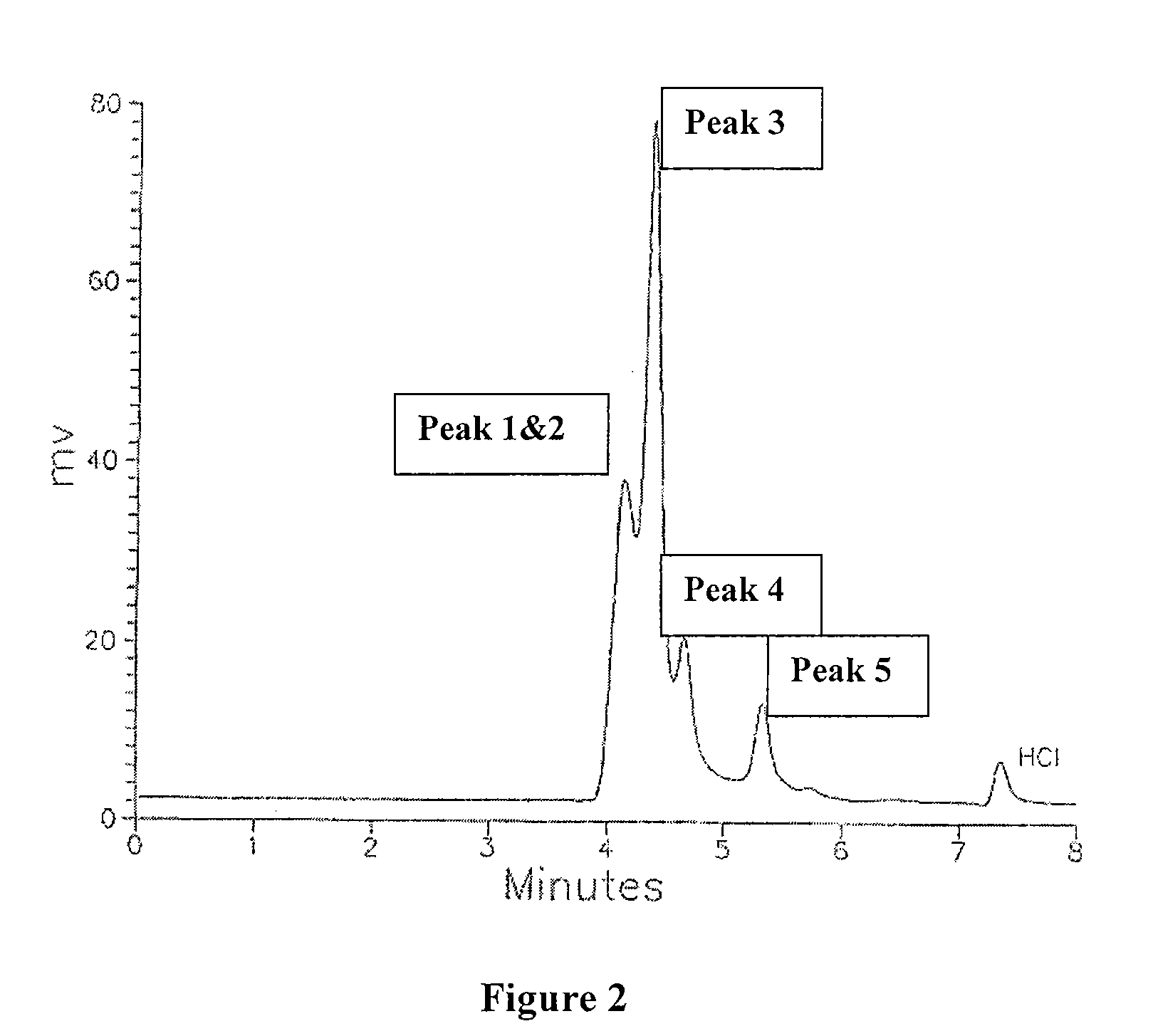

A toner having a negative triboelectric chargeability is constituted by at least a binder resin, a colorant and an organic metal compound. The toner is characterized by: (a) the organic metal compound is an organic zirconium compound comprising a coordination or / and a bonding of zirconium and an aromatic compound as a ligand or / and an acid source selected from the group consisting of aromatic diols, aromatic hydroxycarboxylic acids, aromatic monocarboxylic acids, and aromatic polycarboxylic acids, (b) the binder resin is a resin selected from the group consisting of (i) a polyester resin and (ii) a hybrid resin component comprising a polyester unit and a vinyl polymer unit, (c) the binder resin has an acid value of 2-50 mgKOH / g, and (d) the toner contains a TFT (tetrahydrofuran)-soluble content providing a GPC (gel permeation chromatography) chromatogram exhibiting a main peak in a molecular weight range of 3,000-20,000 and including 3-25% of a component having molecular weights of at least 5x105.

Owner:CANON KK

Surface-treated galvanized steel sheet with superior flat-portion corrosion resistance, blackening resistance, and appearance and corrosion resistance after press forming and aqueous surface-treatment liquid for galvanized steel sheet

ActiveUS20100035055A1Nice appearanceImprove corrosion resistanceOther chemical processesPretreated surfacesParticulatesWater dispersible

An aqueous surface-treatment liquid is a treatment liquid containing a water-soluble zirconium compound, water-dispersive particulate silica, a silane coupling agent, a vanadic acid compound, a phosphoric acid compound, a nickel compound, and an acrylic resin emulsion in particular proportions. A surface-treated galvanized steel sheet produced using the treatment liquid is a galvanized steel sheet having a surface-treatment coating on a surface thereof, and the coating contains a zirconium compound, particulate silica, a silane-coupling-agent-derived component, a vanadic acid compound, a phosphoric acid compound, a nickel compound, and an acrylic resin in particular proportions. The amount of coating on a zirconium basis is 10 to 200 mg / m2. This surface-treated galvanized steel sheet is chromate-free and has superior flat-portion corrosion resistance, blackening resistance, and appearance and corrosion resistance after press forming.

Owner:JFE STEEL CORP

Process for producing ceria-zirconia-alumina composite oxides and applications thereof

InactiveUS20130108530A1Improved hydrocarbon conversionNitrogen compoundsInternal combustion piston enginesCombustionCerium(IV) oxide

A process for producing a ceria-zirconia-alumina composite oxide is disclosed. The process comprises combining a cerium (IV) compound and a zirconium (IV) compound with a slurry of aluminum oxide at a temperature greater than 40° C. to produce a reaction slurry, then contacting the reaction slurry with a precipitating agent to precipitate insoluble cerium and zirconium compounds onto the aluminum oxide and form cerium-zirconium-aluminum oxide particles, and calcining the cerium-zirconium-aluminum oxide particles to produce a ceria-zirconia-alumina composite oxide. The process to produce ceria-zirconia-alumina composite oxides provides a material having a high oxygen storage / release capacity that is suitable for a catalyst with enhanced cleaning of the exhaust gases from internal combustion engines.

Owner:JOHNSON MATTHEY PLC

Well Treatment Composition Crosslinkers and Uses Thereof

This invention relates to compositions used in treating subterranean formations, which include a hydrated polymer, and a dry blended multi-functional component. The hydrated polymer and dry blended multi-functional component are mixed at the ground surface of a wellsite, and subsequently injected into the formation providing controlled delay in crosslinking to achieve targeted fluid viscosity properties. The hydrated polymer may be a guar, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, synthetic polymers, and guar-containing compounds. The dry blended multi-functional component may include a crosslinker and a chelating agent, and the well treatment fluid may further include an activator mixed with the hydratable polymer. The chelating agent may be a polyols, gluconate, sorbitol, mannitol, carbonate, or any mixtures thereof. The crosslinker may be any source of boron, alkaline earth metal borates, alkali metal borates, zirconium compounds, titanium compounds, or any combination thereof, while the activator may be a caustic soda or magnesium oxide compound. The invention further provides methods for producing a well treatment composition including providing a hydrated polymer, and providing a dry blended multi-functional component. Also, methods of hydraulically fracturing a subterranean formation, as well as cleanup operations and gravel packing a wellbore are provided as well.

Owner:DESSINGES MARIE NOELLE +1

Treating fluid for surface treatment of metal and method for surface treatment

The present invention provides surface treatment liquid for a surface treatment capsule, which contains no ingredients that are harmful to the environment, produces no waste sludge, is capable of separating coating on a metal surface, and has excellent corrosion resistance; and the present invention provides a surface treatment method. In particular, the present invention provides metal surface treatment liquid and aqueous surface treatment liquid that can be used for the surface treatment of one or more than two metal materials that are chosen from iron materials, zinc materials, aluminum materials and magnesium materials. The liquid contains metal elements that contain 5ppm to 5000ppm of more than one compound that are chosen from zirconium compounds and titanium compounds, and 0.1ppm to 100 ppm of free fluorion; and the pH value is 2 to 6. Thus the treatment liquid can contain calcium compounds, magnesium compounds or strontium compounds, nitrate, oxyacid and / or oxysalt, polymers and surfactants. The capsule can be formed when a metal material contacts the treatment liquid or is electrolyzed in the liquid.

Owner:NIHON PARKERIZING +2

Ink-jet recording medium and method of improving moisture resistance of same

InactiveCN1572532AImprove moisture resistanceDuplicating/marking methodsCoatingsPolymer sciencePolyvinyl alcohol

An ink-jet recording medium including: a substrate; and an ink receiving layer coated on a surface of the substrate and including an inorganic filler, a polyvinyl alcohol, a cationic core-shell latex with a glass transition temperature (Tg) of at least 50 DEG C., and a zirconium compound.

Owner:SAMSUNG ELECTRONICS CO LTD

Compositions for improved ceramic armor

The present invention contemplates the addition of zirconium compounds to well known ceramic ballistic materials to increase resistance to penetration by projectiles. In the preferred embodiments of the present invention, the zirconium compound that is employed consists of ZrO2 and is provided in the range of about 0.1% to about 11%, by weight, of starting material before densification. Preferred ranges of proportion of ZrO2 in the finished ceramic material are in the ranges of about 0.30% to about 0.75%, by weight, or about 8-9%, by weight. The ballistic material using the combination of SiC with low volume of sintering aid and ZrO2 raises the theoretical density of the ceramic material to between 3.225 and 3.40 g / cc, which is slightly higher than the typical 3.22 g / cc theoretical density for hot pressed fully dense SiC. The unexpected result that accrues through combining silicon carbide and zirconia consists of the creation of controlled defects in the finished ceramic that increase the surface area that is fractured during a ballistic event, enhancing spreading of the forces imposed on the ceramic material by a projectile and, as a result, the ability of the ballistic material to withstand higher forces while resisting penetration.

Owner:BAE SYST ADVANCED CERAMICS

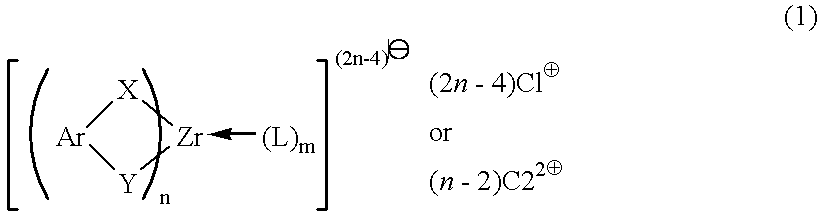

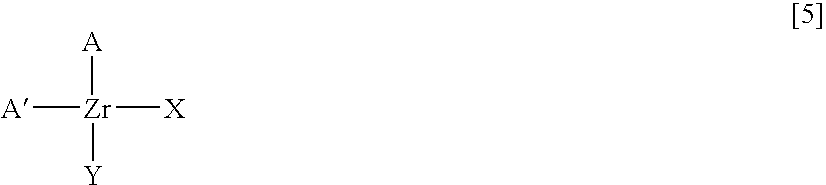

Catalyst for olefin polymerization and method of polymerization of olefin

InactiveUS6943227B2Rapidly enlarge particle sizeImprove liquidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceOlefin polymerization

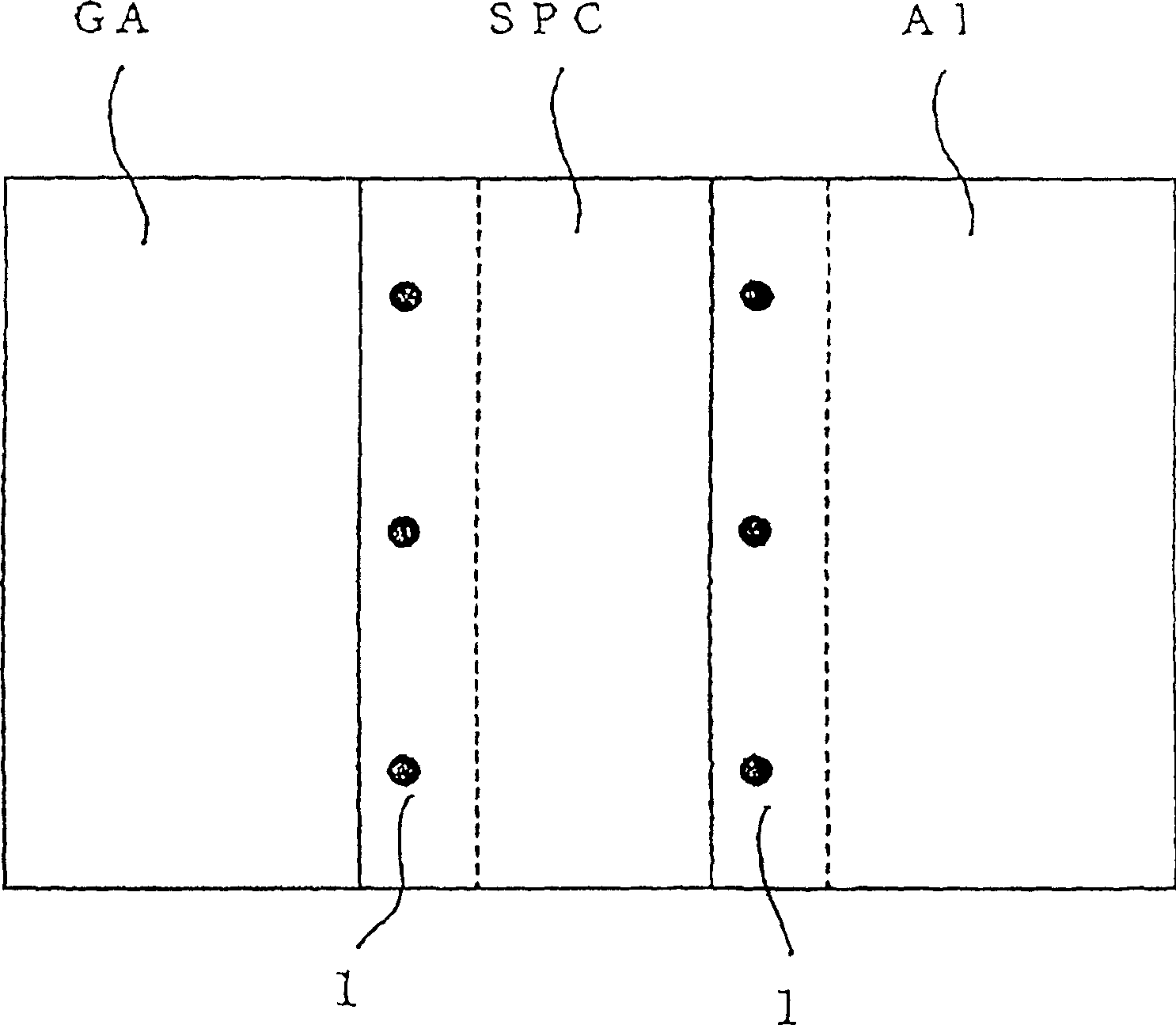

The present invention provides a catalyst for olefin polymerization having high olefin polymerization activity without being accompanied by generation of an adhered polymer on the wall of a polymerization reactor and the wall of pipe line and generation of a locking massive polymer, and capable of manufacturing an olefin polymer industrially and stably for a long period of time. That is, the present invention related to a catalyst for olefin polymerization comprising [A1] a hafnium compound or a zirconium compound having at least one conjugated 5-membered ring ligand, [A2] a zirconium compound having at least one conjugated 5-membered ring ligand but different from [A1], and [B] phyllosilicate, and relates to a method of polymerizing or copolymerizing olefin in the presence of the catalyst.

Owner:JAPAN POLYPROPYLENE CORP

Aluminum alloy product chemical conversion treatment process and nonferrous chromium-free film-forming agent

InactiveCN104264144ANo pollution in the processExcellent adhesionMetallic material coating processesChromium freeCarboxylic acid

The invention provides a film-forming agent capable of obtaining a chemical conversion coating with very good corrosion resistance, hexavalent chromium or heavy metal is not contained, sewage treatment is simple, and no pollution is caused to the environment. An aluminum alloy nonferrous chromium-free film-forming agent contains at least one of water-soluble titanium compounds or water-soluble zirconium compounds, the content is 0.05-3.0g / L (according to metal ions), and the content of organic carboxylic acid is 0.1-1.0g / L. The film-forming agent further comprises 0.1-1.0 g / L of an accelerant and 0.02-5.0g / L of a sealing agent.

Owner:湖州织里天荣铝材添加剂厂

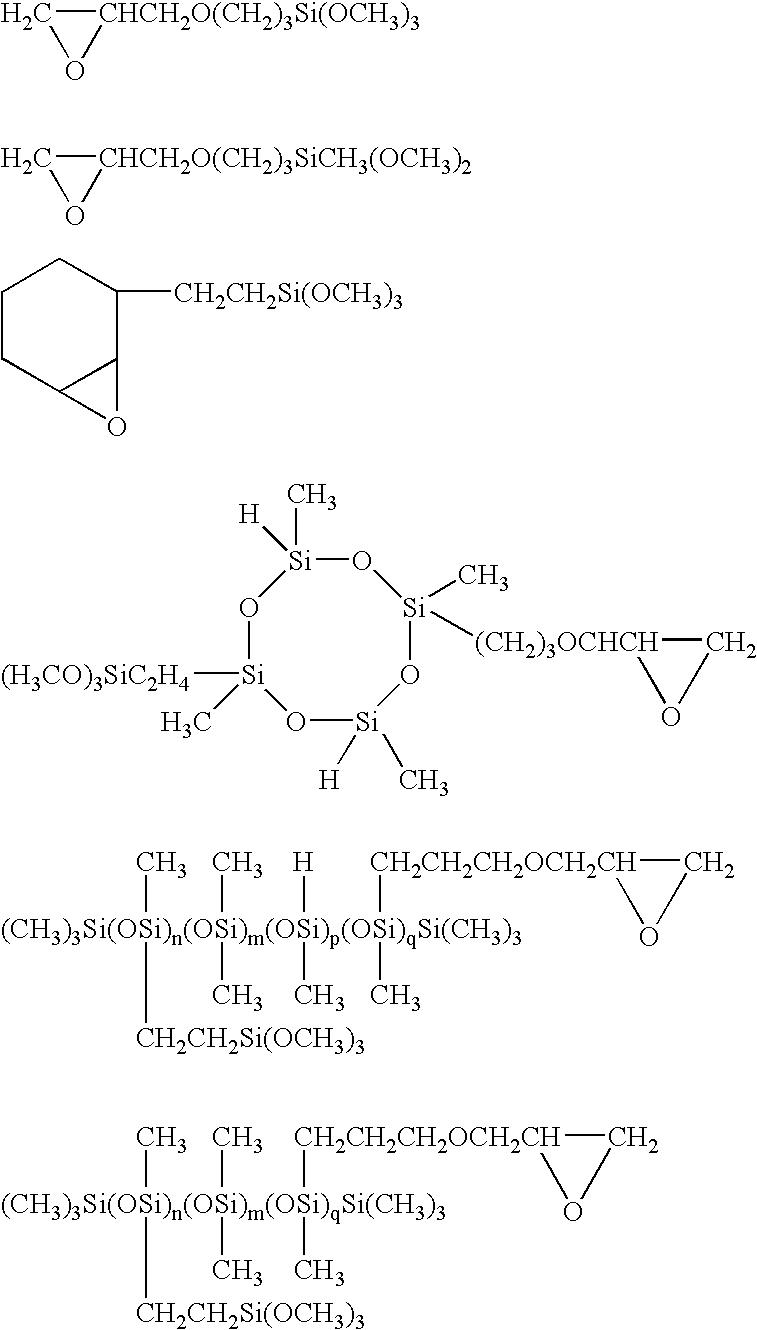

Silane-nanoceramic composite surface conditioning agent

InactiveCN104988563AWon't happenCreate pollutionElectrophoretic coatingsMetallic material coating processesEpoxySilanes

The invention discloses a silane-nanoceramic composite surface conditioning agent. The silane-nanoceramic composite surface conditioning agent is used for surface treatment before metal electrophoresis coating, and 1L of the composite surface conditioning agent comprises 100-100000mg of amino silane or epoxy silane, 1-10000mg of dispersible nanoparticles, 10-50000mg of a zirconium compound or a titanium compound, and the balance of water. The silane-nanoceramic composite surface conditioning agent does not contain phosphorus or other harmful elements, and has pollution to environment in the use process; and compared with present phosphorus-free surface conditioning agents allowing a treated metal to have a thin film on the surface and have poor physical bonding ability with an electrophoresis coating, the silane-nanoceramic composite surface conditioning agent allows a treated metal to have a thick film on the surface in order to enhance the physical binding ability with the electrophoresis coating, so the corrosion resistance and the throwing power of the electrophoresis coated metal are greatly improved.

Owner:NANJING KERUN LUBRICANTS

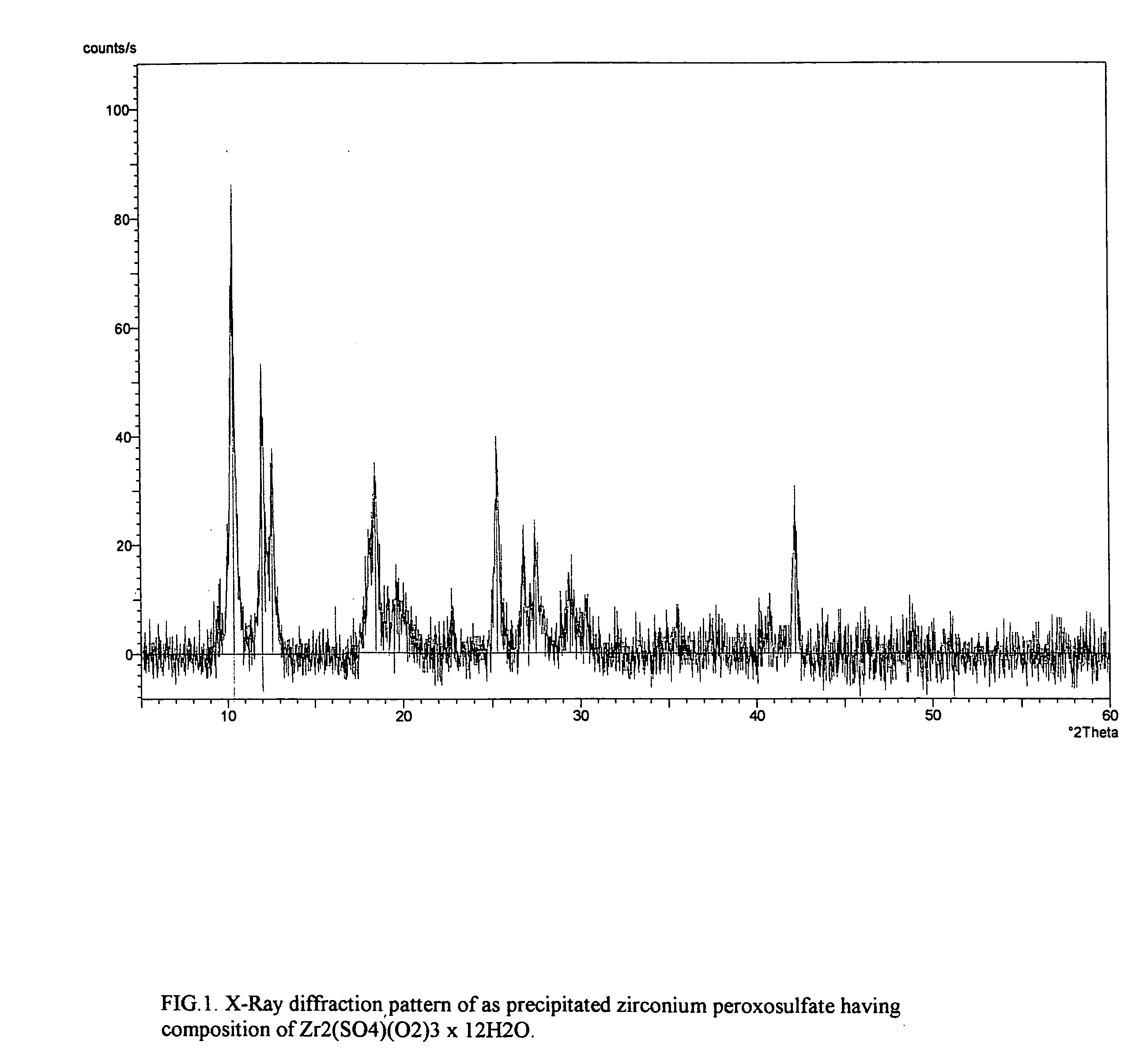

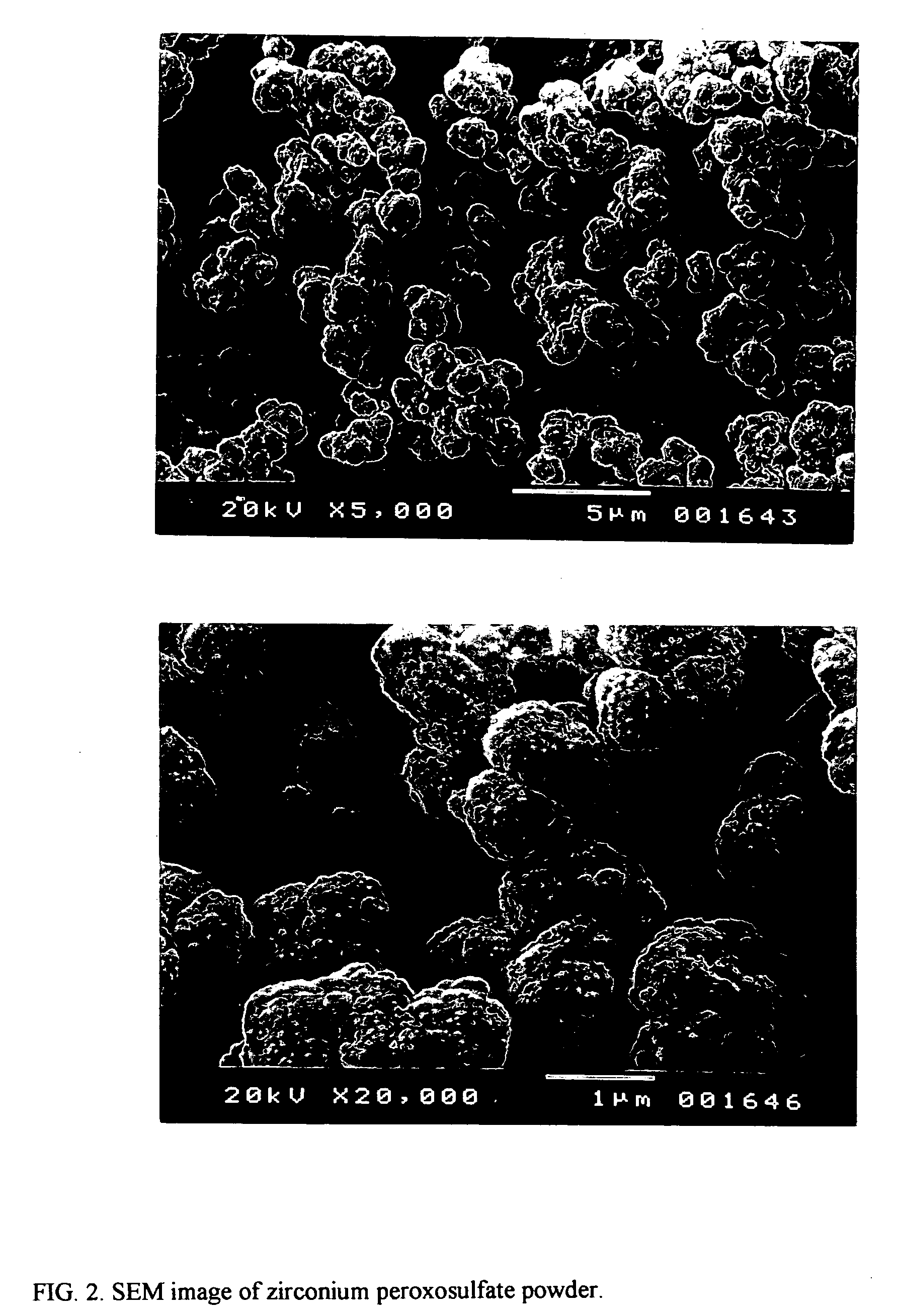

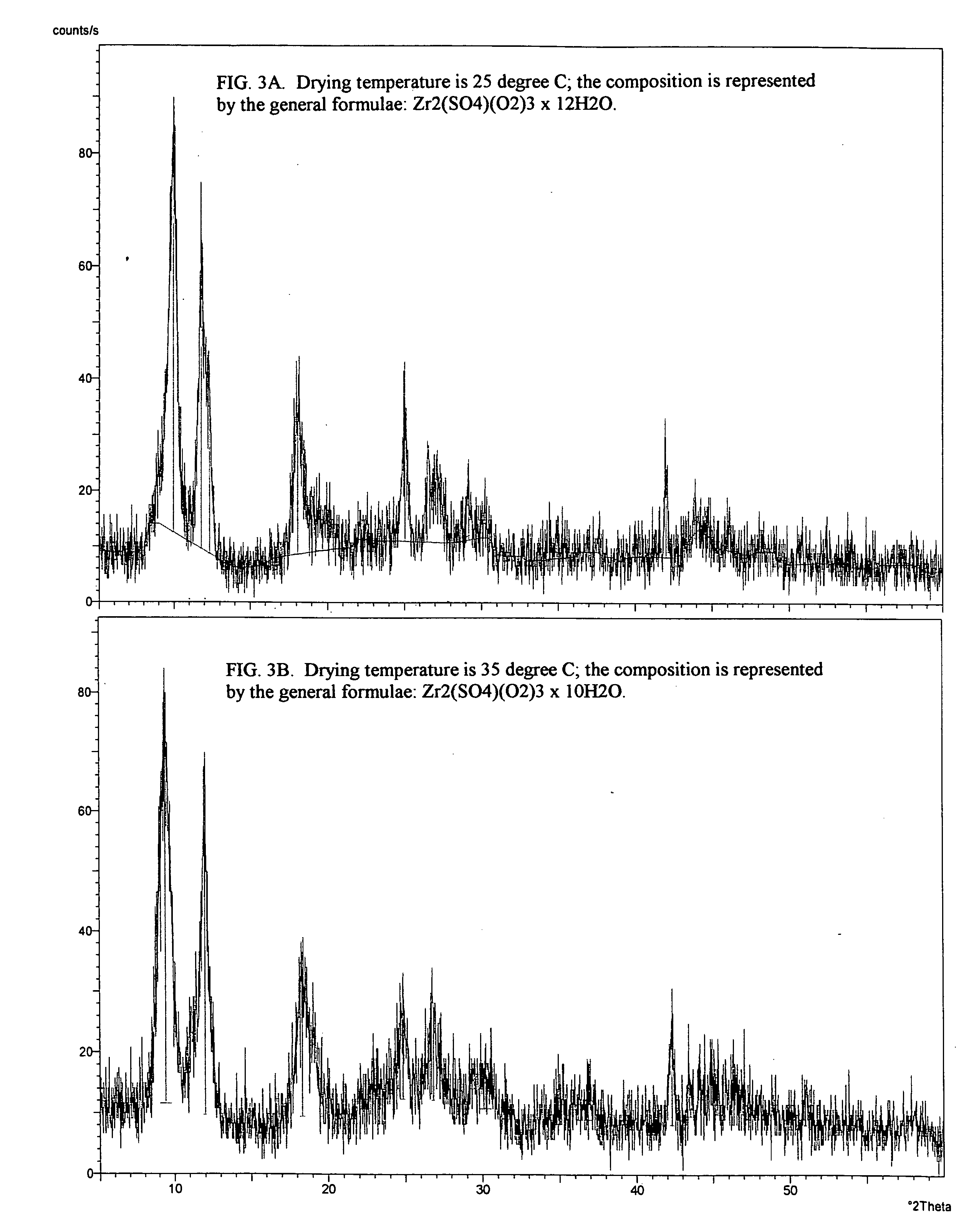

Process for the isolation and purification of zirconium peroxosulfate and uses thereof

InactiveUS20050180911A1High degreeShort processing timePeroxyhydrates/peroxyacidsSulfate preparationPurification methodsZirconium compounds

Provided is a process for isolating zirconium peroxosulfate and its use, either as is or to prepare high purity zirconium compounds including powders of zirconium dioxide and stabilized zirconia. The process is based on precipitating a peroxide compound from an acidic peroxide solution of zirconium and provides a simple, economical method for producing the zirconium peroxosulfate powder and its derivatives with degree of zirconium recovery more than 99%. This process further provides an effective method for the separation and purification of zirconium from a variety of elements and / or naturally occurring ores.

Owner:BELOV VLADIMIR +1

Liquid silicone rubber coating composition, curtain airbag and making method

InactiveUS20070166555A1Improve adhesionLiquid surface applicatorsFibre treatmentPolymer scienceTriallyl isocyanurate

A liquid silicone rubber coating composition comprising (A) an organopolysiloxane containing at least two silicon-bonded alkenyl radicals, (B) an organohydrogenpolysiloxane containing at least two SiH radicals, (C) an addition reaction catalyst, optionally (D) finely divided silica, (E) triallyl isocyanurate, (F) an organosilicon compound containing an epoxy radical and a silicon-bonded alkoxy radical, and (G) a titanium or zirconium compound is coated on a surface of an airbag base fabric and cured to form a rubber coating layer thereon. The composition is suited for curtain airbags.

Owner:SHIN ETSU CHEM IND CO LTD

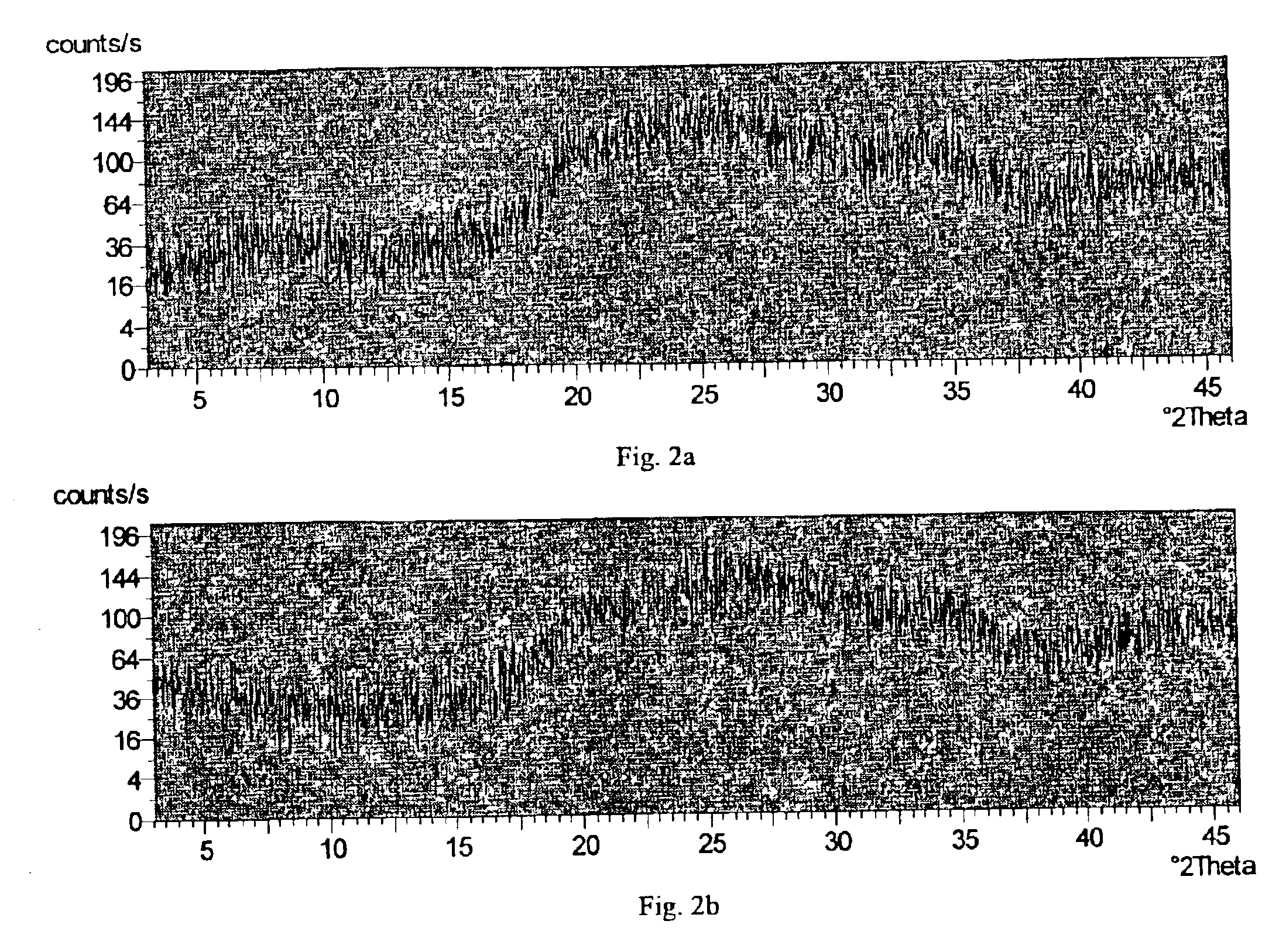

Zirconium phosphate, hafnium phosphate and method of making same

InactiveUS6936175B2Strong dependencySolve the stability is not highPhosphatesSolvent extractionZirconium compoundsHafnium

The invention relates to zirconium phosphate of H form which is characterized by a 31P NMR spectra comprising peaks at −4.7 ppm, −12.8 ppm and −17.0 ppm (all peaks being in a range of ±0.5 ppm). Also featured is a Na form of the material. The zirconium phosphate material is characterized by a unique surface area, pore size distribution and surface morphology, as well as by an affinity for NH4+ ions and moisture insensitivity. Also featured is hafnium phosphate characterized by moisture insensitivity. The zirconium phosphate may be amorphous and possess a framework-type structure. The inventive method of making zirconium phosphate includes the steps of heating an aqueous mixture including a zirconium compound and a phosphorous-containing reagent at a temperature of at least 120° C. to form a reaction product, and treating the reaction product with acid at a temperature of at least 60° C.

Owner:MEL CHEM

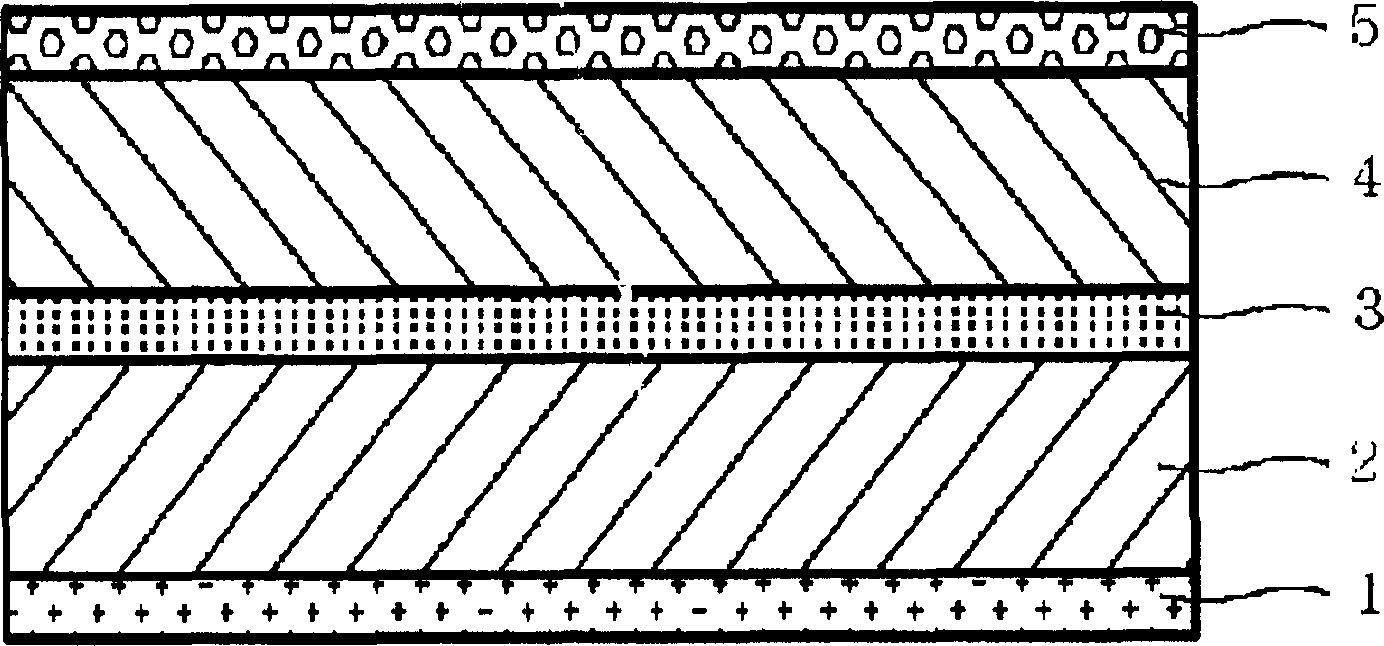

Holographic storage medium comprising metal-containing high refractive index region, and storage article containing same

InactiveUS20050036179A1Material nanotechnologyPigmenting treatmentHolographic storagePolymer science

Holographic storage media comprise two substrates and a core between them, the core comprising thermoplastic photopolymer and a titanium or zirconium compound as a high refractive index material. During photopatterning of the storage medium precursor, the titanium or zirconium compound migrates toward the patterned region or the matrix region surrounding it, causing a refractive index difference which provides optimum holographic properties.

Owner:GENERAL ELECTRIC CO

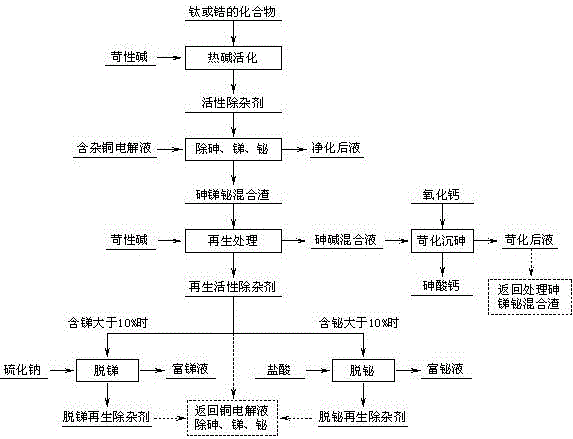

Method for removing arsenic, antimony and bismuth from copper electrolyte

ActiveCN106086935AEfficient impurity removal abilityHas impurity removal activityPhotography auxillary processesProcess efficiency improvementZirconatePhysical chemistry

The invention discloses a method for removing arsenic, antimony and bismuth from a copper electrolyte. The method is characterized in that a titanium or zirconium compound is converted into titanate or zirconate which is insoluble in water, has activity and is adopted as an active impurity removing agent through a hot alkali activation manner, the active impurity removing agent is utilized to react with acid in the copper electrolyte to generate a hydrous oxide in situ, and impurities like arsenic, antimony and bismuth are precipitated and removed. According to the method, the arsenic, antimony and bismuth in the copper electrolyte are efficiently removed under the precondition of no copper and nickel loss, solution loss of titanium or zirconium is remarkably reduced, generation of floating objects is avoided, and the active impurity removing agent can be circularly utilized.

Owner:JIANGXI UNIV OF SCI & TECH +1

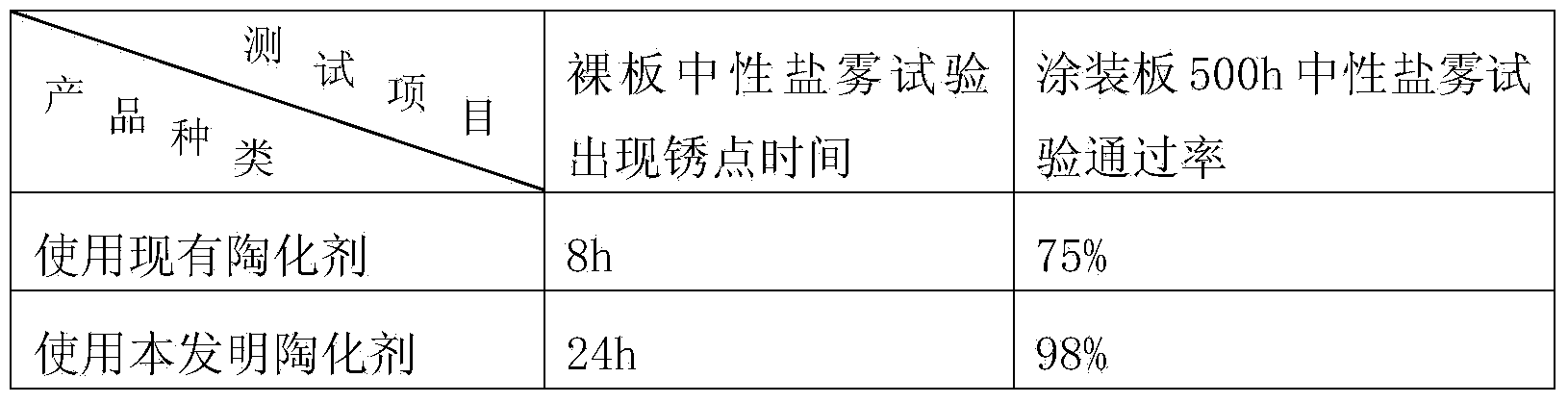

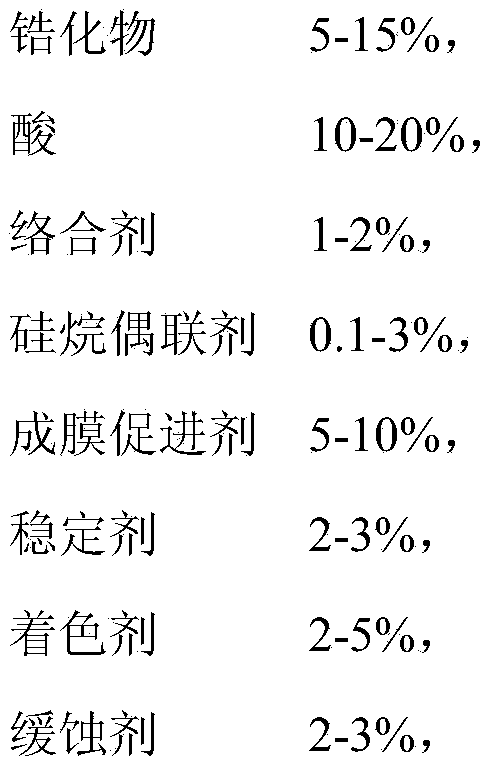

Ceramic agent for hot galvanized plate and preparation method of ceramic agent

ActiveCN103952688AImprove corrosion resistanceImprove stabilityMetallic material coating processesZirconium compoundsAccelerant

The invention relates to a ceramic agent for surface treatment before a hot galvanized plate is coated. The ceramic agent comprises the following components in parts by weight: 5-15% of zirconium compounds, 10-20% of acid, 1-2% of complexing agent, 0.1-3% of silane coupling agent, 5-10% of film forming accelerant, 2-3% of stabilizer, 2-5% of colorant, 2-3% of corrosion inhibitor and the balance of water. The ceramic agent provided by the invention can be rapidly formed into an integrated ceramic film at normal temperature; the formed ceramic film is obviously light yellow and is easy to judge whether the ceramic film is formed on the surface of a workpiece or whether the ceramic film is integrated in an industrial production process; in addition, the formed ceramic film is better in corrosion resistance and stronger in stability as comparison with the ceramic film formed by using the currently used ceramic agent.

Owner:JIANGMEN CHENGXIN PRECISION CHEM FACTORY

Polymetal Hydroxychloride Processes and Compositions: Enhanced Efficacy Antiperspirant Salt Compositions

InactiveUS20070196302A1Materials and reduced eliminatedSteps reduced eliminatedCosmetic preparationsSemi-permeable membranesAluminium chlorideZirconium compounds

The invention describes processes for the production of basic aluminum compounds, including aluminum chlorohydrate, basic zirconium compounds, and basic aluminum zirconium compounds. The process produces products of a wide range of basicities. The products formed by the present invention are comprised of low molecular weight species characteristic of enhanced efficacy antiperspirant salt compositions. The products of this process are suitable for use as water purification agents, as binders in catalyst applications, and in antiperspirant applications. In addition, the invention is directed to the products made by the disclosed process.

Owner:NEXT CHEM LLC

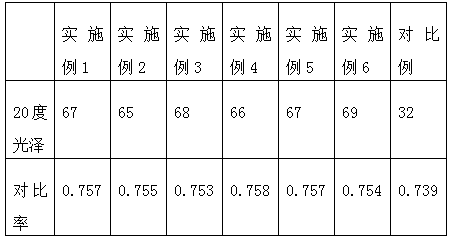

Production method of high-gloss and high-covering-capability rutile titanium dioxide

The invention discloses a production method of high-gloss and high-covering-capability rutile titanium dioxide. The production method comprises the steps of preparing metatitanic acid slurry, sequentially adding a magnesium-containing compound, a zirconium-containing compound and a potassium-containing compound to prepare titanium dioxide primary slurry, then sequentially adding a titanium-containing compound and an aluminum-containing compound, and finally filtering, washing, drying and crushing to obtain high-gloss and high-covering-capability rutile titanium dioxide. According to the production method, saline matters such as magnesium salt, zircon salt, kali salt and the like are added in metatitanic acid, so that the effect of improving the high covering property of titanium dioxide can be achieved; and the surface treatments of hydration of titanium dioxide and hydration of titanium dioxide, and the like can be conducted on the surface of titanium dioxide, so that the effect of improving the gloss of titanium dioxide can be achieved, and the gloss and the covering capability of titanium dioxide are all improved greatly.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Nonchromate metallic surface treating agent for PCM use, method for PCM surface treatment, and treated PCM steel panel

InactiveUS20010037748A1Easy to processIncrease resistancePretreated surfacesSolid state diffusion coatingSilanesZirconium compounds

The present invention has for its object to provide a metallic surface treating agent for PCM use, which is capable of imparting high processability and corrosion resistance to PCM steel panels with the additional advantage of improved storage stability, a method for surface treatment of a PCM steel panel, a method of producing a PCM steel panel, and a PCM steel panel as produced by said method. This invention provides a nonchromate metallic surface treating agent for PCM use which comprises, in each liter thereof, (a) a silane coupling agent and / or a hydrolytic condensation product thereof in an amount of 0.01 to 100 g / l, (b) water-dispersible silica in a proportion of 0.05 to 100 g / l (solids), and (c) a zirconium compound in an amount of 0.01 to 50 g / l in terms of zirconium ion and / or a titanium compound in an amount of 0.01 to 50 g / l in terms of titanium ion.

Owner:NIPPON PAINT CO LTD

Metal surface processing composition

InactiveCN1396226AImprove corrosion resistanceExcellent adhesionLiquid surface applicatorsPolyurea/polyurethane coatingsResin acidSurface finishing

The present invention provides a metal surface treating composition. The metal surface treating composition contains (B) 1 to 100 pts.wt. silica particles, (C) 1 to 100 pts.wt. aziridinyl group- or oxazoline group- containing compound, (D) 0.5 to 30 pts.wt. vanadic acid compound and (E) 0.5 to 30 pts.wt. zirconium compound per (A) 100 pts.wt. carboxyl group- containing urethane resin of a resin acid value 5 to 50. The surface treating composition of a pollution-free type has the rust preventive power equivalent to that of chromate treatment and phosphate treatment. The present invention provides the armor plate which by the metal surface treating composition treating also.

Owner:KANSAI PAINT CO LTD

Resin-coated seamless aluminum can and resin-coated aluminum alloy lid

ActiveUS8349419B2Increase heatHigh strengthLiquid surface applicatorsClosuresAluminum canZirconium atom

The present invention provides a resin coated seamless aluminum can and a resin coated aluminum can lid having adhesiveness and corrosion resistance by applying a non-chromium chemical conversion coated film to an aluminum alloy sheet and by applying an organic resin layer to the non-chromium chemical conversion coated film. For this end, an organic-inorganic composite surface treated layer containing 2 to 20 mg / m2 of zirconium compound expressed in terms of zirconium atoms, 1 to 10 mg / m2 of phosphorus compound expressed in terms of phosphorus atoms, and 5 to 60 mg / m2 of organic compound expressed in terms of carbon atoms is formed on at least one-side surface of an aluminum alloy sheet, and an organic resin coated layer is formed on the organic-inorganic composite surface treated layer.

Owner:TOYO SEIKAN KAISHA LTD

Method for producing rutile titanium white powder applied to decorative laminated paper

ActiveCN104179066AGood weather resistanceMeets high light fastness requirementsCoatings with pigmentsTitanium dioxideWeather resistanceZirconium compounds

The invention discloses a method for producing rutile titanium white powder applied to decorative laminated paper. The method for producing the rutile titanium white powder applied to the decorative laminated paper comprises the following steps: preparing titanium white powder primary pulp, diluting, coating silicon-containing compounds, coating aluminum-containing compounds, curing, filtering, rinsing, drying, calcining, crushing and the like. According to the method for producing the rutile titanium white powder applied to the decorative laminated paper, the surface of the titanium white powder is firstly coated with a silicon film and subsequently coated with an aluminum film, so that the weather resistance of the titanium white powder is greatly improved; meanwhile, hydroxyl groups on the coated films are removed by using a manner of calcining and heating; the reaction of electron pairs is avoided; the requirement of high light resistance on the titanium white powder in the field of the decorative laminated paper can be met, so that the low-cost silicon compounds can be used for replacing zirconium compounds, phosphate, rare earth metals and the like for producing the titanium white powder with high light resistance applied to the decorative laminated paper.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

Composition for metal surface treatment, metal surface treatment method and metal material

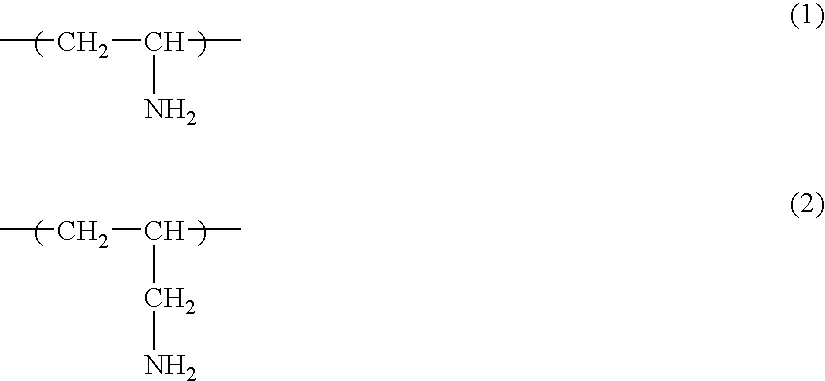

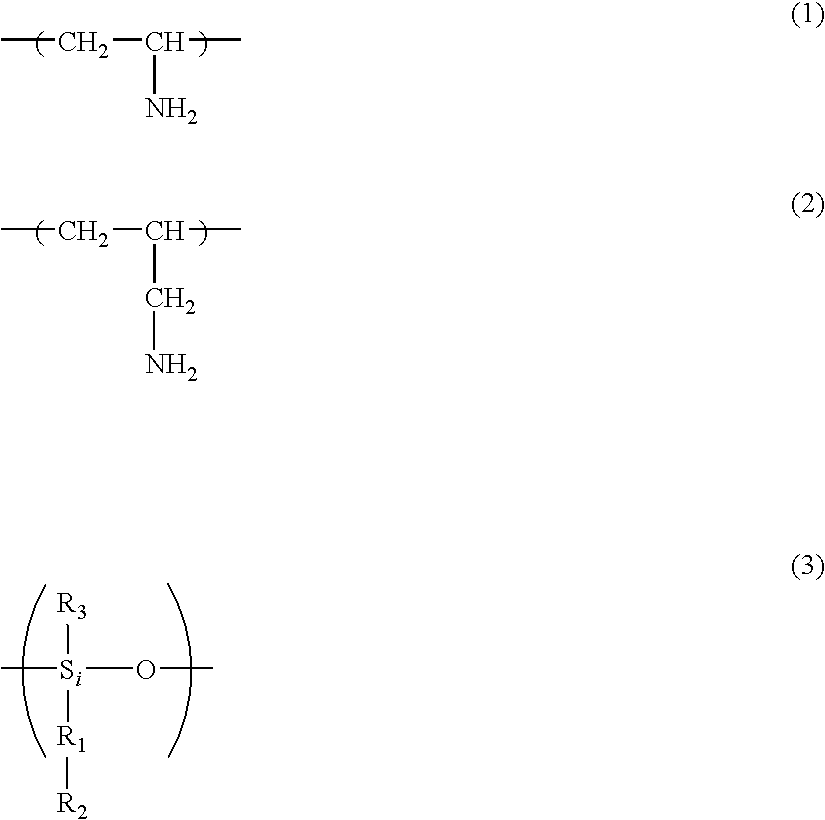

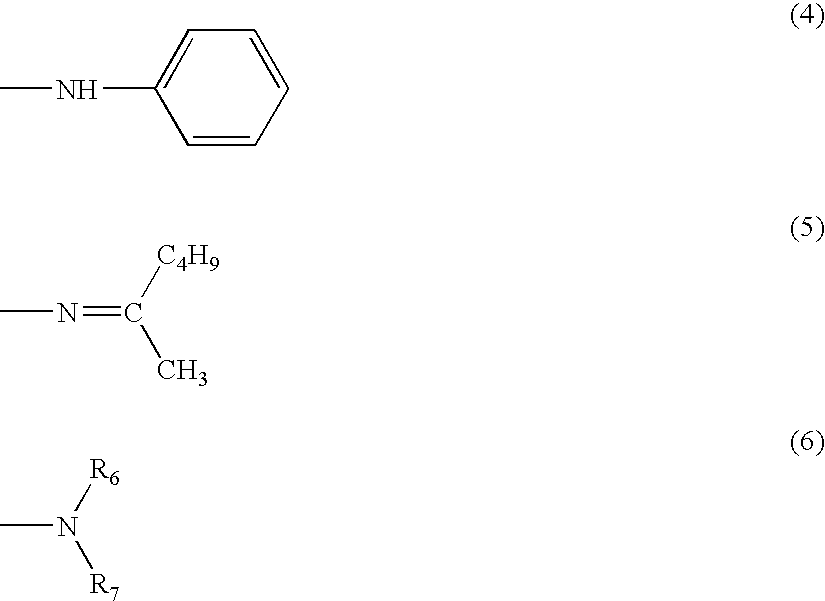

ActiveUS20090239093A1Sufficient base metal concealing propertyLayered productsSurface reaction electrolytic coatingPolyamine CompoundMetallic materials

A composition for metal surface treatment can form a chemical conversion coating film which achieves sufficient foundation surface concealment, coating adhesion and corrosion resistance. A method for treating the surface of a metal material with such a composition for metal surface treatment is used. Specifically a metal surface treatment composition used for a treatment of a metal surface, contains a zirconium compound and / or a titanium compound, and a polyamine compound having a number average molecular weight of not less than 150 but not more than 500,000. The polyamine compound contains not less than 0.1 millimole but not more than 17 millimoles of a primary and / or secondary amino group per 1 g of the solid content, and the content of the zirconium compound and / or titanium compound in the metal surface treatment composition is not less than 10 ppm but not more than 10,000 ppm in terms of metal elements. The mass ratio of the zirconium element and / or titanium element contained in the zirconium compound and / or titanium compound relative to the polyamine compound is not less than 0.1 but not more than 100.

Owner:NIPPON PAINT CO LTD +1

Process for producing ceria-zirconia-alumina composite oxides and applications thereof

InactiveCN103889554AInternal combustion piston enginesHeterogenous catalyst chemical elementsCombustionCerium(IV) oxide

A process for producing a ceria-zirconia-alumina composite oxide is disclosed. The process comprises combining a cerium (IV) compound and a zirconium (IV) compound with a slurry of aluminum oxide at a temperature greater than 40 DEG C to produce a reaction slurry, then contacting the reaction slurry with a precipitating agent to precipitate insoluble cerium and zirconium compounds onto the aluminum oxide and form cerium-zirconium-aluminum oxide particles, and calcining the cerium-zirconium-aluminum oxide particles to produce a ceria-zirconia-alumina composite oxide. The process to produce ceria-zirconia-alumina composite oxides provides a material having a high oxygen storage / release capacity that is suitable for a catalyst with enhanced cleaning of the exhaust gases from internal combustion engines.

Owner:JOHNSON MATTHEY PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com