Method for removing arsenic, antimony and bismuth from copper electrolyte

A copper electrolyte and electrolyte technology, applied in the field of bismuth, removing arsenic and antimony from copper electrolyte, can solve the problems of low activity of purifying agent, poor impurity removal effect, etc., and achieve the effect of high-efficiency impurity removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

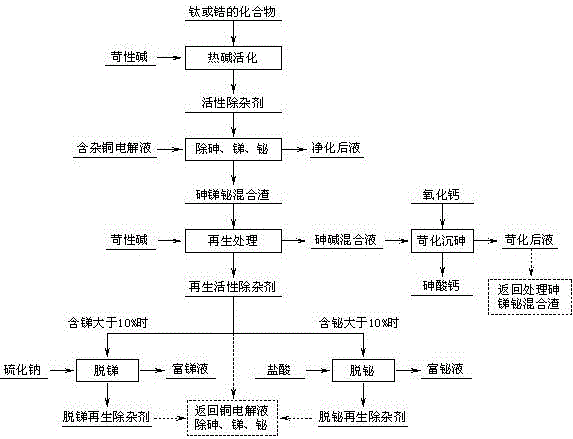

Image

Examples

Embodiment 1

[0022] Mix 150g of titanium dioxide with 12mol / L potassium hydroxide solution, stir and react at 200°C for 3 hours, filter and wash the obtained filter residue with water, which is the active impurity remover, and put the impurity remover into 8L copper electrolytic solution A1 (sulfuric acid concentration 297g / L, containing arsenic 9g / L, antimony 0.1g / L, bismuth 5.1g / L, copper 21g / L, nickel 2.2g / L), after stirring and reacting at 120°C for 4 hours, liquid-solid separation to obtain arsenic-antimony Bismuth mixed slag B1-1 and purified liquid. Through this step, the removal rates of arsenic, antimony and bismuth in the miscellaneous copper-containing electrolytic solution are 91.7%, 27% and 83.6% respectively, and the titanium content in the purified solution is lower than 0.1g / L. The content of copper and nickel in the arsenic-antimony-bismuth mixed slag B1-1 is below 0.2wt.%.

[0023] Mix the above-mentioned arsenic-antimony-bismuth mixed slag B1-1 with 8mol / L sodium hydrox...

Embodiment 2

[0028] Mix 200g of zirconium dioxide with 12mol / L sodium hydroxide solution, stir and react at 130°C for 6 hours, filter and wash the obtained filter residue with water, which is the active impurity remover, and put the impurity remover into 8L copper electrolyte A2 ( Sulfuric acid concentration 51g / L, arsenic 26g / L, antimony 4.9g / L, bismuth 2.5g / L, copper 51g / L, nickel 8.6g / L), after stirring and reacting at 80°C for 2 hours, the liquid and solid were separated to obtain Arsenic-antimony-bismuth mixed slag B2-1 and purified liquid. Through this step, the removal rates of arsenic, antimony and bismuth in the copper-containing electrolytic solution are 82.1%, 87.6% and 80% respectively, and the zirconium content in the purified solution is lower than 0.1g / L. The content of copper and nickel in the arsenic-antimony-bismuth mixed slag B2-1 is below 0.2wt.%.

[0029] Mix the above-mentioned arsenic-antimony-bismuth mixed slag B2-1 with 5mol / L sodium hydroxide solution, stir and r...

Embodiment 3

[0034] Mix 18g of metatitanic acid with 7mol / L potassium hydroxide solution, stir and react at 50°C for 6 hours, filter and wash the obtained filter residue, which is an active impurity remover, and put this impurity remover into 2L copper electrolytic solution A3 ( Sulfuric acid concentration 153g / L, arsenic 1.1g / L, antimony 2.6g / L, bismuth 0.1g / L, copper 36g / L, nickel 9.7g / L), after stirring at 40°C for 0.5 hours, liquid-solid separation The arsenic-antimony-bismuth mixed slag B3-1 and the purified liquid were obtained. Through this step, the removal rates of arsenic, antimony and bismuth in the copper-containing electrolytic solution are 45.1%, 86.9% and 22% respectively, and the titanium content in the purified solution is lower than 0.1g / L. The content of copper and nickel in the arsenic-antimony-bismuth mixed slag B3-1 is below 0.2wt.%.

[0035] Mix the above-mentioned arsenic-antimony-bismuth mixed slag B3-1 with 7mol / L sodium hydroxide solution, stir and react at 120°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com