Patents

Literature

53results about How to "Strong ability to remove impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

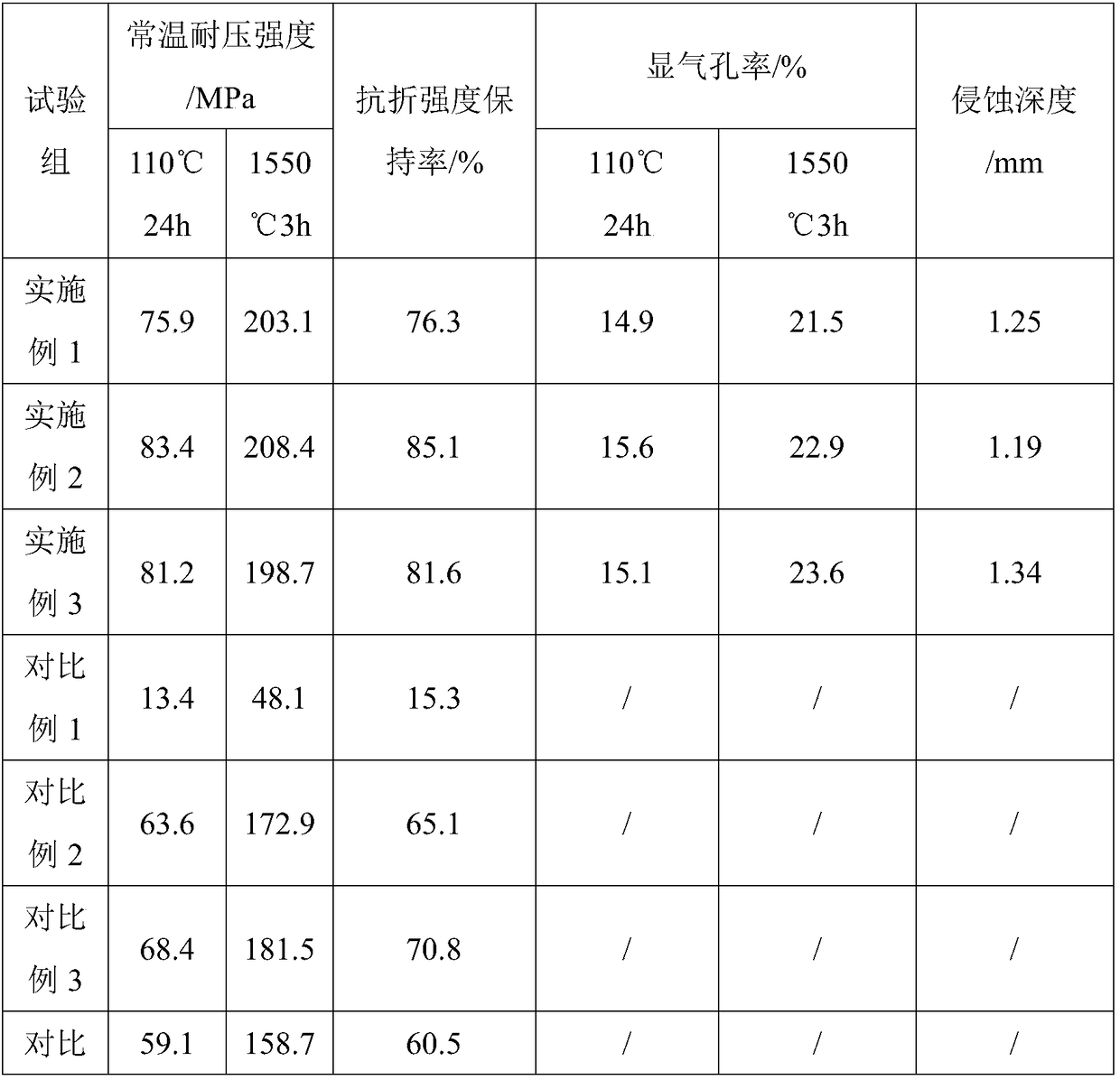

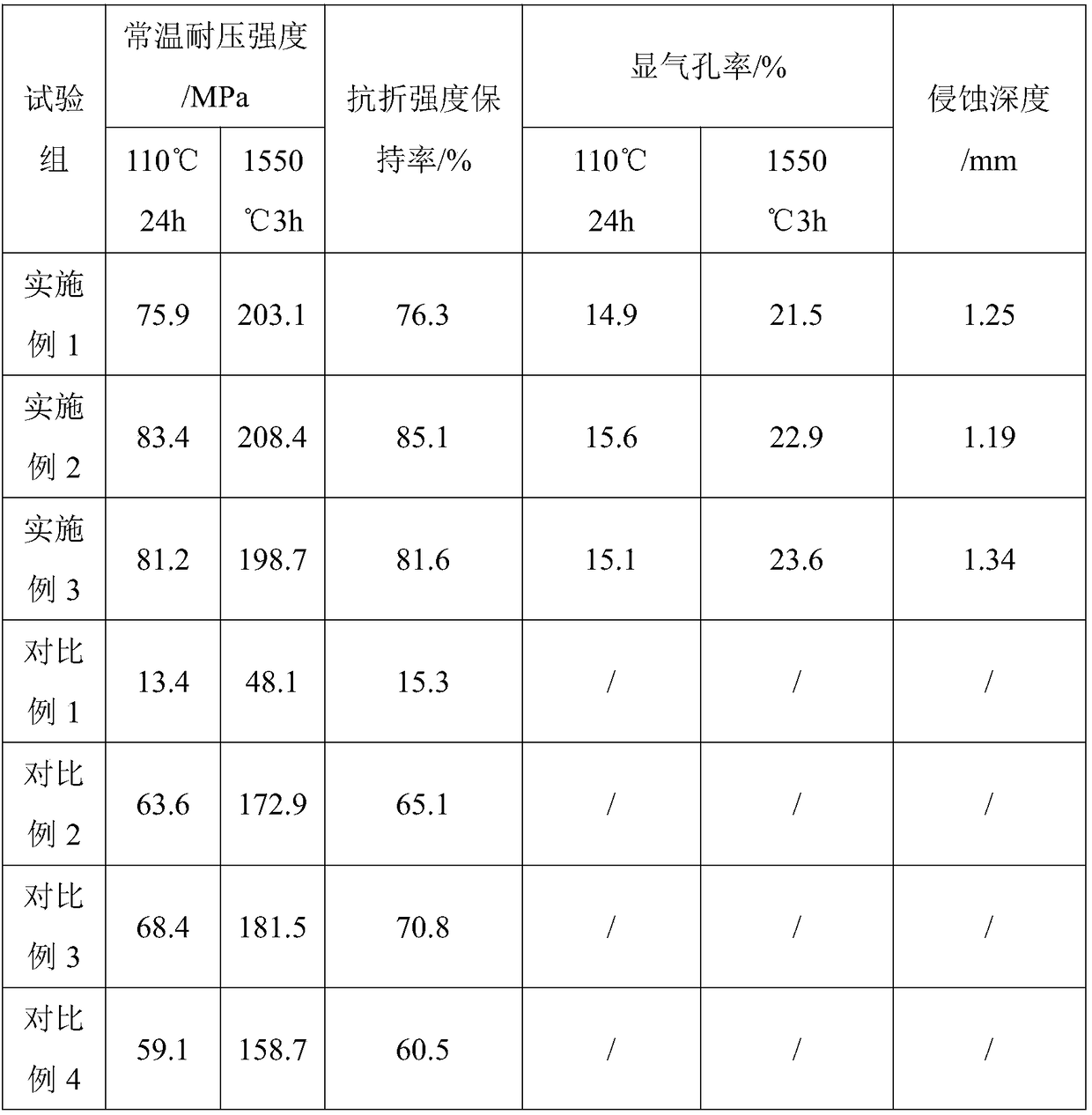

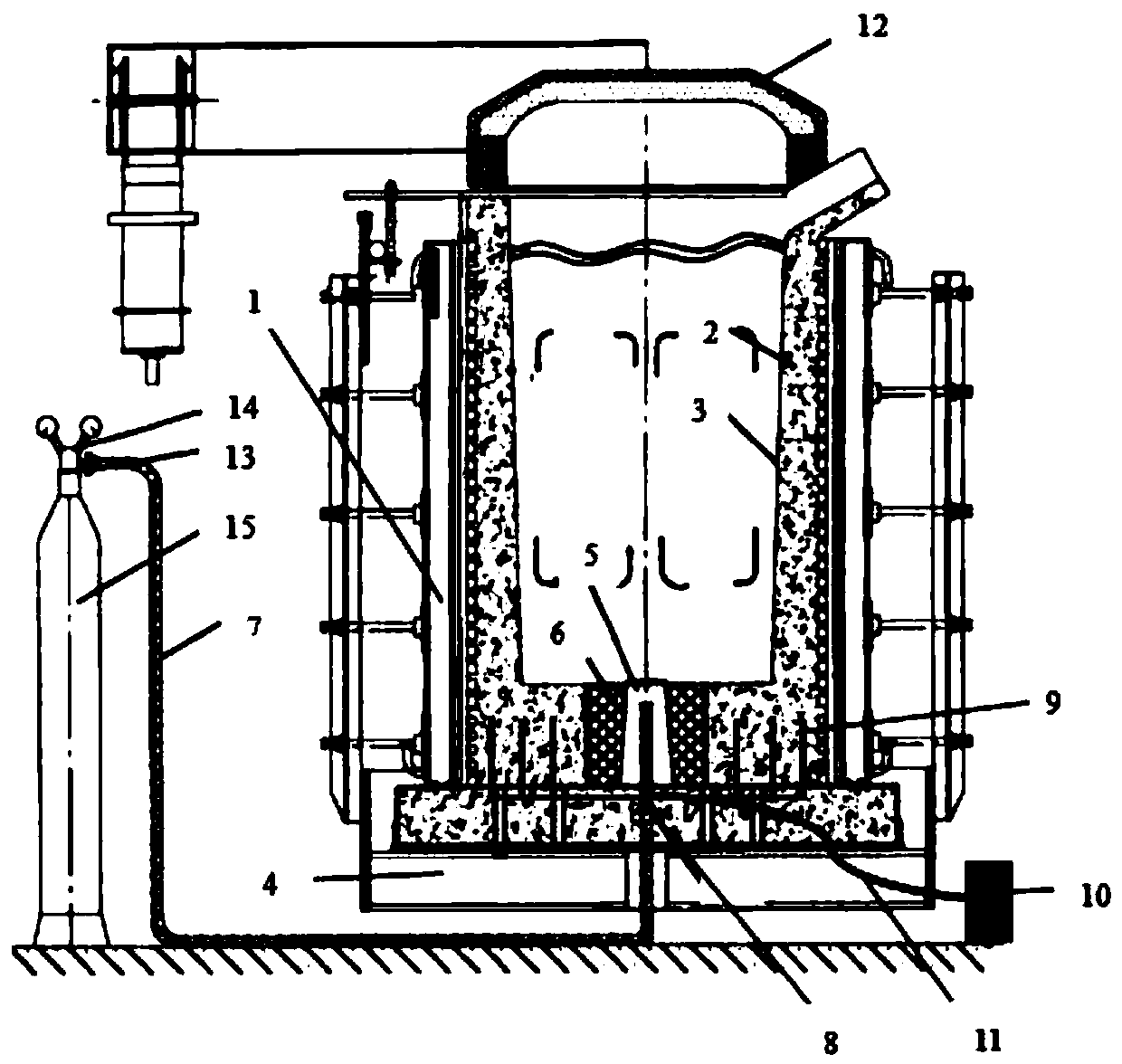

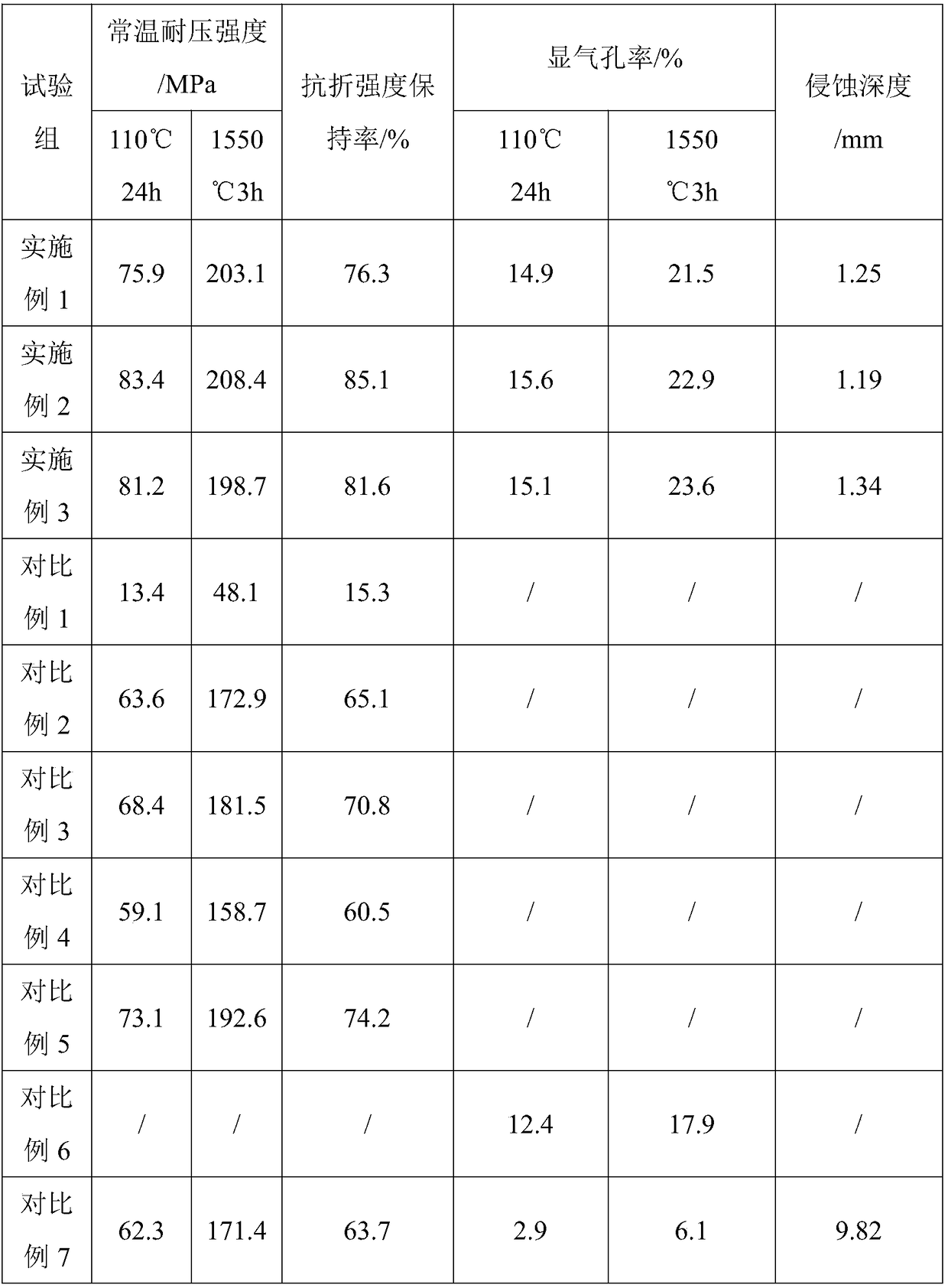

Dispersive air brick and preparation method thereof

The present invention relates to a dispersive air brick and a preparation method thereof. According to the technical scheme of the invention, 50 to 80 wt% of plate-shaped corundum is adopted as an aggregate. 12 to 32 wt% of aluminum oxide fine powders, 5 to 10 wt% of alumina micro powders and 3 to 8 wt% of a binding agent are adopted as matrix materials. According to the method, firstly, the matrix materials are uniformly mixed, and then the matrix materials and the aggregate are put into a mixer. 0.1 to 0.3 wt% of a water reducing agent and 4 to 6 wt% of water, counted relative to the sum of the aggregate and the matrix materials, are additionally added. The obtained mixture is stirred for 3 to 5 minutes, and then is cast and molded. After an obtained product is standing at the room temperature for 20 to 30 hours, the obtained product is dried for 22 to 26 hours at the temperature of 90 to 120 DEG C. then the obtained product is thermally insulated for 3 to 6 hours at the temperature of 1450 to 1650 DEG C. In this way, the dispersive air brick can be obtained. The plate-shaped corundum is in the form of equal-diameter particles, and the particle sizes of the equal-diameter particles are 2 to 5 mm. The method has the advantages of simple process, low labor intensity, high production efficiency, no pollution to the environment, and low cost. The prepared dispersive air brick is good in air permeability, strong in impurity-removing capability, excellent in thermal shock stability and good in penetration resistance performance.

Owner:江苏锦耐新材料科技有限公司

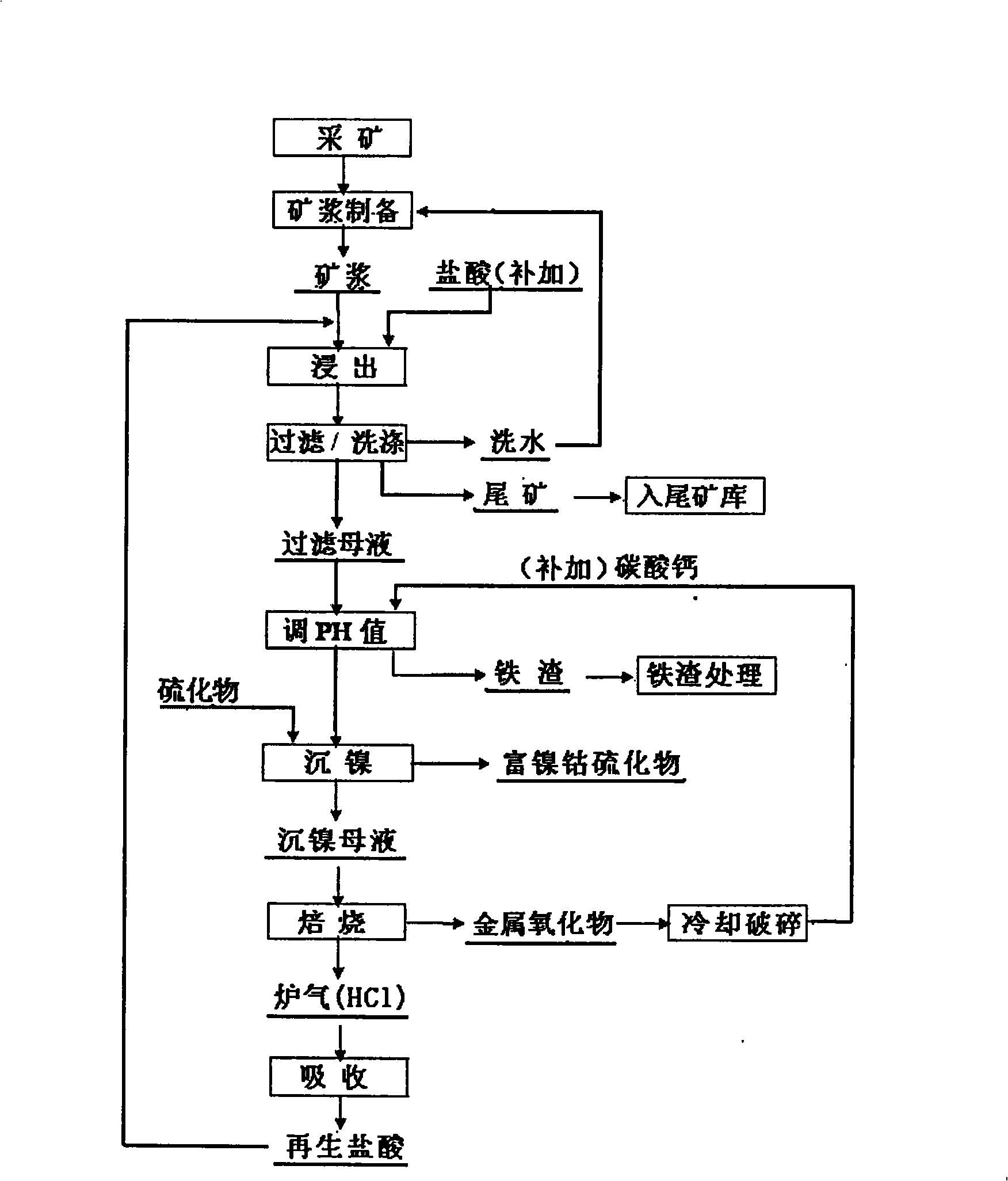

Process for extracting nickel and cobalt from laterite-nickel ore

InactiveCN101338374ARealize closed loop recyclingImprove leaching rateProcess efficiency improvementMetal chlorideSlurry

The invention discloses a method for extracting nickel and cobalt from a lateritic nickel ore which includes the steps of: (1) preparing the slurry of the ore: cracking the ores and preparing the slurry; (2) dipping the ores with muriatic acid: adding the muriatic acid in the slurry of the ore to carry out stirring and extraction under a normal pressure; (3) separating the solid and liquid; (4) neutralizing an extraction liquid; (4) sulfurizing and depositing the nickel; (6) regenerating the muriatic acid: the mother deposition liquid after nickel depositing is concentrated and roasted, the metal chloride in the mother liquid is hydrolyzed into chlorine hydride and metal oxide; the chlorine hydride after being absorbed by water obtains the regenerated muriatic acid and return to the working procedure of ore extraction; the metal oxide after being cracked and grinded returns to the working procedure of neutralizing. The method of the invention has a simple flow and an environment protective technique; the application range to resources is large; besides, the extraction speed is fast; the impurity removing capacity is high; the extraction rate of the nickel and cobalt is high; the method realizes the closed circulation of HCl and the comprehensive utilization of the resources.

Owner:CENT SOUTH UNIV

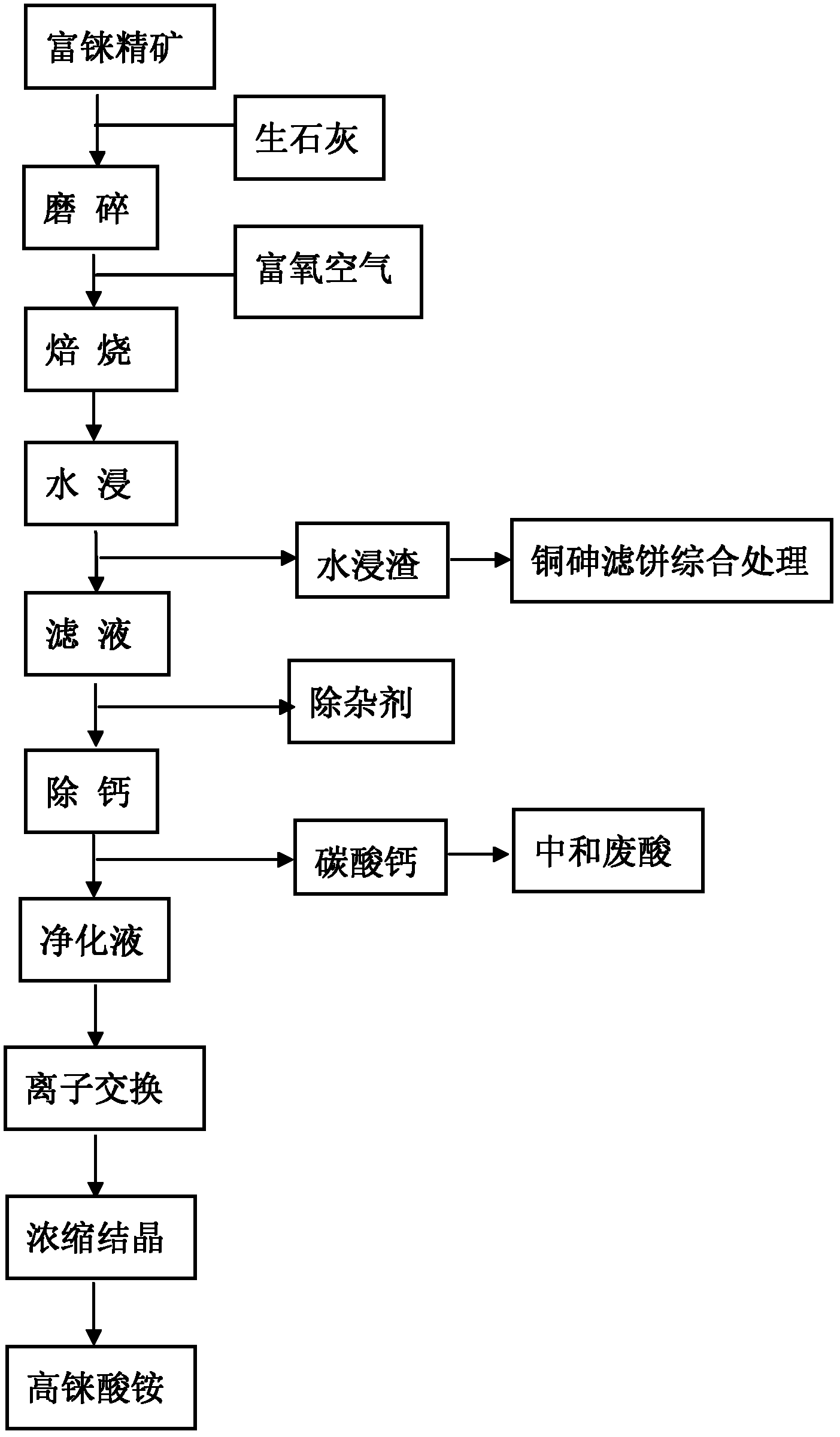

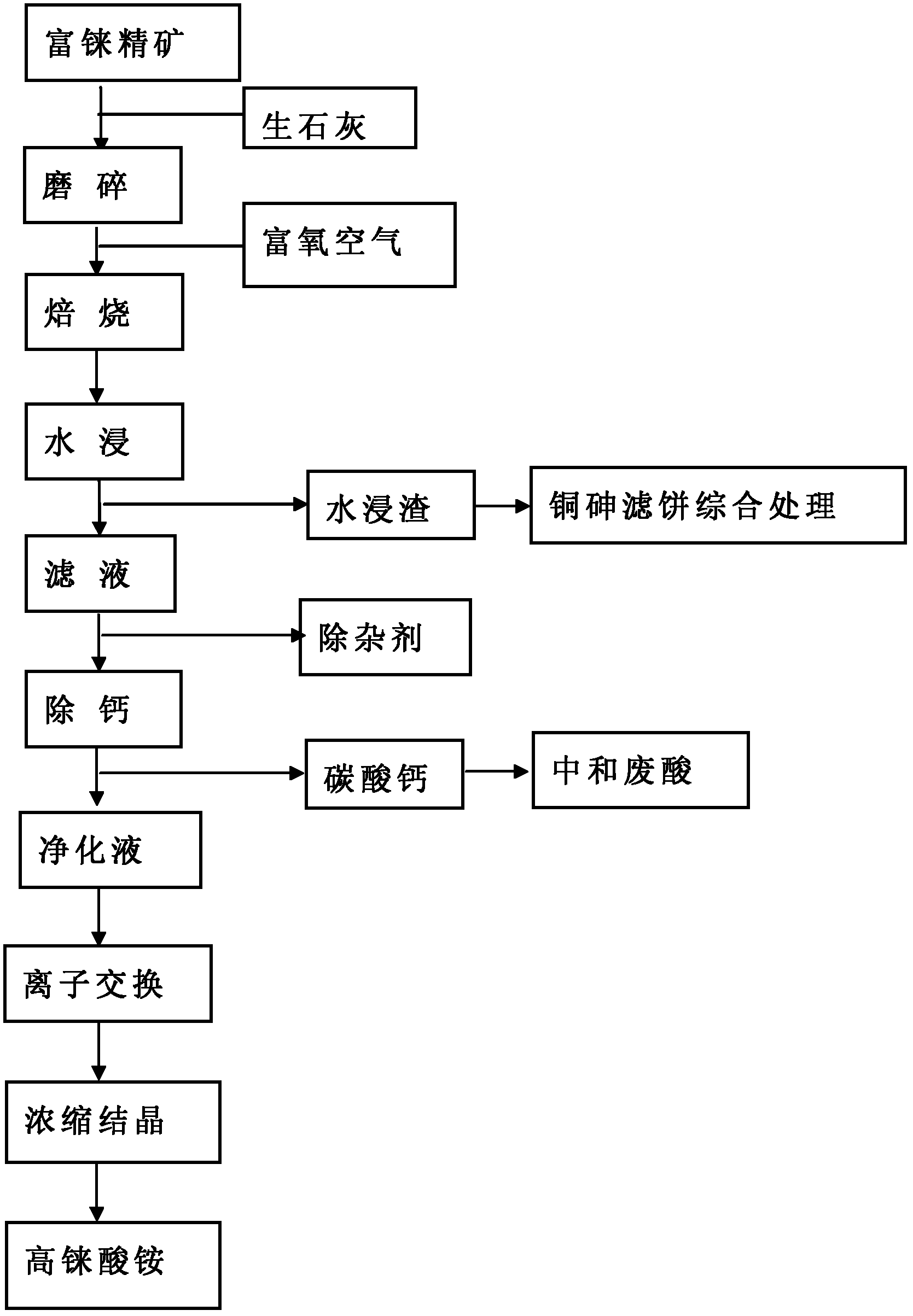

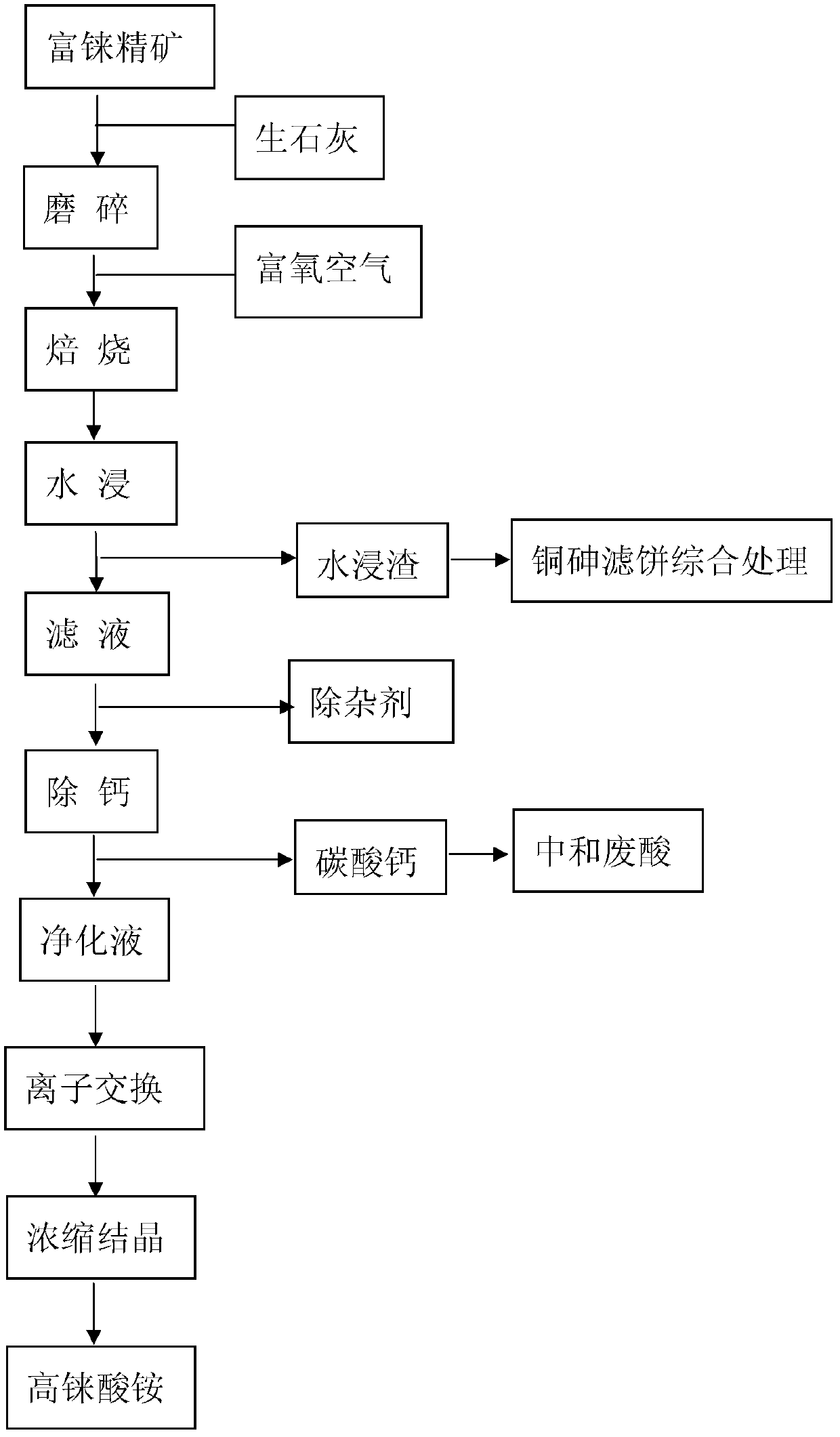

Method for extracting rhenium from rhenium-rich concentrates

ActiveCN102628111AThe effect is thoroughHigh recovery rate of rheniumProcess efficiency improvementIonIon exchange

The invention provides a method for extracting rhenium from rhenium-rich concentrates. The method comprises the following steps of: mixing the rhenium-rich concentrates with quick lime, grinding a mixture, feeding oxygen-enriched air into the mixture, and roasting the mixture at a temperature of 400-900 DEG C; sizing and immersing the roasted mixture by using water, and filtering after the immersion is finished; adding an impurity removing agent into the filtered liquid so as to remove calcium and trace heavy metal ions; filtering after removing impurities; and carrying out ion exchange process on the filtered liquid, which is subjected to impurity removal and filtering, through anion exchange resin, obtaining ammonium rhenate solution after desorption, and obtaining ammonium perrhenate through reconcentration and crystallization. According to the method provided by the invention, quick lime oxygen-enriched roasting and water immersion are used, so that the operations of decoppering, arsenic removal and desulfuration are carried out, therefore rhenium, arsenic and sulfur are oxidized sufficiently under the oxygen enrichment condition; the rhenium, arsenic and sulfur are combined with calcium oxide, so that insoluble substances are generated; the effects of removing copper, arsenic and sulfur are more thorough in the water immersion condition, and the disadvantage that the calcium content is high in the quick lime roasting and water immersion technology is solved through using the impurity removing agent to remove impurities; and the recovery rate of rhenium is high, so that the method provided by the invention is favorable to industrialized application.

Owner:YANGGU XIANGGUANG COPPER

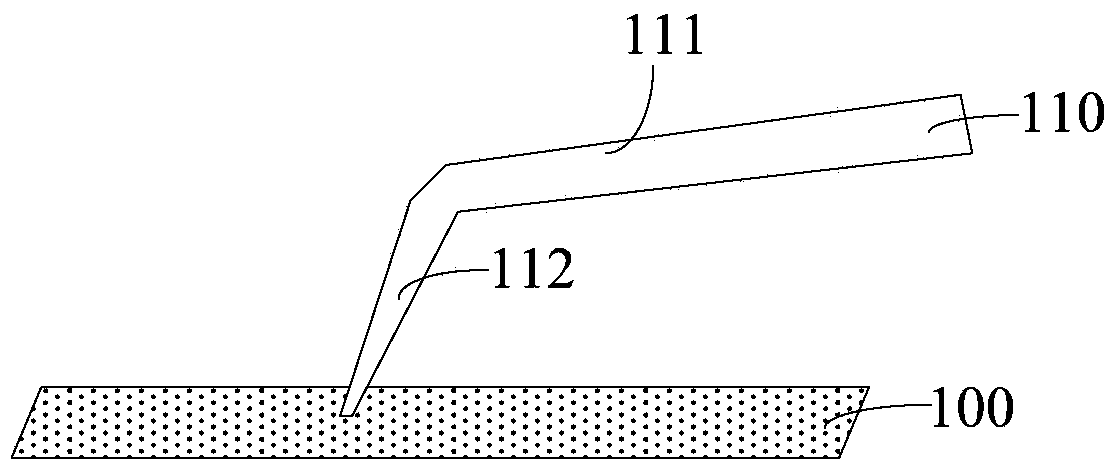

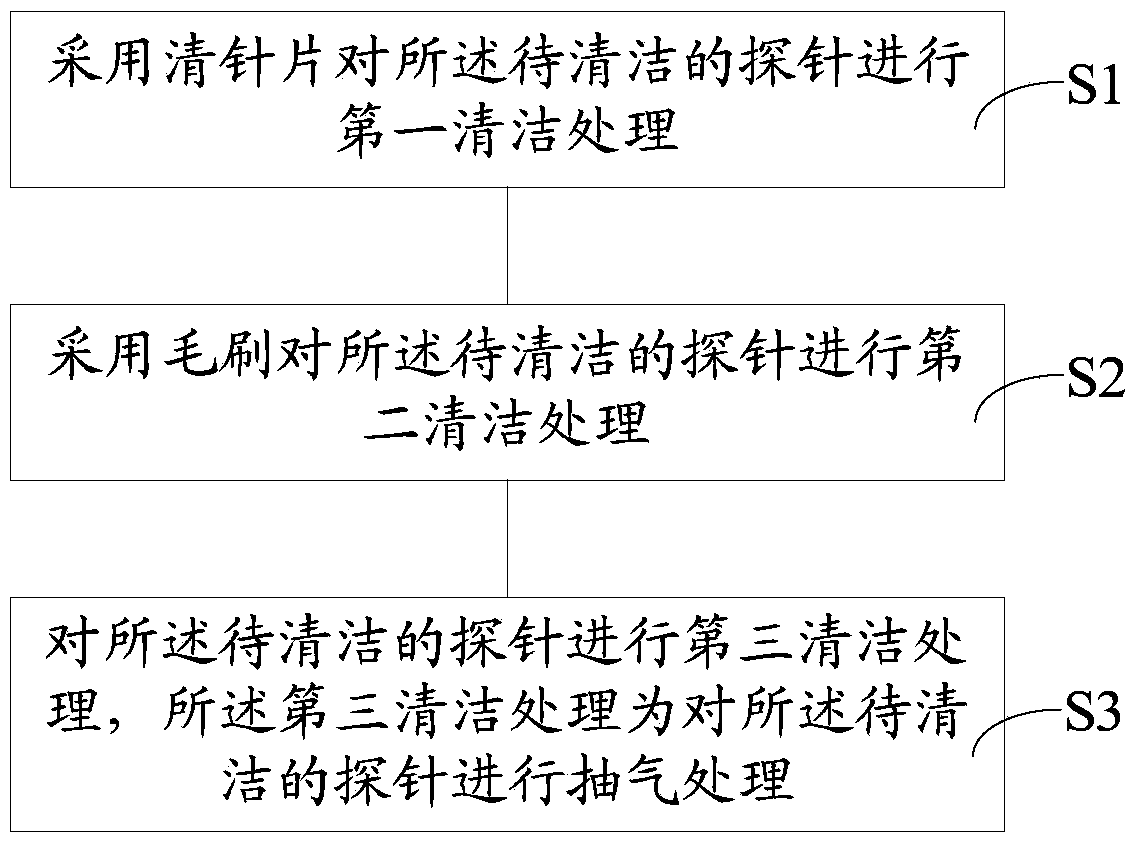

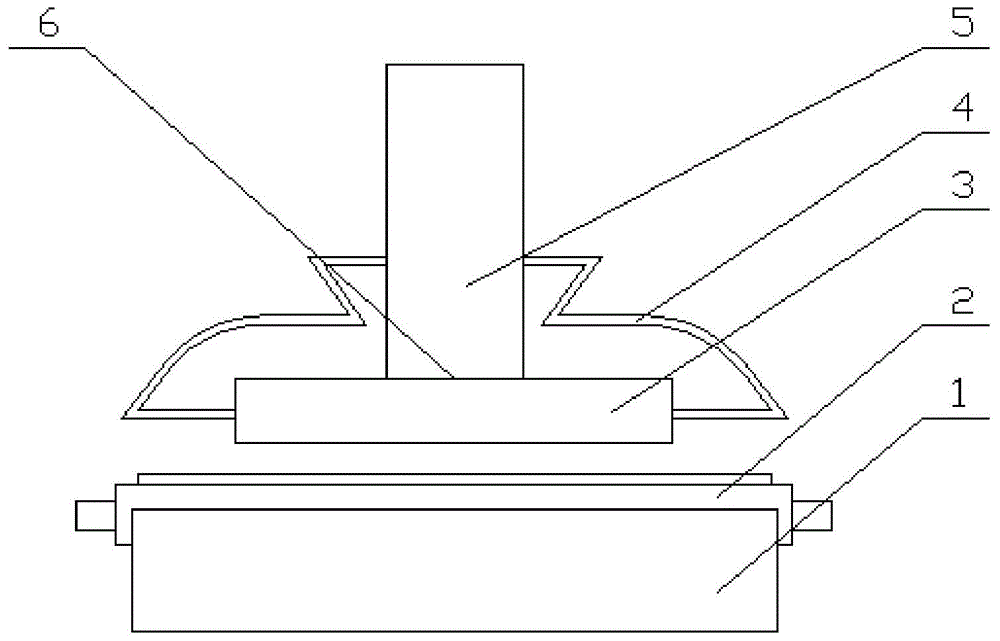

Probe cleaning method and probe cleaning device

ActiveCN103878150AImprove reliabilityImprove accuracyDirt cleaningCleaning using toolsCleaning methodsBiomedical engineering

The invention provides a probe cleaning method and a probe cleaning device. The probe cleaning method comprises the steps of providing a probe to be cleaned, adopting a probe cleaning piece to primarily clean the probe to be cleaned, adopting a brush to secondarily clean the probe to be cleaned, thirdly cleaning the probe to be cleaned, namely extracting air of the probe to be cleaned in the third cleaning process, and carrying out the first cleaning process, the second cleaning process and the third cleaning process at the same time. According to the probe cleaning method and the probe cleaning device, probe cleaning efficiency is improved, impurity removing ability is enhanced, probe cleaning time is shortened, accuracy and reliability of wafer testing results are improved, wafer testing time is shortened, and production efficiency is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Process for preparing deoxidant used in smelting steel and its composite rare-earth deoxidant

A process for prepairng the deoxidant used in steel-smelting procedure includes such steps as proportioning the raw ores, adding carbon as reductor, crushing, continuously loading to horizontal reverberatory furnace, heating to 1300-1450 deg.C by spraying heavy oil and air or oxygen-enriched air into the furnace for 25-100 min, and continuously discharging the finished deoxidant. A composite rare-earth deoxidant prepared by said process contains Fe (20-60%), Al (5-20), Si (2-15), Ca (5-25), Mn (1-15), Ba (0-25) and Re (3-20).

Owner:薛国南

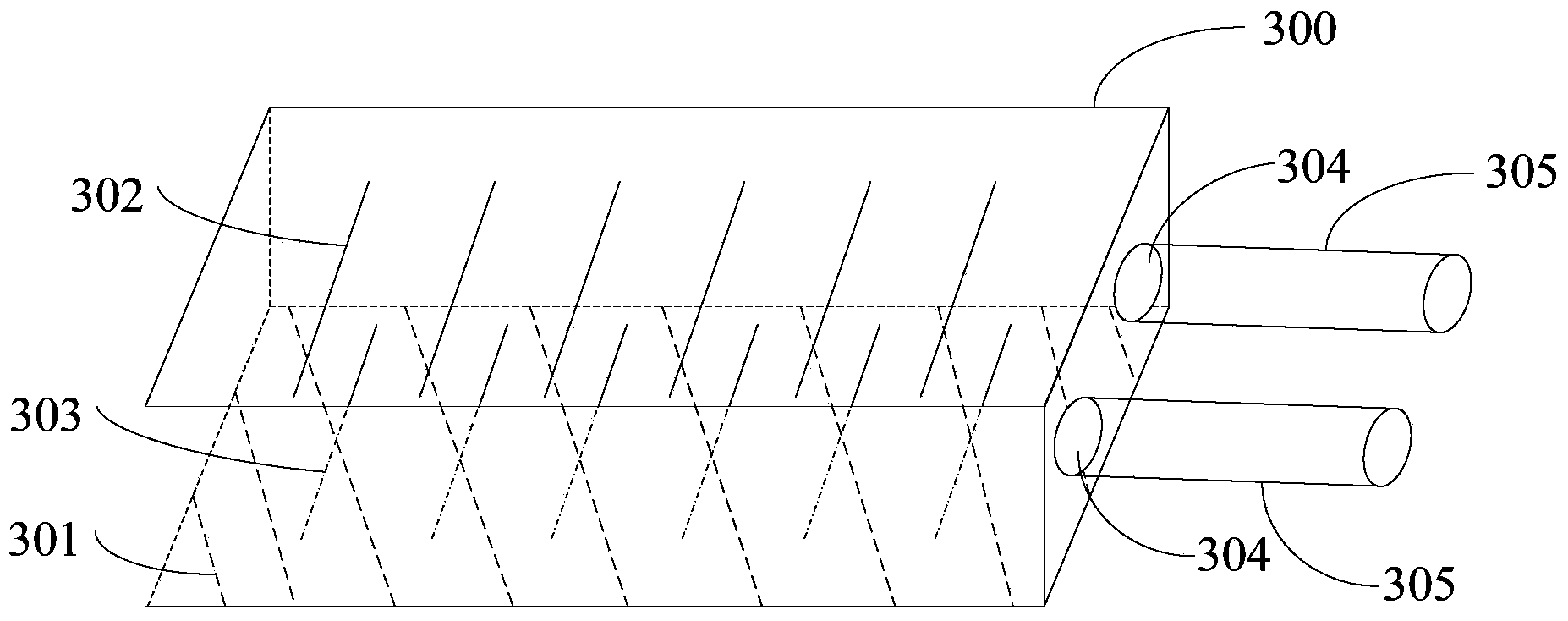

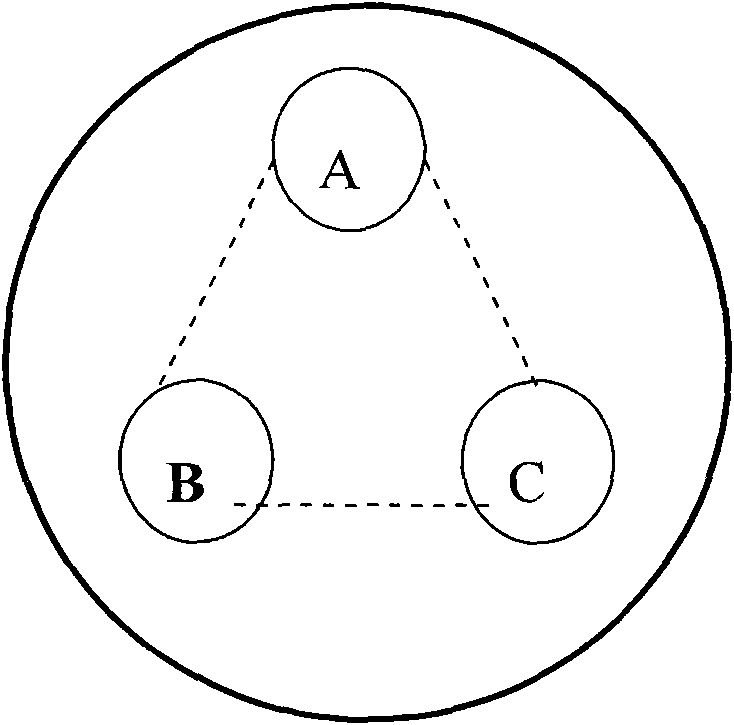

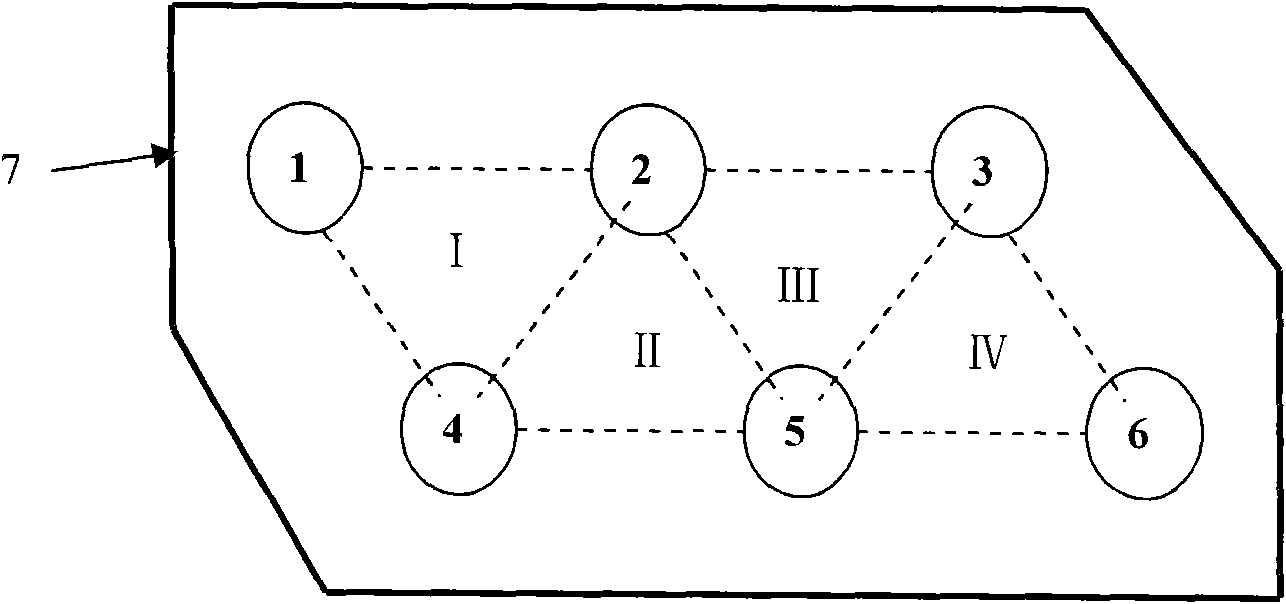

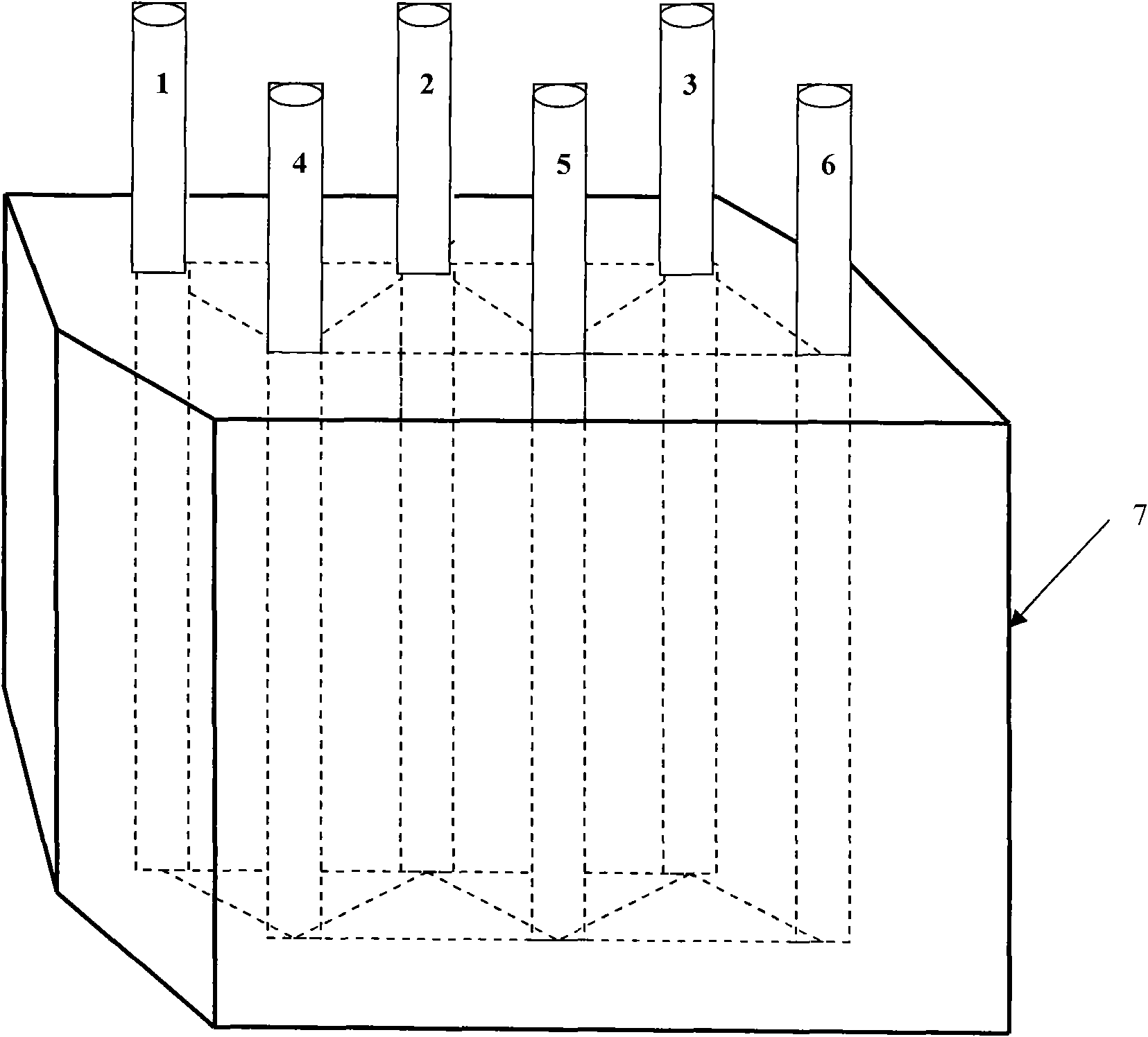

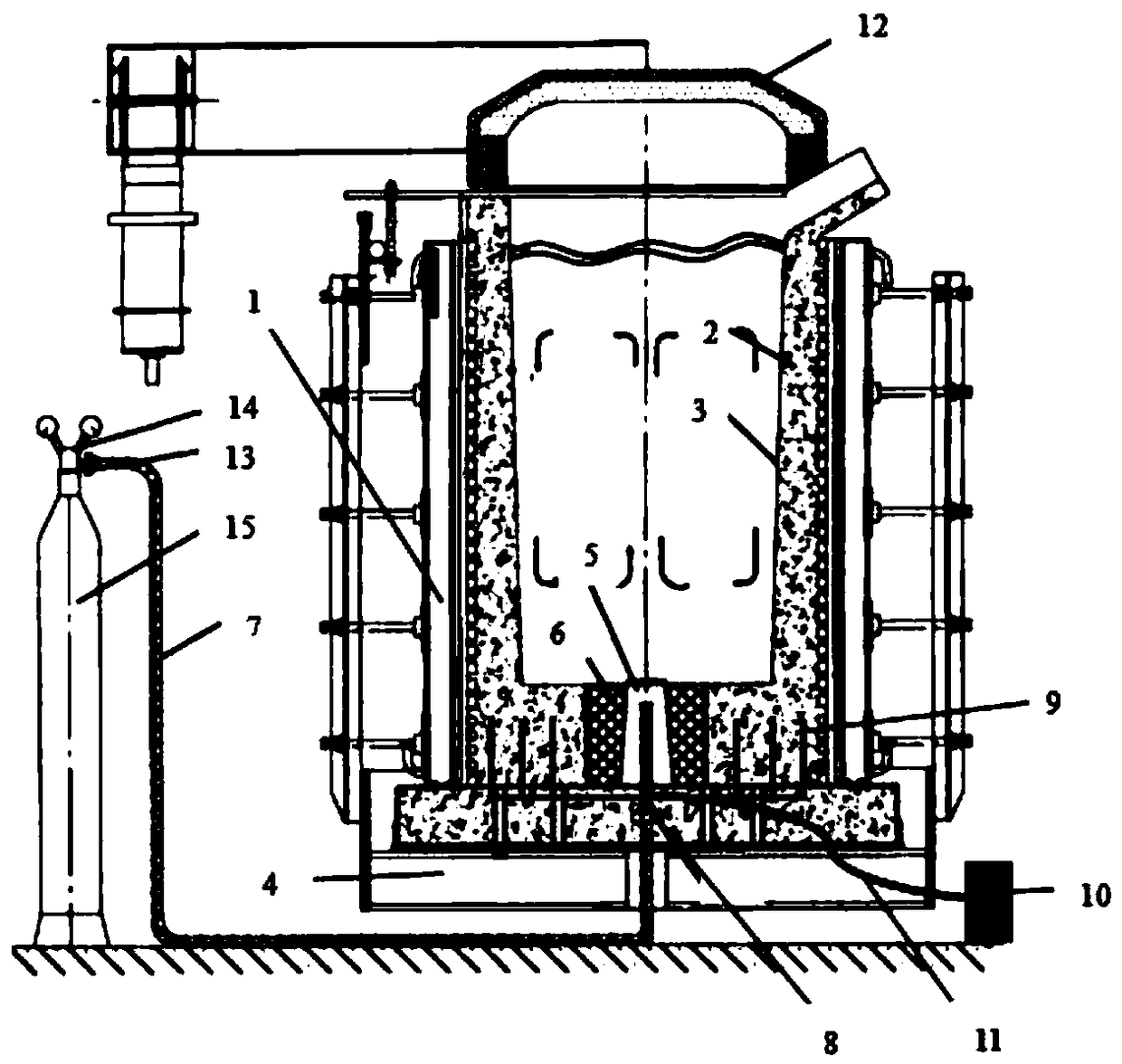

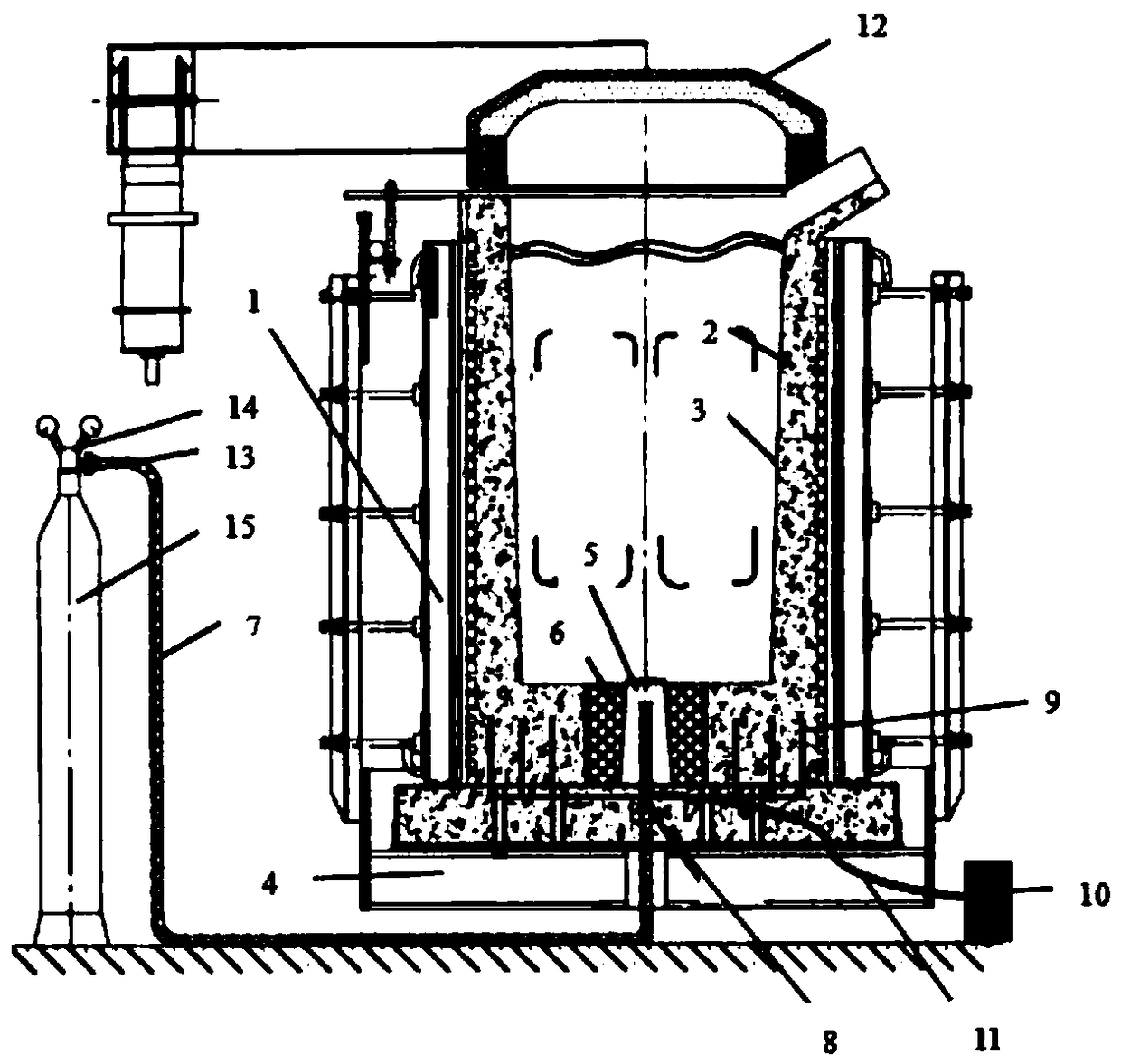

Six phase electrode electric melting furnace

InactiveCN101619928AImproved arc stabilityReduce burning lossCrucible furnacesElectric heating for furnacesFurnace temperatureIsoetes triquetra

The invention provides a six phase electrode electric melting furnace, relating to an electric melting magnesium smelting device, solving the problems of slow temperature rise of furnace temperature, high energy consumption and low yield which exist in current three phase electrode electric melting furnace. In the six phase electrode electric melting furnace, the furnace body is a six-prism body; the six phase electrode is inserted and arranged in the furnace body; the first electrode, the second electrode and the third electrode are arranged in a row with uniform spacing; the fourth electrode, the fifth electrode and the sixth electrode are arranged in a row with uniform spacing; the two rows of electrodes as a whole form a parallelogram; four equilateral triangle hot zones are respectively formed by the first, second, fourth electrodes, the second, fourth, fifth electrodes, the second, third, fifth electrodes, and the third, fifth, sixth electrodes. In the smelting process, the six phase electrode electric melting furnace forms four triangle hot zones, thus achieving concentrated heat, rapid heating of magnesium stones, steady reaction, dramatic lowering of electricity consumption, high speed of temperature rise of furnace temperature which can reach 3500 DEG C, uniform and stable product quality, energy saving and consumption lowering, high yield and good benefit.

Owner:大石桥市金益特种镁质材料厂

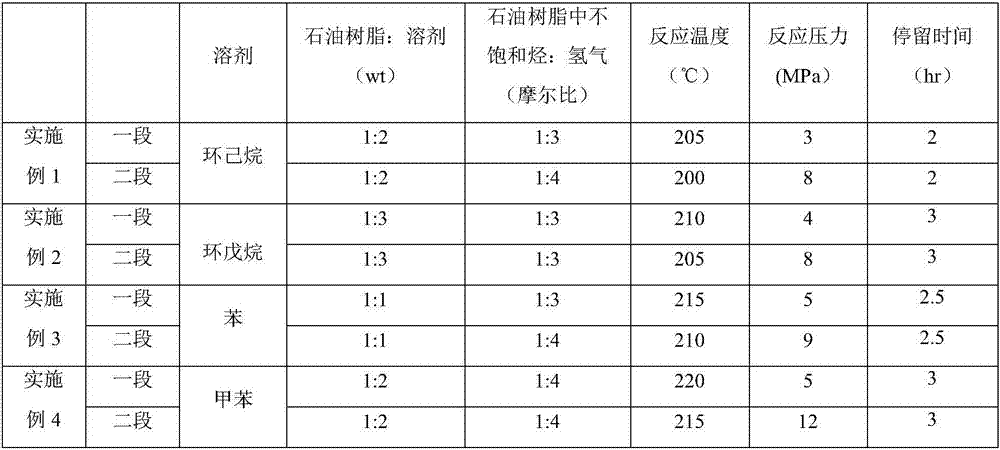

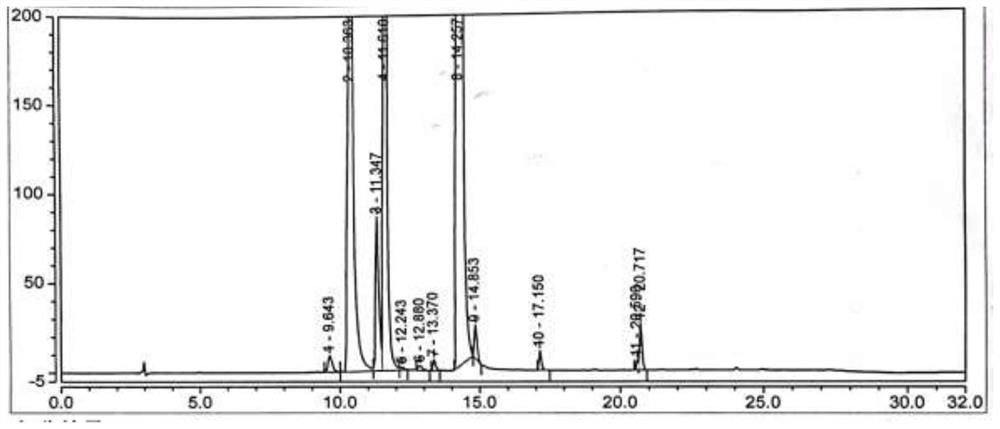

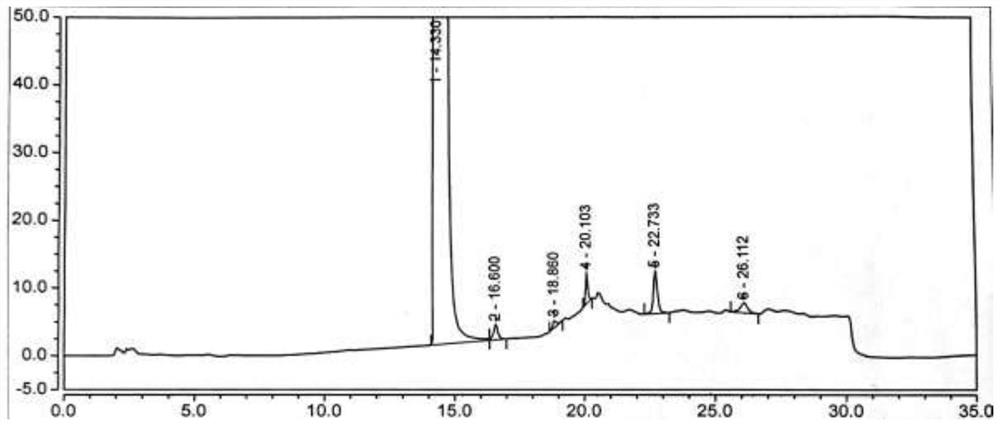

Two-section preparation method of hydrogenated petroleum resin

InactiveCN107880159ACompact distributionEvenly distributedMetal/metal-oxides/metal-hydroxide catalystsActivated carbonHydrogenation reaction

The invention belongs to the technical field of organic chemical industry and particularly relates to a two-section preparation method of hydrogenated petroleum resin. The hydrogenated petroleum resinis prepared by virtue of two hydrogenation catalysts and the two-section preparation method. The two-section preparation method particularly comprises the following steps: firstly, preparing gamma-Al2O3 film coated activated carbon carrier by virtue of a multi-sizing method, loading with catalyst activity components and an active aid by virtue of a dipping method, drying, and roasting so as to respectively prepare a nickel-series catalyst and a palladium-series catalyst; and secondly, carrying out hydrogenation reaction by virtue of a two-section hydrogenation fixed bed reactor, wherein a first-section hydrogenation fixed bed is filled with the nickel-series catalyst, and the second-section hydrogenation fixed bed is filled with the palladium-series catalyst. The method is particularly suitable for a hydrogenation decoloration process of C5 petroleum resin; and by virtue of utilizing two-section hydrogenation, the high-quality hydrogenated petroleum resin can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

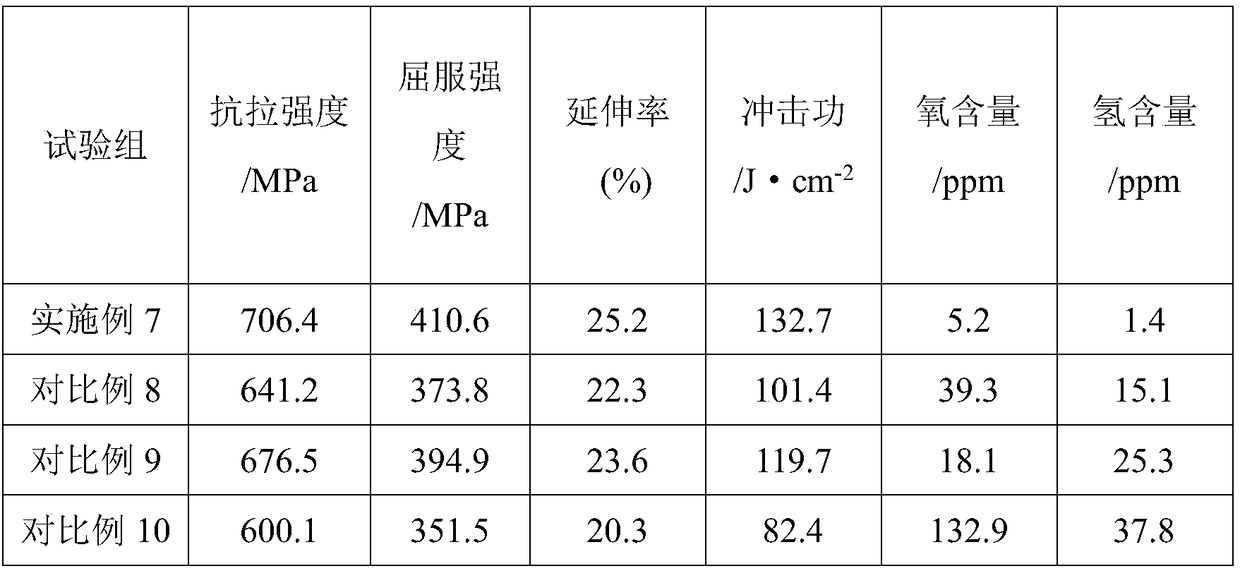

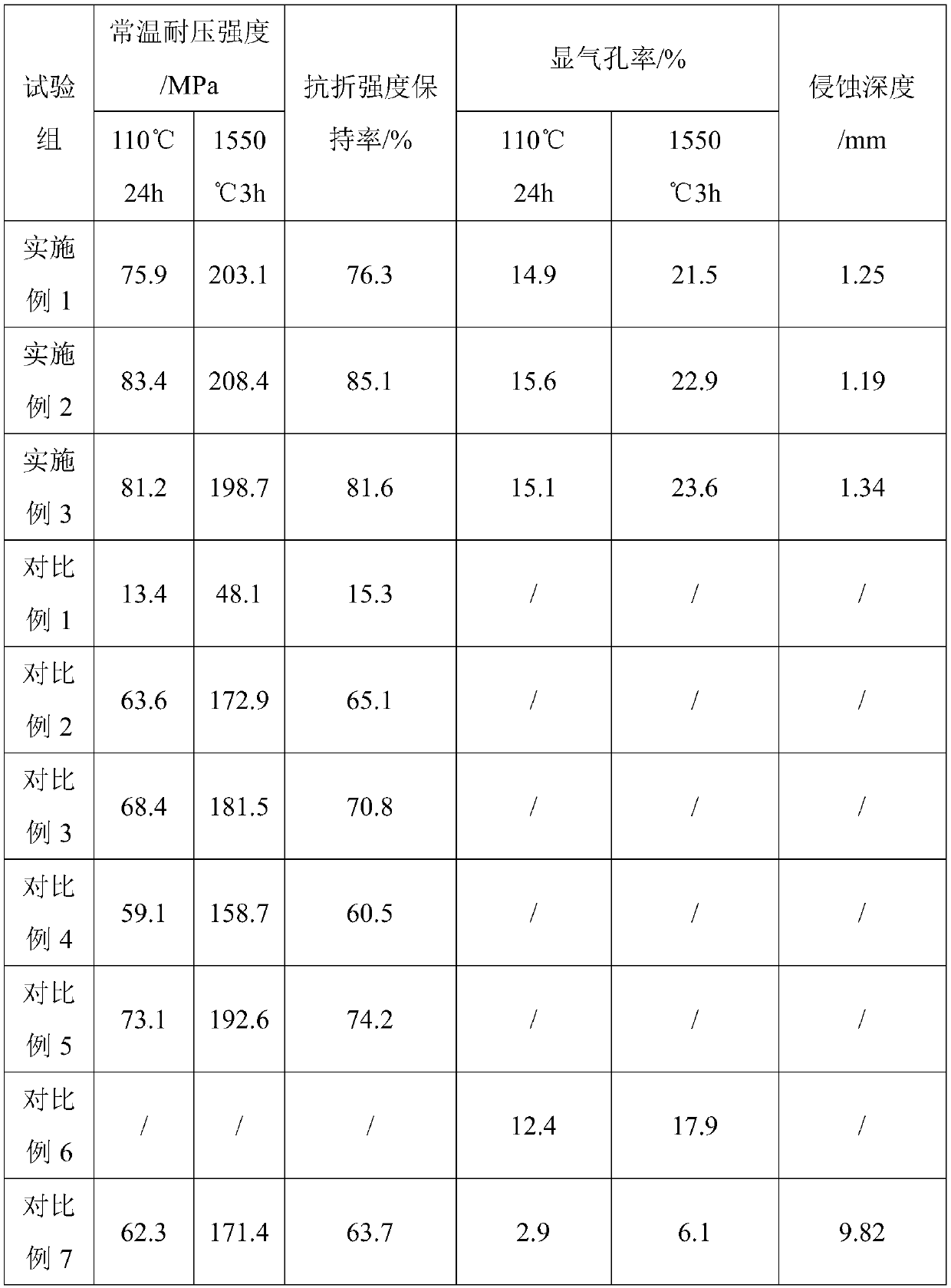

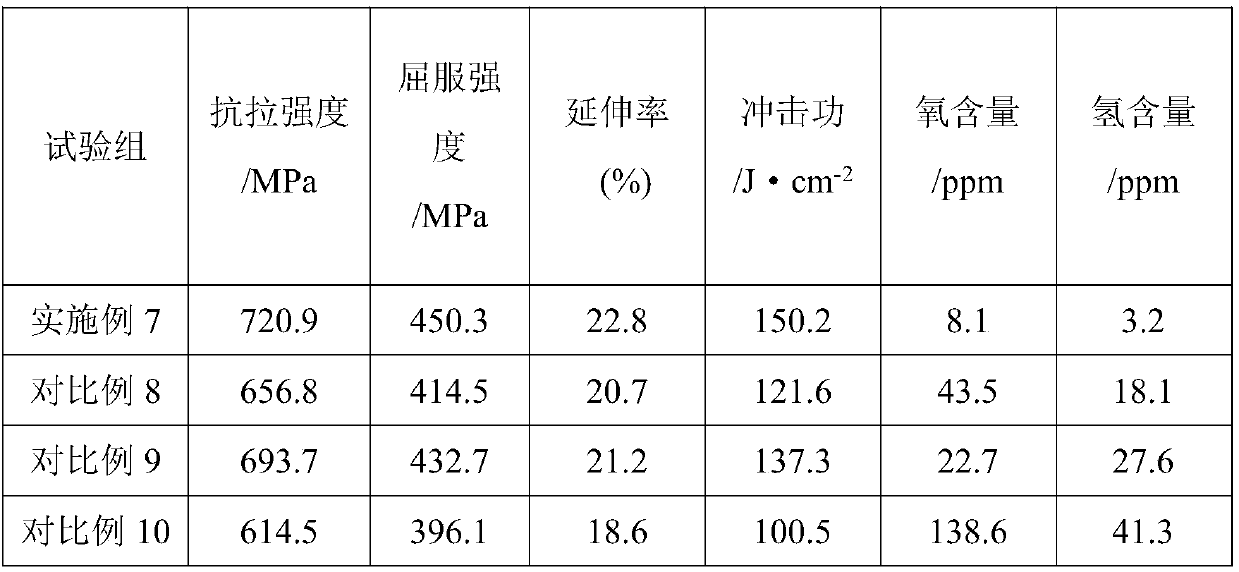

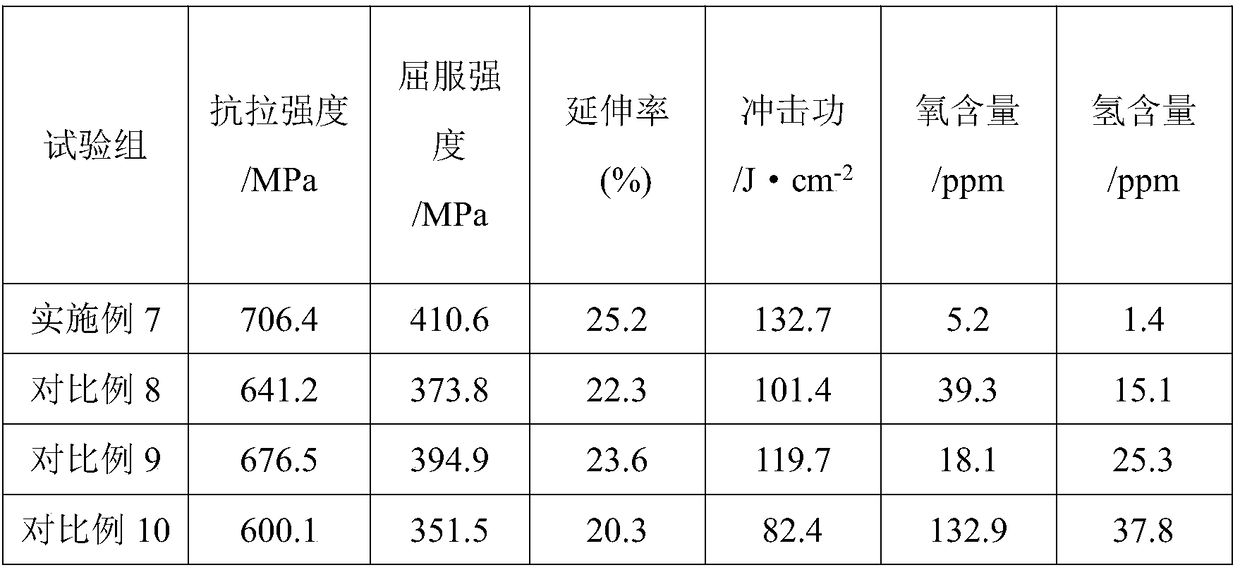

High-purity super-high manganese steel and preparation process thereof

ActiveCN109487178ALess investmentFine and fully evenly dispersedProcess efficiency improvementElectric furnaceHydrogenTrace element

The invention discloses high-purity super-high manganese steel which is prepared from the following components in percentage by mass: 0.75 to 1.76 percent of C, 22.0 to 30.0 percent of Mn, 0.1 to 0.8percent of Si, 0.021 to 0.043 percent of P, 0.016 to 0.035 percent of S, 0.07 to 2.5 percent of Cr, 0.52 to 2.3 percent of Mo, 0.01 to 1.34 percent of Ni, 0.03 to 1.5 percent of Cu, 0.01 to 0.2 percent of Nb, 0.032 to 0.083 percent of Al, 0.0006 to 0.0010 percent of O, 0.00014 to 0.00042 percent of H, less than or equal to 0.82 percent of other trace element, and the balance Fe. By adopting a preparation process of the high-purity super-high manganese steel provided by the invention, the contents of oxygen and hydrogen are effectively reduced, and a synthesized mechanical property of the highmanganese steel is improved.

Owner:广西长城机械股份有限公司

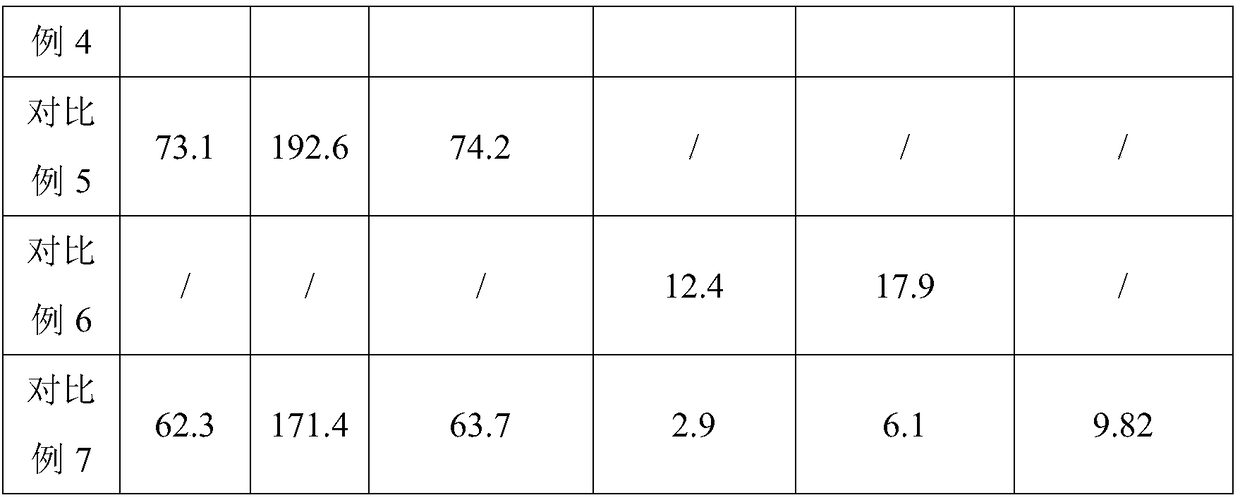

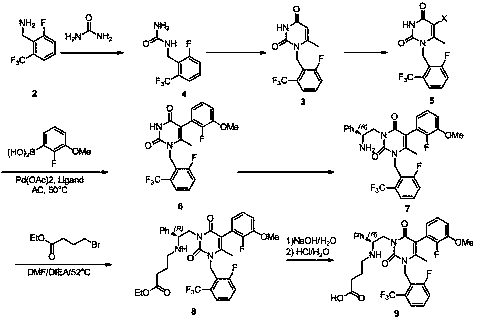

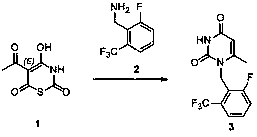

Preparation method of compound containing 6-methyluracil structure

The invention relates to a preparation method and application of a medical intermediate 6-methyluracil derivative. Compared with the prior art, the method disclosed by the invention for synthesizing medical active molecules has the following advantages of good atom economy, high reaction yield, simple post-treatment and high impurity removal capability, and the obtained product has high purity.

Owner:SUZHOU PENGXU PHARM TECH CO LTD +1

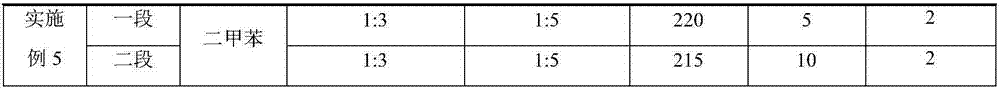

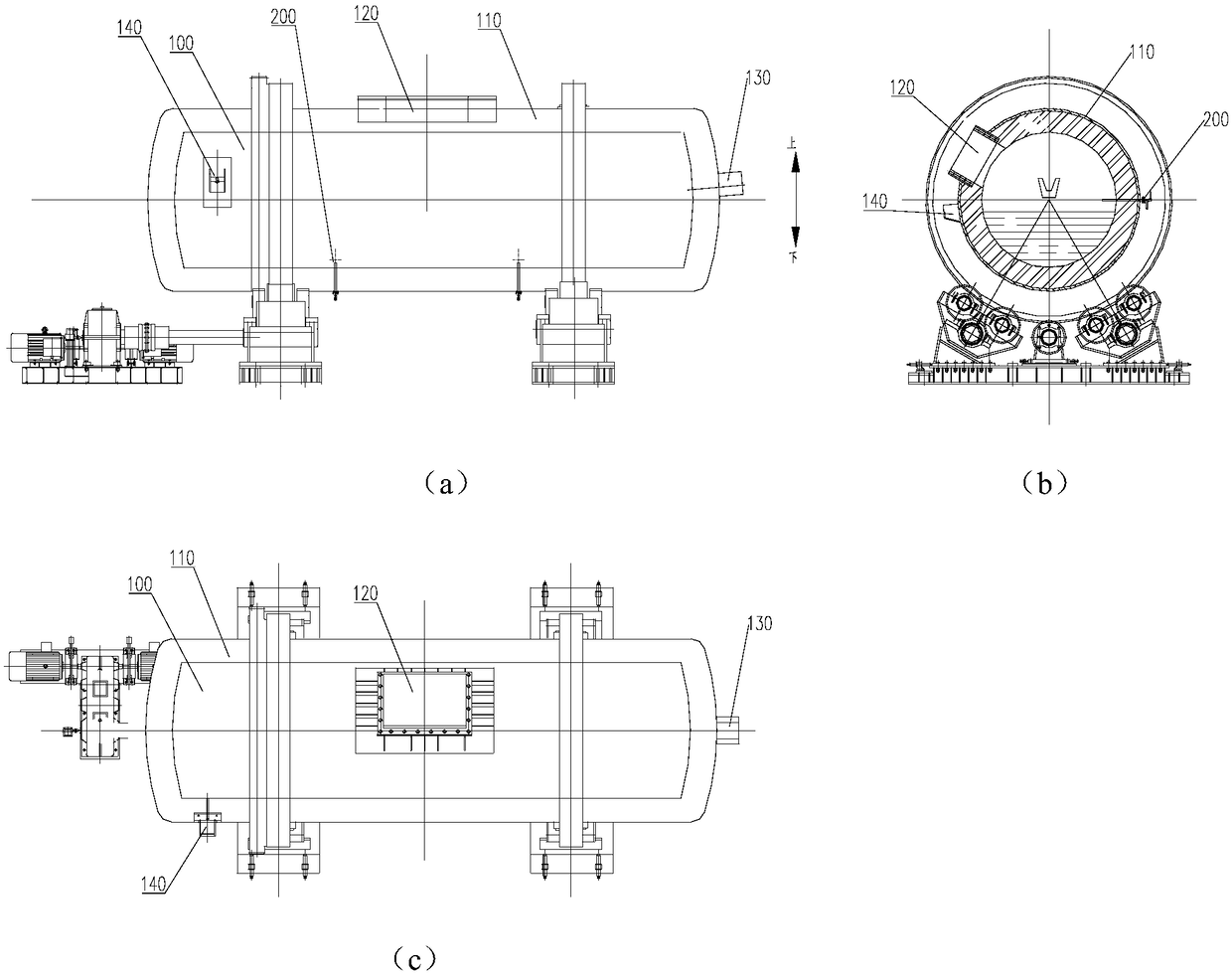

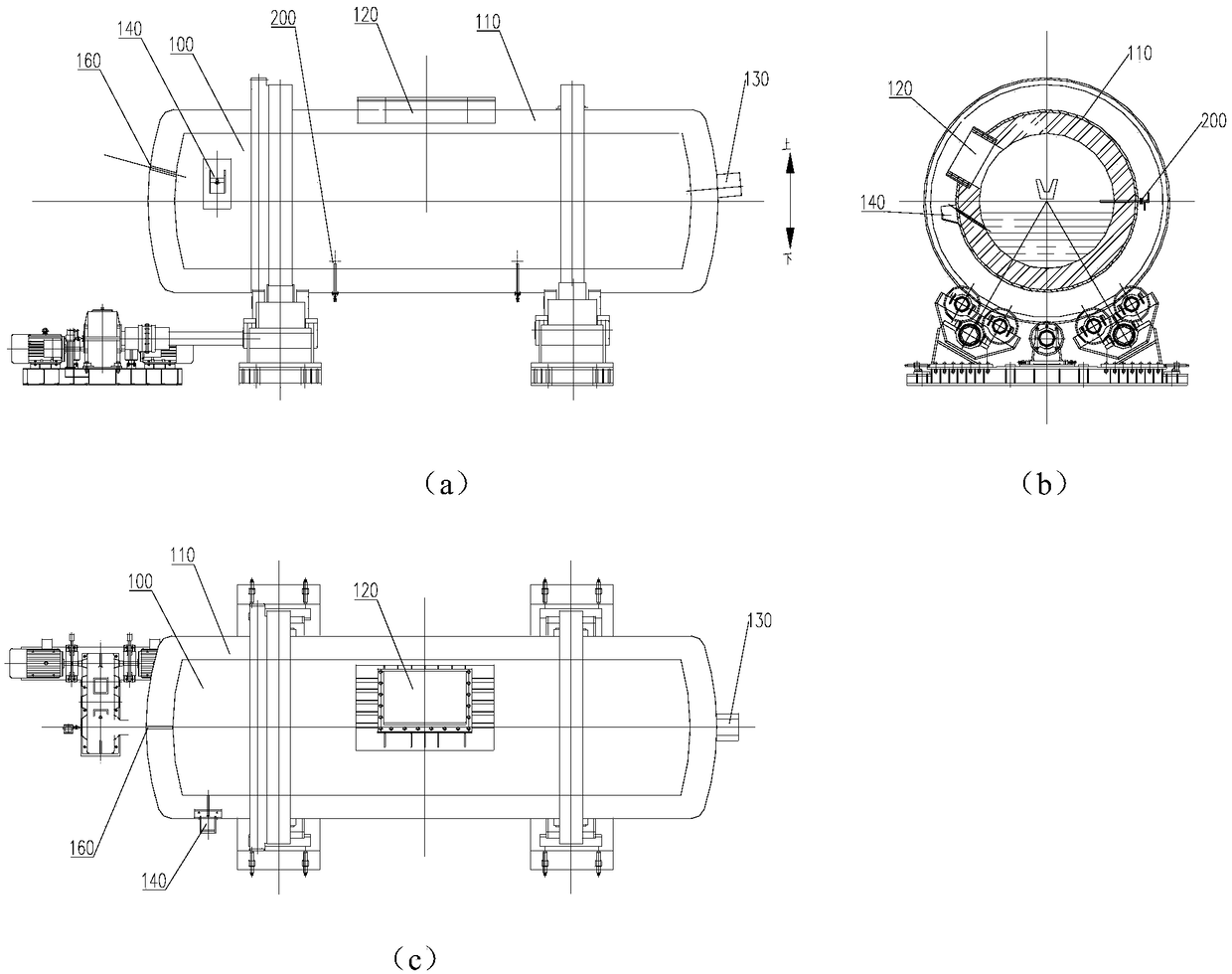

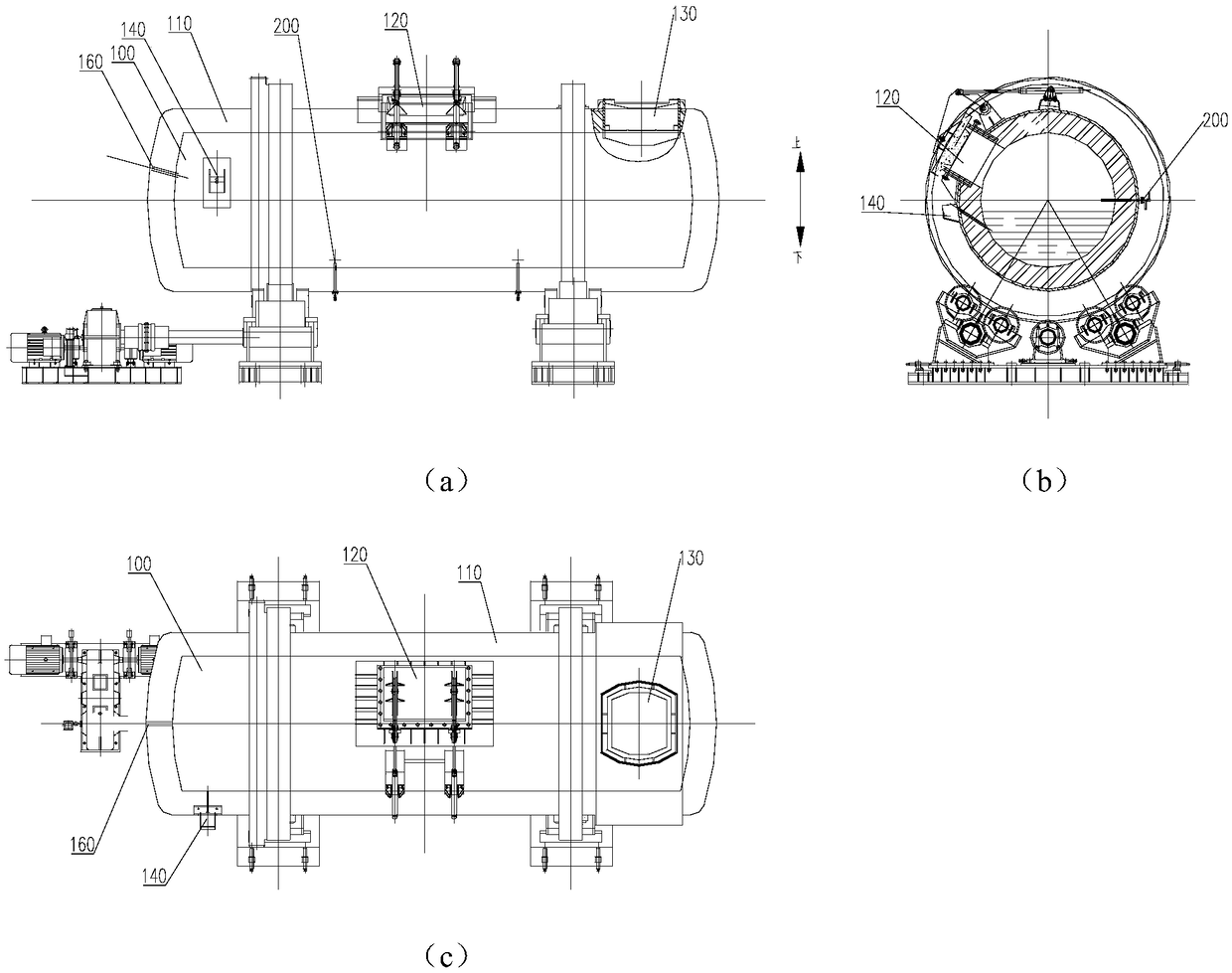

Bottom blowing refining furnace and application thereof

The invention discloses a bottom blowing refining furnace and application thereof. The bottom blowing refining furnace comprises a rotary furnace and a bottom blowing redox gun; specifically, the rotary furnace comprises a rotary furnace casing, a furnace opening, a copper inlet and a copper outlet; a hearth space is limited in the rotary furnace casing; the furnace opening is formed in the upperpart at the middle section of the rotary furnace casing; the copper inlet is formed in the rotary furnace casing; the copper outlet is formed in the side wall of the end part of the rotary furnace casing; the bottom blowing redox gun is arranged at the bottom of the rotary furnace casing and extends into the hearth space; the diameter of the bottom blowing redox gunrefining furnace is 38 to 75 cm.The bottom blowing refining furnace does not need to arrange gas permeable bricks or separately arrange a smoke outlet or a burner; a furnace body is simple in structure and low in equipment cost, and can avoid energy consumption loss because the gas permeable bricks are blown with nitrogen; besides, when the bottom blowing refining furnace refines crude copper, the redox efficiency can be remarkably improved, the refining cycle of the crude copper is shortened and the refining effect is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

High-purity manganese13 high manganese steel

ActiveCN109487037AImprove high temperature resistanceGood thermal shock resistanceProcess efficiency improvementHydrogenManganese

The invention discloses high-purity manganese13 high manganese steel. The high-purity manganese13 high manganese steel comprises following components including, by mass percent, 0.90 to 1.85% of C, 9.0 to 15.0% of Mn, 0.1 to 1.0% of Si, 0.01 to 0.05% of P, 0.01 to 0.05% of S, 0.01 to 3.0% of Cr, 0.01 to 2.0% of Mo, 0.01 to 0.1% of Al, 0.0005 to 0.00012% of O, 0.0001 to 0.0005% of H, not larger than 1% of the remaining microelement and the balance Fe. The high-purity manganese13 high manganese steel preparing process effectively reduces the amount of oxygen and hydrogen, and the comprehensive mechanical property of high manganese steel can be improved.

Owner:广西长城机械股份有限公司

Method for preparing refining agent from egg shell carrier

The invention discloses a method for preparing a refining agent from an egg shell carrier, and belongs to the technical field of preparation of refining agents. The method comprises the following steps that an egg shell is used as a carrier, the egg shell is carbonized after the surface of the egg shell is processed, the carbonized egg shell is put in a solution containing potassium chloride, magnesium chloride, sodium sulfate, zinc chloride and sodium nitrate to be soaked and adsorbed, the adsorbed egg shell and the solution are dried, and the dried material, calcium fluoride, pyrophyllite, diatomaceous earth, pulverized fuel ash and rare earth are mixed, and the mixture is ball-milled to obtain the refining agent. The stability of a refining agent additive obtained after the egg shell is adsorbed can be improved. The inclusion adsorbing capability of the egg shell is high, the cost is low, the prepared refining agent is high in chemical stability, the slagging performance is high, the gas and inclusion removing capability is high, and the method has a wide market prospect.

Owner:陈建峰

High-purity manganese 18 high manganese steel and preparation method thereof

ActiveCN109487036AImprove high temperature resistanceGood thermal shock resistanceProcess efficiency improvementSlagManganese

The invention discloses high-purity manganese 18 high manganese steel which is prepared from the following components in percentage by mass: 0.80 to 1.80 percent of C, 15.0 to 22.0 percent of Mn, 0.3to 0.9 percent of Si, 0.012 to 0.045 percent of P, 0.02 to 0.04 percent of S, 0.03 to 3.5 percent of Cr, 0.05 to 2.8 percent of Mo, 0.02 to 2.5 percent of Ni, 0.06 to 2.3 percent of Cu, 0.014 to 0.096percent of Al, 0.0007 to 0.0013 percent of O, 0.0002 to 0.00045 percent of H, less than or equal to 0.94 percent of other trace element, and the balance Fe. According to the high-purity manganese 18high manganese steel provided by the invention, new slag is casted in the refining period, molten steel in a furnace can fully participate in a steel slag interface reaction, and through the double functions of argon purification and the steel slag full-reaction carried out on the molten steel, oxygen and hydrogen are fully removed, and occluded foreign substances are cleared, so that a synthesized mechanical property of the high manganese steel is improved.

Owner:广西长城机械股份有限公司

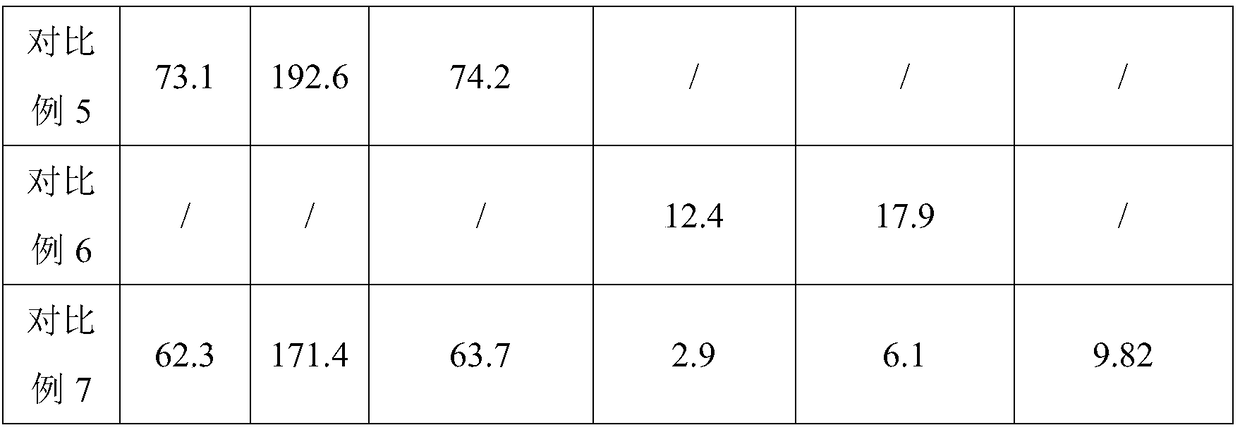

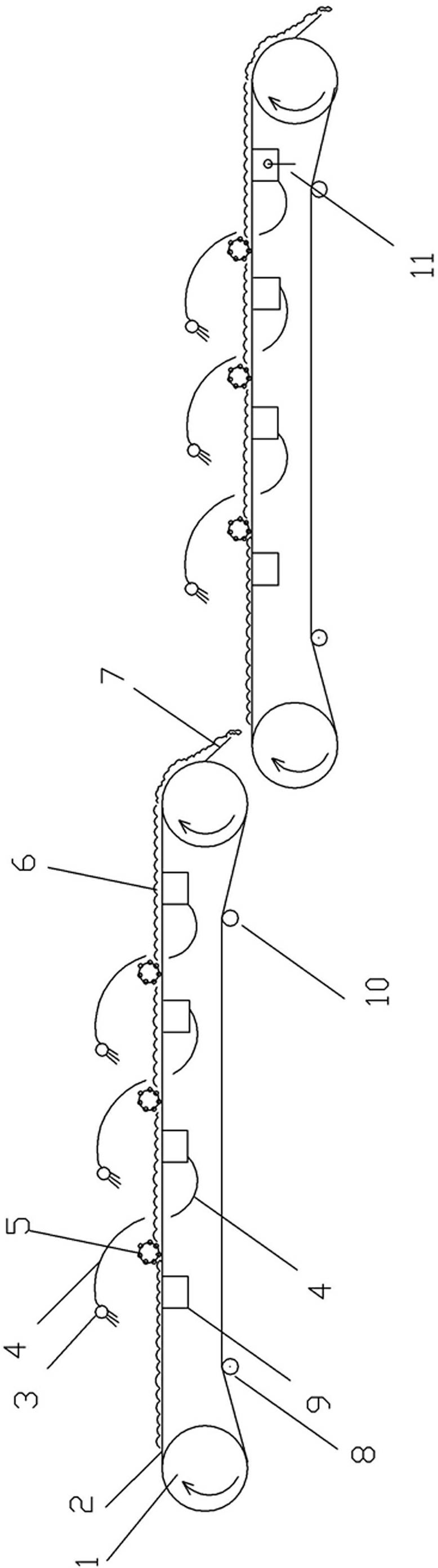

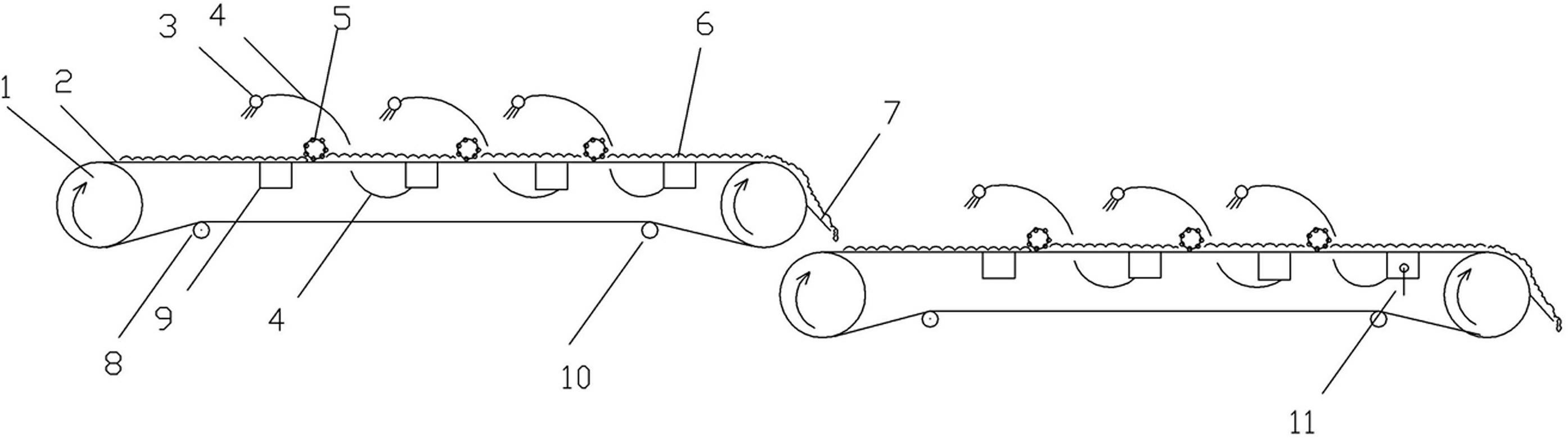

Device and method for continuously washing and purifying polyether sulfone/polyether ketone resin

The invention discloses a device and a method for continuously washing and purifying polyether sulfone / polyether ketone resin. The method comprises the following steps of: conveying a material on a conveying caterpillar; washing the material by uniformly spraying a cleaning solution through a multi-stage spraying device; sucking the cleaning solution out by using a vacuum suction filter box which is clung to the lower side of the conveying caterpillar; conveying the material to a previous stage spraying device, and treating the material step by step in turn; and simultaneously, stirring up the materials which are treated in each step and remixing by using a material stirring roller until the materials are washed and purified to be qualified. The equipment adopted by the invention is simple, the automation degree is high, and by the progressive recursion type continuous washing method, energy sources are greatly saved and water consumption is greatly reduced, the production capacity and the production efficiency are improved, the production cost is reduced, and the product performance is improved.

Owner:KINGFA SCI & TECH CO LTD +2

Refining agent for waste iron steelmaking and refining technology

InactiveCN110819767AAdjustable temperatureQuality improvementProcess efficiency improvementSteelmakingMetallic aluminum

The invention discloses a refining agent for waste iron steelmaking. The refining agent comprises following raw materials including, by mass, 40-70 parts of calcium oxide, 20-30 parts of calcium fluoride, 40-60 parts of metal aluminum, 5-30 parts of graphite powder, 10-30 parts of silicon carbide, 5-15 parts of metal magnesium, 5-10 parts of titanium dioxide, 1-3 parts of biomass, 3-6 parts of kaolin and 1-3 parts of sulfonated phenolic resin. A waste iron steelmaking refining technology comprises the following steps that firstly, deoxidation treatment is conducted, in the tapping process, carbon powder is added in a steel ladle, then a deoxidizing agent and active lime are added for deoxidation treatment, sampling is conducted after tapping is finished, and after sampling, a layer of calcium carbide is scattered on the steel slag surface of molten steel; and secondly, refining is conducted, after the steel ladle is transferred into a refining furnace, the refining agent is added in the steel ladle three times, and after refining is finished, the casting technology is conducted. Whole-process control is conducted on the whole refining process, and the refining time can be shortenedwhile the cleanliness and quality of the molten steel are improved.

Owner:曲靖促创科技有限公司

Method for extracting rhenium from rhenium-rich concentrates

ActiveCN102628111BImprove curing rateFully oxidizedProcess efficiency improvementAmmonium perrhenateIon exchange

Owner:YANGGU XIANGGUANG COPPER

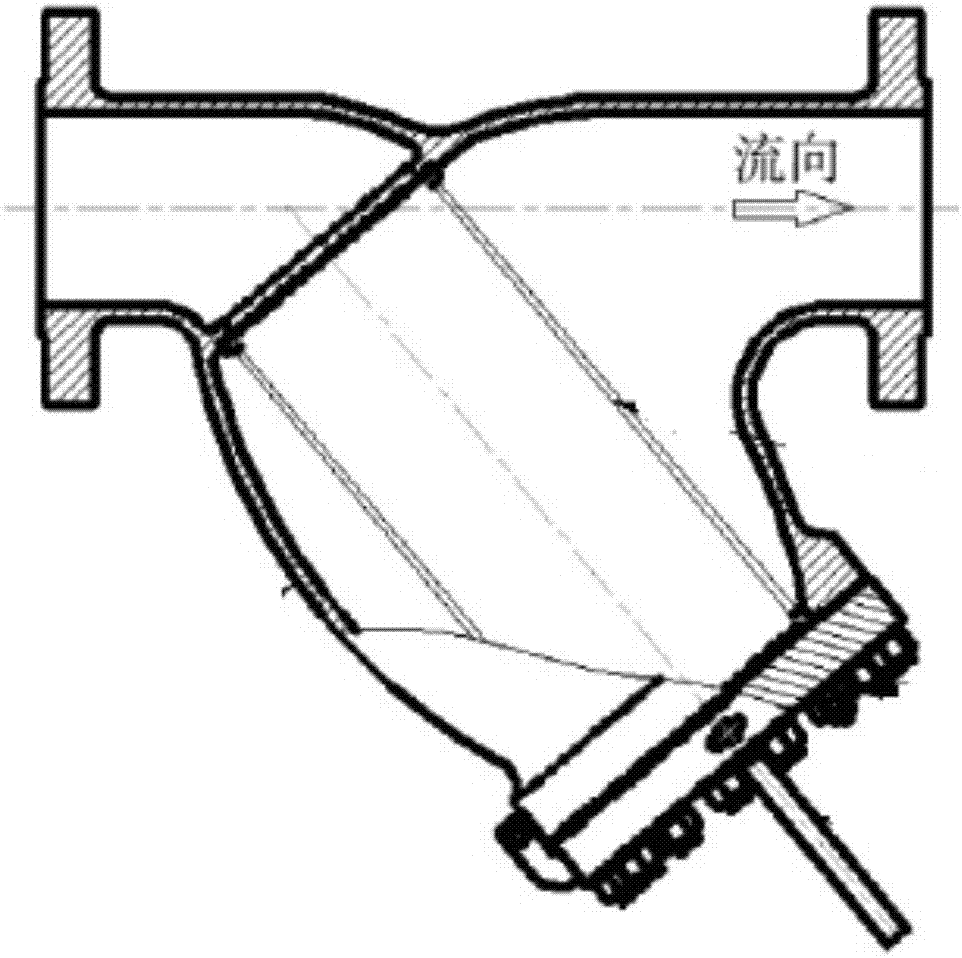

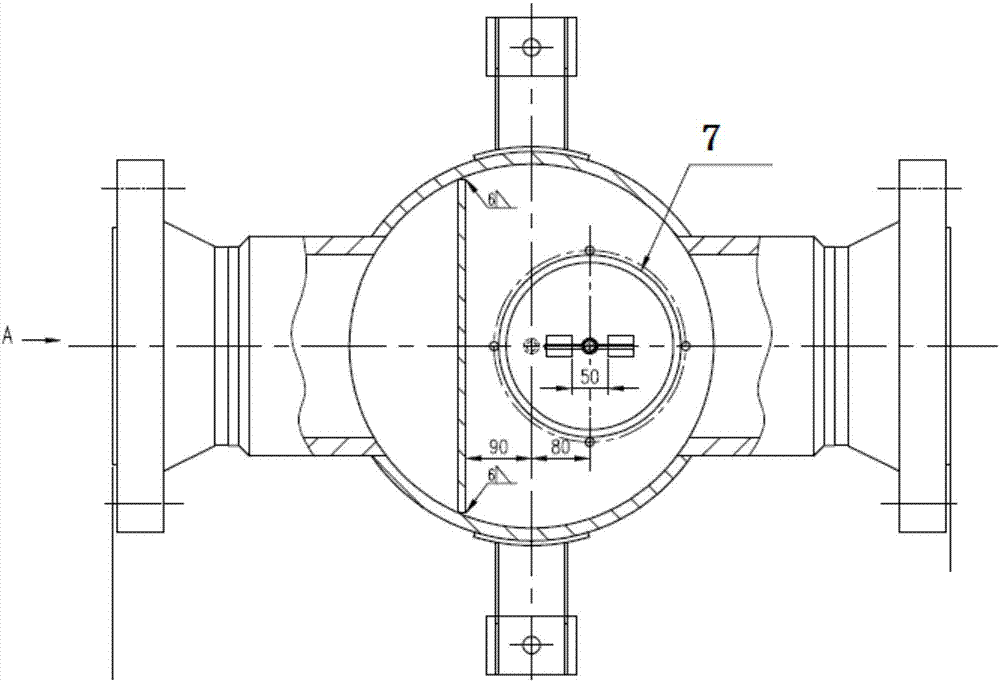

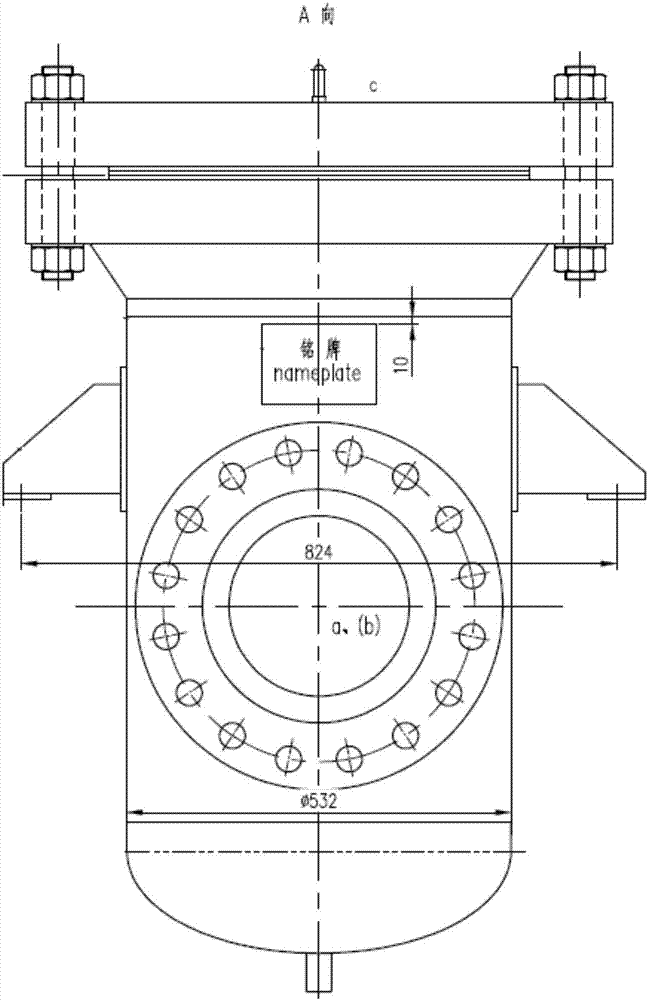

Terminal filter device in front of combustion gas turbine

InactiveCN107174908AImprove filtration capacityStrong ability to remove impuritiesCombination devicesGaseous fuelsGas turbinesEngineering

The invention relates to a terminal filter device in front of a combustion gas turbine. The terminal filter device comprises a main body, an air inlet end and an air outlet end, wherein the main body is of a vertical cylinder structure, and the air inlet end and the air outlet end are formed on two sides of the main body; and an L-shaped baffle is arranged at a part corresponding to the air inlet end in the main body, a vertical cylindrical filter element is arranged on the rear side of the L-shaped baffle, and the upper end of the vertical cylindrical filter element is opened and is fixed in the main body. The terminal filter device has the beneficial effects that the strength of the filter element is relatively high, the structure is relatively reasonable, and fragments do not enter the downstream to damage downstream equipment even when the filter element is damaged; the volume of an inner cavity of a filter is increased, so that the processing property of the filter is improved; and by modifying a filter net of the filter into a three-layer filter net structure, the filtration area is increased, the strength is enhanced, and the filtration schedule is accelerated.

Owner:SHANGHAI AEROSPACE ENERGY

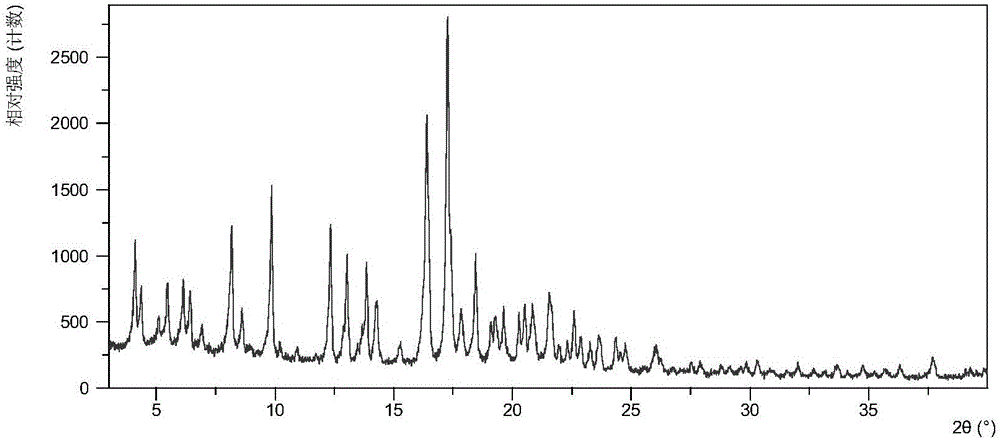

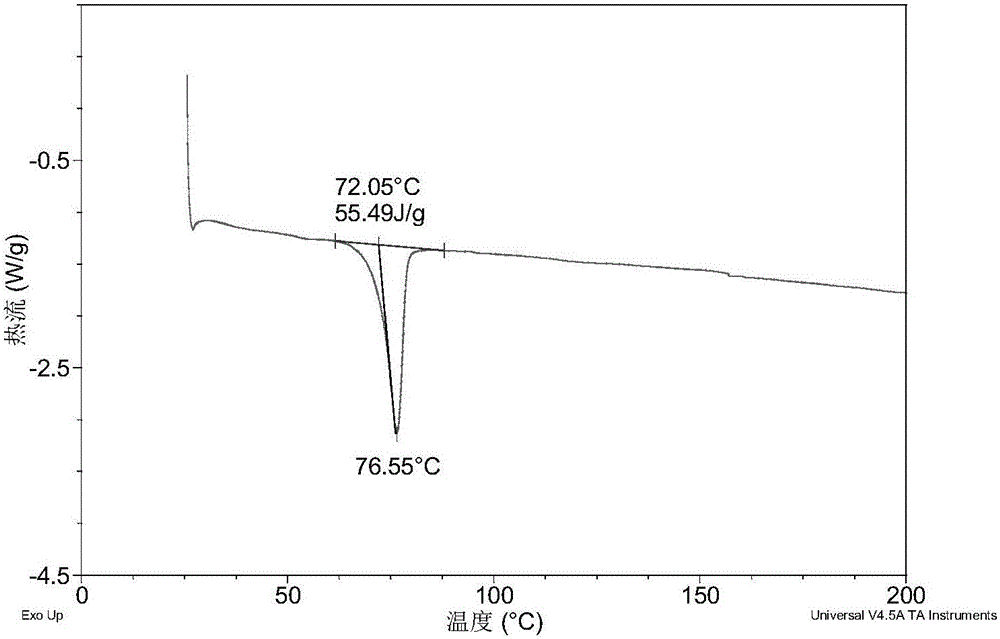

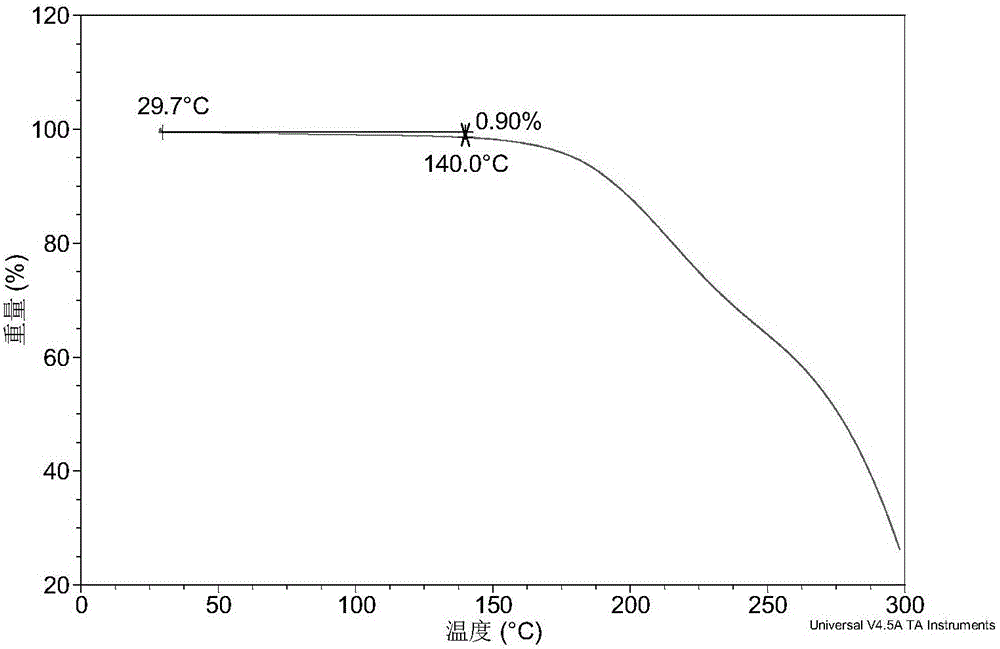

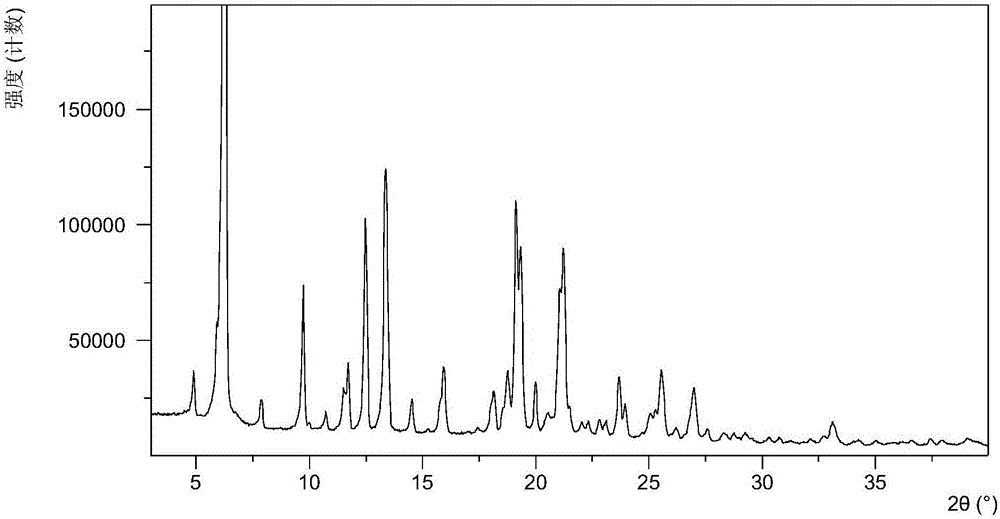

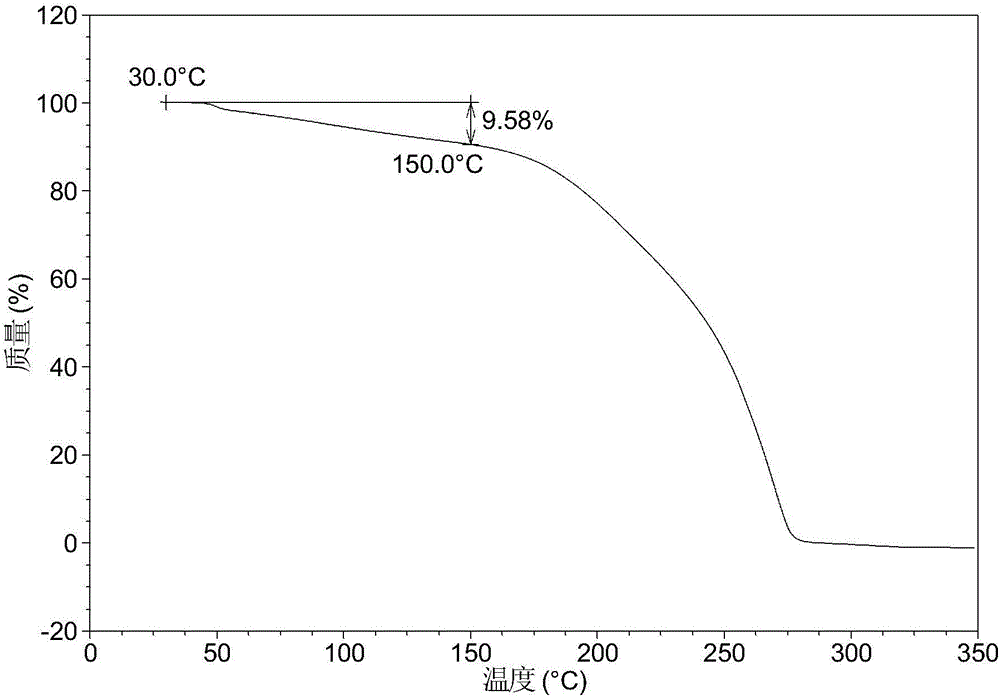

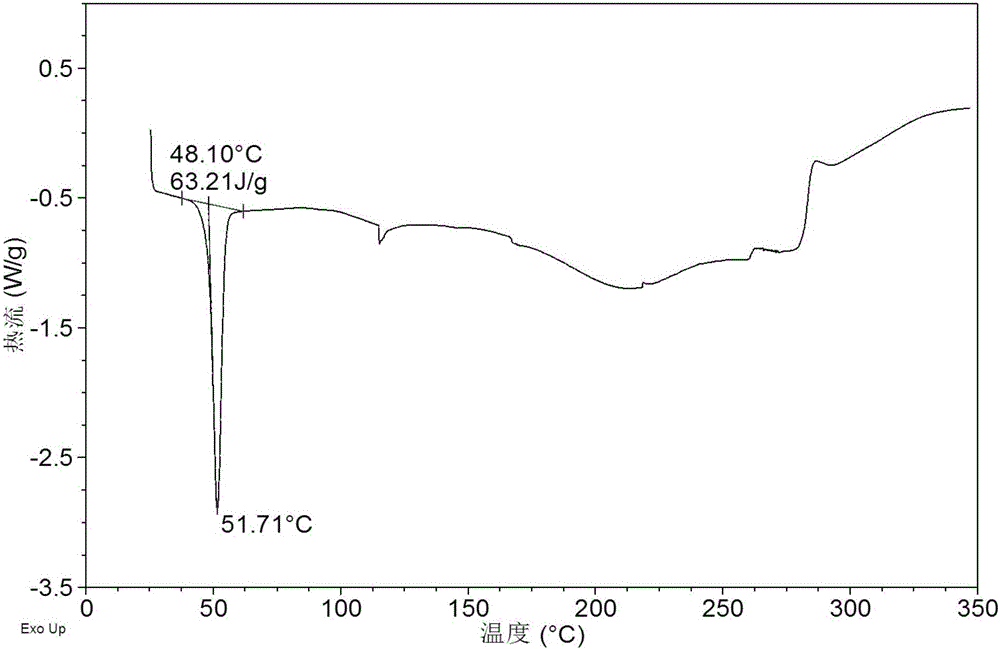

Crystal form of AHU377 as well as preparation method and application thereof

ActiveCN105753732AImprove stabilityReduce humidityOrganic chemistry methodsCarboxylic acid amide separation/purificationCombinatorial chemistryCrystal

The invention relates to a crystal form of AHU377 as well as a preparation method and an application thereof. The novel crystal form is good in stability, low in hygroscopicity and remarkable in technological purification effect. The novel crystal form of the compound AHU377 represented in a formula (I) can be applied to preparation of an anti-heart-failure drug.

Owner:CRYSTAL PHARMATECH CO LTD +1

Rupatadine fumarate intermediate and preparation method of rupatadine fumarate

PendingCN114133353AHigh purityHigh yieldOrganic compound preparationCarboxylic acid salt preparationChemical synthesisCombinatorial chemistry

The invention belongs to the technical field of chemical synthesis, and particularly relates to a rupatadine fumarate intermediate and a preparation method of rupatadine fumarate. The method comprises the following steps: (1) reacting a compound shown in a formula VI with a halogenating reagent to obtain a rupatadine fumarate intermediate shown in a formula V; (2) adding the intermediate of formula V and a compound of formula IV into an acid-binding agent for reaction to obtain a compound of formula III; (3) reacting the compound in the formula III with a reducing agent to obtain a compound in a formula II; and (4) reacting the compound shown in the formula II with fumaric acid to obtain rupatadine fumarate. According to the preparation method, 3, 5-dimethylpyridine-N-oxide is used for carrying out bromination or chlorination, and compared with bromination or chlorination carried out by using 3, 5-dimethylpyridine, the purity and the yield of a halogenated product are higher. Moreover, after the compound shown in the formula V reacts with the compound shown in the formula IV, column chromatography is not needed, the compound shown in the formula III is obtained through solvent refining, post-treatment operation is simple, and industrial production is facilitated.

Owner:CHONGQING HUAPONT PHARMA

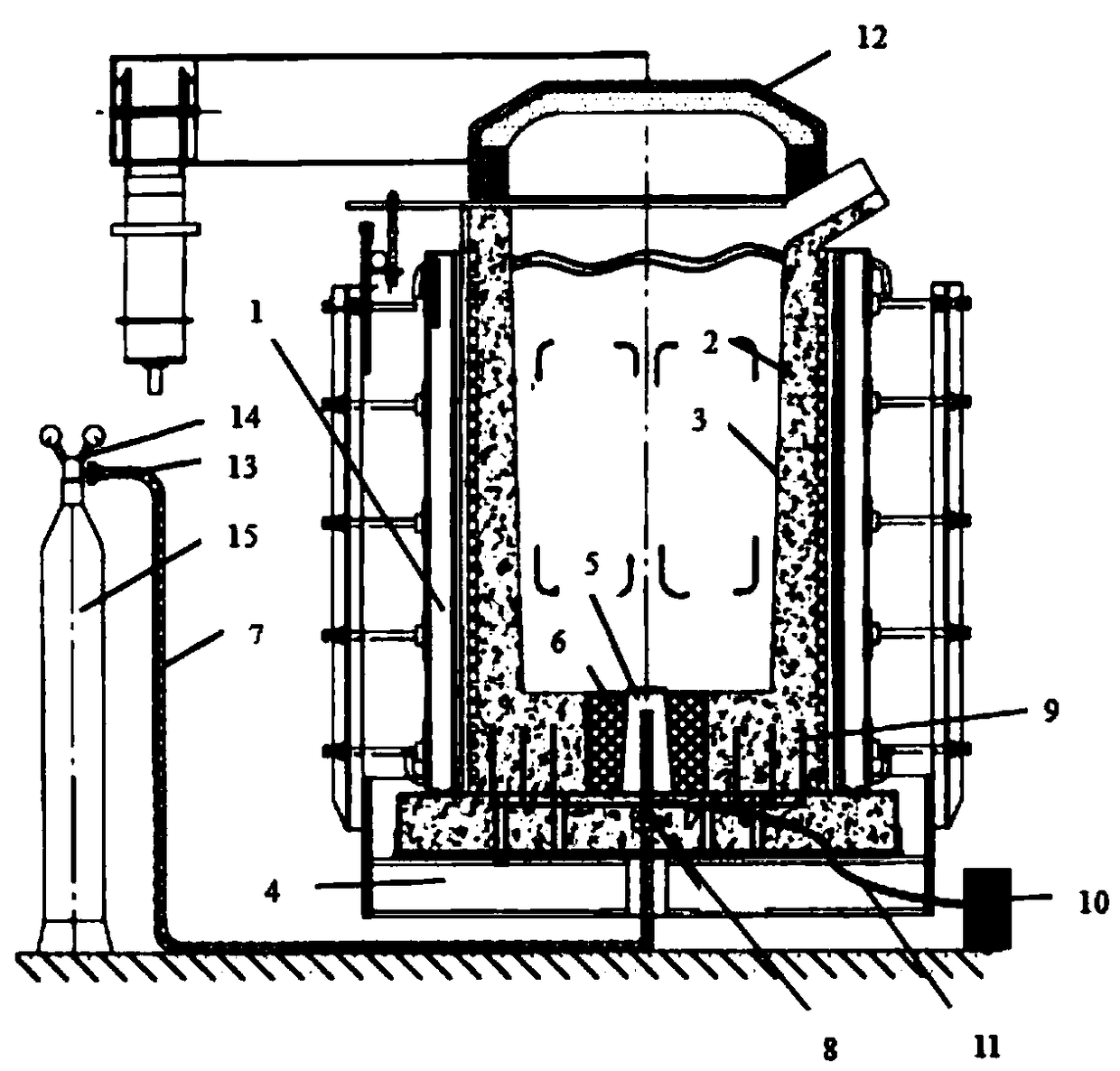

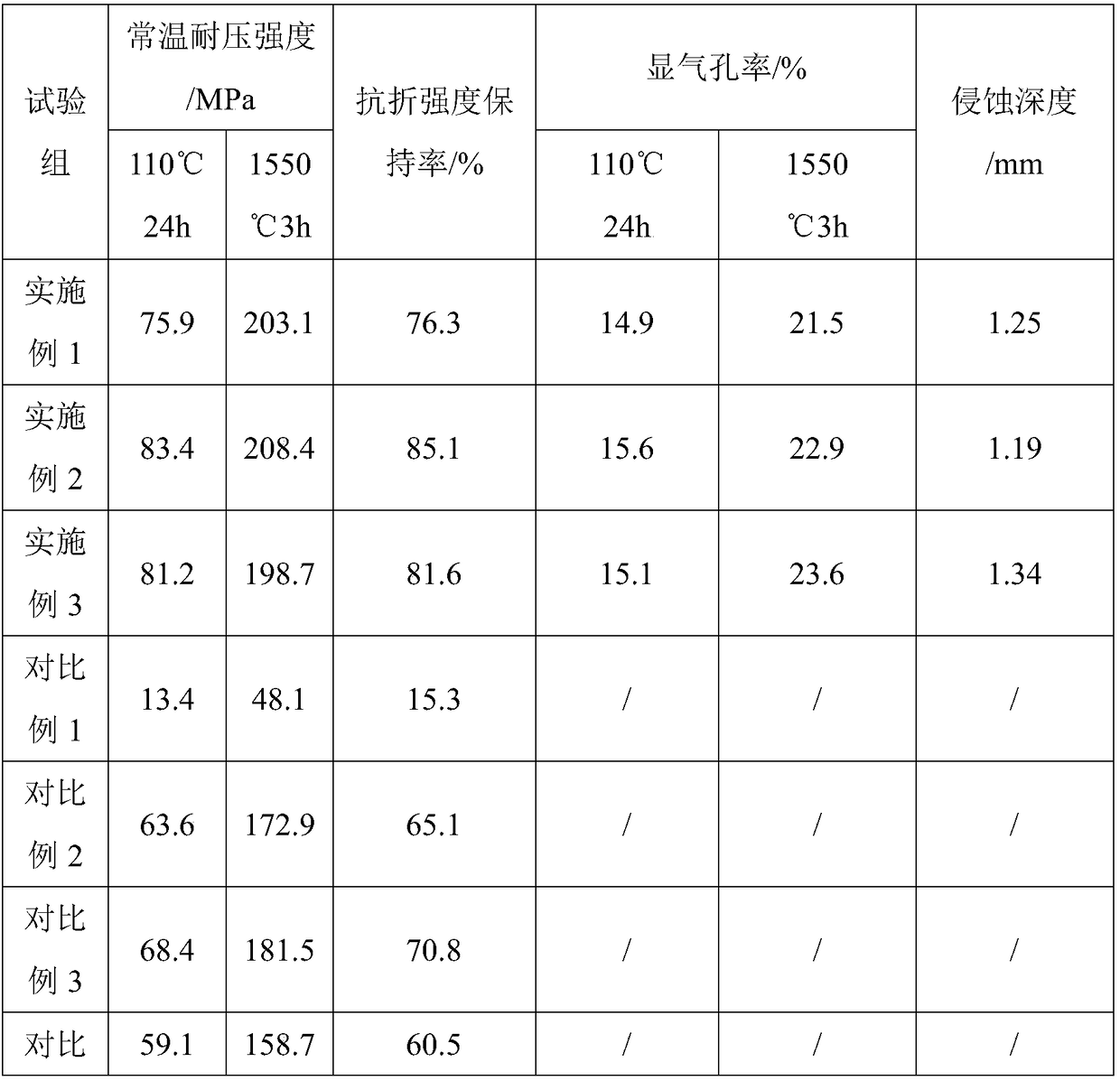

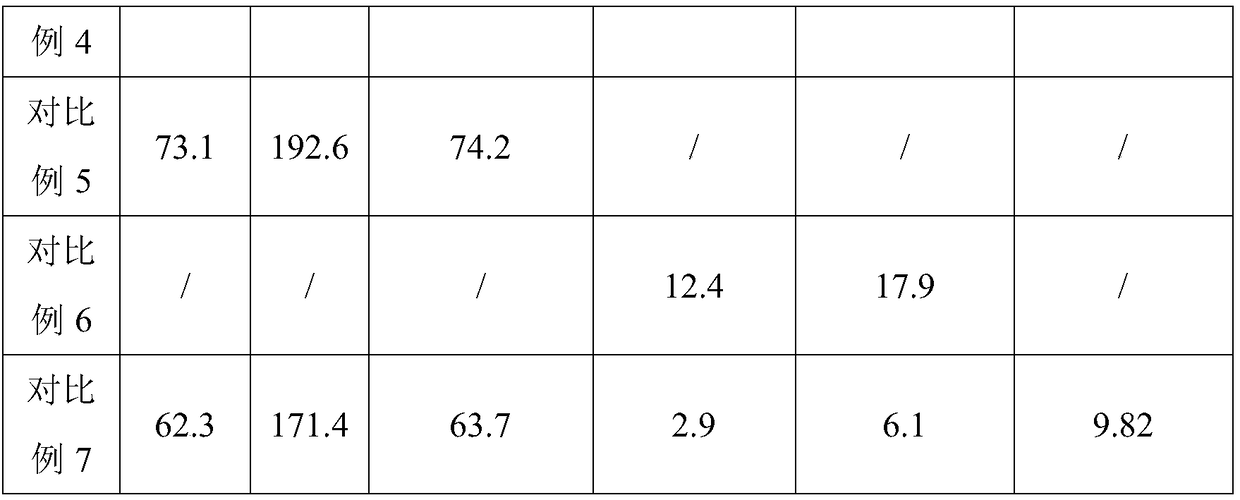

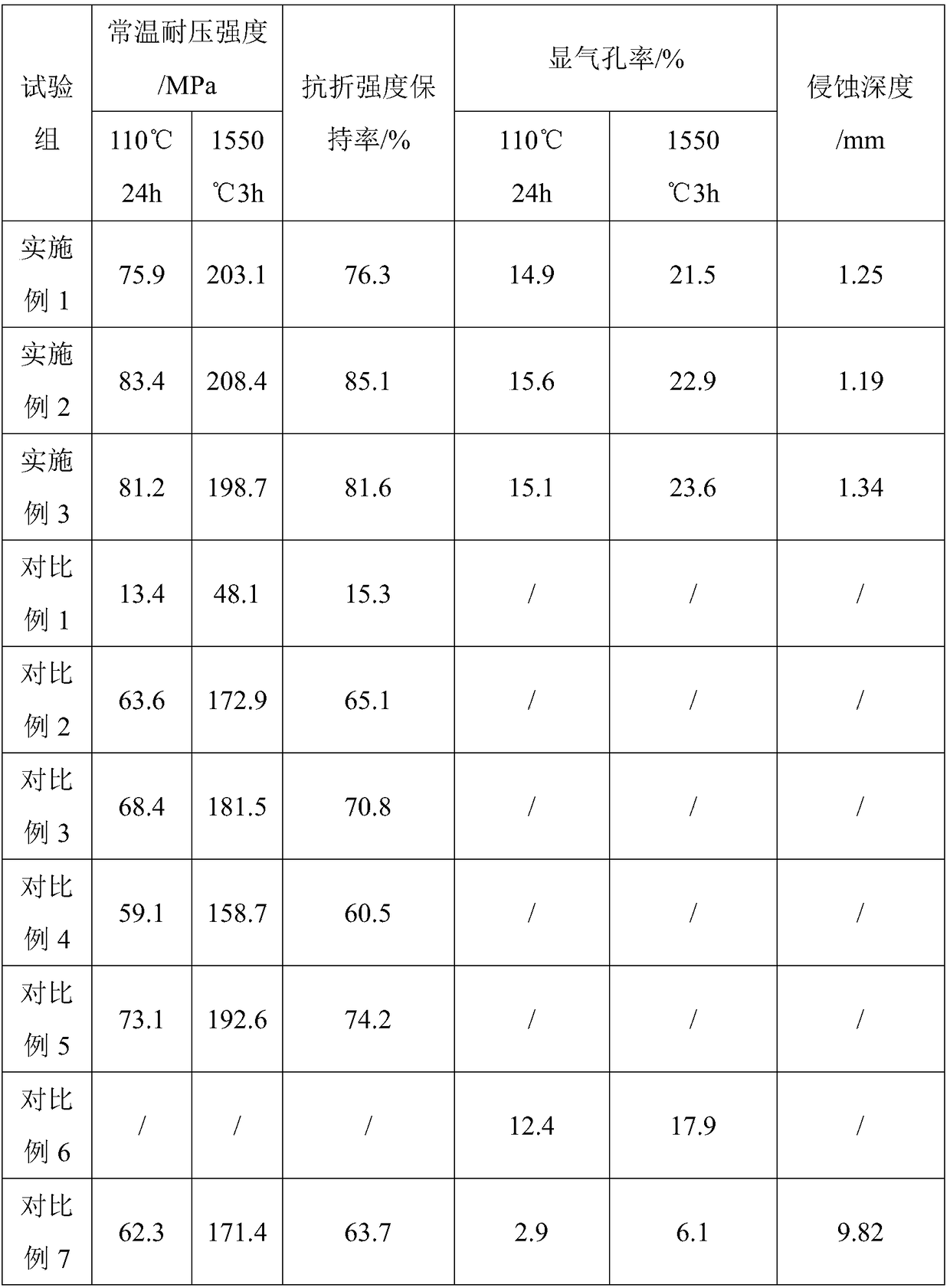

A kind of diffuse type air permeable brick and its preparation method

The present invention relates to a dispersive air brick and a preparation method thereof. According to the technical scheme of the invention, 50 to 80 wt% of plate-shaped corundum is adopted as an aggregate. 12 to 32 wt% of aluminum oxide fine powders, 5 to 10 wt% of alumina micro powders and 3 to 8 wt% of a binding agent are adopted as matrix materials. According to the method, firstly, the matrix materials are uniformly mixed, and then the matrix materials and the aggregate are put into a mixer. 0.1 to 0.3 wt% of a water reducing agent and 4 to 6 wt% of water, counted relative to the sum of the aggregate and the matrix materials, are additionally added. The obtained mixture is stirred for 3 to 5 minutes, and then is cast and molded. After an obtained product is standing at the room temperature for 20 to 30 hours, the obtained product is dried for 22 to 26 hours at the temperature of 90 to 120 DEG C. then the obtained product is thermally insulated for 3 to 6 hours at the temperature of 1450 to 1650 DEG C. In this way, the dispersive air brick can be obtained. The plate-shaped corundum is in the form of equal-diameter particles, and the particle sizes of the equal-diameter particles are 2 to 5 mm. The method has the advantages of simple process, low labor intensity, high production efficiency, no pollution to the environment, and low cost. The prepared dispersive air brick is good in air permeability, strong in impurity-removing capability, excellent in thermal shock stability and good in penetration resistance performance.

Owner:江苏锦耐新材料科技有限公司

Slag making material for high manganese steel purification treatment

InactiveCN109487038ALess investmentFine and fully evenly dispersedProcess efficiency improvementHydrogenSlag

The invention discloses a slag making material for high manganese steel purification treatment. The slag making material for high manganese steel purification treatment is prepared from the followingraw materials in parts by weight: 25 to 53 parts of activated clay powder, 7 to 13 parts of talcum powder, 10 to 16 parts of palygorskite powder, 4 to 6 parts of montmorillonite powder, 32 to 64 partsof quicklime powder, 9 to 15 parts of fluorite powder, 5 to 8 parts of mineral wool, and 1 to 2 parts of binding agent. The slag making material provided by the invention contains the activated claypowder, the talcum powder, the palygorskite powder, the montmorillonite powder, the quicklime powder and the fluorite powder with low melting points and high activity, so that impurities such as hydrogen and oxygen in molten steel are favorably removed, the contents of harmful elements and impurities in steel are reduced, a slag sucking effect is achieved, the quality of the molten steel is greatly improved, the high-purity wear-resistant material is made favorably, meanwhile, the dosage of the slag making material is reduced, and the cost is reduced.

Owner:广西长城机械股份有限公司

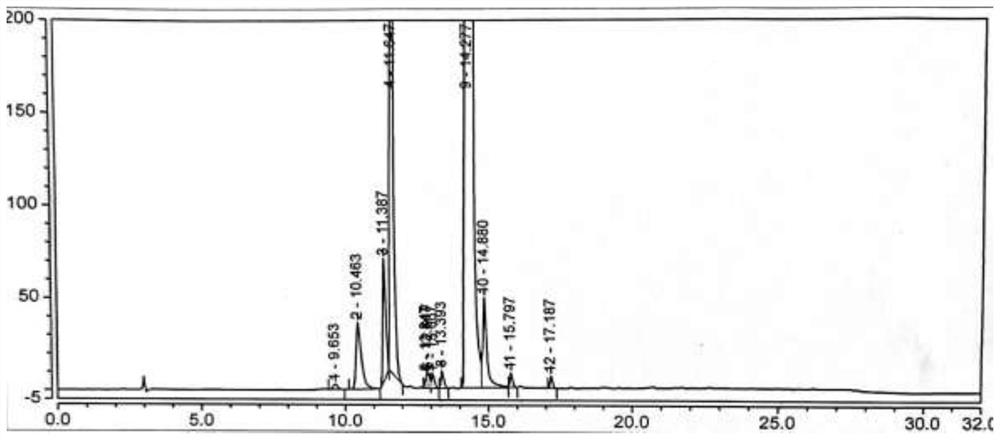

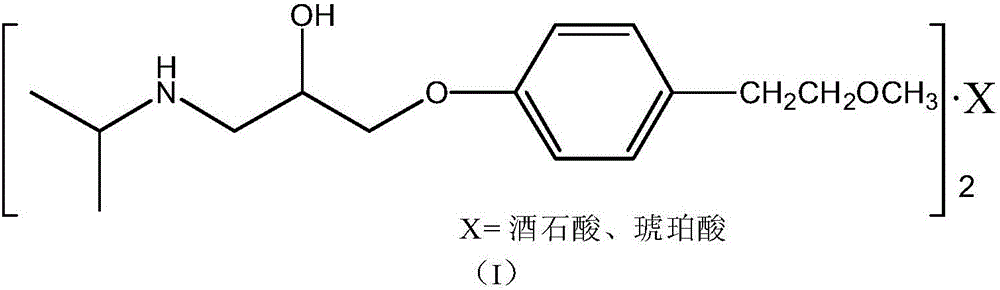

Method for preparing metoprolol salt

ActiveCN106083614AStrong ability to remove impuritiesImprove solubilityOrganic compound preparationAmino-hyroxy compound preparationOrganic acidMetoprolol

The invention relates to a method for preparing a metoprolol salt which is simple to operate, high in yield, good in quality, low in cost and good in environmental-friendliness. According to the method provided by the invention, an acetone / water mixed solvent system is adopted, and an adverse dropping mode, that is, a mode that metoprolol is dropped into an organic acid solution, is adopted, so that the organic acid can be sufficiently dissolved, and a reaction can be sufficiently implemented, the reaction time can be greatly shortened, and the reaction conversion rate and the yield can be increased. The operation procedures are simplified, the time is shortened, the cost is lowered, and moreover, the quality of a product is greatly improved.

Owner:ZHEJIANG YONGTAI PHARMA

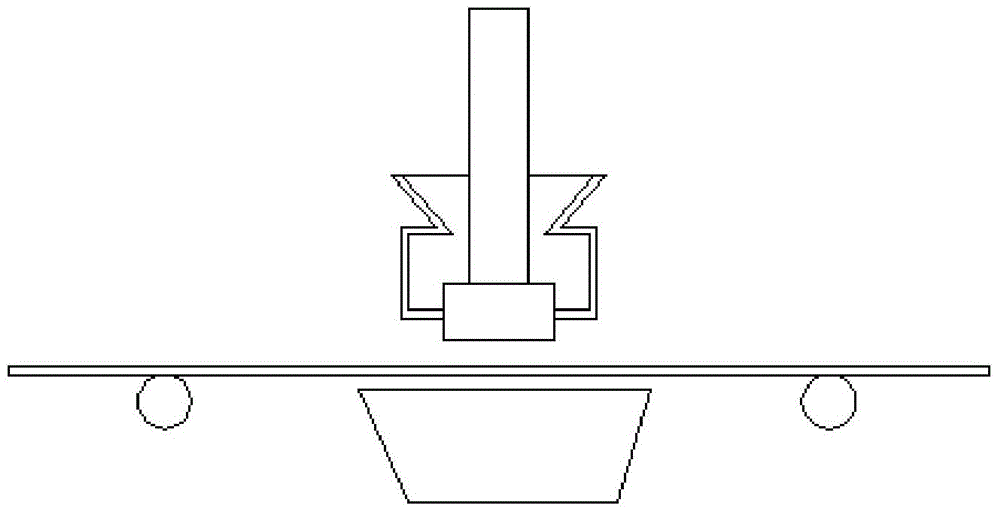

Ultrasonic dust removing device for spinning

InactiveCN104984975AStrong ability to remove impuritiesFully removedDirt cleaningScrapUltrasonic generator

The invention discloses an ultrasonic dust removing device for spinning. The ultrasonic dust removing device for spinning comprises an ultrasonic mechanism, a conveying mechanism, an air cover and a waste hopper, wherein the ultrasonic device comprises a welding head and an ultrasonic generator; the ultrasonic mechanism is placed rightly above the conveying mechanism; a distance from the ultrasonic welding head to a spinning material is within 1-10 mm; the air cover penetrates through the ultrasonic generator to cover the welding head; an air inlet is an inverted conical structure; and the waste hopper is positioned rightly below the conveying mechanism. The ultrasonic dust removing device for spinning has the following advantages: the spinning material is vibrated with high frequency through ultrasonic dust removal, so that the impurity removing capacity is stronger; and the air cover adopts the inverted conical structure, the airflow pressure is higher, and the impurity removal is more thorough.

Owner:WUJIANG XINJIN TEXTILE

AHU377 crystal form and preparation method and uses thereof

ActiveCN105753733AImprove stabilityReduce humidityOrganic chemistry methodsCarboxylic acid amide separation/purificationCrystallographyCombinatorial chemistry

Owner:CRYSTAL PHARMATECH CO LTD

Production technology of molten steel refining furnace slag melting agent

InactiveCN109593899ALess investmentFine and fully evenly dispersedProcess efficiency improvementHydrogenSlag

The invention discloses a production technology of a molten steel refining furnace slag melting agent. The production technology comprises the following steps that (1) activated clay powder, talcum powder, palygorskite powder, smectite powder, quicklime powder, fluorite powder, mineral wool and a binder are added into a mixer by weight, meanwhile, 22-30 parts of water is added, mixing is performedfor 1-1.5 h under the rotating speed of 300-500 r / min, and uniform slurry is prepared; (2) the uniform slurry is added into a mould and made into particles with the grain size being 0.8-1.2 cm through vacuum suction filter forming; and (3) the particles are fed into a drying oven, drying is performed for 8-10 h under the temperature of 82-93 DEG C, and the slag melting agent is prepared. The slagmelting agent provided by the invention contains the components including the activated clay powder, the talcum powder, the palygorskite powder, the smectite powder, the quicklime powder and the fluorite powder with the low melting points and high activity, impurities including hydrogen, oxygen and the like in molten steel can be removed easily, the contents of the harmful elements such as the hydrogen and the oxygen in the steel are decreased, and accordingly, the mechanical performance of high-purity 18 high manganese steel is improved.

Owner:广西长城机械股份有限公司

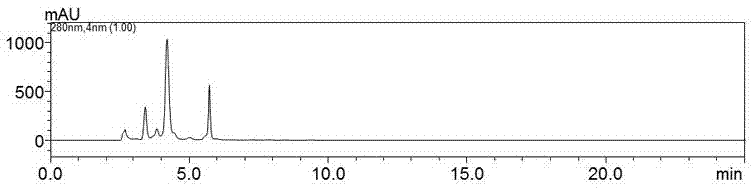

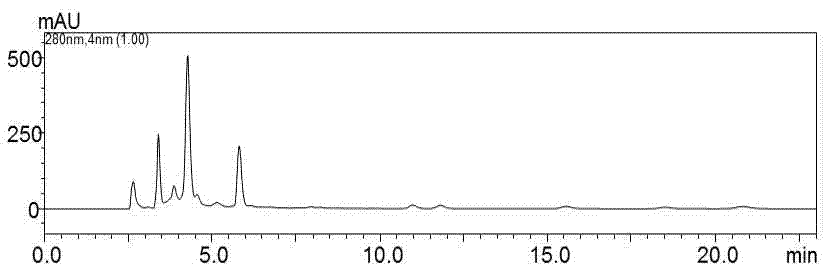

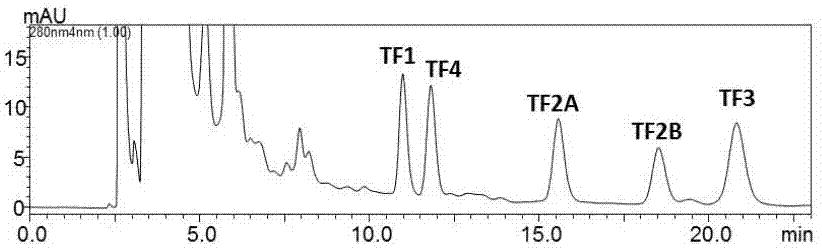

Preparation method of theaflavin composite

InactiveCN106977484AEasy to separateLarge adsorption capacityOrganic chemistryTheaflavinChromatographic column

The invention discloses a preparation method of a high purity theaflavin composite, MCI resin is used for separation of a theaflavin sample without dead adsorption, the recovery rate is close to 100%, part of theaflavin composite with lower high purity can be separated again by column chromatography, repeated utilization degree is high, and no sample is lost. In the prior art, no chromatographic packed column is capable of recovering theaflavins by 100%, so that the MCI chromatographic column is especially suitable for the efficient extraction of the theaflavins. In particular, the method can improve the recovery rate, and meanwhile the purity of the theaflavin composite in a prepared product is 85% or more, even 90% or more.

Owner:SUN YAT SEN UNIV

Using method of low-melting point and high-activity molten slag

ActiveCN109504821AUniform chemical compositionUniform temperatureProcess efficiency improvementTemperature controlMechanical components

The invention discloses a using method of low-melting point and high-activity molten slag. The molten slag is applied to preparing high pure and high manganese steel, in the charging smelting step ofpreparing the high pure and high manganese steel, when furnace charge melts to form molten steel, the surface of the molten steel is covered with the molten slag, until the furnace charge melts down,and after the steps of adjusting mechanical components, cooling in a furnace and temperature control tapping to prepare the high pure and high manganese steel. The molten slag has lower melting pointand high activity, rapidly melts under the condition of intermediate frequency furnace smelting, participates in metallurgical reaction sufficiently, deoxygenation, dehydrogenation, impurity removal and other capacity are high, the quality of the molten steel is greatly improved, and the preparation of the high pure and high manganese steel is facilitated.

Owner:广西长城机械股份有限公司

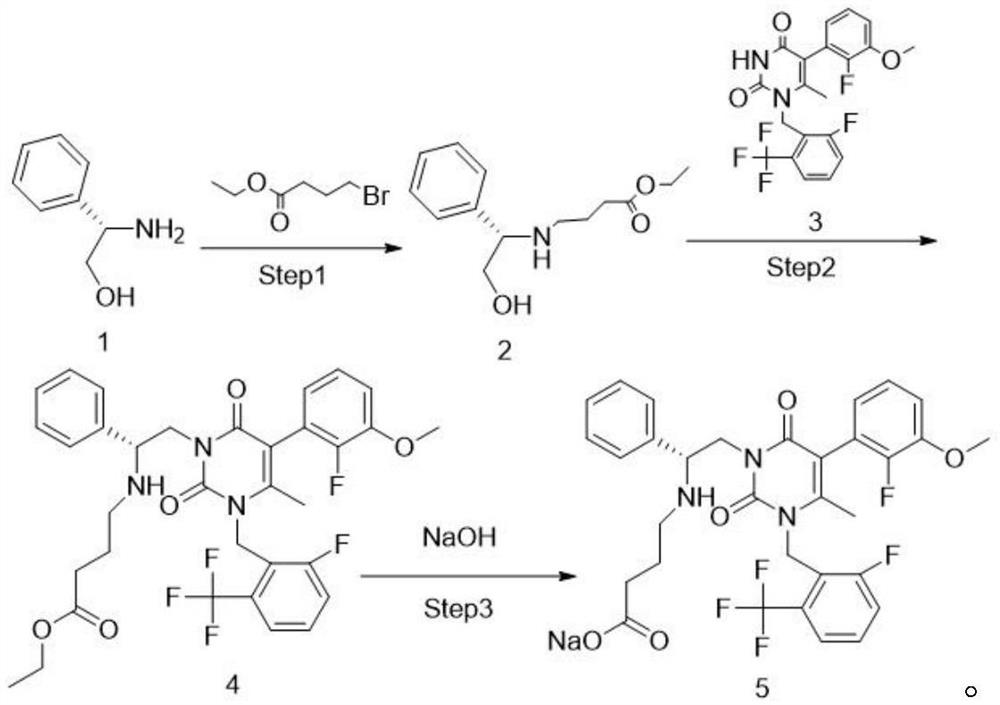

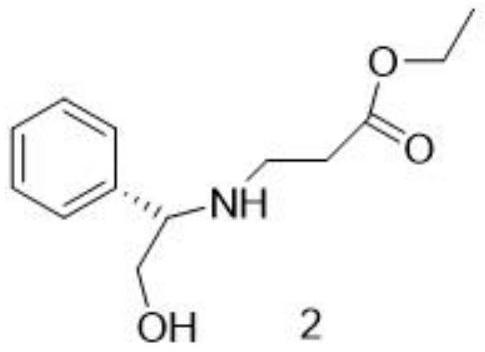

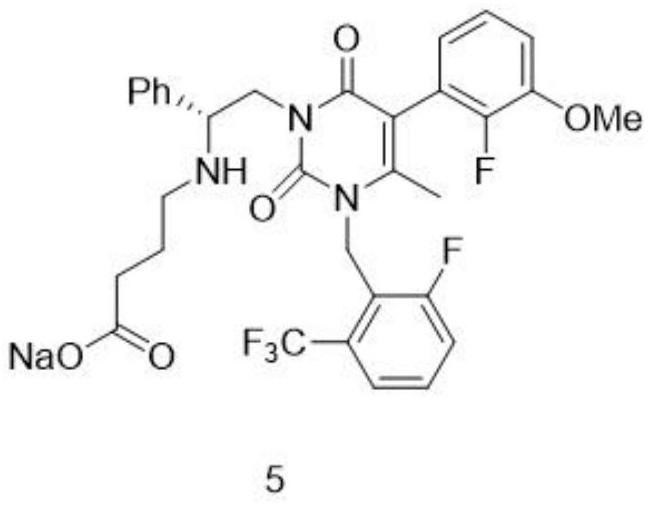

Preparation method of elagolix sodium and intermediate thereof

InactiveCN112457258AEasy to routeSave raw materialsOrganic compound preparationAmino-carboxyl compound preparationButyrateChemical compound

The invention relates to a preparation method of elagolix sodium and an intermediate thereof, and relates to the technical field of medicine synthesis and preparation. The preparation method comprisesthe following synthesis steps: (1) synthesizing a compound 2 by taking D-phenyl glycinol 1 and ethyl 4-bromobutyrate as raw materials through a substitution reaction; (2) reacting with a compound 3 to generate a compound 4; and (3) salifying to obtain a target product 5, namely elagolix sodium. The preparation method disclosed by the invention has the characteristics of suitability for industrialproduction, lower cost, high purity of the prepared product and high yield.

Owner:CHENGDA PHARM CO LTD

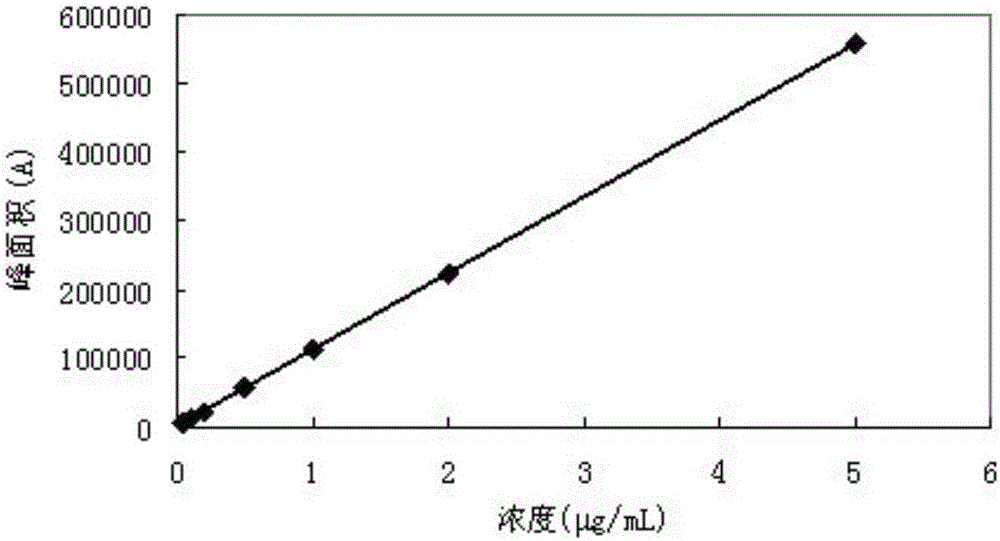

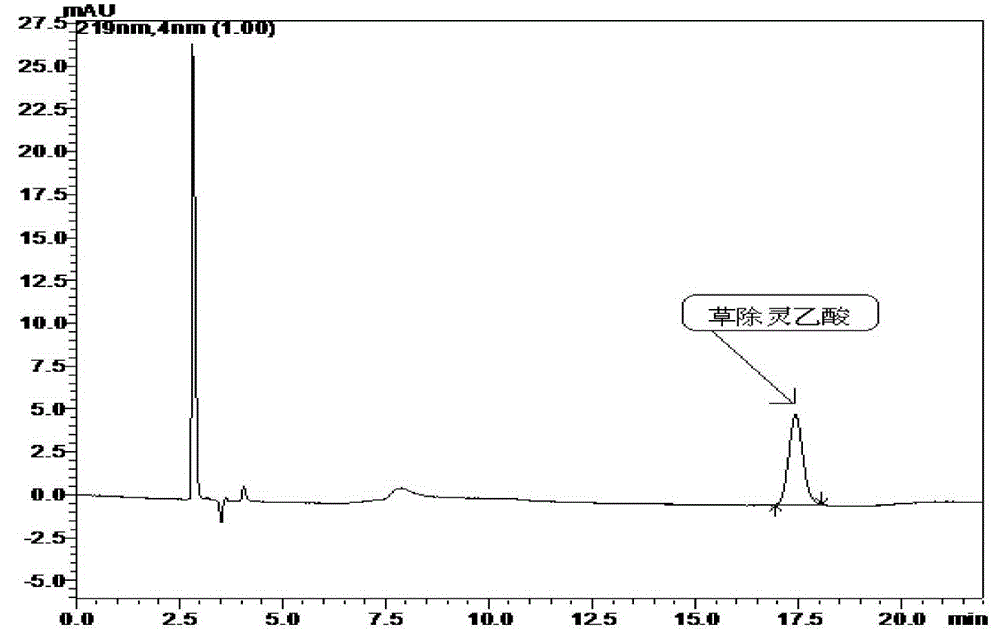

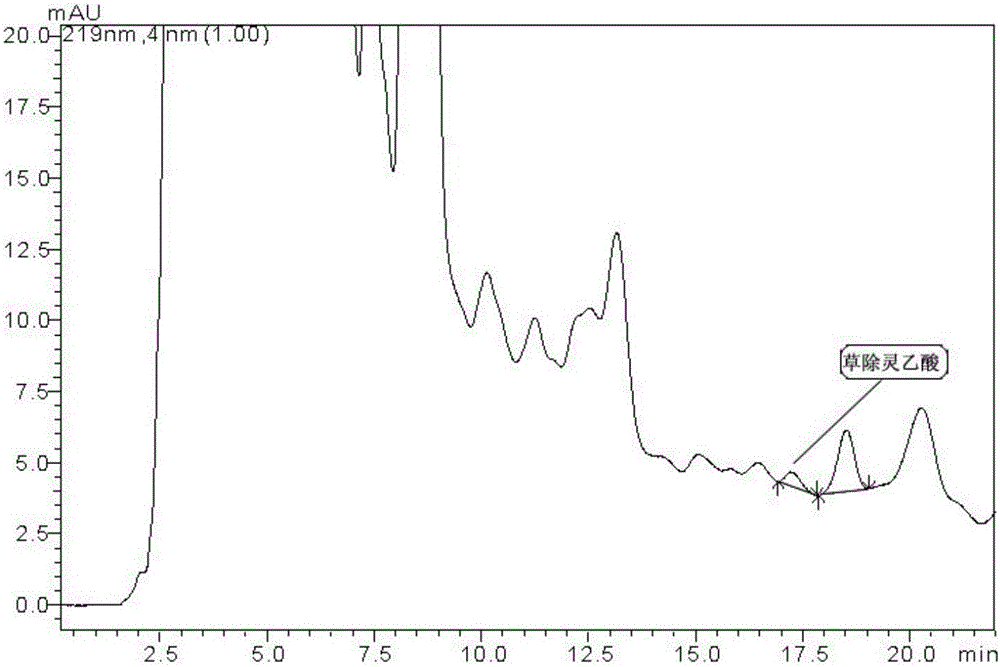

A kind of detection method of acetaminophen acetic acid in plant-derived food

InactiveCN104122341BStrong ability to remove impuritiesEasy to separateComponent separationHybrid typeAcetic acid

The invention discloses a detection method of benazolin acetic acid in plant-based food. The detection method comprises the following steps: step I, extracting benazolin acetic acid in a sample; step II, purifying the extracted liquid through a mixed anion exchange column; step III, detecting a benazolin acetic acid standard product by adopting liquid chromatogram to be matched with an ultraviolet detector; step IV, establishing a benazolin acetic acid standard curve; and step V, detecting the purified sample by adopting the method in the step III, and calculating the content of the benazolin acetic acid in the sample to be detected according to the standard curve. By adopting the detection method, the current situation that no method is used for detecting the benazolin acetic acid in the plant-based food at present can be solved. The detection method is strong in impurity interference resistance, and is accurate, reliable, sensitive and quick.

Owner:河南省农业科学院农业质量标准与检测技术研究所

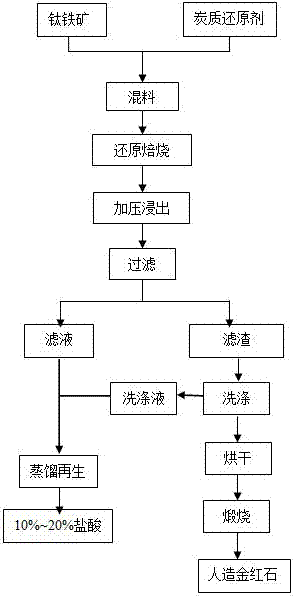

A process for preparing artificial rutile by leaching ilmenite with hydrochloric acid

The invention relates to a process for making artificial rutile by leaching of mohsite hydrochloric acid and belongs to the technical field of metallurgy. The process includes using mohsite graded at 45-52% as raw materials, and distributing carbonaceous reducing agent for reducing roasting, pressure leaching, filtering, roasting, and regenerating of hydrochloric acid, so that impurity removal of mohsite and recycling of hydrochloric acid are effectively realized and artificial rutile is made. The process is characterized in that mohsite and carbonaceous reducing agent are uniformly mixed for reducing roasting, and leaching rate of impurities like silicon, iron, calcium and magnesium is increased; hydrochloric acid is regenerated by distilling leaching mother liquor and can be reused in leaching; filter slag can be roasted after pressurized leaching and filtering so as to obtain artificial rutile. The process has the advantages of high leaching speed, high impurity removal efficiency, high grade and recyclability of hydrochloric acid. In addition, the process is applicable to industrial production in the aspects of technique, equipment, economy and environment protection.

Owner:KUNMING METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com