A process for preparing artificial rutile by leaching ilmenite with hydrochloric acid

An artificial rutile and hydrochloric acid leaching technology, which is applied in the field of metallurgy, can solve problems such as complex process, lower product quality, and complicated side processes, and achieve the effects of fast leaching speed, reduced powder generation, and strong impurity removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

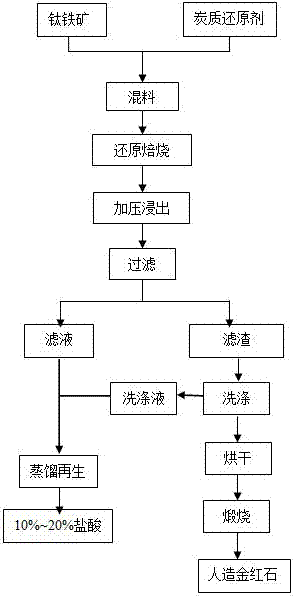

[0041] Such as figure 1 As shown, take 200 g of ilmenite, add 20 g of calcined petroleum coke as a reducing agent according to 10% by mass, mix well and add into a graphite crucible, and the graphite crucible is roasted in a closed atmosphere furnace at 900 ° C for 60 min; 150g of ilmenite was leached under pressure, the concentration of hydrochloric acid was 20%, the leaching temperature was 140°C, the liquid-solid ratio was 8:1, the stirring speed was 400r / min, and the leaching time was 6h. After leaching, it was filtered, and the filtrate was sampled and analyzed. HCl 138.7g / L, Fe in the filtrate T 37.14g / L, Fe 2+30.7g / L. After filtration, the filter residue was washed with dilute hydrochloric acid with a mass concentration of 1.8% until the filtrate was colorless, then dried at 78°C for 11 hours, and then calcined at 1000°C for 2 hours. 2 The content is 91.37%.

Embodiment 2

[0043] Such as figure 1 As shown, take 200 g of ilmenite, add 20 g of calcined petroleum coke as a reducing agent according to 10% by mass, mix well and add into a graphite crucible, and the graphite crucible is roasted at 900 ° C for 120 min in a closed atmosphere furnace; 150g of ilmenite was leached under pressure, the concentration of hydrochloric acid was 20%, the leaching temperature was 140°C, the liquid-solid ratio was 9:1, the leaching time was 8h, the stirring speed was 400r / min, after the leaching was completed, it was filtered, and the filtrate was sampled and analyzed. HCl 144.08g / L, Fe in the filtrate T 35.29g / L, Fe 2+ 28.72g / L. After filtration, the filter residue was washed with dilute hydrochloric acid with a mass concentration of 1.3% until the filtrate was colorless, then dried at 82°C for 10 hours, and then calcined at 1000°C for 2 hours. 2 The content is 93.24%.

Embodiment 3

[0045] Such as figure 1 As shown, take 200 g of ilmenite, add 20 g of calcined petroleum coke as a reducing agent according to 10% by mass, mix well and add into a graphite crucible, and the graphite crucible is roasted at 900 ° C for 120 min in a closed atmosphere furnace; 150g of ilmenite was leached under pressure, the concentration of hydrochloric acid was 24%, the leaching temperature was 140°C, the liquid-solid ratio was 9:1, the leaching time was 8 hours, the stirring speed was 400r / min, after the leaching was completed, it was filtered, and the filtrate was sampled and analyzed. HCl 165.71g / L, Fe in the filtrate T 36.72g / L, Fe 2+ 18.22g / L. After filtration, the filter residue was first dried at 85°C for 10h, and then calcined at 1000°C for 2h, the TiO in the obtained rutile 2 The content is 91.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com