Slag making material for high manganese steel purification treatment

A high-manganese steel, purification technology, applied in the direction of improving process efficiency, etc., can solve problems affecting product quality, unsmooth argon blowing, peeling, etc., to reduce the content of harmful elements and impurities, improve comprehensive mechanical properties, simplify The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation process of the high-purity high-manganese steel includes the design of the system for preparing the high-purity high-manganese steel and the control of process parameters and components.

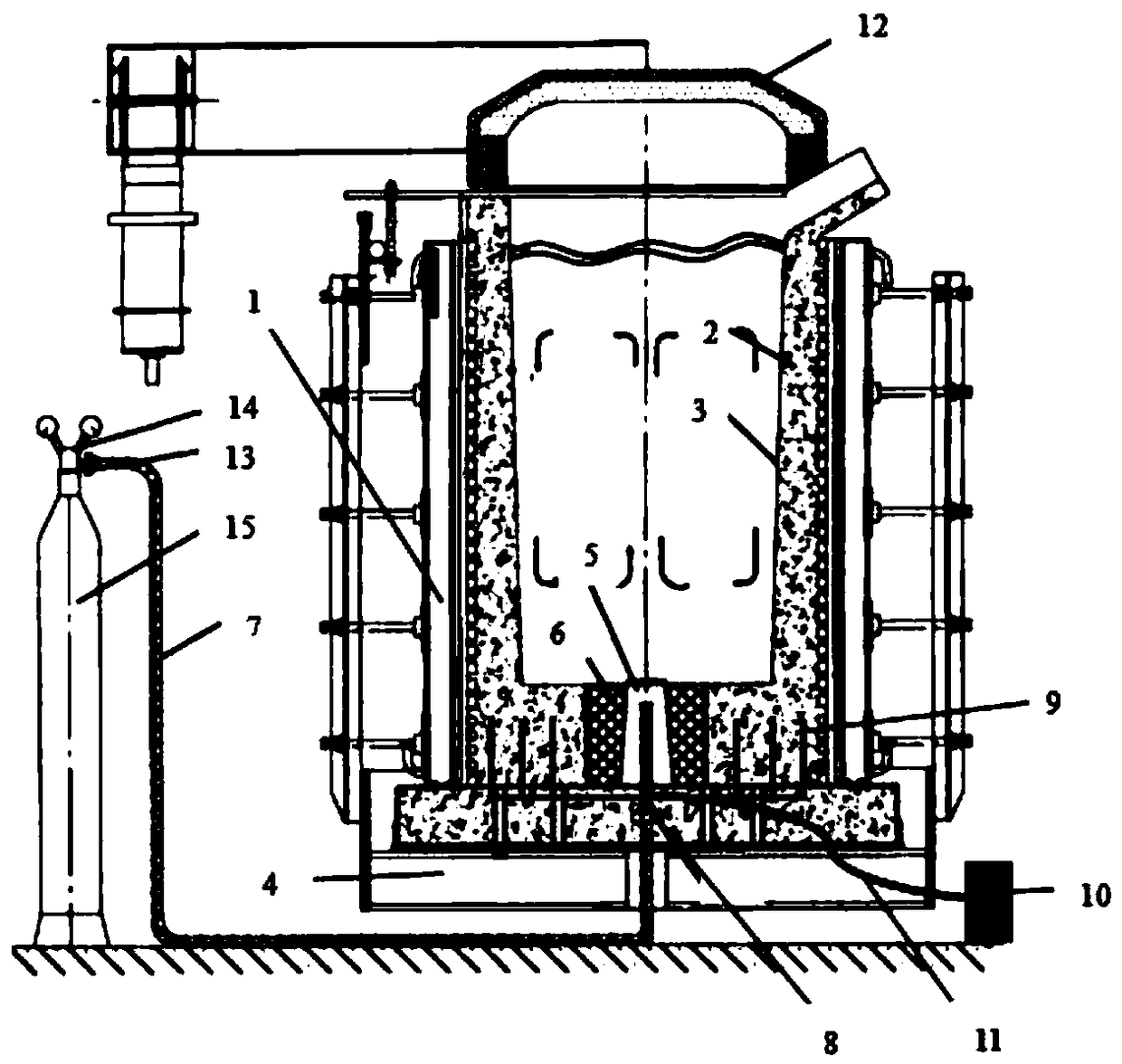

[0055] (1) Design and prepare high-purity high-manganese steel system

[0056] like figure 1 As shown, it includes: furnace shell 1, furnace lining 2, furnace wall layer (crucible) 3, base 4, gas diffuser 5, ventilation brick 6, air intake pipe 7, live joint 8, furnace body protection contact 9, contact protection device 10, wire 11, furnace cover 12, flow regulator 13, pressure reducing valve 14, argon gas bottle 15, the furnace shell 1 wraps the furnace lining 2, the outer surface of the furnace lining 2 is provided with a furnace wall layer 3, the The bottom of the furnace shell 1 is provided with a base 4, and above the base 4 is provided a gas diffuser 5 and a gas diffuser 6, the gas diffuser 5 is wrapped by the gas diffuser 6, and the gas inlet pipe 7 is connect...

Embodiment 1

[0136] A breathable brick, in parts by weight, comprising the following raw materials: 32 parts of forsterite sand with a particle radius of 1.62-2.31mm, 12 parts of forsterite sand with a particle radius of 1.08-1.62mm, and a particle radius of 0.87- 20 parts of forsterite sand of 1.08mm, 11 parts of fused magnesia with a particle radius of 1.34-1.79mm, 6 parts of fused magnesia with a particle radius of 0.92-1.34mm, and fused magnesia with a particle radius of 0.81-0.92mm 12 parts of magnesia, 12 parts of corundum with particle radius of 1.56-2.08mm, 4 parts of corundum with particle radius of 1.07-1.56mm, 5 parts of magnesium silicate cement, 3 parts of sodium silicate with particle radius of 1.52-2.94nm, 5 parts of sodium permanganate, 0.2 parts of explosion-proof admixture, 0.4 parts of polycarboxylic acid dispersion water reducer, 12 parts of water;

[0137] Forsterite sand MgO of the three different particle radii: ≥43.46%; SiO 2 : 36.92-39.27%;

[0138] The fused mag...

Embodiment 2

[0150] A breathable brick, in parts by weight, comprising the following raw materials: 36 parts of forsterite sand with a particle radius of 1.62-2.06mm, 16 parts of forsterite sand with a particle radius of 1.08-1.62mm, and a particle radius of 0.94- 22 parts of forsterite sand of 1.08mm, 14 parts of fused magnesia with a particle radius of 1.34-1.76mm, 8 parts of fused magnesia with a particle radius of 0.92-1.34mm, and fused magnesia with a particle radius of 0.81-0.92mm 10 parts of magnesia, 15 parts of corundum with particle radius of 1.56-1.96mm, 6 parts of corundum with particle radius of 1.35-1.56mm, 6 parts of magnesium silicate cement, 4 parts of sodium silicate with particle radius of 1.23-3.07nm, 6 parts of sodium permanganate, 0.4 parts of explosion-proof admixture, 0.6 parts of polycarboxylic acid dispersion water reducer, 13 parts of water;

[0151] Forsterite sand MgO of the three different particle radii: ≥46.02%; SiO 2 : 36.92-39.04%;

[0152] The fused mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com