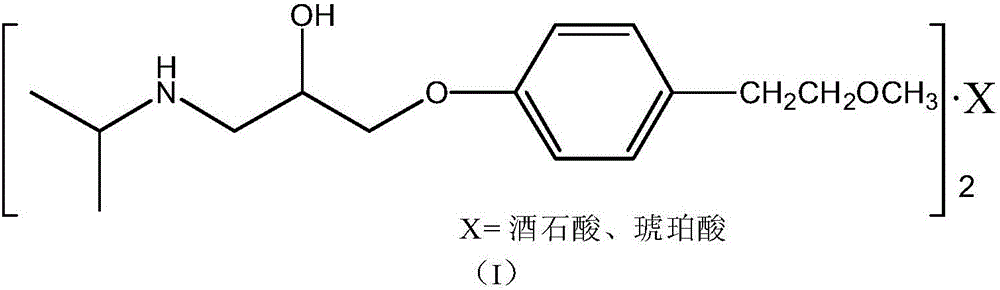

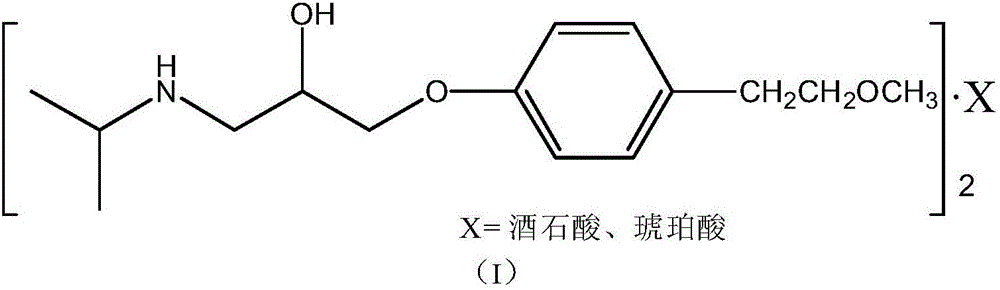

Method for preparing metoprolol salt

A technology of mixed solvent and acetone, which is applied in the field of metoprolol salt preparation, can solve the problems of complex pH value detection process, difficult removal of impurities, long reaction time, etc., and achieve easy recycling, reduction of three wastes discharge, and simple treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First the mixed system of tartaric acid (0.5mol, 75g), acetone (890g) and water (61.4g) was warmed up and refluxed until tartaric acid was completely dissolved, then under reflux, formula (II) metoprolol (1mol, 267g) Add the mixed solution of acetone (311.5g) dropwise to the solution, after the dropwise addition, keep it warm at 50-65°C for 0.5 hours, cool to 0-5°C, stir and crystallize for 1 hour, after the crystallization , suction filtration, drying to obtain formula (I) metoprolol salt 307.22g, productive rate 89.7%.

Embodiment 2

[0031] First the mixed system of tartaric acid (0.5mol, 75g), acetone (890g) and water (61.4g) was warmed up and refluxed until tartaric acid was completely dissolved, then under reflux, formula (II) metoprolol (1mol, 267g) Add the mixed solution of acetone (311.5g) dropwise to the solution, after the dropwise addition, keep it warm at 50-65°C for 1 hour, cool to 0-5°C, stir and crystallize for 1 hour, after the crystallization , suction filtration, drying to obtain formula (I) metoprolol salt 307.57g, productive rate 89.8%.

Embodiment 3

[0033] First the mixed system of tartaric acid (0.5mol, 75g), acetone (890g) and water (61.4g) was warmed up and refluxed until tartaric acid was completely dissolved, then under reflux, formula (II) metoprolol (1mol, 267g) Add the mixed solution of acetone (311.5g) dropwise to the solution, after the dropwise addition, keep it warm at 50-65°C for 0.5 hours, cool to 0-5°C, stir and crystallize for 2 hours, after the crystallization , suction filtration, drying to obtain formula (I) metoprolol salt 320.24g, productive rate 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com