Preparation method of theaflavin composite

A theaflavin and complex technology, which is applied in the field of preparation and purification of high-purity theaflavin complex, can solve the problems of high cost, large dead adsorption, low content of theaflavin, etc. The effect of strong miscellaneous ability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

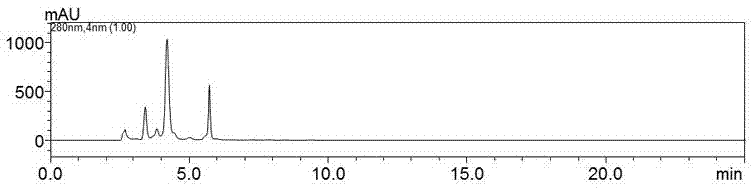

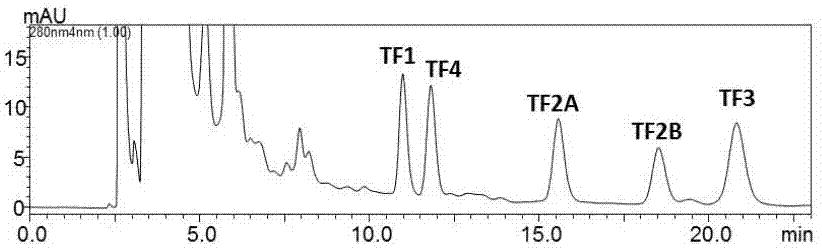

[0024] Crude theaflavins are green tea polyphenol extracts (catechins>80%, of which epigallocatechin gallate EGCG>40%) are produced by polyphenol oxidase reaction. The total substance content is 4.06% (of which TF1 is 0.67%, TF2A is 1.20%, TF2B is 0.86%, TF3 is 0.88%, and TF4 is 0.45%). According to the ratio of 19g crude theaflavin (containing 770 mg of theaflavin complex) plus 50 mL of 30% volume concentration ethanol aqueous solution, the above crude theaflavin was dissolved in ethanol aqueous solution, and the sample was loaded on the chromatograph equipped with MCI CHP20P Column (5.5cm×30cm), first eluted with 2 BV of 30% ethanol water at a flow rate of 1.0 BV / h, and then eluted with 70% ethanol water at a flow rate of 1.0 BV / h, and collected 70 % volume concentration of the ethanol water eluate, the eluate was concentrated in vacuo at 30°C to recover ethanol; then fully extracted with an equal volume of ethyl acetate, the ester layer was vacuum-dried at 45°C, and ethyl a...

Embodiment 2

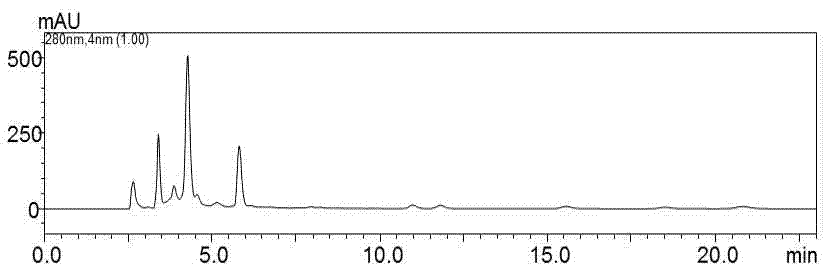

[0026] Crude theaflavins are produced from green tea polyphenol extracts by polyphenol oxidase, and the content of theaflavins is 8.65% (of which TF1 is 0.98%, TF2A is 2.30%, TF2B is 2.32%, TF3 is 2.11%, TF4 is 0.93%). According to the ratio of 16 g crude theaflavin (containing 1.38 g of theaflavin complex) plus 40 mL of 40% volume concentration ethanol aqueous solution, the above crude theaflavin was dissolved in ethanol aqueous solution, and the sample was loaded on the chromatograph equipped with MCI CHP20P The column was first eluted with 4 BV 40% volume concentration of ethanol water at a flow rate of 1.0 BV / h, and then 60% volume concentration of ethanol water was eluted at a flow rate of 1.0 BV / h, and the 60% volume concentration of ethanol water was collected. Eluate, concentrate the eluate in vacuum at 30°C to recover ethanol; then fully extract with an equal volume of ethyl acetate, dry the ester layer in vacuum at 45°C, recover ethyl acetate, and dry to obtain high-pu...

Embodiment 3

[0028] The crude product of theaflavins is the commercially available Keemun black tea extract, the content of the theaflavins complex is 7.26% (0.95% for TF1, 1.40% for TF2A, 1.94% for TF2B, 2.18% for TF3, 0.80% for TF4 %). According to the ratio of 15 g of crude theaflavin (containing 1.09 g of theaflavin complex) plus 40 mL of 25% volume concentration of methanol aqueous solution, the above crude theaflavin was dissolved in methanol aqueous solution, and the sample was loaded on a chromatograph equipped with MCI CHP20P The column was first eluted with 2 BV of 25% volume concentration of methanol water at a flow rate of 1.0 BV / h, and then 80% volume concentration of methanol water was eluted at a flow rate of 1.0 BV / h, and the 80% volume concentration of methanol water was collected. Eluate, concentrate the eluate in vacuum at 30°C to recover ethanol; then fully extract with an equal volume of ethyl acetate, dry the ester layer in vacuum at 45°C, recover ethyl acetate, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com