Two-section preparation method of hydrogenated petroleum resin

A hydrogenated petroleum resin, a two-stage technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of affecting the service life of catalyst hydrogenation activity, Poisoning and deactivation of palladium precious metal catalysts, etc., to achieve good hydrogenation effect, good activity stability, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

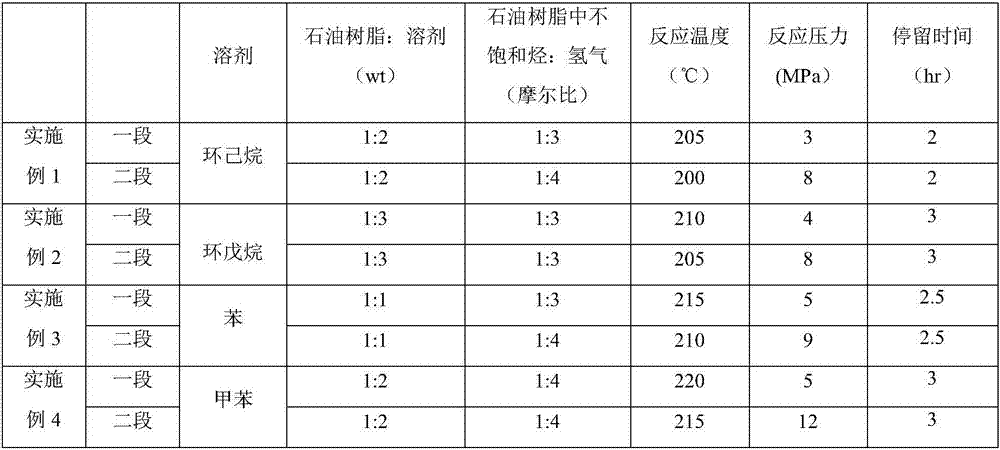

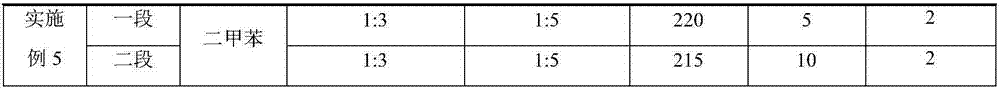

Examples

Embodiment 1

[0041] Preparation of carrier: firstly equip with γ-Al 2 O 3 The sol was coated on the surface of 80g spherical activated carbon by 7 times dipping method. The dipping time was 10 minutes each time. The dipping temperature was normal temperature and pressure. After filtration, it was dried at 40℃, and then dried in N 2 Γ-Al can be obtained by firing at 400 ℃ in the atmosphere 2 O 3 Film-coated activated carbon carrier, the weight ratio of alumina and activated carbon is 4:1;

[0042] Preparation of the palladium catalyst: prepare an aqueous solution of palladium nitrate with a concentration of 0.7 mol / L, and the concentration of the ammonium metatungstate solution of the metal promoter is 0.8 mol / L. Using an equal volume impregnation method, 100 g of the carrier prepared above is immersed in nitric acid Soak in salt and ammonium metatungstate solution for 5 hours at room temperature, and dry the catalyst precursor at 110°C for 6 hours. 2 After calcining at 500°C for 7 hours, the fi...

Embodiment 2

[0046] Preparation of carrier: firstly equip with γ-Al 2 O 3 The sol was coated on the surface of 80g spherical activated carbon by 9 times dipping method. The dipping time is 15 minutes each time. The dipping temperature is normal temperature and pressure. After filtration, it is dried at 45°C, and then fired at 450°C under N2 atmosphere. You can get γ-Al 2 O 3 The membrane-coated activated carbon carrier, the weight ratio of alumina or activated carbon is 5:1.

[0047] Preparation of the palladium catalyst: prepare an aqueous solution of palladium nitrate with a concentration of 0.6 mol / L, and the concentration of the ammonium metatungstate solution of the metal promoter is 0.5 mol / L. Using an equal volume impregnation method, 100 g of the carrier prepared above is immersed in nitric acid In the salt solution, immerse the catalyst precursor at a temperature of 40℃ for 4h, and dry the catalyst precursor at 110℃ for 5h. 2 It is calcined at 600°C for 8 hours to obtain a finished pr...

Embodiment 3

[0051] Preparation of carrier: firstly equip with γ-Al 2 O 3 The sol is coated on the surface of 80g spherical activated carbon by 10 times dipping method, each dipping time is 13min, the dipping temperature is normal temperature and pressure, after filtering, drying at 38℃, and then drying in N 2 Γ-Al can be obtained by firing at 500 ℃ in the atmosphere 2 O 3 The membrane-coated activated carbon carrier, the weight ratio of alumina or activated carbon is 6:1.

[0052] Preparation of palladium catalyst: prepare an aqueous solution of palladium nitrate with a concentration of 0.8 mol / L, the concentration of the ammonium metatungstate solution of the metal promoter is 0.9 mol / L, and use an isometric dipping method to immerse 100 g of the above-prepared carrier in nitric acid Soak in salt solution for 6h at room temperature, and dry the catalyst precursor at 115℃ for 5h. 2 It is calcined at 450°C for 8 hours to obtain a finished product with a metal palladium content of 0.34% and a me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com