Ultrasonic dust removing device for spinning

A technology of dust removal device and ultrasonic wave, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as production stagnation, equipment failure, interference, etc. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

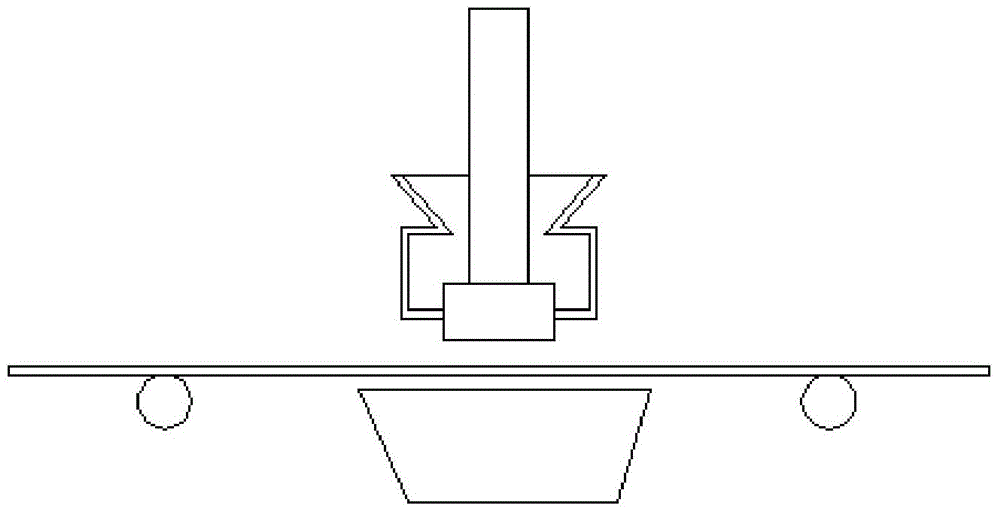

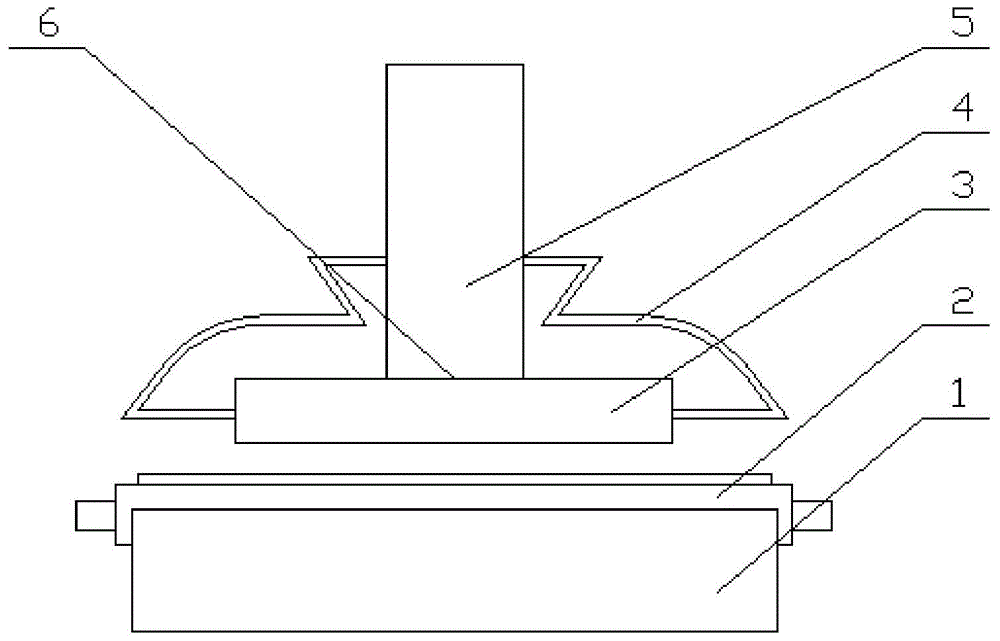

[0013] Such as figure 1 with figure 2 As shown, a textile ultrasonic dedusting device includes an ultrasonic mechanism 6, a transmission mechanism 2, a wind cover 4, and a waste hopper 1; the ultrasonic mechanism 6 includes a welding head 3 and an ultrasonic generator 5, and the ultrasonic mechanism 6 is placed on Above, the distance between the welding head 3 and the textile material is between 1-10mm, and its width is slightly smaller than the width of the textile material. This mechanism uses ultrasonic dust removal to make the textile material vibrate at high frequency to remove impurities, and its effect is more obvious than the existing airflow dust removal effect ; The windshield 4 passes through the ultrasonic generator 5 and covers the welding head 3, the air outlet of the windshield 4 is consistent with the textile material, and the height of the air outlet is 2-3cm higher than the bottom of the welding head 3, and its air inlet is an inverted cone structure, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com