Bottom blowing refining furnace and application thereof

A refining furnace and furnace mouth technology, which is applied in the field of bottom blowing refining furnaces, can solve the problems that refining efficiency needs to be improved and the structure is complicated, and achieve the effects of improving redox efficiency, simplifying furnace body structure and reducing equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

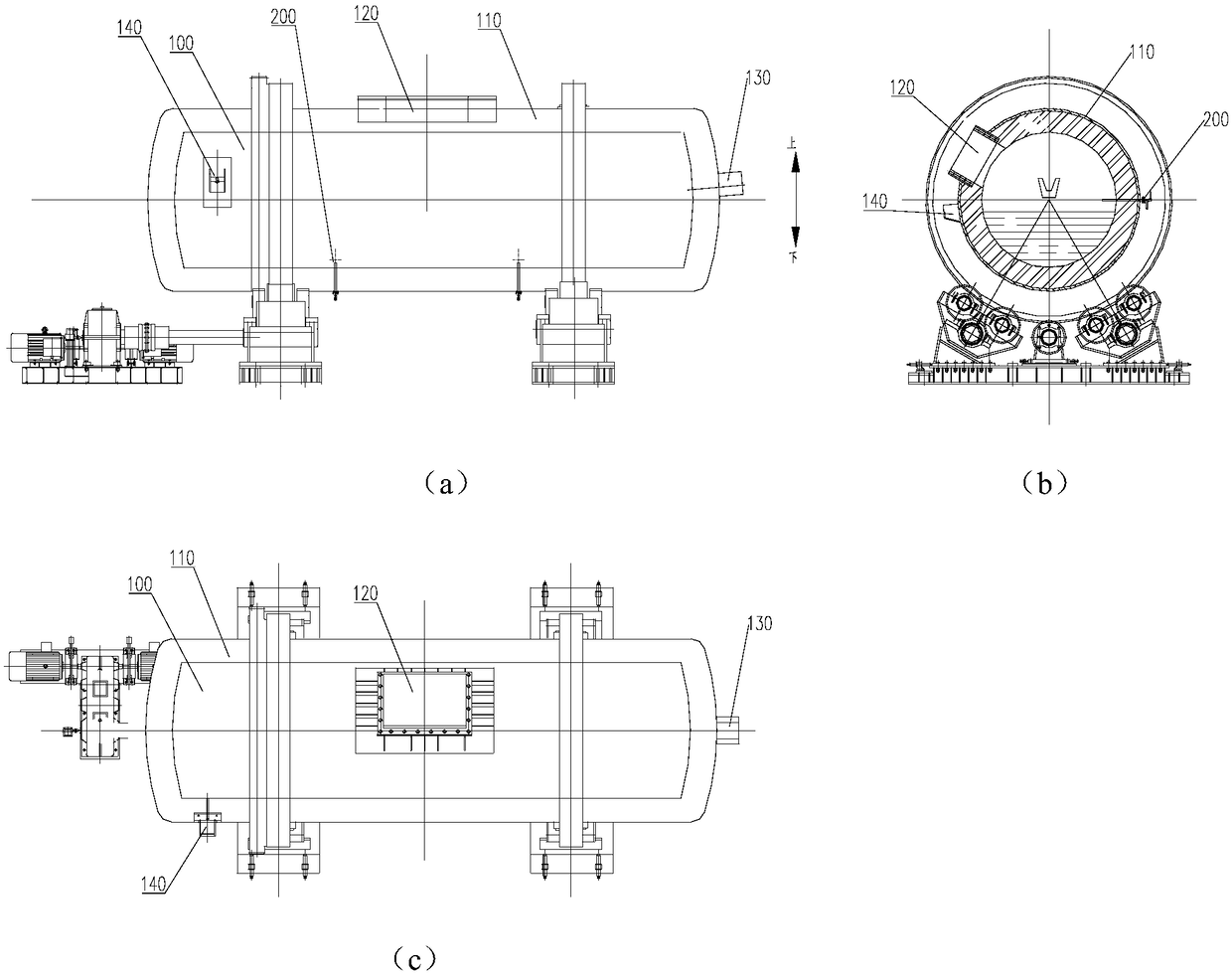

[0084] The furnace body specification of the bottom-blown refining furnace is Ф5.0m×15.5m, including the rotary furnace and the bottom-blown redox gun. The copper port, the copper discharge port and the burner port, the shell of the rotary furnace is steel structure, lined with refractory material, the copper inlet is also used as the smoke outlet, and there is a smoke hood around it. The copper outlet is set on the side wall of the end of the rotary furnace shell, the copper inlet is set on the upper part of the cylindrical side of the rotary furnace shell at the other end opposite to the copper outlet, and the furnace mouth is set on the middle section of the rotary furnace shell. In the upper part, there is a cooling water jacket at the furnace mouth, and the flue gas is discharged from the copper inlet. The burner mouth is set on the end wall of the rotary furnace shell near the copper outlet, and the burner mouth is equipped with a pure oxygen burner to heat the furnace bo...

Embodiment 2

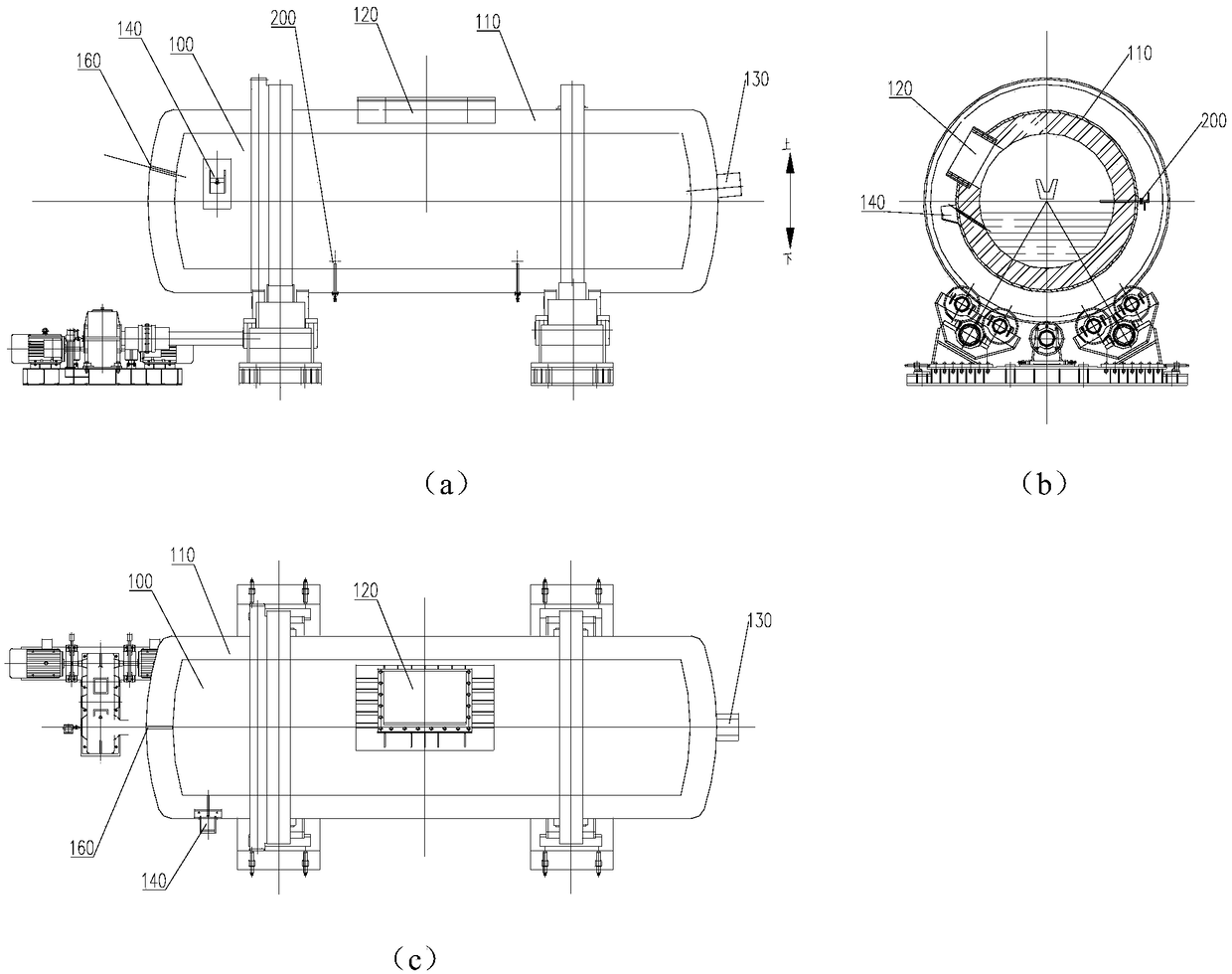

[0087] The furnace body specification of the bottom-blown refining furnace is Ф4.0m×12.5m, including the rotary furnace and the bottom-blown redox gun. The rotary furnace includes the rotary furnace shell, the furnace mouth, the smoke outlet, the copper inlet, the copper discharge port and the burner mouth. The copper inlet is set on the side wall of the end of the rotary furnace shell, and the copper inlet is set on the end wall of the other end of the rotary furnace shell opposite to the copper outlet, and is located at 300mm from the center line of the furnace body. The mouth is set on the upper part of the middle section of the rotary furnace shell, and the flue gas is discharged from the smoke outlet. The smoke outlet is set on the side wall of the upper part of the furnace body near the copper inlet of the rotary furnace shell, and along the radial direction Above, the smoke outlet is located between the furnace mouth and the bottom blowing redox gun, and close to the fu...

Embodiment 3

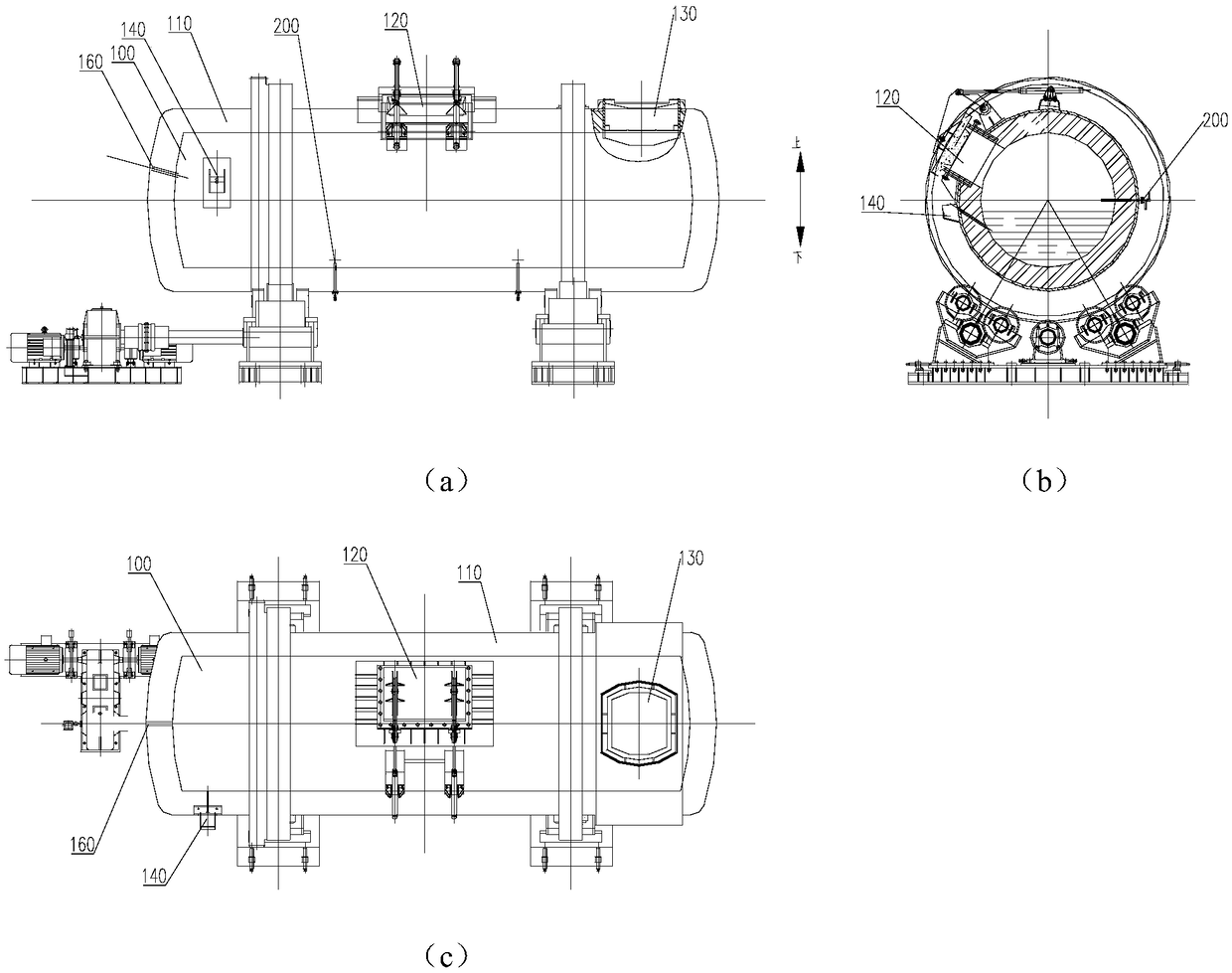

[0090]The furnace body specification of the bottom-blown refining furnace is Ф3.6m×11.5m, including the rotary furnace and the bottom-blown redox gun. The rotary furnace includes the rotary furnace shell, the furnace mouth, the copper inlet, and the copper discharge port. structure, lined with refractory material. The copper inlet is set on the side wall of the end of the rotary furnace shell, and the copper inlet is set on the end wall of the other end of the rotary furnace shell opposite to the copper outlet, and is located at 200mm from the center line of the furnace body. The mouth is set on the upper part of the middle section of the rotary furnace shell, and the furnace mouth is equipped with a fume cover, and the flue gas is discharged from the furnace mouth. Seen from the radial direction of the rotary furnace, the bottom blowing redox gun and the copper outlet are located on both sides of the furnace mouth. , and along the circumferential direction of the rotary furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com