Food processing stirrer

A technology for food processing and mixers, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of general mixing effect of mixing rods, single mixing form, and insufficient mixing, and achieves increased mixing effect. Improve mixing efficiency and increase the effect of diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

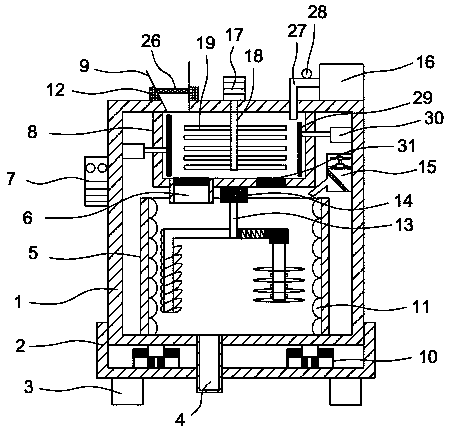

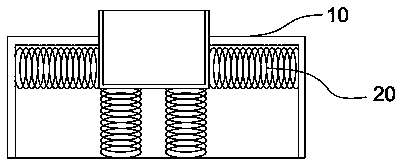

[0024] Such as Figure 1-3As shown, the scheme adopted by the present invention to achieve the above object is: a food processing mixer, comprising a housing 1, the side wall of the housing 1 is provided with a control panel 7, the top of the housing 1 is provided with a crushing box 8, and the lower end of the crushing box 8 is A stirring box 5 is provided, and push plates 29 are provided on both sides of the crushing box 8, and the surface of the pushing plate 29 is connected to the output end of the electric push rod 30 provided on the top of the housing 1, and a weight sensor 31 is provided on the bottom side of the crushing box 8 , by setting a control panel on the side wall of the housing, it is used to control the intelligent operation of each power component in the device and improve the intelligent level of the device. The weight sensor installed at the bottom of the box detects that the weight of food accumulated on one side of the crushing box exceeds the preset val...

Embodiment 2

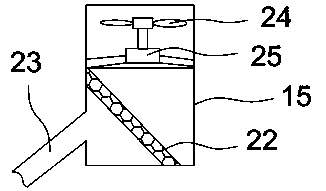

[0032] Such as Figure 4-5 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the inner wall of the stirring box 5 is evenly distributed with spoilers 11, and the upper part of the stirring box 5 is provided with a stirring motor a14 installed at the bottom of the crushing box 8, stirring The output end of the motor a14 is connected to the main shaft 13, one side of the main shaft 13 is connected with the L-shaped stirring rod 137, and the vertical side of the L-shaped stirring rod 137 is evenly arranged on one side near the stirring box 5 with arc-shaped scraping bars 136, and the L-shaped stirring rod 137 is vertical A stirring wire 131 is provided on the other side of the side. A stirring motor a is installed above the mixing box and installed at the bottom of the crushing box. The output end of the stirring motor a is connected to the main shaft. By running the stirring motor a, the main shaft is rotated, which drives the L-shaped stirrin...

Embodiment 3

[0035] The working principle of the food processing mixer of the present invention is: put the food to be processed into the pulverizing box 8 from the discharge port 9, start the pulverizing motor 17 through the control panel 7 to drive the pulverizing pieces 19 on the rotating shaft to pulverize the food, and pulverize the pulverized food. The food falls into the mixing box 5 from the bulk material port 6 and stirs. When processing different foods, the water feeder 16 can be started to add water at a suitable temperature to the mixing box 5 for stirring. The dust collector 15 can Dust generated during the stirring process is adsorbed, and the anti-vibration base 10 plays a role of shock absorption during the crushing and stirring process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com