Patents

Literature

34results about How to "Shorten the refining cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

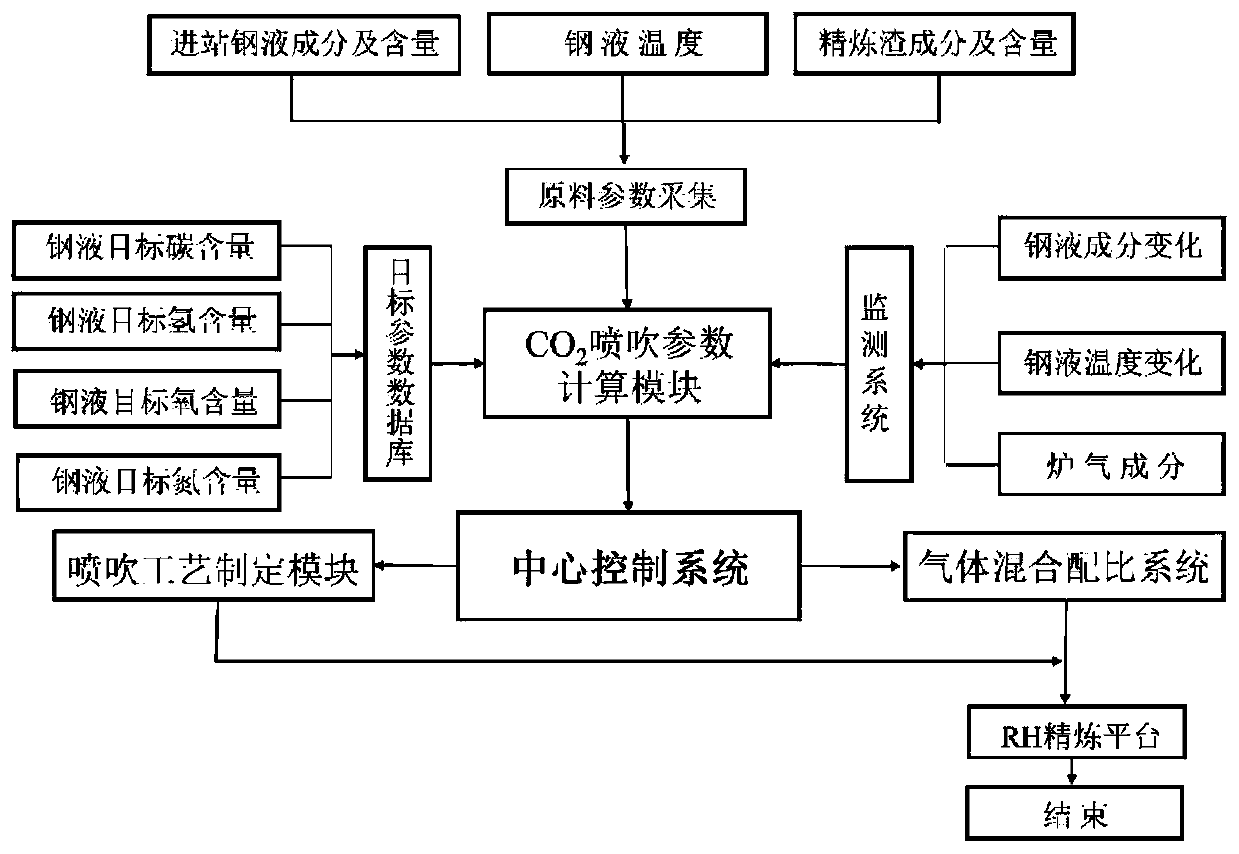

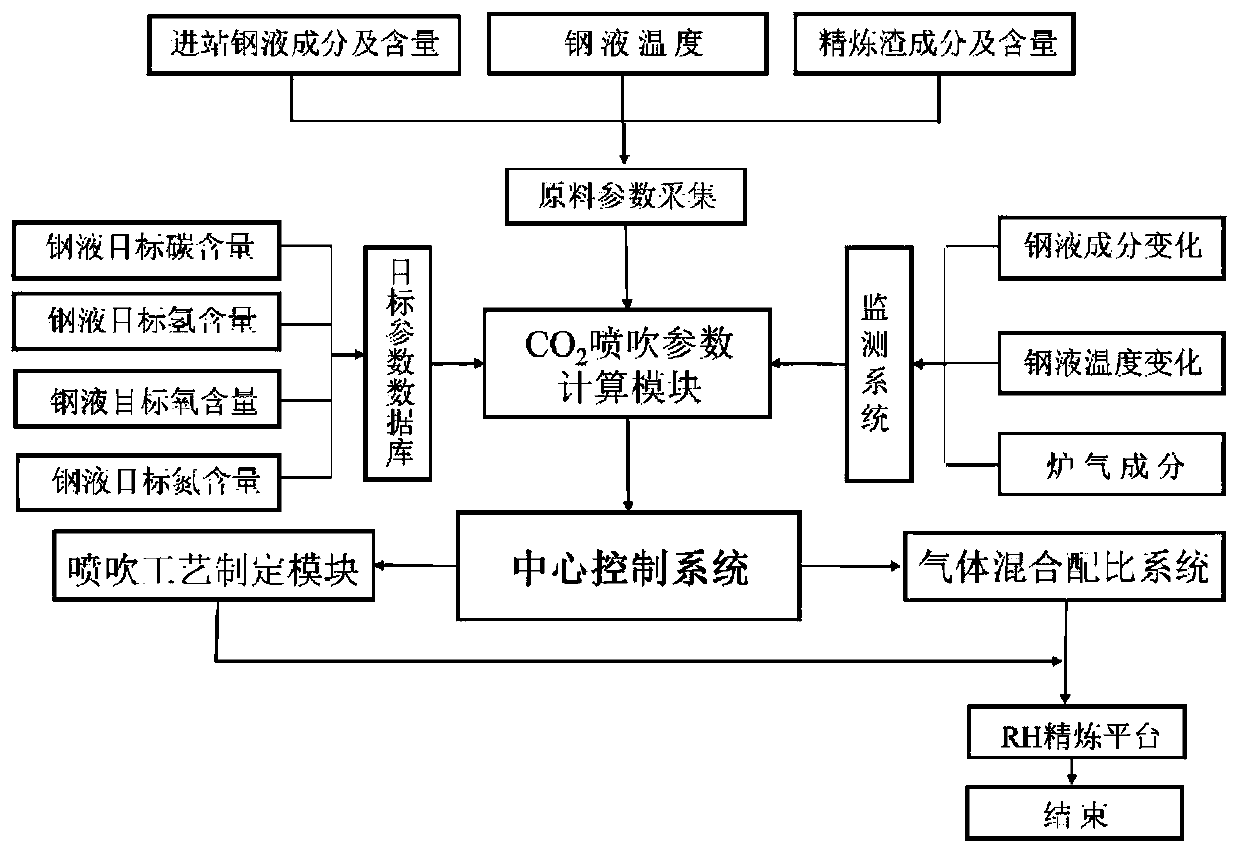

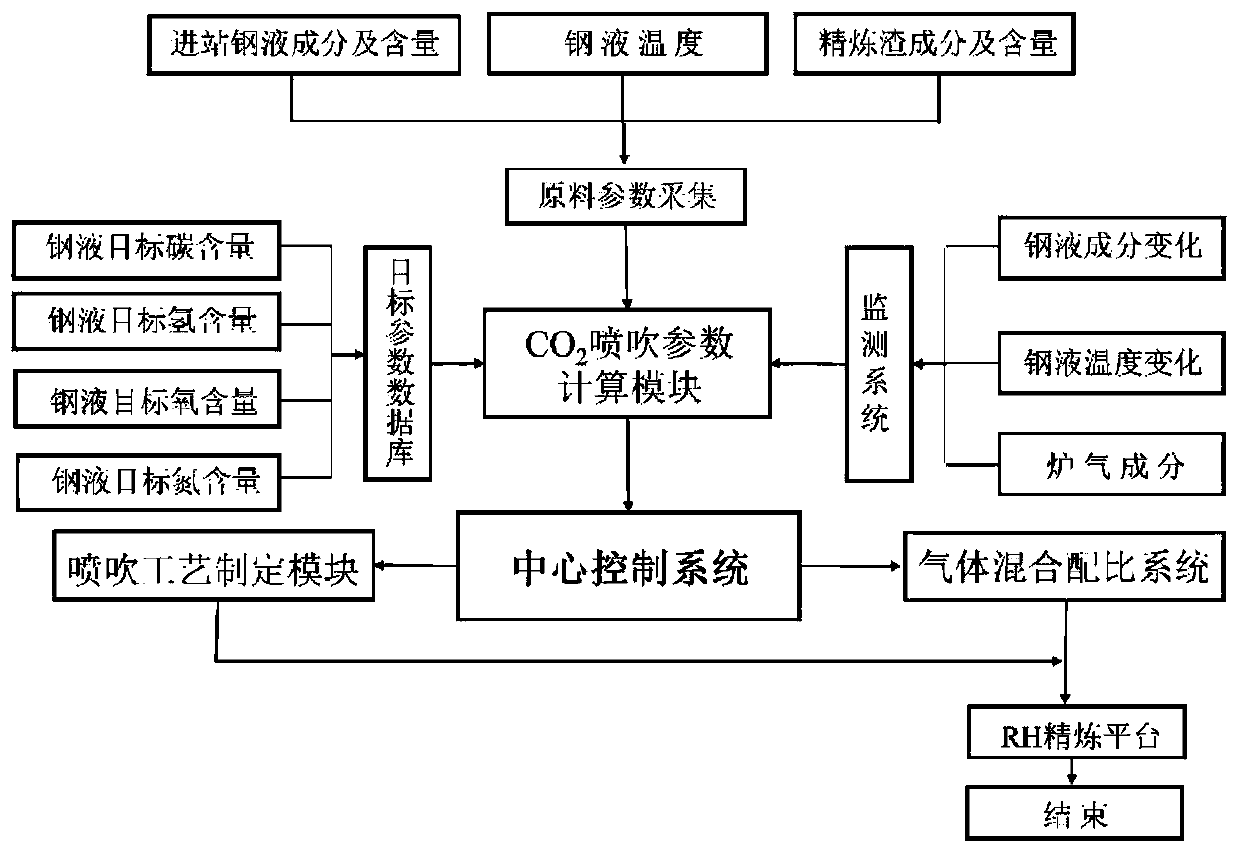

Dynamic control method for refining ultra-low carbon steel through RH CO2 spraying

The invention belongs to the technical field of steelmaking, and particularly relates to a dynamic control method for refining ultra-low carbon steel through RH CO2 spraying. The dynamic control method is suitable for a 30-300 t RH ladle refining process. In the RH refining process, O2 and CO2 are adopted as top-blowing gases, Ar and CO2 are used as lifting gases; molten steel components in the refining process are predicted based on material conservation according to RH refining in-station molten steel component data, refining process furnace gas component data and vacuum equipment working conditions; the top blowing and lifting gas flow is dynamically adjusted according to requirements of target components of refined molten steel stage by stage; on the basis of strengthening the stirringeffect of the RH refining process, the nitrogen content in the molten steel is further reduced, and the quality of molten steel is improved; and meanwhile, excessive oxidation of the molten steel inthe RH decarbonization process is avoided, the consumption of a deoxidized alloy is reduced, and on the basis of reducing the consumption of Ar, the production cost is further reduced, and the refining period is shortened. As a result, the alloy consumption is reduced by 3%-8%, the RH refining period is shortened by 1-2 minutes, the denitrification amount is increased by (3-10)*10<-6>, and the quality of the molten steel is improved.

Owner:UNIV OF SCI & TECH BEIJING

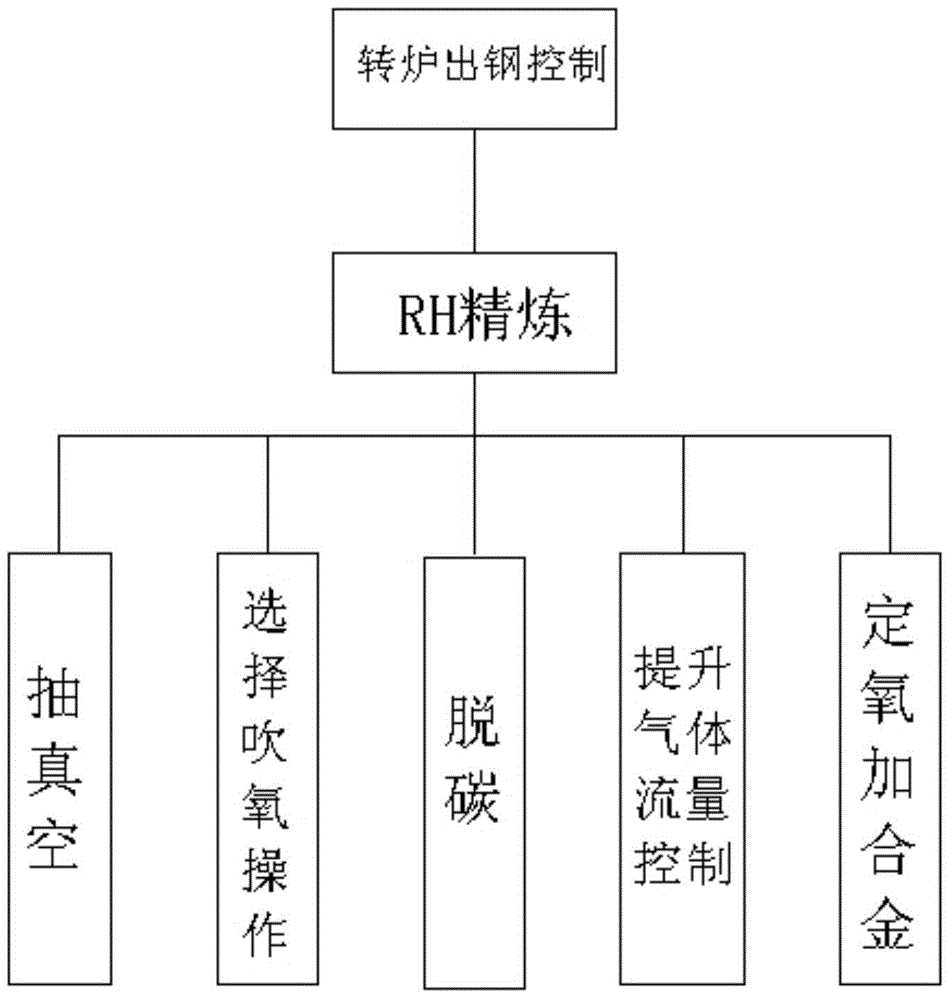

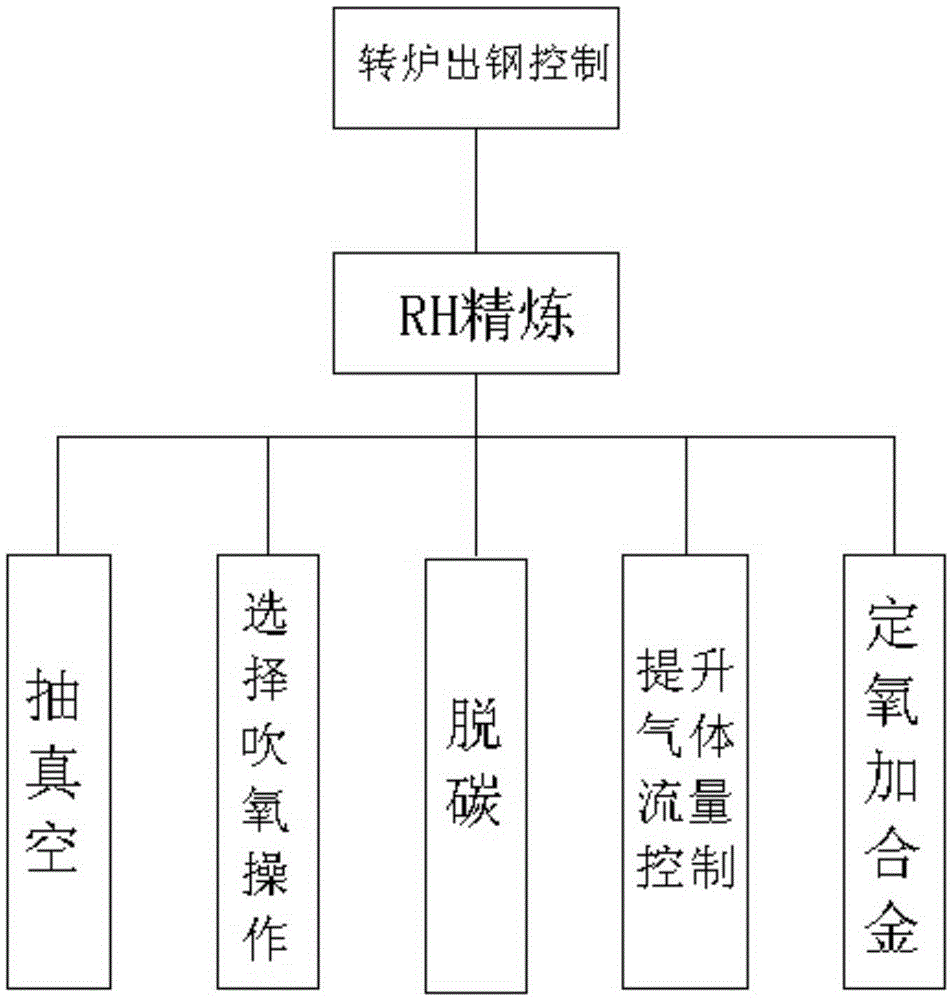

RH fast decarbonization method

ActiveCN104099445AShorten the refining cycleEfficient and fast decarbonizationMetallurgyOxygen content

The invention relates to an RH fast decarbonization method. The method comprises the following steps: the terminal control of a converter is performed; the temperature of the steel tapping terminal of the converter is controlled within 1675-1705 DEG C; by the mass percentage, the C content at the steel tapping terminal of the converter is controlled within 0.02-0.045%; by the mass percentage, the oxygen content is controlled within 900 ppm; after the steel tapping of the converter is finished, the RH refining is performed; the inlet temperature of molten steel is controlled within 1610-1640 DEG C; an RH judges if the oxygen blowing decarbonization is needed according to the inlet conditions and the carbon-oxygen relation, if so, the oxygen blowing should be performed within 4 min at the beginning of the vacuumizing, and the oxygen blowing quantity is not greater than 150 m3; and the gas flow is increased in the refining process. The method is suitable for the deep decarbonization process of ultralow carbon steel, and can decarbonize the molten steel C below 10*10-6 within 12 min, so that the efficient and fast decarbonization is realized, the RH refining period is shortened, and the temperature drop in the refining process is reduced.

Owner:SHOUGANG CORPORATION

Method for controlling aluminum component in steel

InactiveCN102021276AReduce entryReduce deoxygenation burdenProcess efficiency improvementMolten steelMolten slag

The invention belongs to the technical field of ferrous metallurgy and relates to a method for controlling an aluminum component in steel. In order to solve technical problems, the invention provides the method for precisely and stably controlling the aluminum component in steel, particularly the aluminum component in low-carbon aluminium steel. The control method comprises the following steps of: A, smelting in an electric furnace or a converter, wherein the primarily smelted molten steel is deoxidized by aluminum after the molten steel is discharged; B, low-frequency (LF) refining; and C, continuous casting. The control method is characterized in that: in the LF refining process, the adding amount of slag is 12 to 14Kg per ton of steel during slagging; and based on 100 weight parts, the slag mainly comprises the following components in part by weight: 60 to 68 parts of CaO, 15 to 20 parts of Al203, more than zero part and less than or equal to 5.0 parts of SiO2, more than zero part and less than or equal to 3.0 parts of MgO and 10 to 15 parts of CaF2. When the control method is used, the activity of SiO2 in the slag can be reduced, and the probability of reaction between aluminum in the steel and SiO2 in the slag can be reduced, so that the aluminum component in the molten steel is precisely controlled and the desulfurization rate of the molten slag is also improved at the same time.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

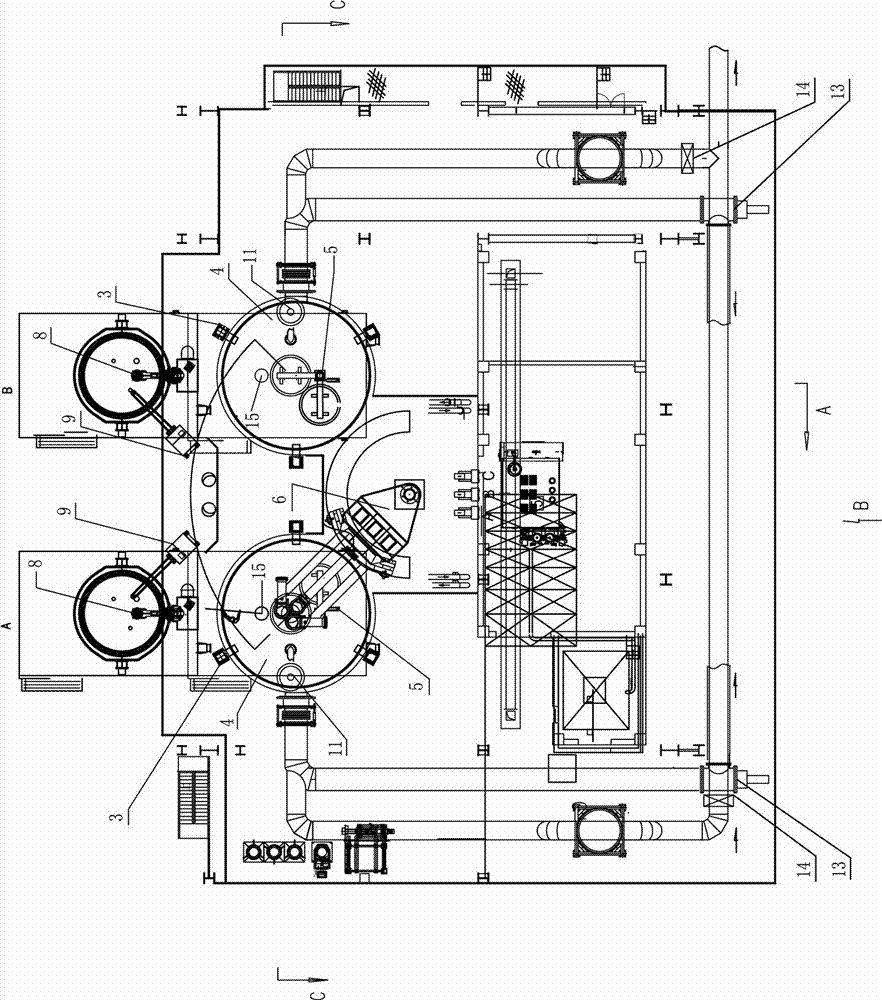

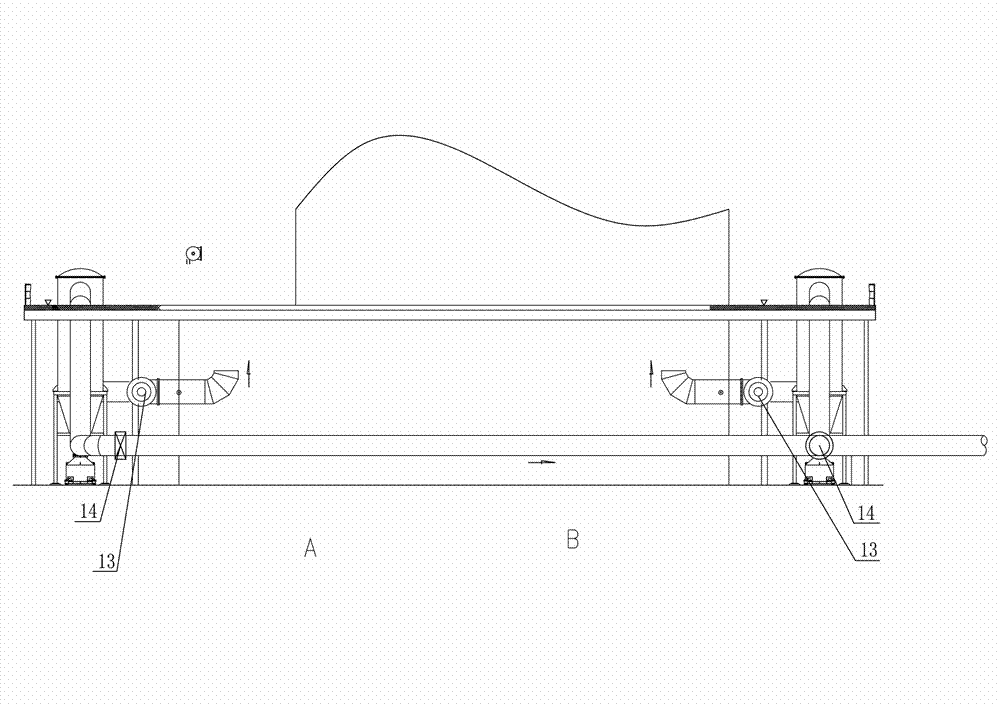

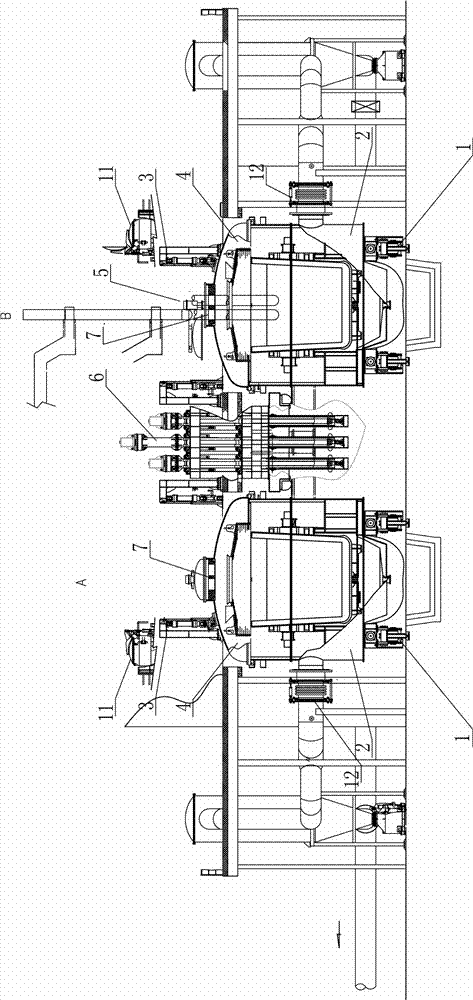

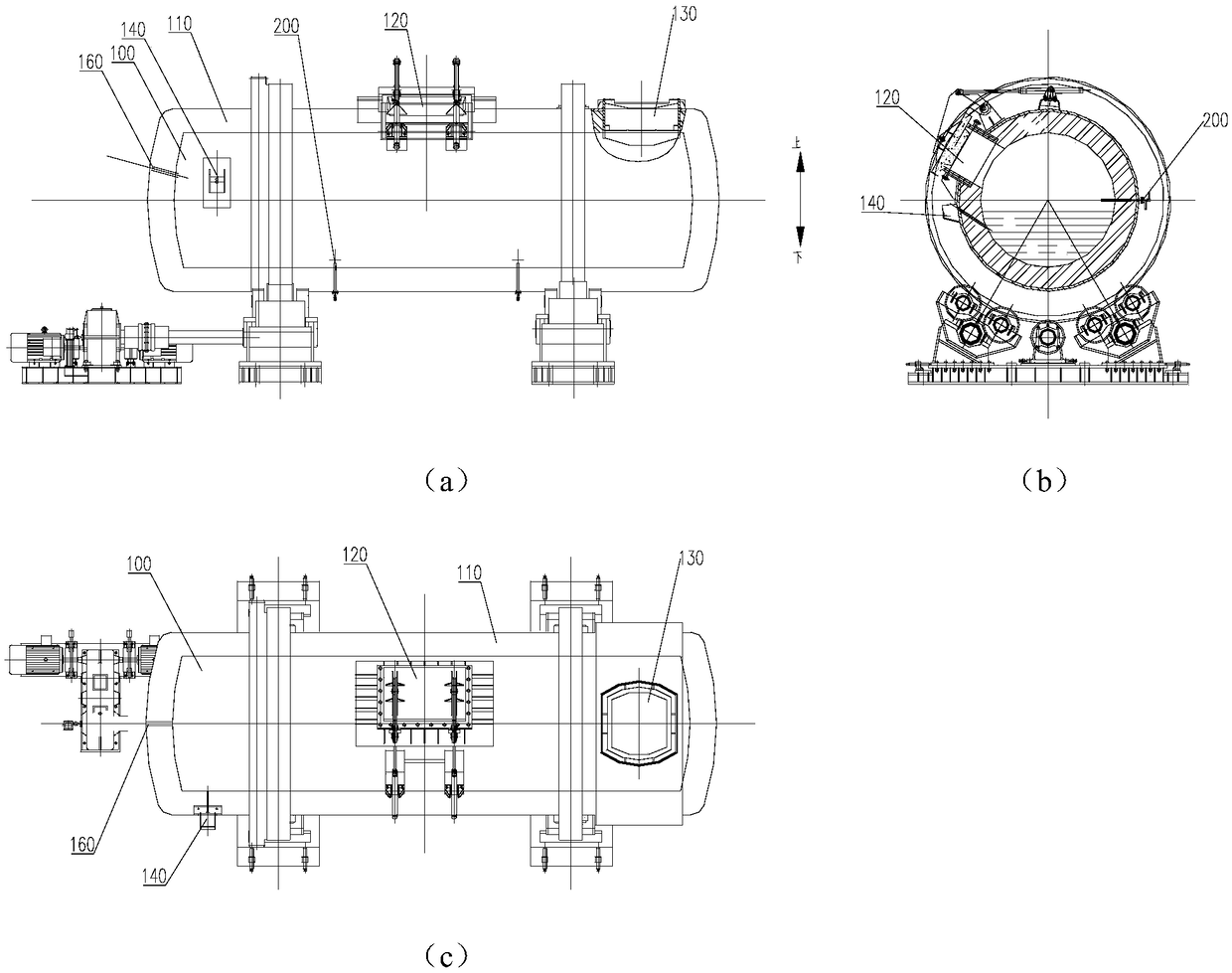

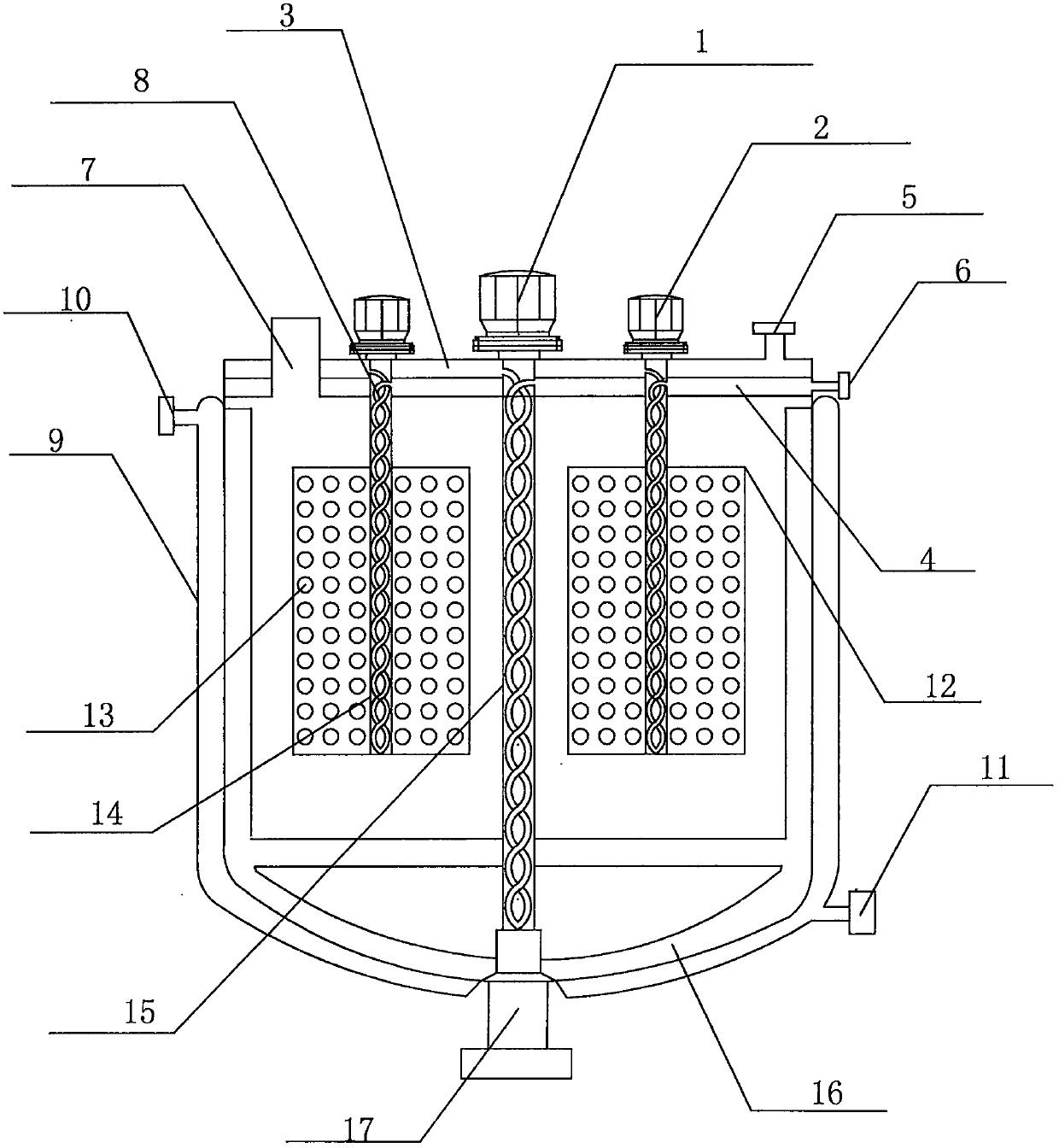

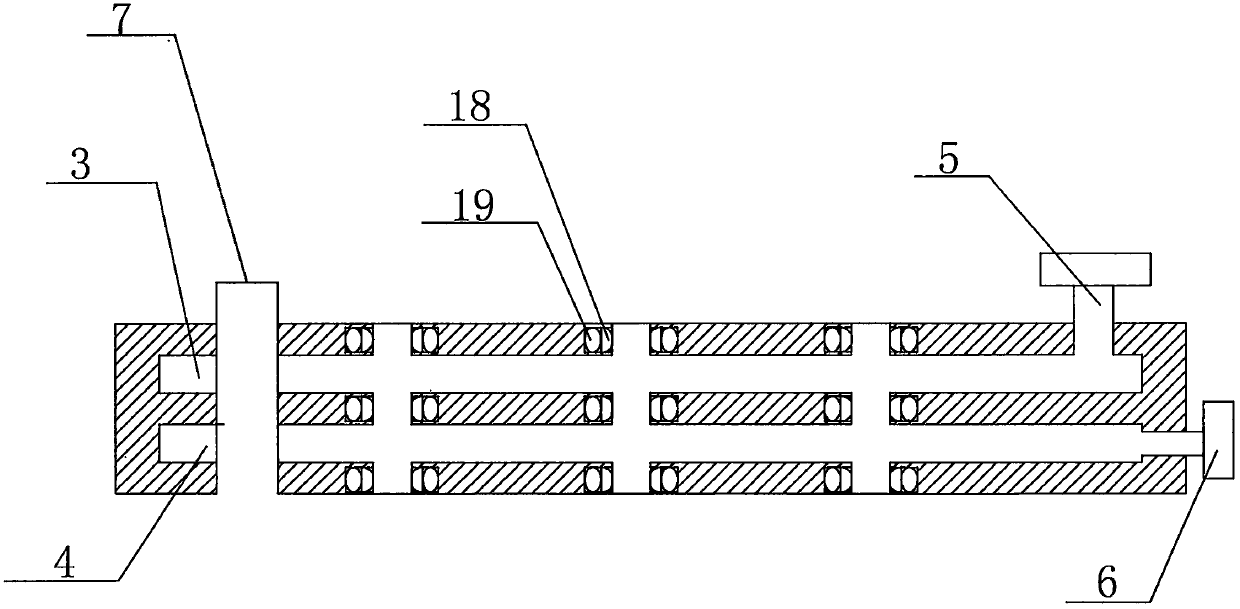

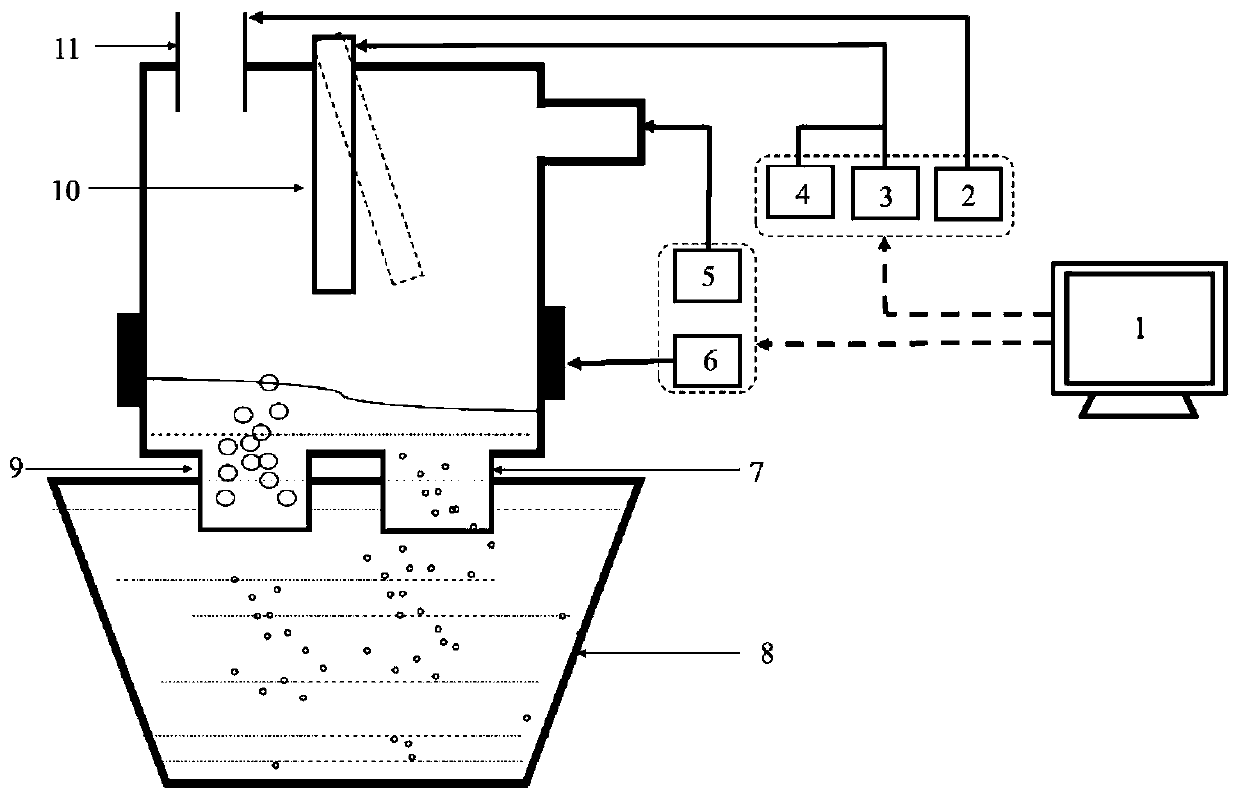

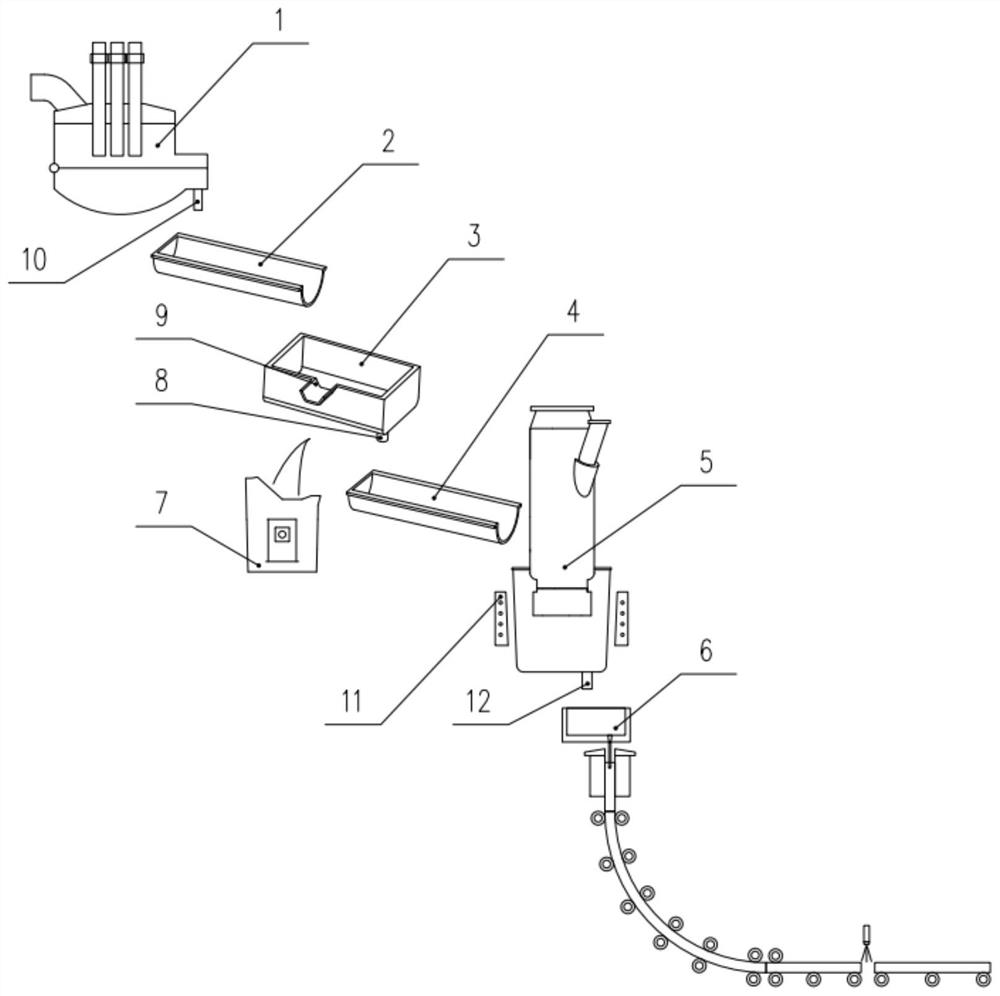

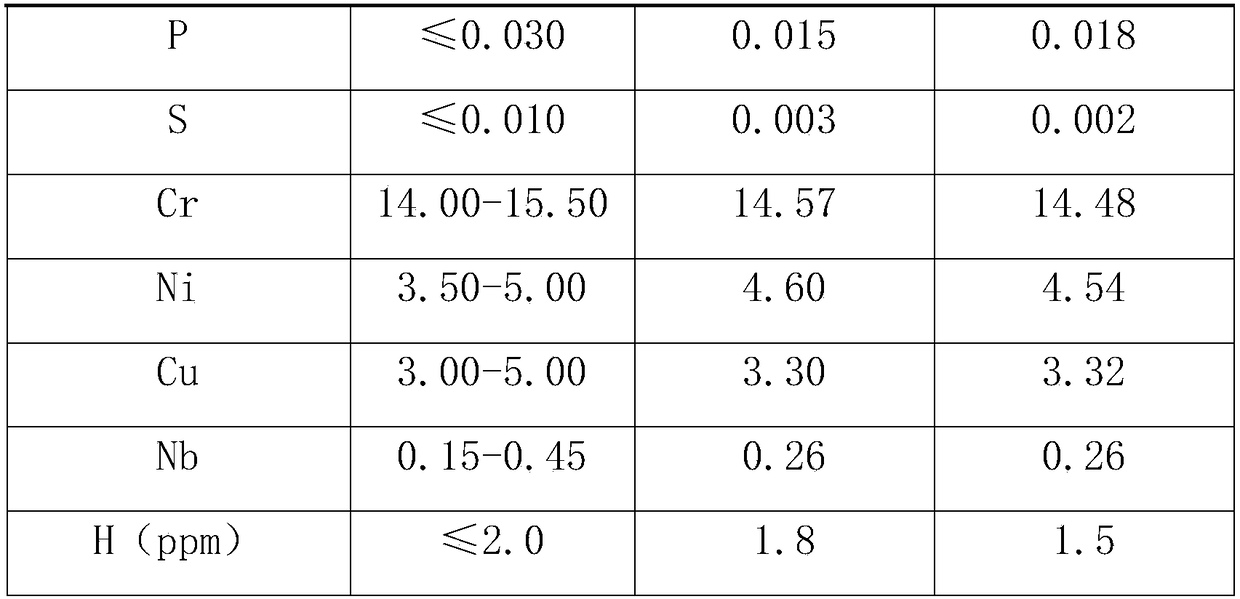

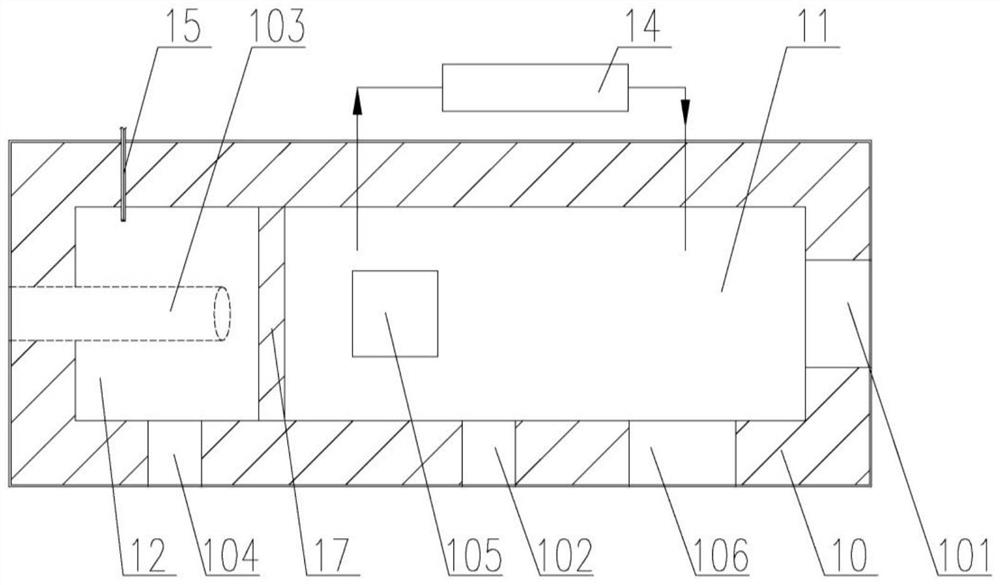

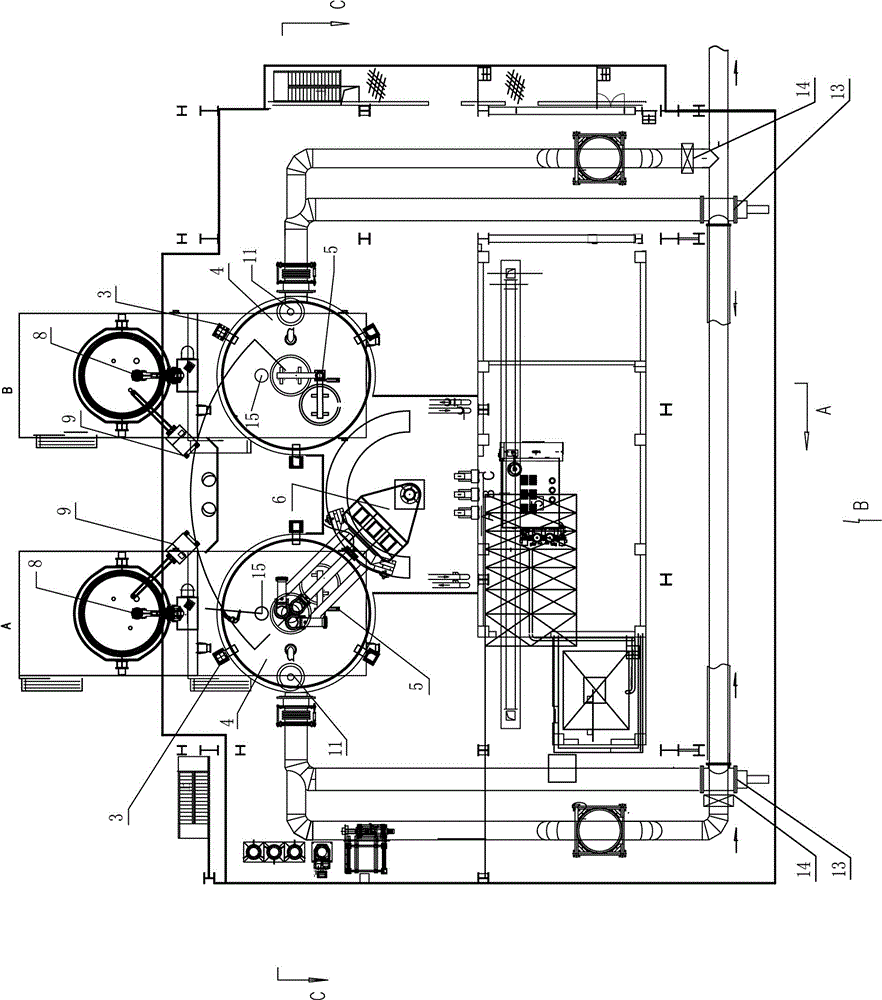

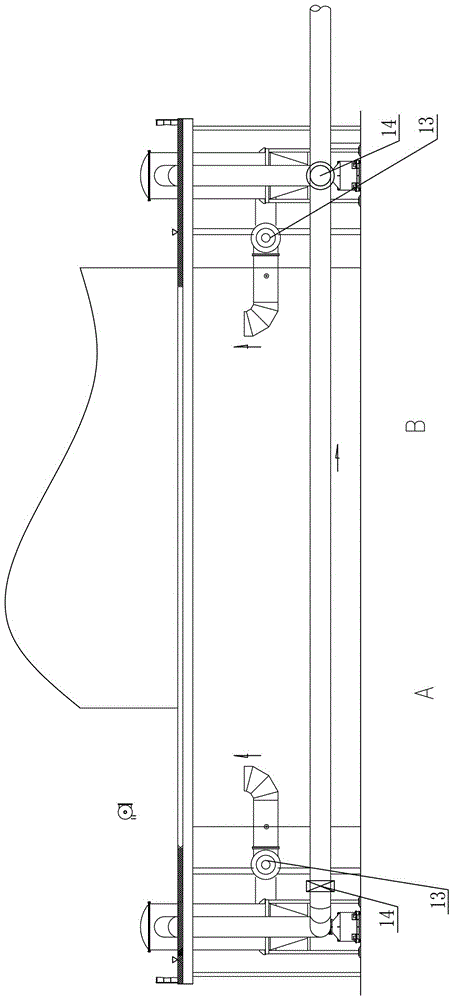

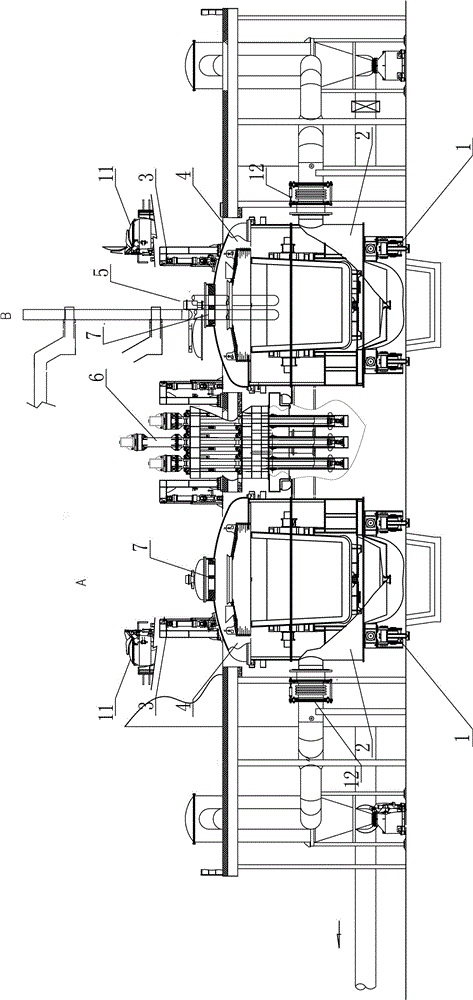

Electrode rotation double-station electric arc heating vacuum treatment device and using method thereof

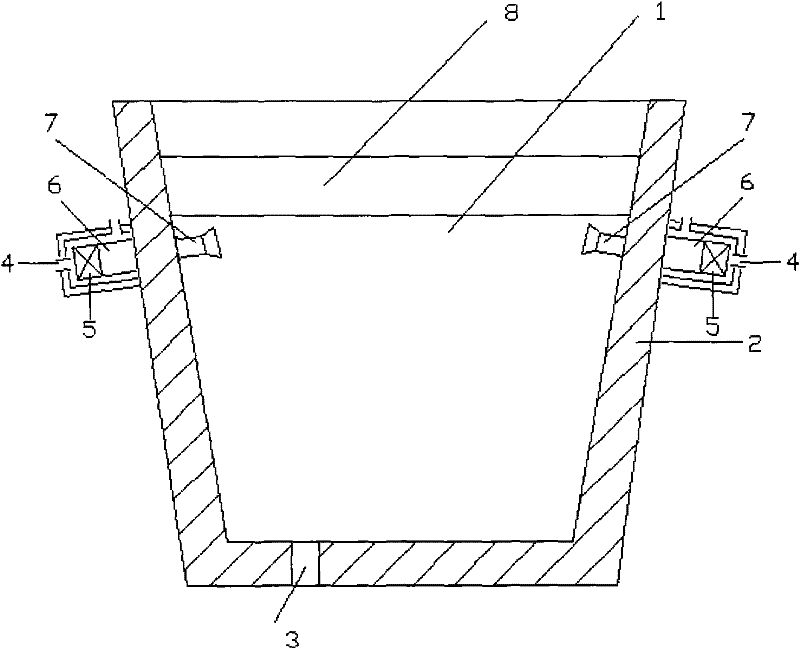

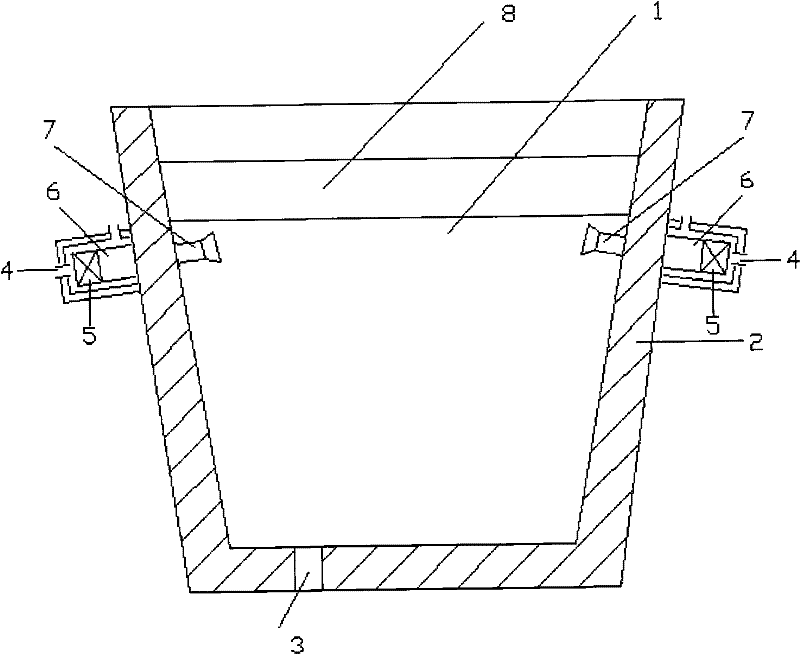

The invention relates to the refining field of the steel through vacuum treatment and particularly relates to an electrode rotation double-station electric arc heating vacuum treatment device and a using method thereof. The electrode rotation double-station electric arc heating vacuum treatment device comprises two treatment stations. Each treatment station comprises a vacuum tanker (1) and a vacuum tank (2). The device is characterized in that each treatment station further comprises a lifting device (3), a vacuum tank cover (4), a jacking device (5) and the like. The using method of the electrode rotation double-station electric arc heating vacuum treatment device comprises the following steps of: heating the electrode; blowing argon at bottom and stirring; and degassing in vacuum. The device provided by the invention has the advantages of low equipment investment, short refining period, high refining quality and flexible combination.

Owner:BAOSTEEL ENG & TECH GRP +1

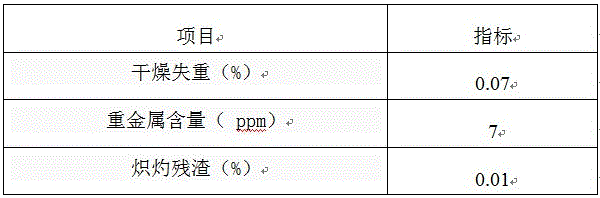

Process for purifying ioversol

ActiveCN101337907AHigh yieldImprove efficiencyCarboxylic acid amide separation/purificationX-ray constrast preparationsPurification methodsX-ray

The invention relates to a method for purifying ioversol that is x-ray nonionic contrast agent. The method adopts ethanol as recrystallization solvent to recrystallize ioversol crude-product, and the content of the obtained ioversol pure-product is more than 98.5 percent. The method is simple, easy to operate, economical and practical, and suitable for large-scale industrial production.

Owner:JIANGSU HENGRUI MEDICINE CO LTD +1

Bottom blowing refining furnace and application thereof

The invention discloses a bottom blowing refining furnace and application thereof. The bottom blowing refining furnace comprises a rotary furnace and a bottom blowing redox gun; specifically, the rotary furnace comprises a rotary furnace casing, a furnace opening, a copper inlet and a copper outlet; a hearth space is limited in the rotary furnace casing; the furnace opening is formed in the upperpart at the middle section of the rotary furnace casing; the copper inlet is formed in the rotary furnace casing; the copper outlet is formed in the side wall of the end part of the rotary furnace casing; the bottom blowing redox gun is arranged at the bottom of the rotary furnace casing and extends into the hearth space; the diameter of the bottom blowing redox gunrefining furnace is 38 to 75 cm.The bottom blowing refining furnace does not need to arrange gas permeable bricks or separately arrange a smoke outlet or a burner; a furnace body is simple in structure and low in equipment cost, and can avoid energy consumption loss because the gas permeable bricks are blown with nitrogen; besides, when the bottom blowing refining furnace refines crude copper, the redox efficiency can be remarkably improved, the refining cycle of the crude copper is shortened and the refining effect is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

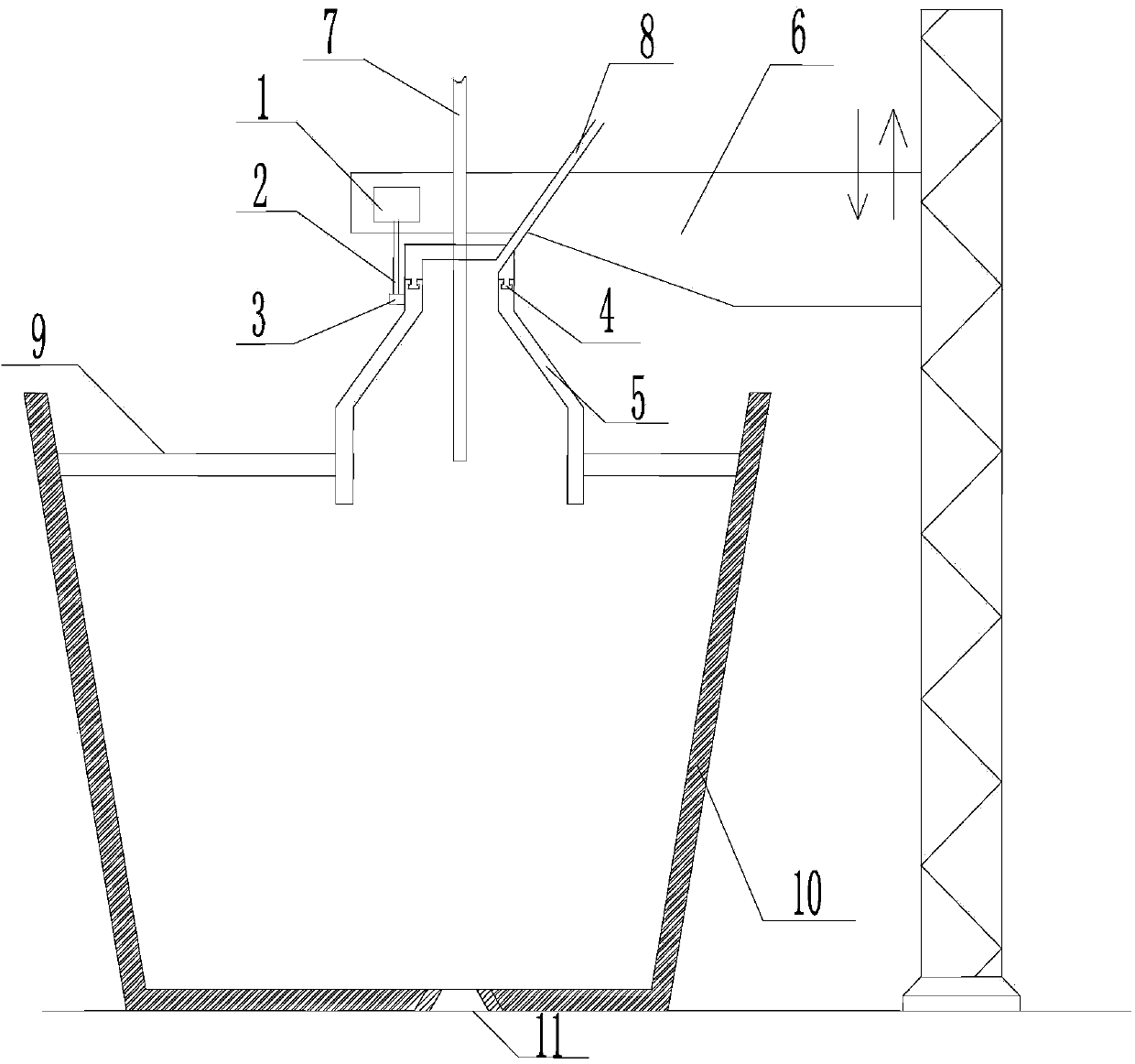

Erosion-resistant CAS-OB refining device for dipping cover

The invention provides an erosion-resistant CAS-OB refining device for a dipping cover. The service life of the dipping cover can be prolonged, the production cost is reduced, and the refining efficiency is improved. The erosion-resistant CAS-OB refining device for the dipping cover provided by the invention comprises a dipping cover, a dipping cover lifting device, an oxygen lance, an alloy material chute, slag, a steel ladle and perforated bricks, and is characterized by also comprising a motor, a transmission shaft, a gear and a concave-convex connection buckle, wherein the upper part of the dipping cover is a fixed part, and the lower part of the dipping cover is a rotating part, and the two parts are connected by virtue of the concave-convex connection buckle. According to the erosion-resistant CAS-OB refining device provided by the invention, the structure of the CAS-OB dipping cover is changed, the asymmetric erosion degree of the dipping cover is alleviated, the utilization rate and operation rate of equipment are improved, the refining cycle is shortened, and the aim of prolonging the service life of the dipping cover is achieved.

Owner:UNIV OF SCI & TECH LIAONING

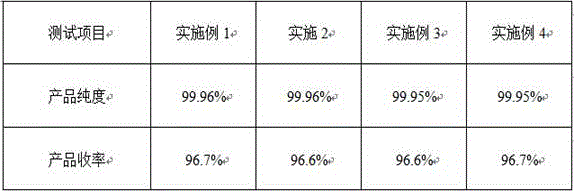

A kind of production method of high-purity metformin hydrochloride

InactiveCN104788345BLower the temperature of the addition reactionLow impurity contentOrganic chemistryOrganic compound preparationMetformin HydrochlorideHydrochloride

The invention discloses a high-purity metformin hydrochloride preparation method. N-methyl pyrrolidone is used as a solvent, dicyandiamide and dimethylamine hydrochloride are taken as a solute, the solvent and the solute are added into a synthesis kettle for reaction, and metformin hydrochloride is prepared through steps of stirring, cooling, spin-drying, washing, crystallizing and drying. The metformin hydrochloride prepared through the preparation method provided by the invention has the advantages that the yield is higher than 96.4 percent, and the product purity is higher than 99.93 percent.

Owner:TAISHAN MEDICAL UNIV

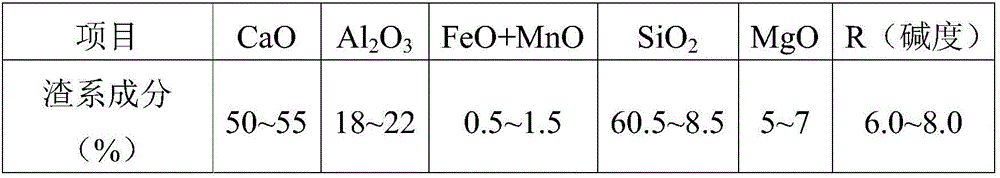

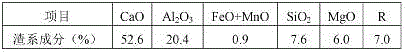

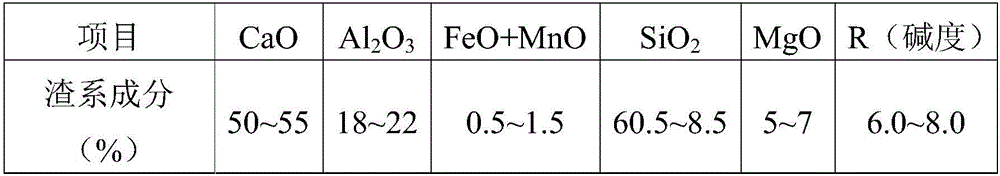

Efficient ladle furnace refining method based on thin-slab casting and rolling production of high-strength steel

InactiveCN106399638AImprove refining efficiencyShorten the processing cycleLime productionThin slabSlag

The invention discloses an efficient ladle furnace refining method based on thin-slab casting and rolling production of high-strength steel. The efficient ladle furnace refining method is characterized in that in a converter tapping stage, the converter tapping temperature ranges from 1,680 DEG C to 1,700 DEG C; quick oxygen probing is performed on molten steel in an argon station, and the addition of aluminum is determined according to the oxygen content; the ingredients and the alkalinity of an appropriate slag system are determined in the ladle furnace slagging stage; in the ladle furnace heating stage, after molten steel arrives at a station, a lower electrode heats up the molten steel, the heating power is controlled in a segmented manner, crusting on the slag surface is realized in the earlier stage, and slugging is performed at low gear; and after melting of slag, the slag surface is uniformly coated, heating is performed at high gear, point heating is adopted in the later stage, and one-time heating is performed to reach the required temperature. The efficient ladle furnace refining method can shorten the refining cycle by about 5 min, and therefore, shortens the procedure period; the electrode heating time is averagely shortened by 1 min, so that the power consumption is reduced; and after adoption of the ingredients of the new slag system, the desulphurization efficiency is improved, and the lime consumption is reduced by 3 kg / ton steel.

Owner:武汉钢铁有限公司

Smelting method for rapidly heating refining furnace under low-alkalinity slag condition

The invention relates to a smelting method for rapidly heating a refining furnace under a low-alkalinity slag condition. When sulfur-containing non-quenched and tempered steel is produced, the adding amount of quartz sand is controlled in the earlier stage of LF furnace refining, namely the alkalinity of slag is controlled, a certain amount of carbonaceous deoxidizing agent is added for deoxidation, the foaming performance of the slag is improved, and therefore power transmission and temperature rising are carried out under the condition that the electrode submerged arc effect is good, the temperature of molten steel is raised to the outbound temperature range, and finally low-alkalinity slag adjustment is carried out. By means of the smelting method, the heating rate of the refining furnace is greatly increased, the heating rate of the refining furnace is increased by 30%-40%, the refining period is shortened by 10-15 minutes, and the actual use and popularization value is obvious.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

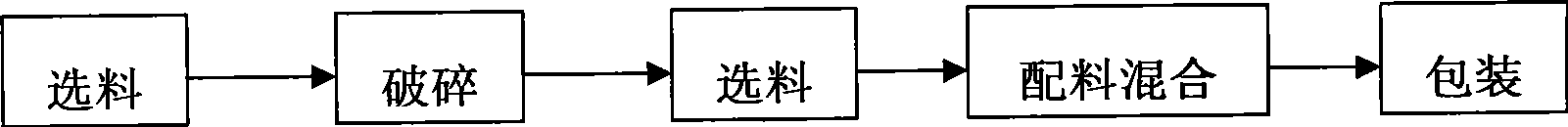

Aluminum-calcium deoxidation and desulphurization slag remover for metallurgy

The invention provides an aluminum calcium deoxidization desulfuration slagging agent for quick deoxidizing, quick desulfurizing, removing foreign matters in molten steel and effectively improving inherent quality of steel in metallurgy.The main technical point is that weight parts of each component are calcium carbide of 1, calcium-aluminum alloy and calcium-aluminum slag of 6-14, calcium-silicon alloy and calcium-silicon slag of 2-6, lime or iimestone of 1-6, aluminum and AD powder of 1-4.According to the invention, process steps of material selecting, pulverizing, drying, ingredient mixing and the like are performed according to the above matching, production processes of LF(VD), CAS, RH and the like can be all adapted, therefore, technique effects of shortening the refining operation period, reducing material consumption of deoxidization, accelerating slag forming speed and arc burying speed, reducing electricity consumption and reducing temperature of molten steel; by replacing CaF2 by CaC2, the furnace liner is protected effectively, service life of the furnace liner can be assured, and the production cost can be reduced. The preparation method of the invention is simple and the deoxidization and desulfuration guideline of the product exceeds that of the existing product.

Owner:沈阳慧通远达冶金技术研发有限公司

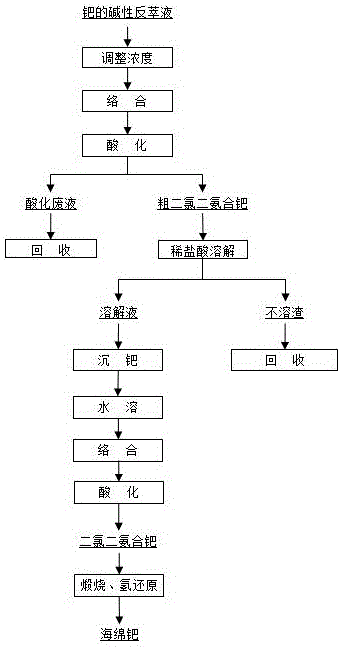

Method for refining palladium from alkaline strip liquor

ActiveCN106222437AImprove friendlinessEasy to handleProcess efficiency improvementDissolutionAmmonia

The invention discloses a novel method for refining palladium from alkaline strip liquor. The novel method comprises the following steps that (1) the concentration of the palladium in the alkaline palladium strip liquor is concentrated and adjusted; (2) preliminary purification is conducted through complexation and acidification; (3) rough trans-diamminedichloropalladium is dissolved with diluted hydrochloric acid; and (4) follow-up refining is conducted through traditional palladium sediment, water dissolution, complexation and acidification methods, and a 99.99% sponge palladium product is produced. Compared with the prior art, the novel method for refining the palladium from the alkaline strip liquor has the advantages that the yield is high, waste gas containing ammonia is not produced, conversion between the trans-diamminedichloropalladium and ammonium chloropalladite is easy and convenient, the product quality is stable, and industrialization is easy to achieve; and the palladium yield can reach 99.3% or above.

Owner:JINCHUAN GROUP LIMITED

The method of shortening the slag melting time of ladle refining furnace by frequency conversion ultrasonic wave

The invention discloses a method for shortening the slag melting time of a ladle refining furnace by frequency-conversion ultrasonic waves, and solves the problems of long smelting cycle and low production efficiency due to slow slag melting speed. The method includes the following steps: tapping out of the converter or electric furnace, pouring molten steel into the ladle, placing the ladle in the refining station, starting the argon blowing and stirring, and adding the slagging material and deoxidizing material while starting the ultrasonic generator, the ultrasonic generator Installed on the side wall of the ladle, the ultrasonic stirring position is on the contact interface between the synthetic slag and the molten steel. The invention can shorten the refining time by more than 10 minutes, can also promote the reaction between synthetic slag and molten steel, and improve the efficiency of removing inclusions and gases. Ultrasonic high-frequency vibration and radiation pressure can form effective agitation and flow in gas and liquid. Improve the operating efficiency of production equipment.

Owner:UNIV OF SCI & TECH LIAONING

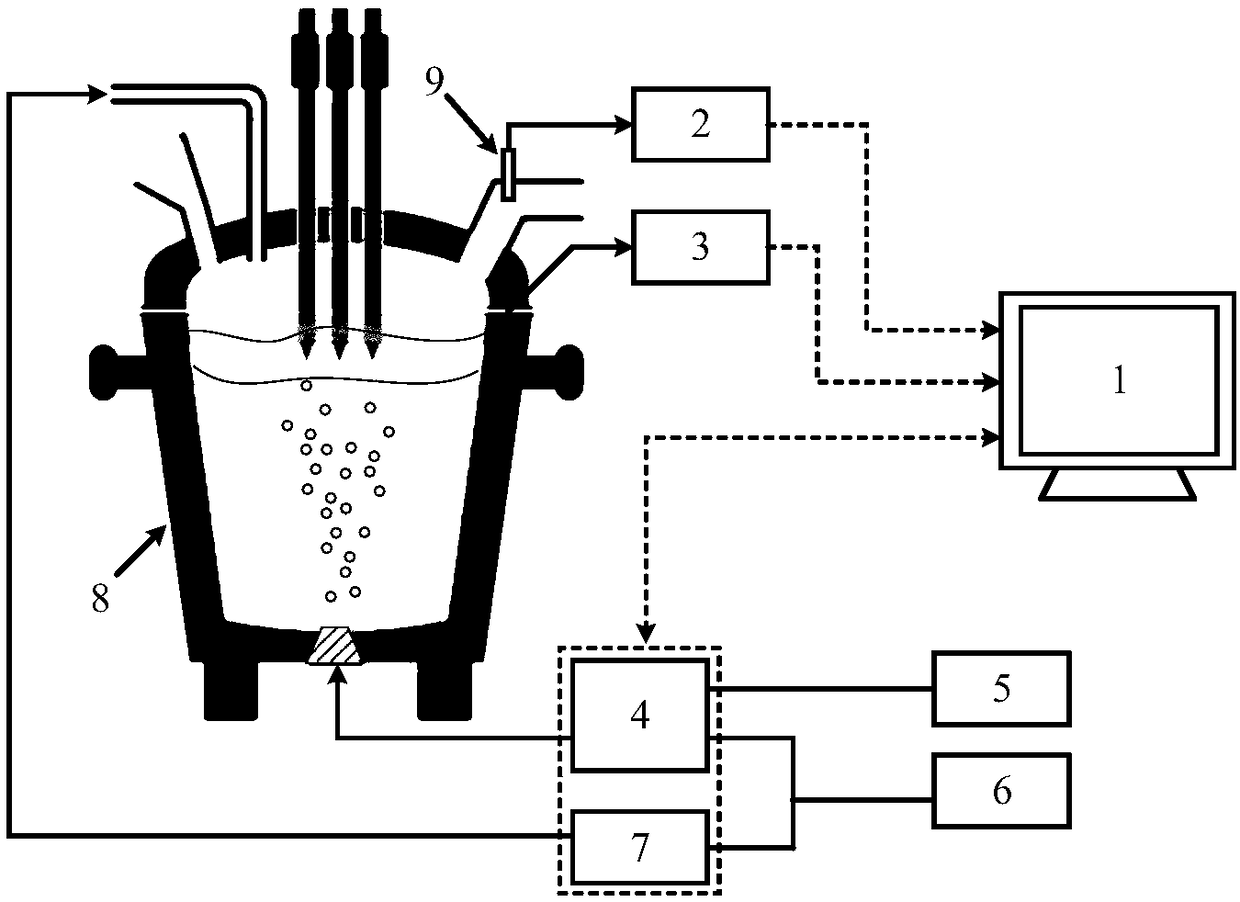

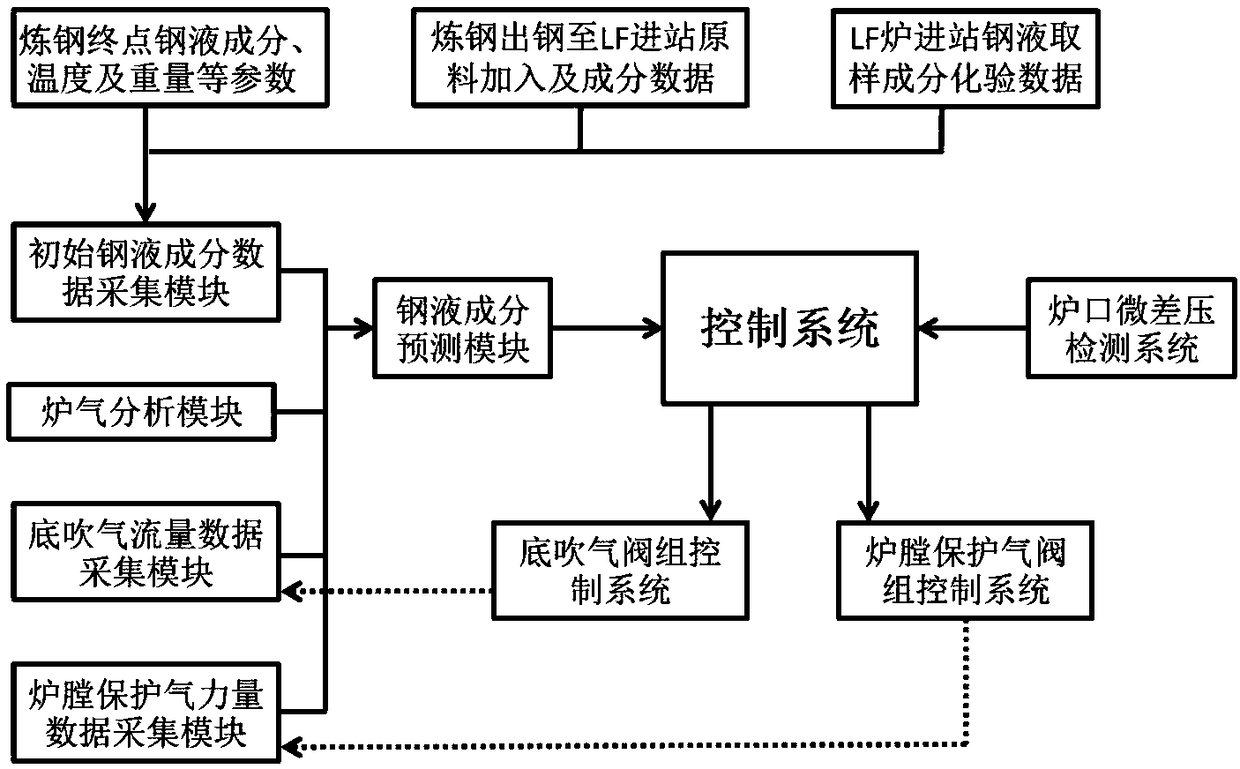

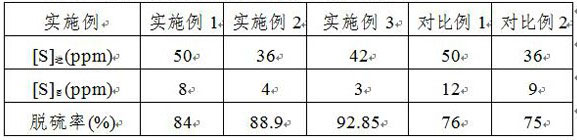

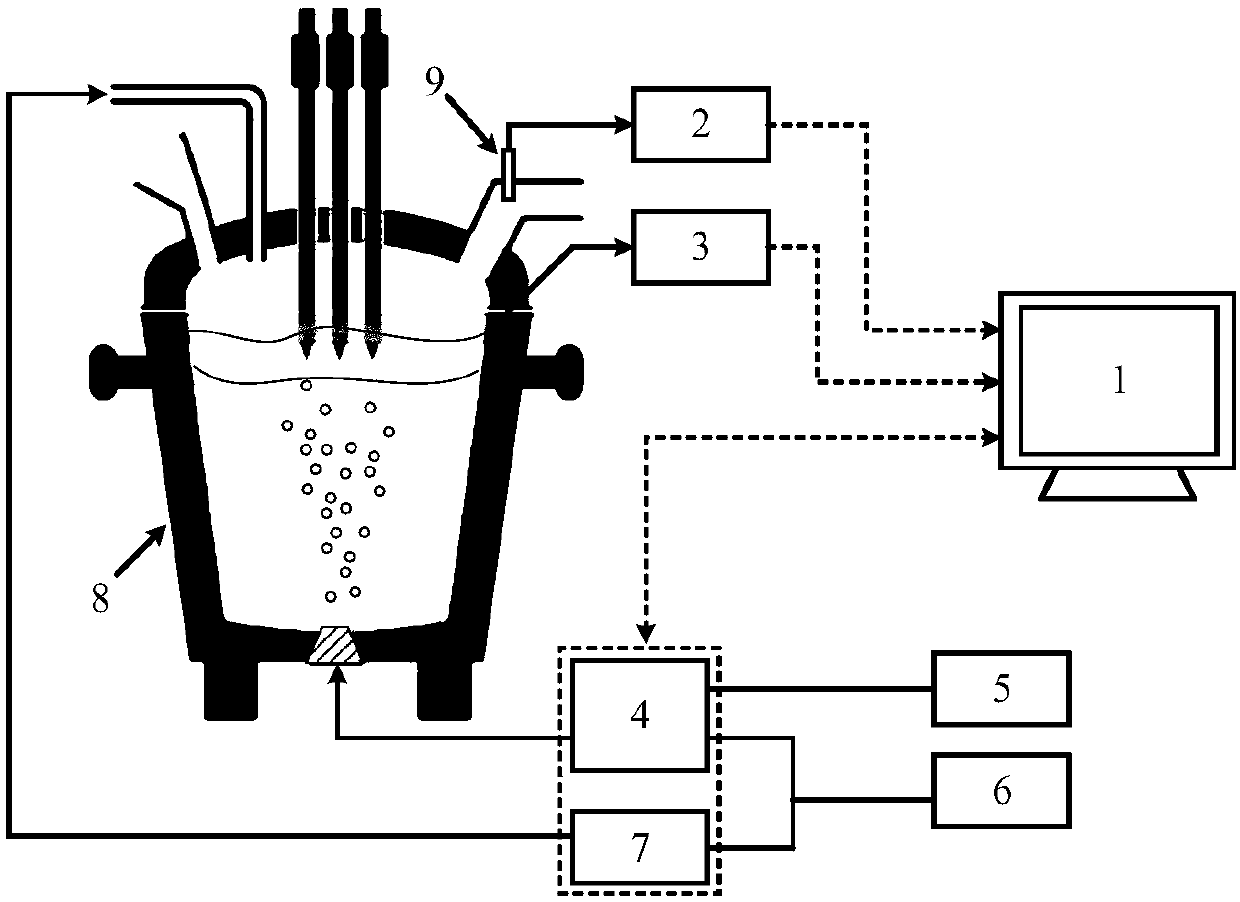

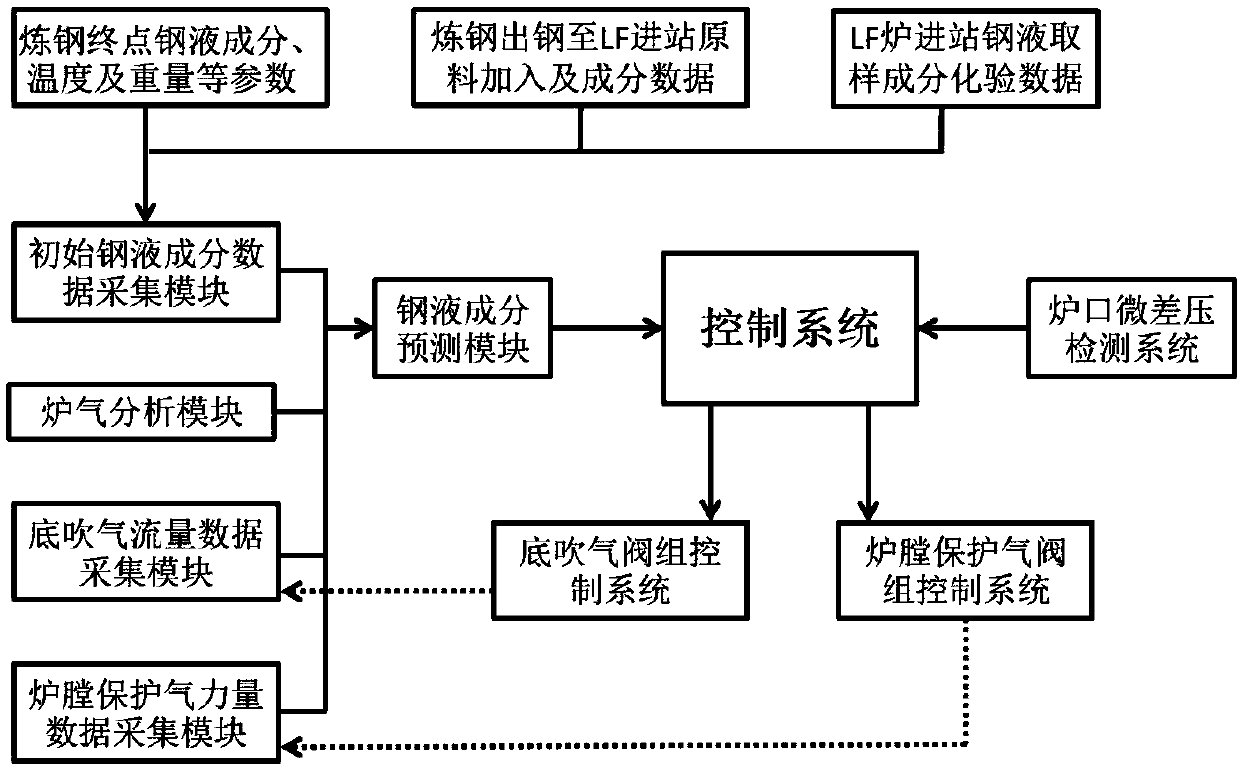

LF furnace refining method and device adopting dynamic bottom blowing for CO2-Ar

The invention belongs to the technical field of steelmaking, and particularly relates to a LF furnace refining method adopting dynamic bottom blowing for CO2-Ar and applicable to a 30-300t LF furnacerefining process. CO2 and Ar are adopted as a LF furnace bottom blowing medium and hearth protection gas; molten steel components in a refining process are predicted in combination with entering molten steel component data of LF furnace refining and furnace gas component data of the refining process, and on the basis of Ar tracing conservation; the bottom blowing flow rates of CO2 and Ar and the blowing flow rate of the hearth protection gas are dynamically adjusted in different periods of time according to the target molten steel component parameter requirements of the refining; molten pool stirring is carried out in strengthened steel ladle, and a nitrogen content in molten steel is further lowered while rapid deep desulfurization is realized, so that the quality of the molten steel is improved; and meanwhile, CO2 is used for replacing a part of Ar and completing the refining operation, so that the consumption of Ar is reduced, and the production cost is lowered. The LF furnace refining period is shortened by 3-6min, the desulfurization rate achieves 90% above, and the nitrogen content in the molten steel is lowered by 10-30*10<-6>.

Owner:UNIV OF SCI & TECH BEIJING

Steelmaking method with efficient refining

ActiveCN111893247AShorten the refining cycleConverter rapid slagging time shortenedProcess efficiency improvementSteelmakingManganese

The invention discloses a steelmaking method with efficient refining. The steelmaking method includes the steps that smelting is carried out by a conventional converter; tapping is carried out, specifically, silico-manganese alloy is added when tapping is carried out to one third; lime and a fast-refining fluoride-free slag-regulating agent are added at the same time when tapping is carried out two thirds; deoxidation is carried out at argon station: firstly aluminum wires are added, and then ferro-aluminum is added to the surface of ladle slag; and continuous casting and post processes are carried out. Through the technical measures such as adding the fast-refining fluoride-free slag-regulating agent, the rapid slagging time of the converter is shortened by 3 minutes, the refining slagging time is reduced, and the LF refining cycle is shortened by at least 5 min.

Owner:武汉钢铁有限公司

Stirring device for processing tea oil

PendingCN109806788AAvoid gas lossShort cycleRotary stirring mixersTransportation and packagingHeating efficiencyEngineering

The invention discloses a stirring device for processing tea oil. The stirring device comprises a reaction cylinder and a cylinder cover matched with the reaction cylinder, the periphery of the cylinder cover is provided with an oil inlet, a shell is arranged outside the reaction cylinder, a heating cavity is reserved between the shell and the reaction cylinder, the lower part of the shell is provided with a liquid inlet, the upper part of the shell is provided with a liquid outlet, an end cover with the same diameter as the diameter of the cylinder cover is fixed on the cylinder cover, a low-speed shaft motor is arranged at the center position of the top of the end cover, high-speed shaft motors are arranged on the two sides of the low-speed shaft motor, high-speed shafts are arranged onthe two high-speed shaft motors, stirring blades are arranged on the high-speed shafts, turbulent flow holes are uniformly distributed on the stirring blades, a low-speed shaft is arranged on the low-speed shaft motor, and an anchor stirrer is arranged on the low-speed shaft. The stirring device for processing the tea oil has the advantages of being reasonable in structure, flexible to use and high in heating efficiency.

Owner:浙江共向农业开发有限公司

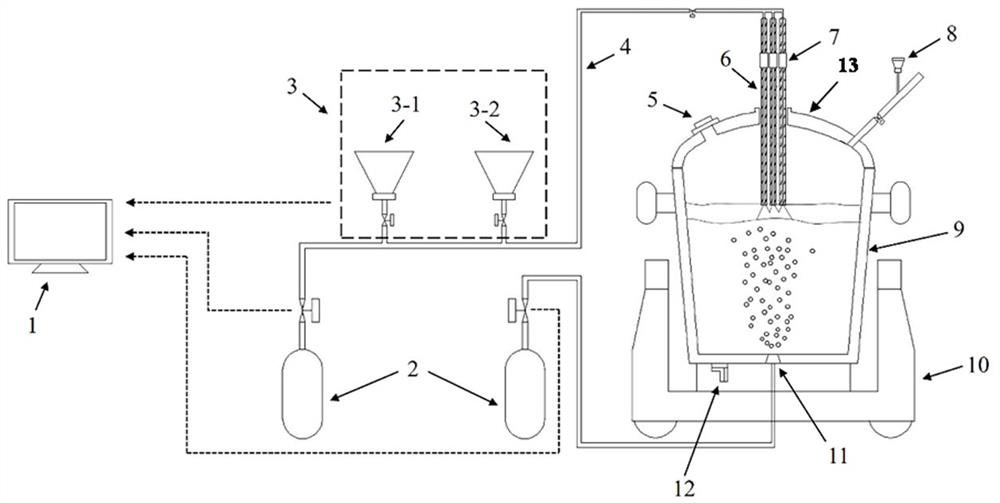

Method for deep desulfurization of molten steel refining, device and application for molten steel refining

The invention relates to a method for deep desulfurization of molten steel refining, a device for refining molten steel and its application. The method is as follows: S1, tapping the molten steel to be refined into a ladle and adding smelting materials into the ladle containing the molten steel to be refined, to obtain the steel material to be refined; S2, according to the Initial sulfur content of molten steel [S] 进 and target sulfur content [S] 目 , to determine the process parameters of lime powder injection, carbon powder injection and top-blown argon gas injection when the steel material to be refined is refined; S3, the steel material to be refined is refined; , injecting lime powder-carbon powder-argon mixed powder flow into the steel material to be refined through the hollow electrode to deeply desulfurize the molten steel. The present invention carries out deep desulfurization by dynamically injecting lime powder and carbon powder through hollow electrodes, which can not only ensure reasonable decarburization and desulfurization of molten steel, improve desulfurization kinetic conditions, increase desulfurization efficiency, shorten smelting time, but also reduce power consumption and electrode loss , to reduce production costs.

Owner:UNIV OF SCI & TECH BEIJING

RH efficient deep decarburization control method based on plasma jet

The invention belongs to the technical field of steelmaking, and particularly relates to an RH efficient deep decarburization control method based on plasma jet. The RH efficient deep decarburizationcontrol method is suitable for a 30-300 t RH steel ladle refining process. In the RH refining process, O2 and Ar plasmas are adopted to act on molten steel, and a traditional gas lifting and vacuum operation system is matched; a control system is combined with RH pull-in molten steel component data and a refining process monitoring system, a top-blown gas control valve set, a plasma spray gun anda vacuum chamber axial electrode are used for adjusting gas plasma arcs, and while rapid decarburization is achieved, the molten steel is ensured to be heated rapidly, molten steel peroxidation is avoided, the oxygen utilization rate is increased, deoxidation alloy consumption is reduced, the refining rhythm is accelerated, and the molten steel quality is improved. The O2 utilization rate is increased by 10-20%, the deoxidation alloy consumption is reduced by 3-10%, the RH refining period is shortened by 3-10 min, inclusions in steel are greatly reduced, and the molten steel quality is improved.

Owner:UNIV OF SCI & TECH BEIJING

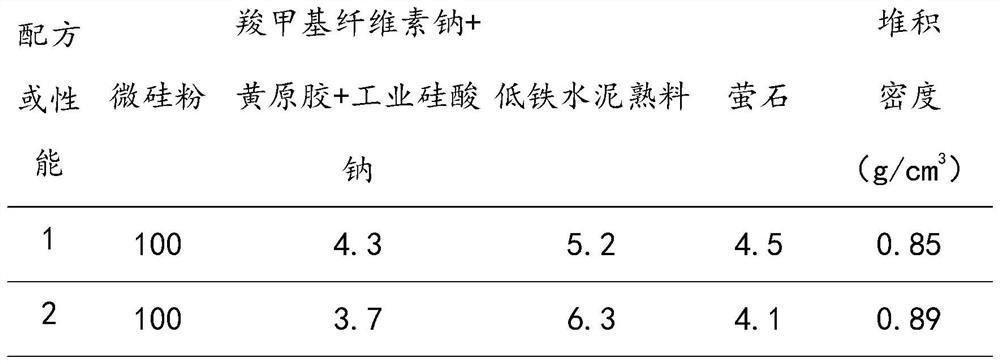

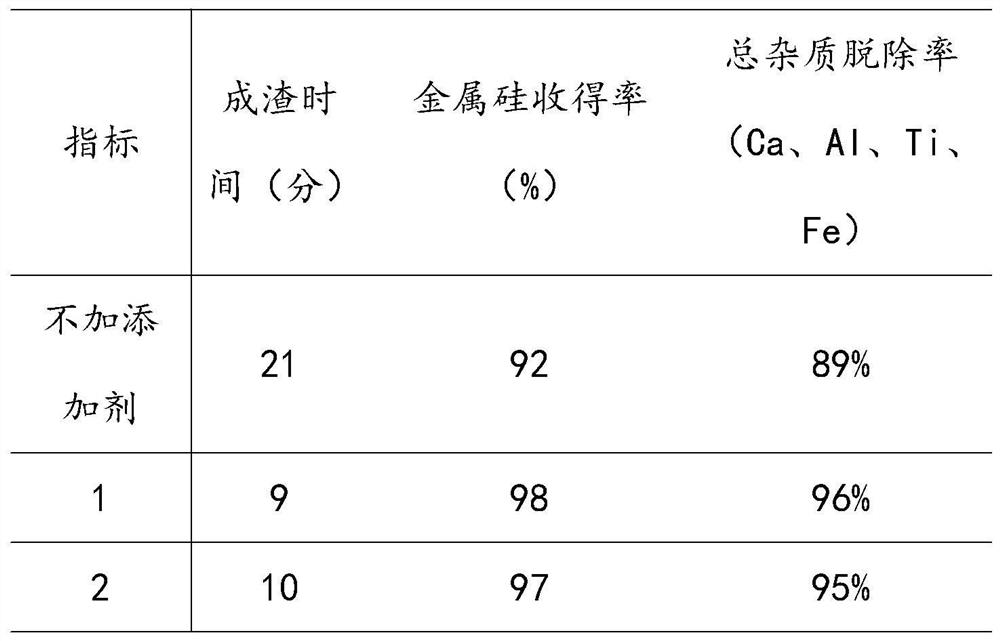

Method for preparing industrial silicon refining slag agent by using silica fume as raw material

PendingCN114538449AHigh activityFast slagSolid waste managementSilicon compoundsCarboxymethyl celluloseCellulose

The invention relates to a method for preparing an industrial silicon refining slag agent by using micro-silicon powder as a raw material, which can achieve the purposes of effectively utilizing low-grade micro-silicon powder and improving the total yield and refining efficiency of metal silicon. The invention relates to a method for preparing an industrial silicon external refining additive by using micro-silicon powder as a raw material, which comprises the following steps: weighing a certain mass of micro-silicon powder, adding 0.8-1.2 times by weight of water and a combination which accounts for 2-7% of the mass of the micro-silicon powder to obtain a mixture, the combination is composed of at least one or two of sodium carboxymethyl cellulose, xanthan gum and sodium silicate, the sodium carboxymethyl cellulose is 1t; 4% of xanthan gum; 3% of sodium silicate; 6%. Low-iron cement clinker accounting for 3%-7% of the mass of the silica fume and fluorite accounting for 2%-5% of the mass of the silica fume are added into the mixture, ball milling is conducted on mixed slurry, the ball milling time is longer than 20 minutes, and uniform slurry is obtained; and spraying, drying and granulating the uniform slurry at the drying temperature of 300-350 DEG C to obtain the porous hollow additive with the bulk density of less than 1g / cm < 3 >.

Owner:GUIZHOU INST OF TECH

Node control method for treating low-carbon-aluminum molten killed steel through LF refining furnace

InactiveCN109722500AImprove production capacityMeet the processing requirements for efficient production of low-carbon aluminum-killed steelSlagOxygen

The invention discloses a node control method for treating low-carbon-aluminum molten killed steel through an LF refining furnace. The node control method includes the following steps that pull-in large argon stirring is carried out for 0.5-1.5 min; temperature measuring and oxygen measuring are carried out for 0.5-1.5 min, aluminum wires and first-batch lime are added at 1-3 min, aluminum is controlled at 0.05-0.06%, and large argon stirring is carried out for 1-3 min; sampling and temperature measuring are carried out for 1-3 min; energization is carried out, aluminum slag is added, and slagging and temperature rising are carried out for 5-10 min; aluminum preparing and temperature measuring are carried out for 0.5-1.5 min; large argon stirring is carried out for 0.5-1.5 min; temperatureadjusting is carried out for 1-3 min; calcification treatment is carried out for 1-3 min; sampling is carried out; and soft blowing is carried out. By means of the method, the power consumption of the LF refining furnace can be reduced, and meanwhile the refining period is shortened so that the requirement of the high yield can be conveniently met.

Owner:SHANDONG IRON & STEEL CO LTD

A rapid decarburization method of rh

ActiveCN104099445BShorten the refining cycleEfficient and fast decarbonizationMetallurgyMolten steel

The invention relates to an RH fast decarbonization method. The method comprises the following steps: the terminal control of a converter is performed; the temperature of the steel tapping terminal of the converter is controlled within 1675-1705 DEG C; by the mass percentage, the C content at the steel tapping terminal of the converter is controlled within 0.02-0.045%; by the mass percentage, the oxygen content is controlled within 900 ppm; after the steel tapping of the converter is finished, the RH refining is performed; the inlet temperature of molten steel is controlled within 1610-1640 DEG C; an RH judges if the oxygen blowing decarbonization is needed according to the inlet conditions and the carbon-oxygen relation, if so, the oxygen blowing should be performed within 4 min at the beginning of the vacuumizing, and the oxygen blowing quantity is not greater than 150 m3; and the gas flow is increased in the refining process. The method is suitable for the deep decarbonization process of ultralow carbon steel, and can decarbonize the molten steel C below 10*10-6 within 12 min, so that the efficient and fast decarbonization is realized, the RH refining period is shortened, and the temperature drop in the refining process is reduced.

Owner:SHOUGANG CORPORATION

a rh jet co 2 Dynamic control method for refining ultra-low carbon steel

Owner:UNIV OF SCI & TECH BEIJING

Clean steel smelting system and method

The invention relates to a clean steel smelting system and method, and belongs to the technical field of metallurgy. The clean steel smelting system comprises a primary smelting furnace, a slag-steel separation device, a refining furnace and a continuous casting ladle which are sequentially arranged in the flowing direction of molten steel, the slag-steel separation device is used for removing high-oxidability steel slag in the molten steel, deoxidation alloying operation is not carried out during primary smelting tapping, and deoxidation and alloying are carried out in sequence during refining. By arranging the slag-steel separation device, the high-oxidability steel slag of the primary smelting furnace is prevented from entering the refining process, the possibility that the molten steel is polluted is reduced, and the consumption of alloy for steel slag deoxidation is reduced; and meanwhile, the alloying operation is carried out in the refining furnace after deoxidation is finished, so that the alloy yield is increased, and generation of oxide inclusions is inhibited from the source.

Owner:CISDI ENG CO LTD

Process for purifying ioversol

ActiveCN101337907BHigh yieldImprove efficiencyCarboxylic acid amide separation/purificationX-ray constrast preparationsPurification methodsX-ray

Owner:JIANGSU HENGRUI MEDICINE CO LTD +1

Refining method of difenoconazole crude product

The invention discloses a refining method of a difenoconazole crude product. Difenoconazole is refined by adopting an extraction and crystallization method, extraction is performed firstly and then crystallization is performed, strong acid and alkali liquor are not introduced in the whole refining process, and no waste salt is generated in the refining process; and rectification is not needed, and rectification residues and high-COD wastewater are not generated. The low-content difenoconazole obtained after the extraction solvent of the extraction mother liquor and the crystallization mother liquor is removed is light in color and can be directly made into a 10% difenoconazole emulsion in water, the emulsion in water is high in quality, waste recycling is achieved, and the utilization rate of the difenoconazole crude product reaches 98% or above.

Owner:JIANGSU HEBEN BIOCHEM

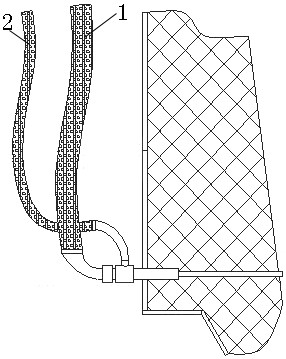

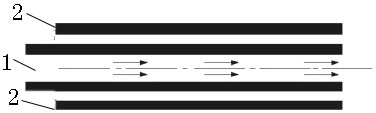

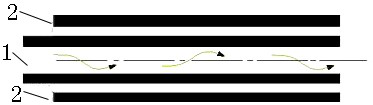

Novel AOD spiral side gun

PendingCN112458238AImprove stirring performanceReduce and inhibit mechanical scourStructural engineeringStainless steel material

The invention relates to a novel AOD spiral side gun. The novel AOD spiral side gun comprises a main gun, an auxiliary gun and a spiral lining plate, wherein the main gun serves as a center pipe, theauxiliary gun is arranged outside the main gun in a sleeving mode, the main gun and the auxiliary gun are coaxially arranged, the spiral lining plate is arranged in the main gun, so that gas in the main gun rotates, the spiral lining plate is made of red copper, the thickness of the spiral lining plate is 2 mm, the screw pitch of the spiral lining plate is 700 mm, the main gun is made of red copper, the thickness of the main gun is 3 mm, the diameter of the outer wall of the main gun is 21 mm, the auxiliary gun is made of stainless steel, the thickness of the auxiliary gun is 4 mm, the diameter of the outer wall of the auxiliary gun is 34 mm. According to the novel AOD spiral side gun, the structure is simple, transformation is convenient, implementation is easy, refractory bricks, a masonry mode and the like do not need to be specially changed, and application and popularization are facilitated.

Owner:BAOSTEEL ENG & TECH GRP

A kind of lf furnace dynamic bottom blowing co2-ar refining method and device

The invention belongs to the technical field of steelmaking, and particularly relates to a LF furnace refining method adopting dynamic bottom blowing for CO2-Ar and applicable to a 30-300t LF furnacerefining process. CO2 and Ar are adopted as a LF furnace bottom blowing medium and hearth protection gas; molten steel components in a refining process are predicted in combination with entering molten steel component data of LF furnace refining and furnace gas component data of the refining process, and on the basis of Ar tracing conservation; the bottom blowing flow rates of CO2 and Ar and the blowing flow rate of the hearth protection gas are dynamically adjusted in different periods of time according to the target molten steel component parameter requirements of the refining; molten pool stirring is carried out in strengthened steel ladle, and a nitrogen content in molten steel is further lowered while rapid deep desulfurization is realized, so that the quality of the molten steel is improved; and meanwhile, CO2 is used for replacing a part of Ar and completing the refining operation, so that the consumption of Ar is reduced, and the production cost is lowered. The LF furnace refining period is shortened by 3-6min, the desulfurization rate achieves 90% above, and the nitrogen content in the molten steel is lowered by 10-30*10<-6>.

Owner:UNIV OF SCI & TECH BEIJING

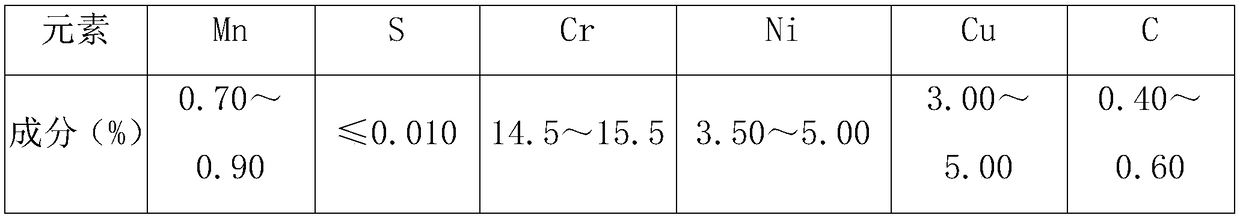

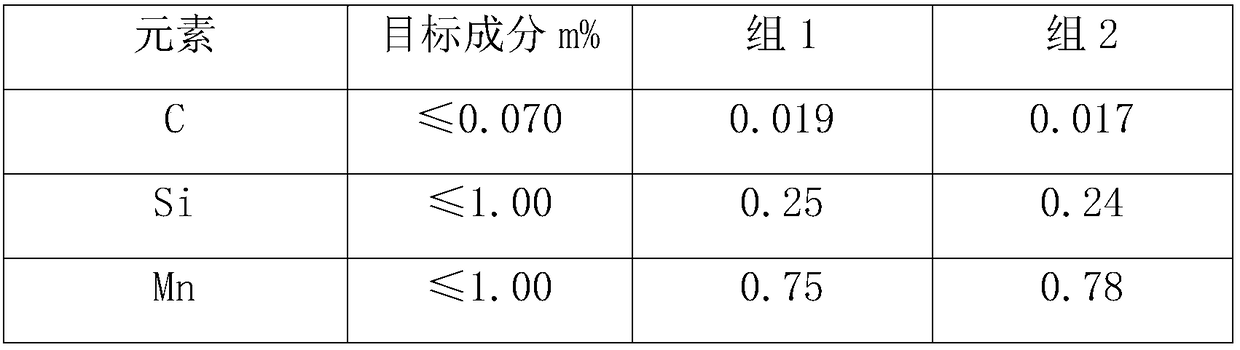

The process of smelting precipitation hardening steel by vacuum decarburization furnace

ActiveCN107604127BReduce dosageReduce manufacturing costProcess efficiency improvementElectric furnaceCopperFerrochrome

The invention discloses a process for smelting precipitation-hardening steel through a vacuum decarburization furnace, and the process is high in production efficiency and shorts refining smelting time. The process raw materials are high-quality waste steel, pig iron, sponge iron, a carburant, ferrochrome, a copper plate, a nickel plate, and ferromanganese; in an LF furnace alloy micro-regulatingprocess, Mn content is regulated through middle-carbon ferromanganese, so that the production cost is reduced; a VOD furnace adopts ten steps of preparing, calculating oxygen gas amount, starting a pump, primarily blowing oxygen, blowing oxygen, stopping oxygen, transferring to a VCD stage, relieving a vacuum stage, sampling and measuring a temperature and vacuum-reducing, and sampling-tapping tooperate, so that [H] content can be guaranteed, the refining period can be shortened, and a C content hit rate further can be effectively guaranteed; and waste heat is utilized for reducing under vacuum, so that gas content is favorably reduced and the cost is favorably controlled. The process is suitable for smelting stainless steel with Mn content lower than 2.00%.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

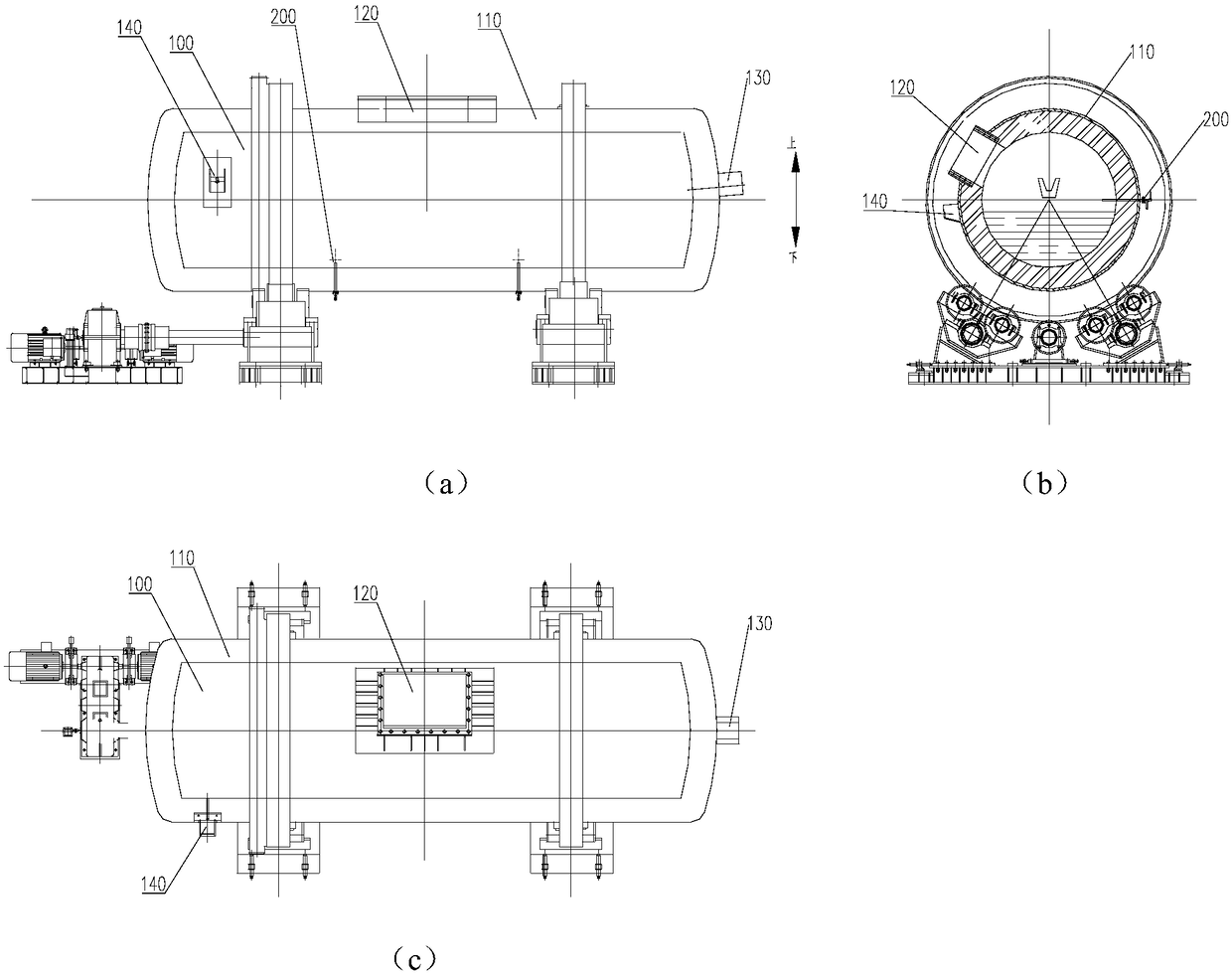

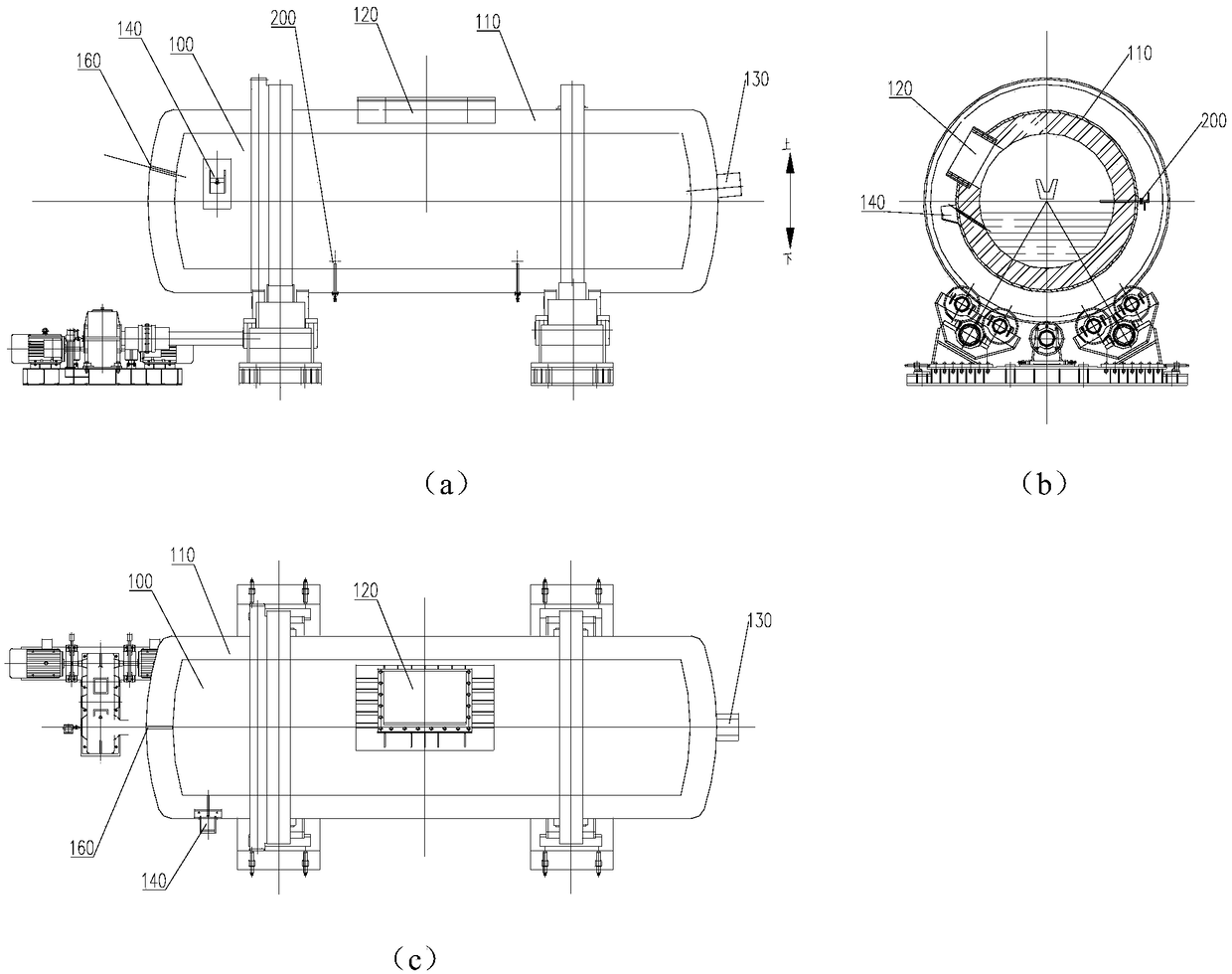

Lead bullion refining device and lead bullion refining method

PendingCN114686925AShorten crude lead refining cycleReduce energy consumptionPhotography auxillary processesProcess efficiency improvementCooling UnitsEngineering

The invention provides a lead bullion refining device and a lead bullion refining method. The crude lead refining device comprises a refining furnace, the refining furnace is provided with a furnace cavity, the furnace cavity is horizontally divided into a first refining area and a second refining area, and the bottoms of the first refining area and the second refining area are communicated; wherein the first refining area is used for conducting refining and copper removal on lead bullion to produce lead matte and copper-removed lead bullion; a first heat supply unit is arranged at the upper part of the first refining area; a cooling unit is arranged outside the first refining area, the first refining area is further provided with an outer circulation flow path, and the cooling unit is arranged on the outer circulation flow path; the second refining area is used for oxidizing the copper-removed lead bullion to remove arsenic, antimony and tin so as to form softened lead, and the second refining area is provided with an oxygen supply unit and a second heat supply unit. The lead bullion refining period is effectively shortened, the energy consumption of lead refining is reduced, and the project construction investment is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Electrode rotating double-station arc heating vacuum processing device and its application method

The invention relates to the refining field of the steel through vacuum treatment and particularly relates to an electrode rotation double-station electric arc heating vacuum treatment device and a using method thereof. The electrode rotation double-station electric arc heating vacuum treatment device comprises two treatment stations. Each treatment station comprises a vacuum tanker (1) and a vacuum tank (2). The device is characterized in that each treatment station further comprises a lifting device (3), a vacuum tank cover (4), a jacking device (5) and the like. The using method of the electrode rotation double-station electric arc heating vacuum treatment device comprises the following steps of: heating the electrode; blowing argon at bottom and stirring; and degassing in vacuum. The device provided by the invention has the advantages of low equipment investment, short refining period, high refining quality and flexible combination.

Owner:BAOSTEEL ENG & TECH GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com