Patents

Literature

74results about How to "Improve stirring performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

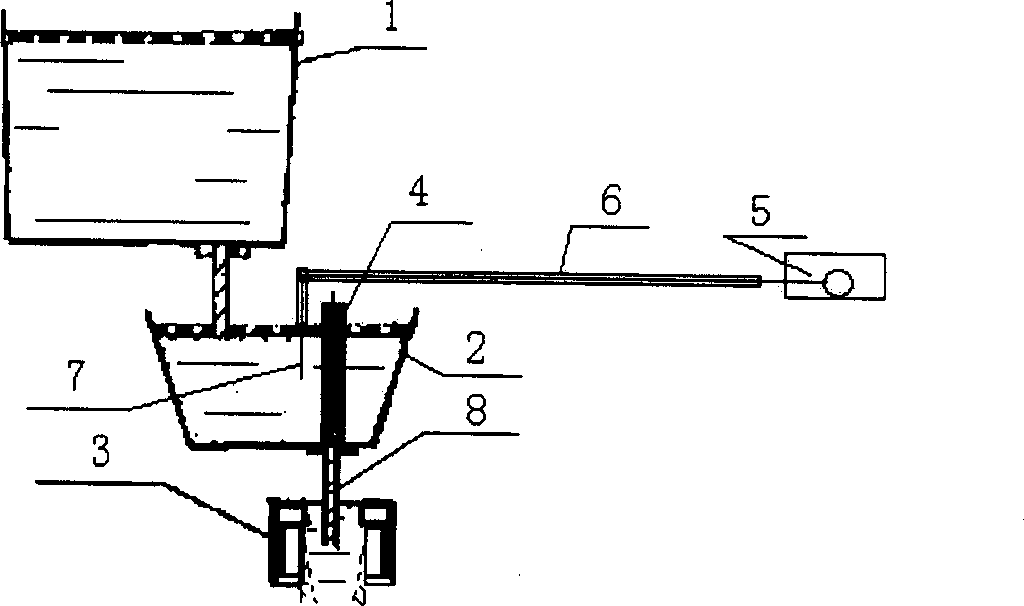

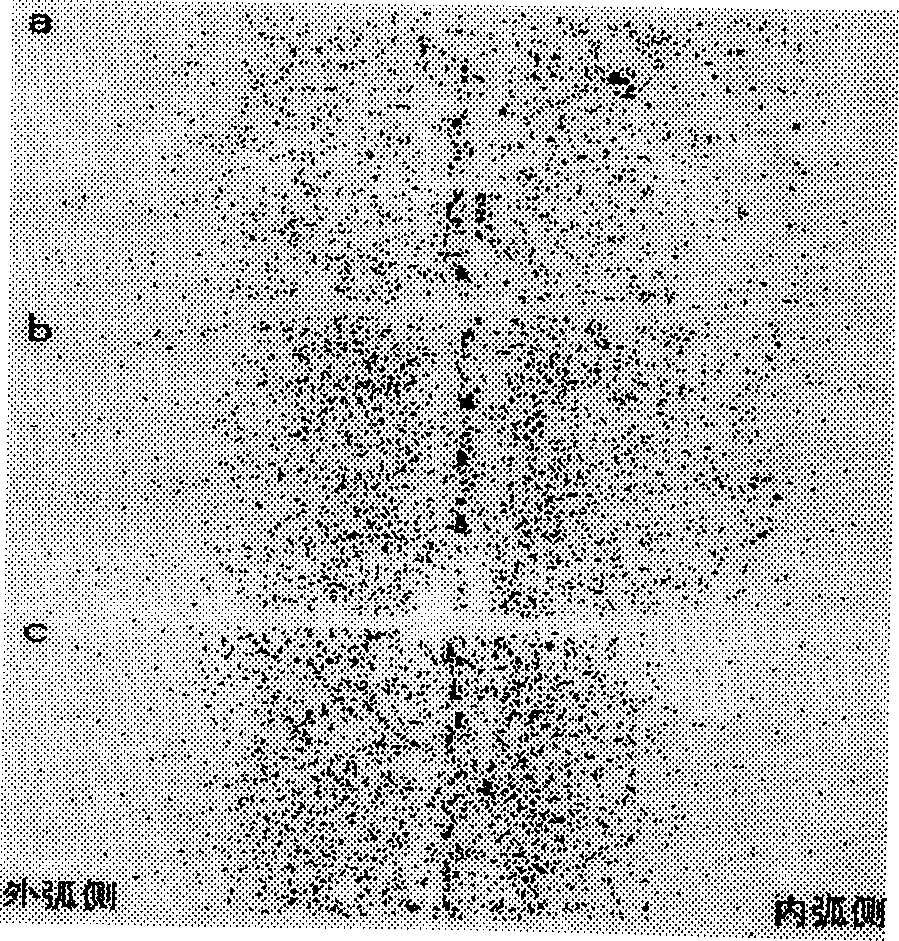

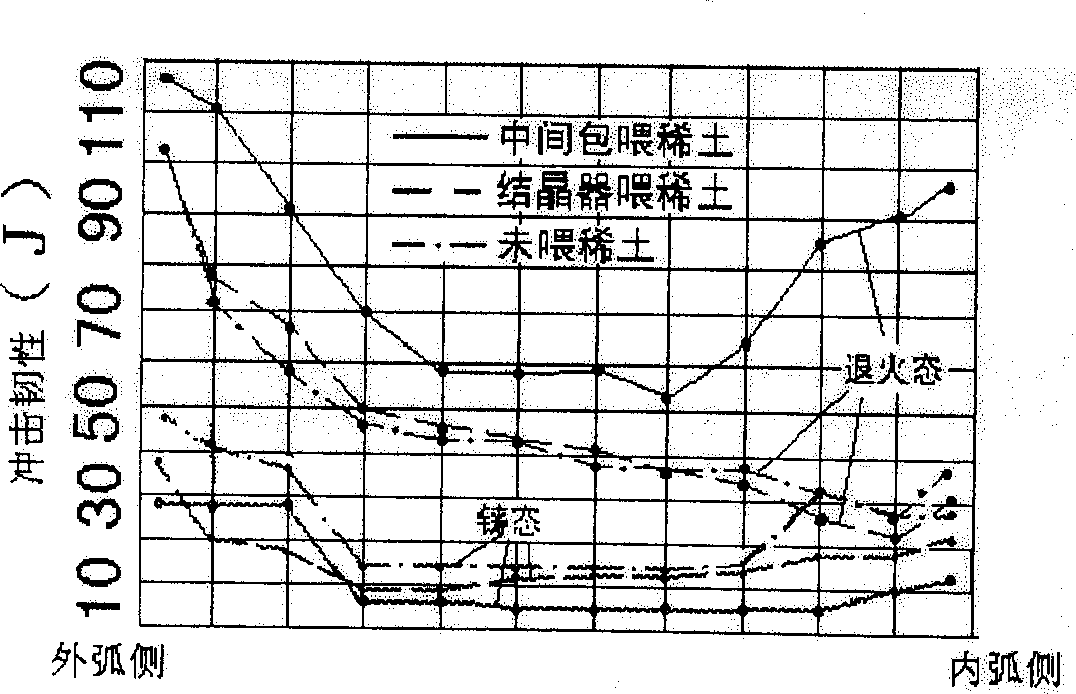

Conticasting technology for feeding rare-earth wires into tundish

A technology for feeding the rare-earth wire into conticasting tundish features that the molten steel flows from ladle into tundish and then into the crystallizer under the control of stopper, and the rare-earth wire comes into molen steel near the stopper in the tundish and is molten. Its advantages are uniform distribution of rare earth is molten steel, high effect on modifying sulfide, high rate of finished products and impact toughness, for conticast plate, and simple operation.

Owner:NANJING UNIV OF SCI & TECH +1

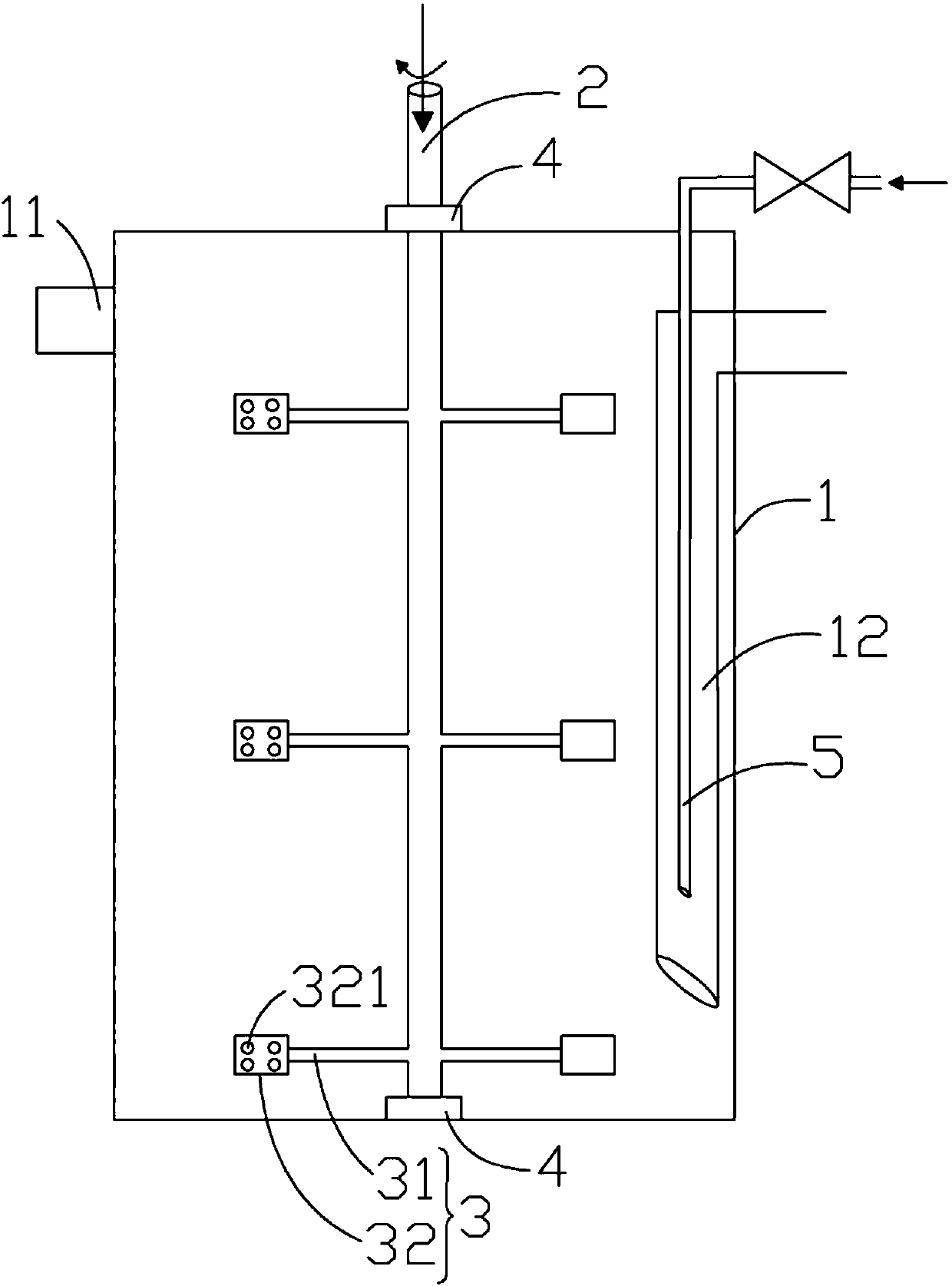

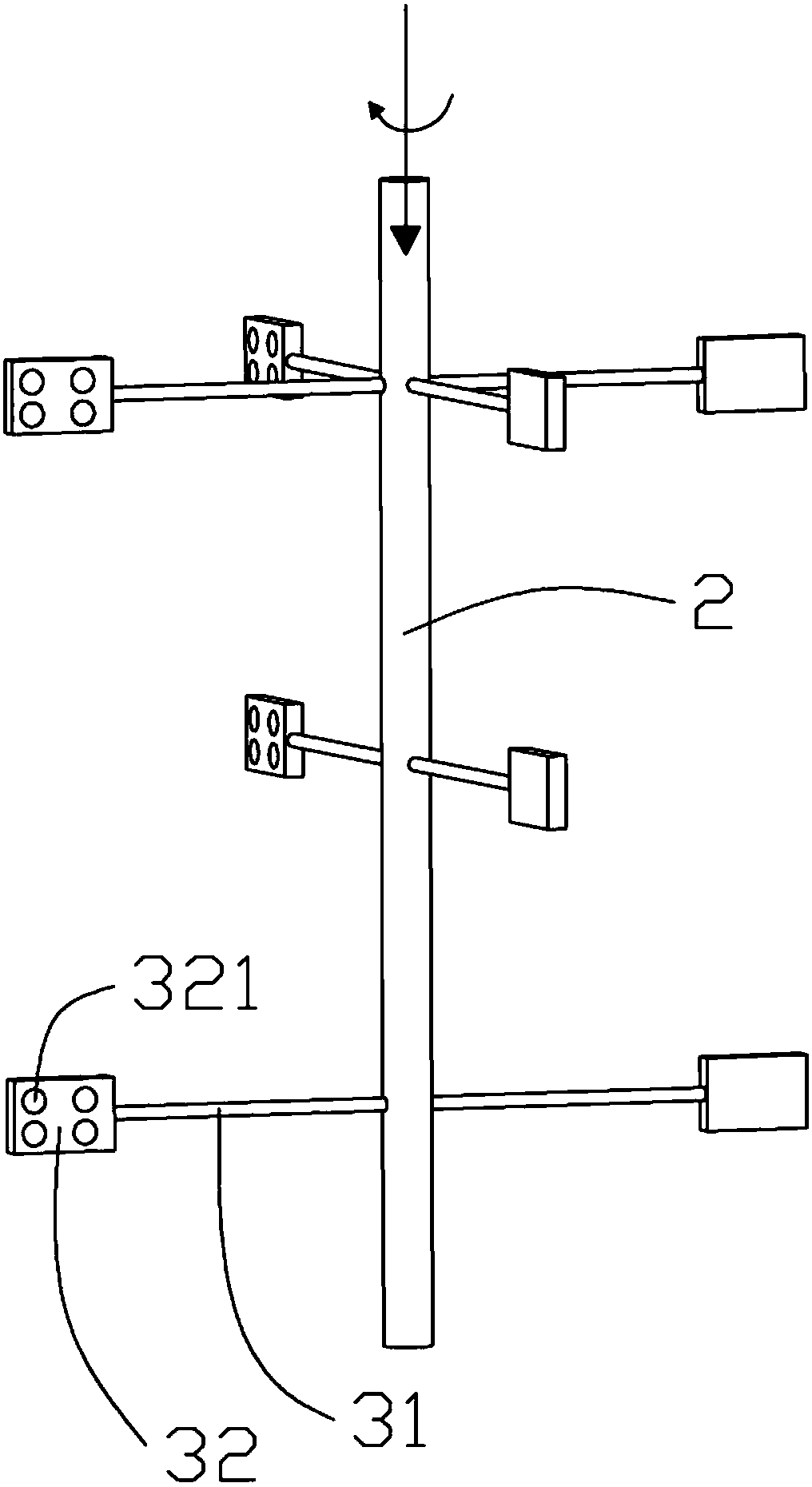

Stirring device capable of realizing cascading fermentation of solid waste and reactor

ActiveCN105436193AReduce mixImprove degradation efficiencySolid waste disposalAxial thrustEngineering

The invention discloses a stirring device capable of realizing cascading fermentation of solid waste and a reactor. The stirring device comprises a center shaft, a conveying screw and a plurality of stirring blades, wherein the conveying screw is used for axially pushing materials, is concentrically fixed on one side of the center shaft and extends from the shaft end to the middle of the shaft in tapered manner; the stirring blades and the conveying screw are coaxially fixed on the other side of the center shaft. The stirring device can be arranged in a barrel to form the reactor used for the solid waste. The layout standard of the stirring blades is that the axial thrust along the center shaft is not generated in the rotation process. Thus, a layered fermentation system can be formed in the reactor. The system can greatly reduce the mixing ratio of new and old materials, effectively control the standing time of solid materials in the reactor, improve the degradation efficiency of output materials, and increase the final product quality.

Owner:ZHEJIANG UNIV

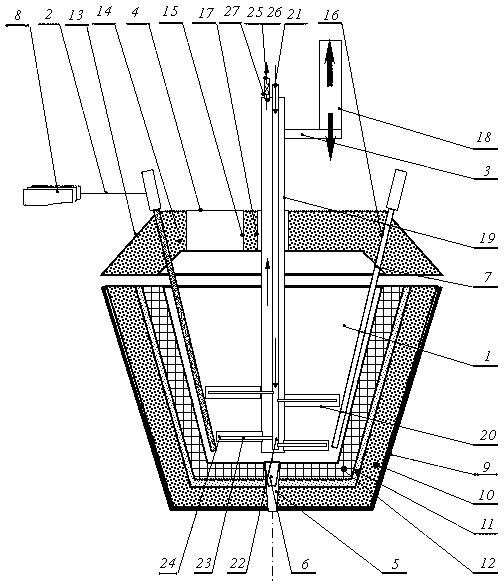

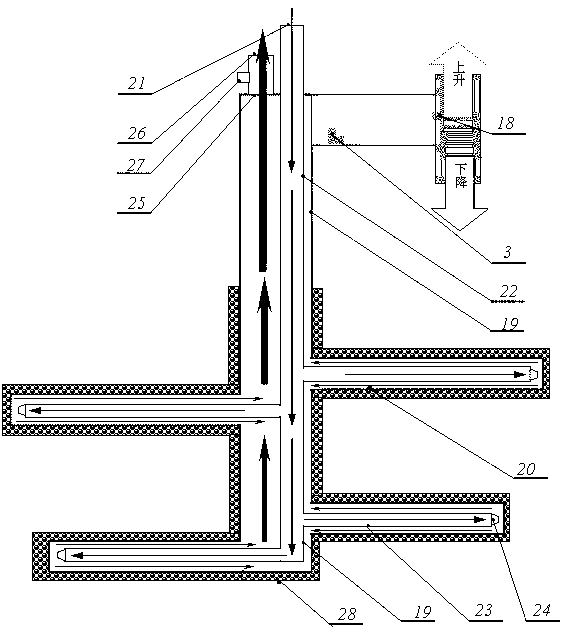

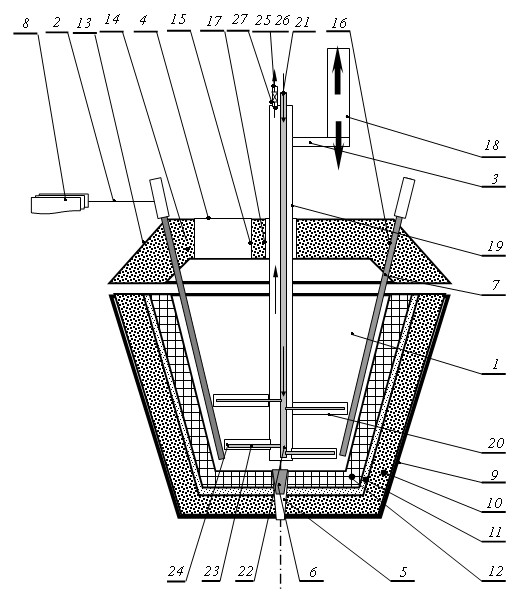

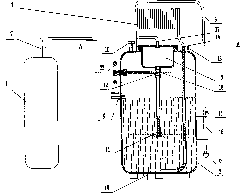

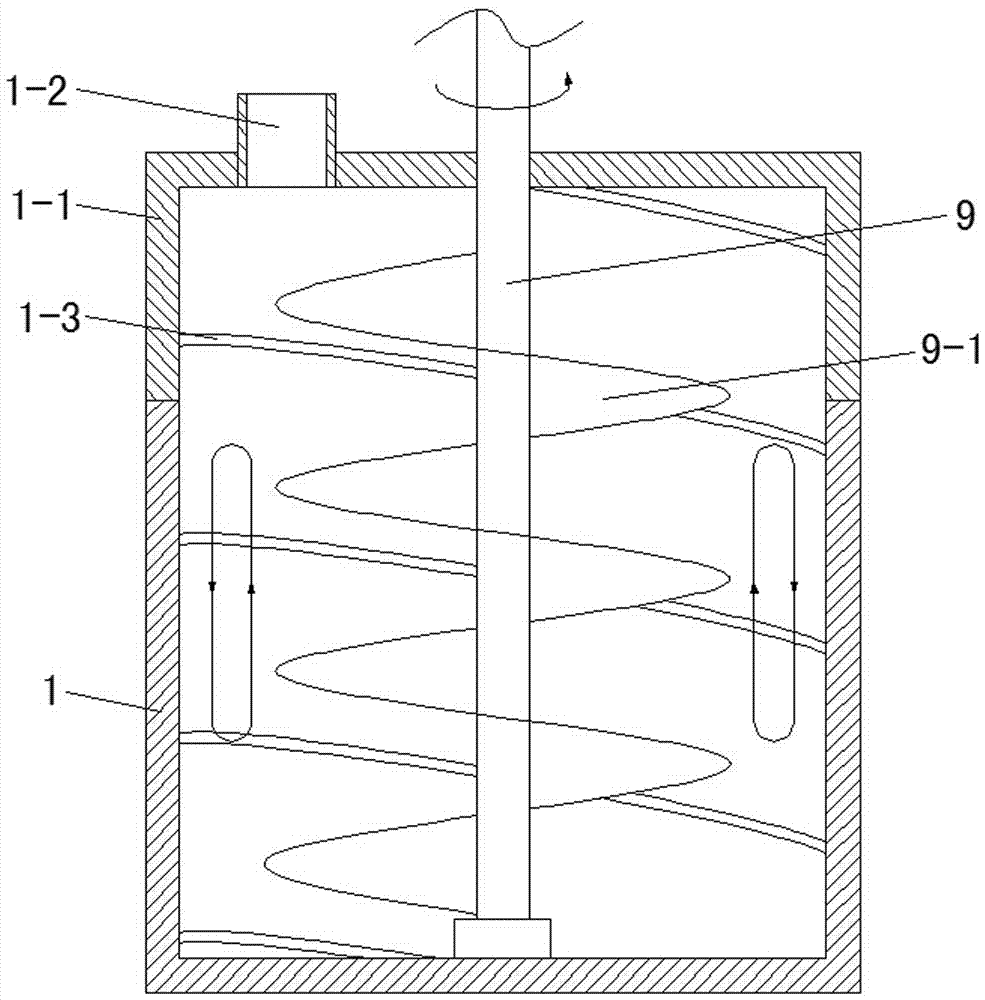

Device and method for homogenizing high-temperature melt

InactiveCN102698634AStirring power is smallIncrease the stirring areaRotary stirring mixersTransportation and packagingSlagHeating system

The invention provides a device and a method for homogenizing high-temperature melt and belongs to the technical field of melt homogenization. The device provided by the invention consists of three parts, namely a melting tank, a stirring system and a heating system. The detailed steps for homogenizing high-temperature melt carried out by the device provided by the invention are as follows: adding hot silicate slag and quenching-tempering material into the melting tank; after heating to melt the raw material, turning off the power supply; enabling the stirring part of the cooled stirring system to fall into the high-temperature melt, and finishing fall-rise-fall operating actions for stirring the melt in order, wherein the stirring process and the heating process are carried out alternatively; and under the condition that the test result of the samples shows that the composition uniformity and viscosity of the melt are suitable for the process conditions that the fiber is formed or the glass ceramics is prepared, opening a choke plug of the melting tank and making the melt flow out via the flow hole by the gravity of the melt to finish the homogenization process. The homogenizing device and the homogenizing method, provided by the invention, have the advantages of good homogenizing effect, good high-temperature strength and long service life of the stirring part.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

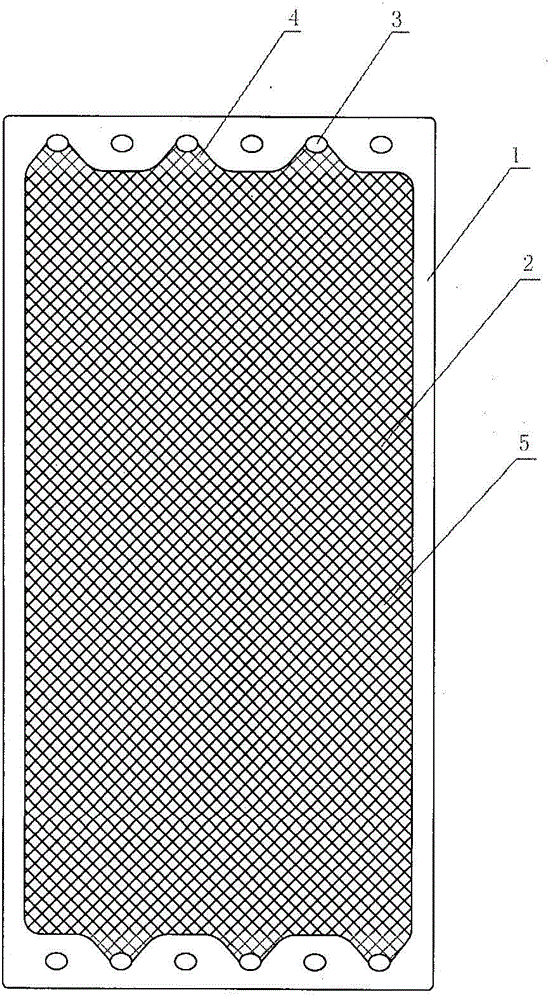

Electrodialysis separation plate for homogeneous membrane and preparation method thereof

InactiveCN105169950ACorrosion resistanceThe overall thickness is thinDispersed particle separationElectrodialysisPolyesterPower flow

The invention relates to the water treatment technical field, provides an electrodialysis separation plate for a homogeneous membrane and a preparation method thereof. The separation plate is composed of a separation plate frame and a separation plate net; the separation plate frame is a thermoplastic elastomer (TPE), the separation plate net is a polyester (PET) net, and the separation plate frame and the separation plate net are laminated together through high temperature heating. Through improvement of materials and a processing technology, the high-performance electrodialysis separation plate having the advantages of environmental-protection materials, thin thickness, good elasticity, good electrical insulativity and corrosion resistance is provided, is widely used in electrodialysis equipment using the homogeneous membrane, and improves the current efficiency of a homogeneous membrane electrodialysis system.

Owner:XIAMEN KENING WOTE WATER TREATMENT TECH

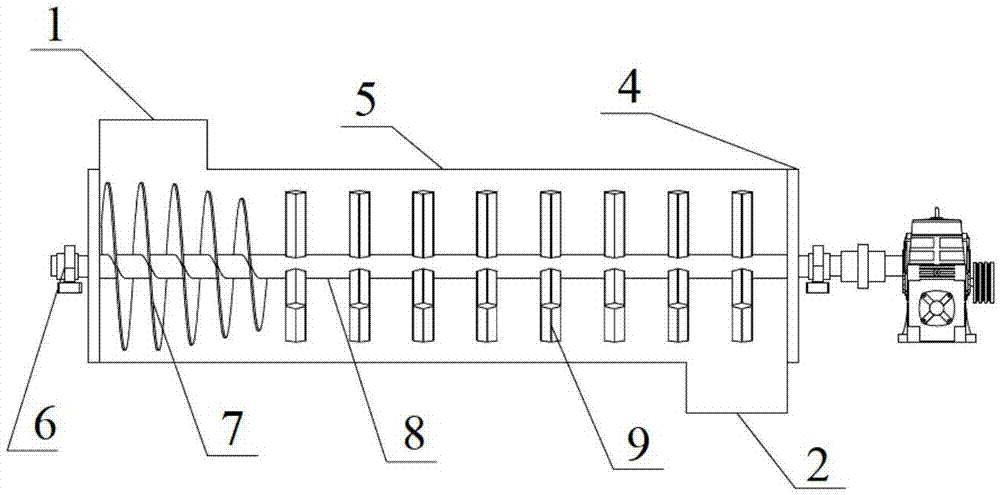

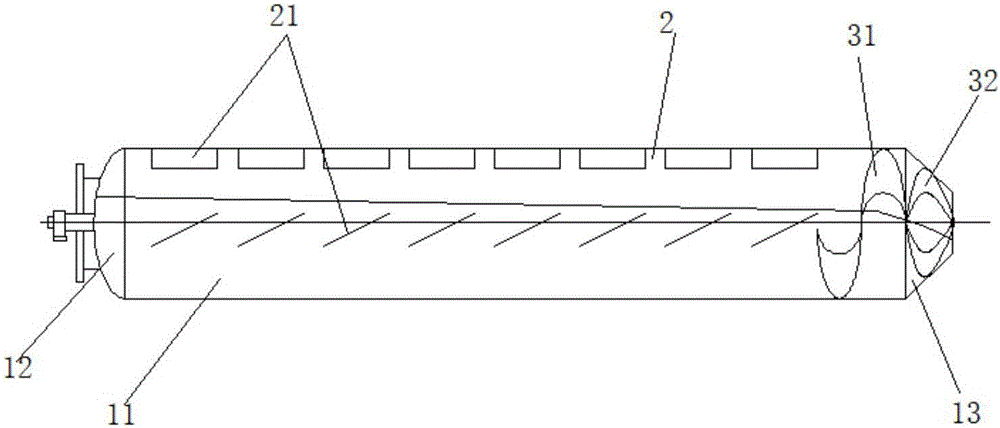

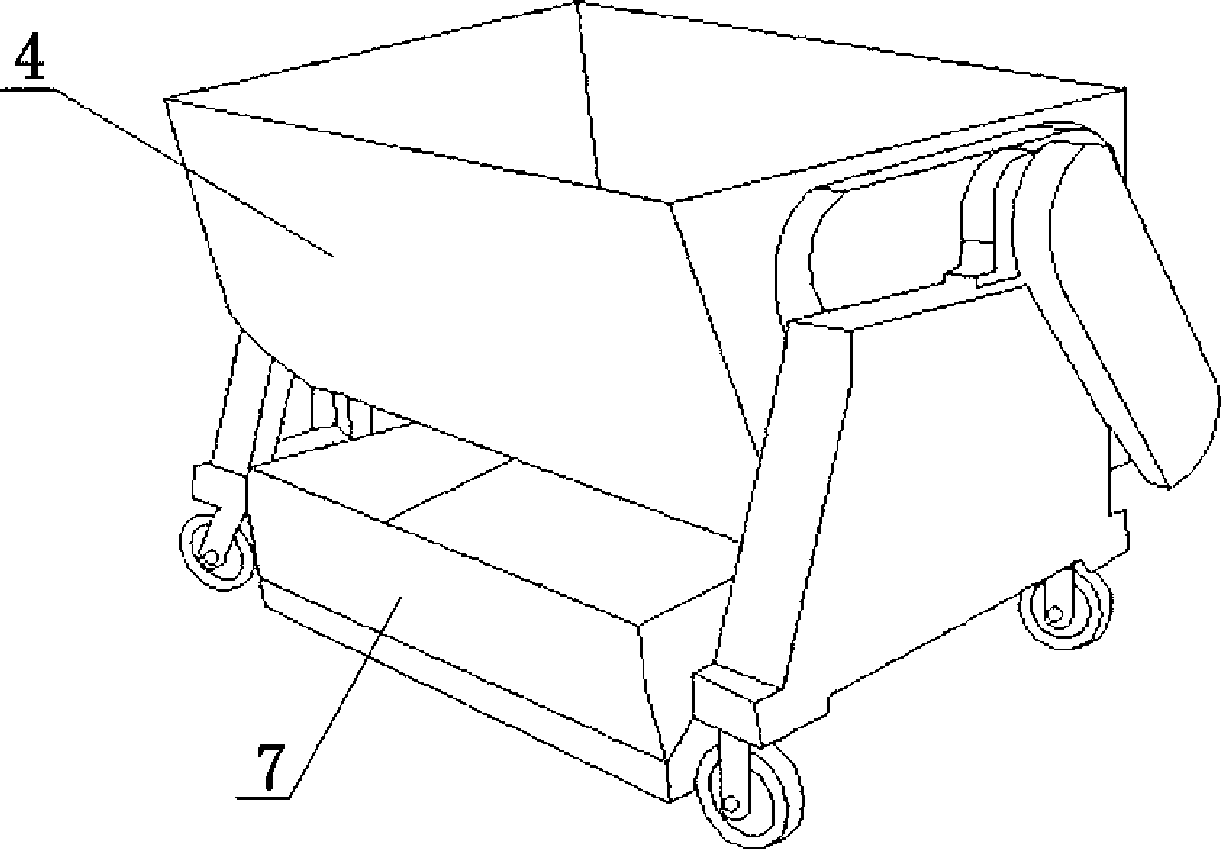

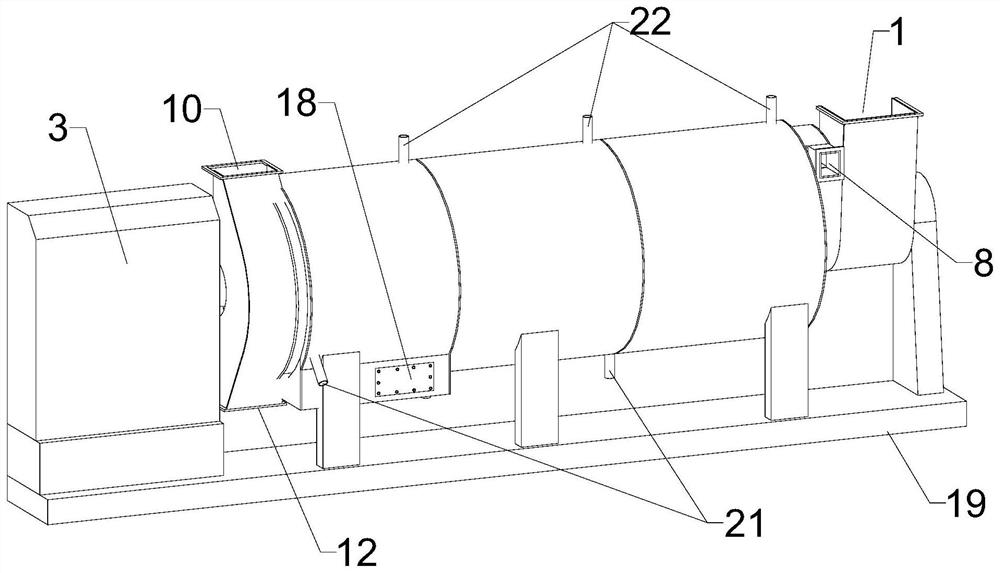

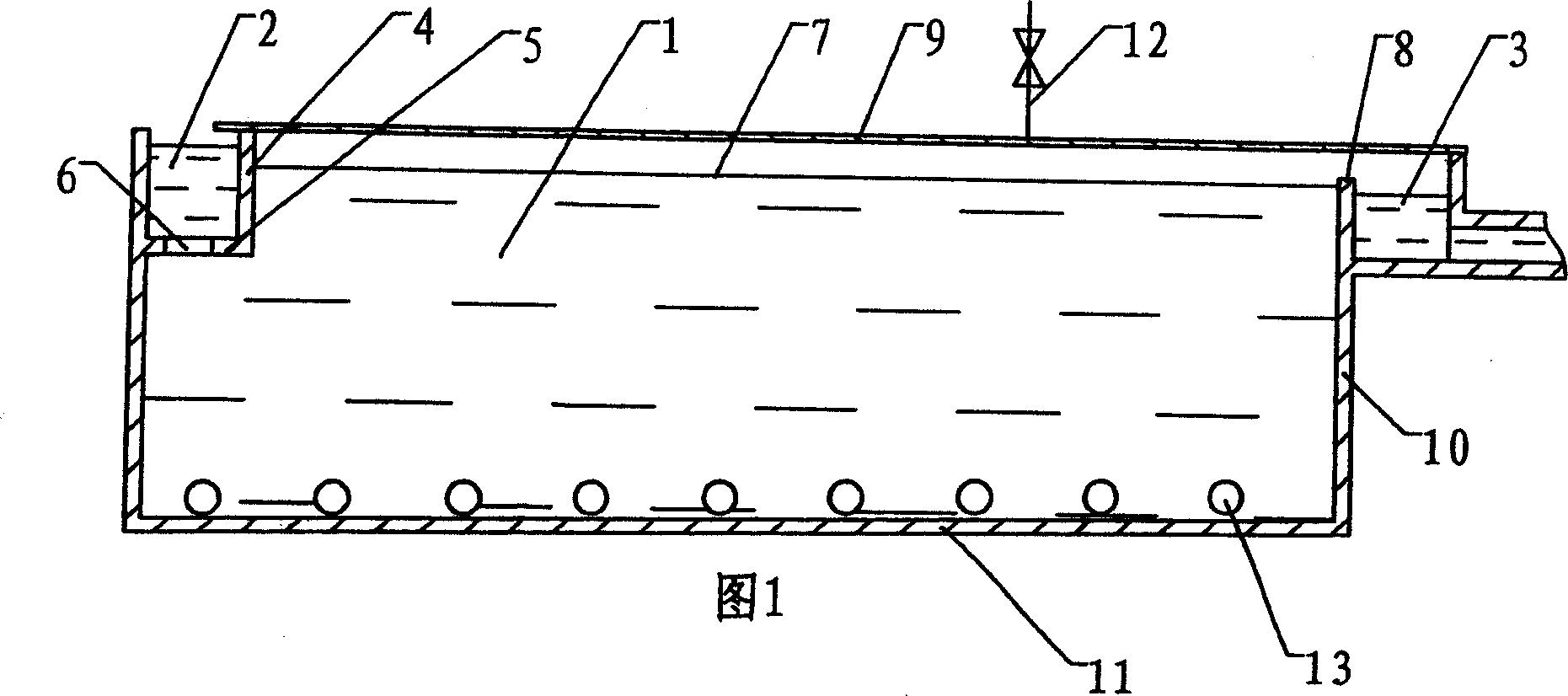

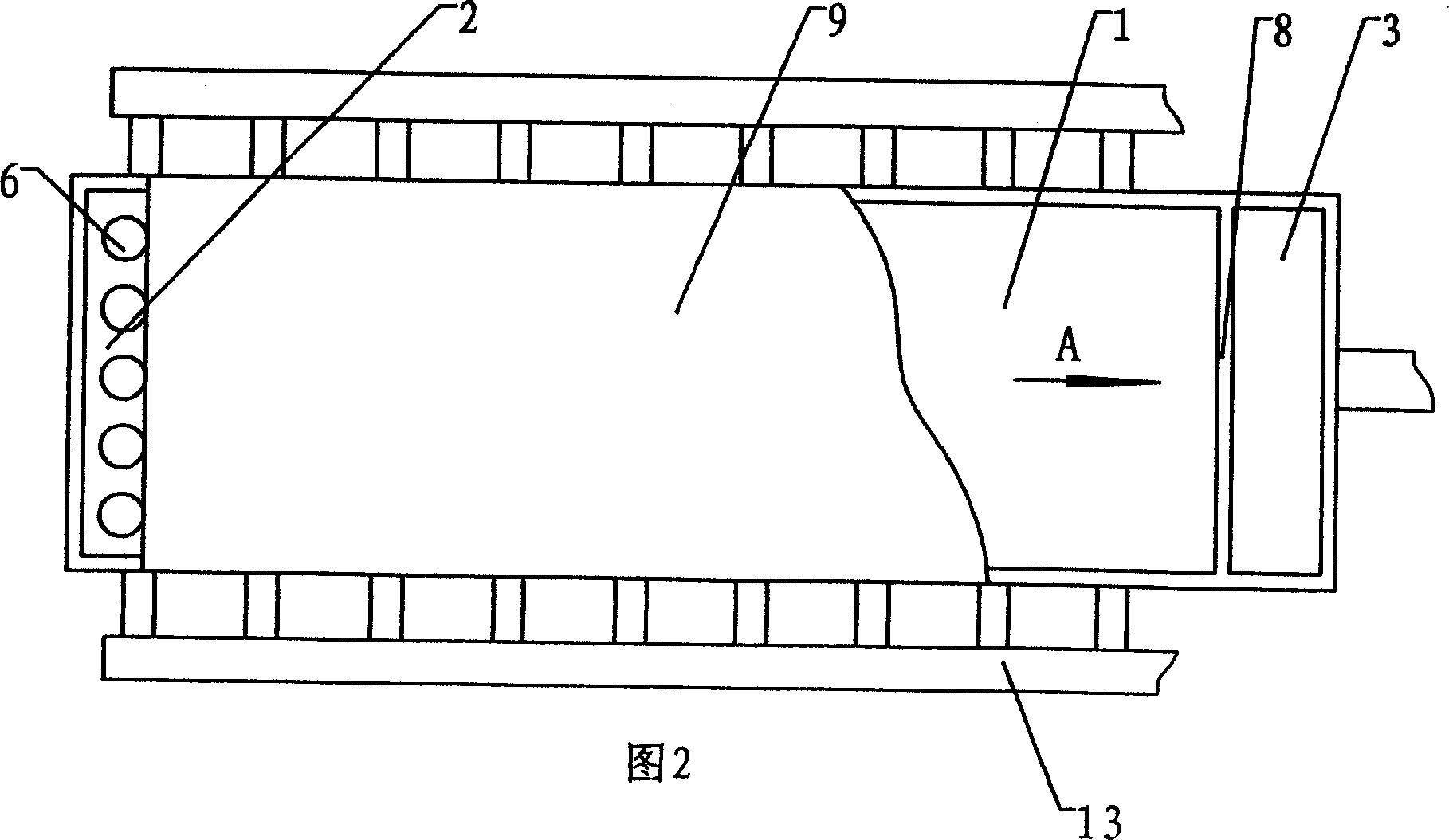

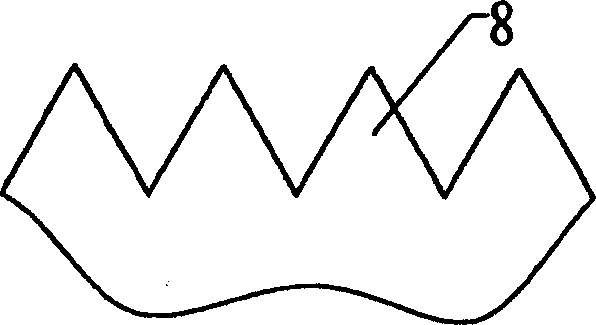

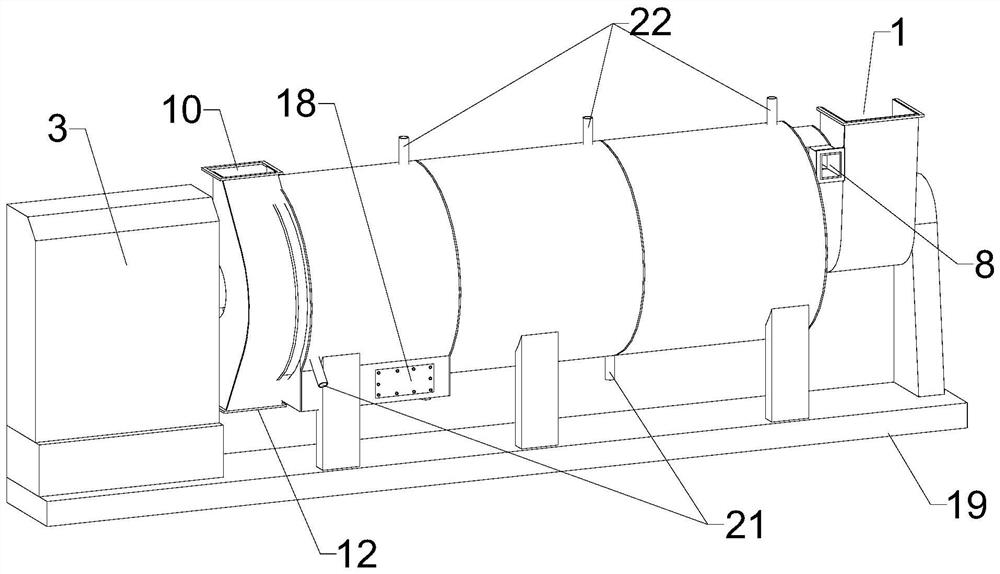

Horizontal type rotary drum stirring, feeding and discharging device

PendingCN106701530AWell mixedUniform output speedBioreactor/fermenter combinationsBiological substance pretreatmentsSpiral bladeFermentation

The invention relates to a horizontal type rotary drum stirring, feeding and discharging device which comprises a rotary drum body and a stirring device. A fermentation tank comprises a columnar cylinder body, a left sealing head and a right sealing head, the stirring device is arranged in the columnar cylinder body and is disconnected blades, the disconnected blades include sub-blades, and the sub-blades are fixed to the inner wall of the rotary drum body in an axial equally-spaced arrangement mode. The device further comprises a feeding and discharging device, wherein the feeding and discharging device is feeding and discharging screw blades, and the feeding and discharging screw blades are spiral blades fixed to one end of the inner wall of the rotary drum body. The horizontal type rotary drum stirring, feeding and discharging device has the advantages that the disconnected blades can spread a material and can also push materials towards two sides, a stirring effect can be achieved only through one-way rotation, a stirring effect is stronger compared with traditional common spiral blades, the fermentation efficiency is improved, the designed feeding and discharging screw blades achieve forward feeding and reverse discharging, the feeding and discharging speed is uniform and rapid, and the material level is flat.

Owner:山西金龙鱼梁汾醋业有限公司

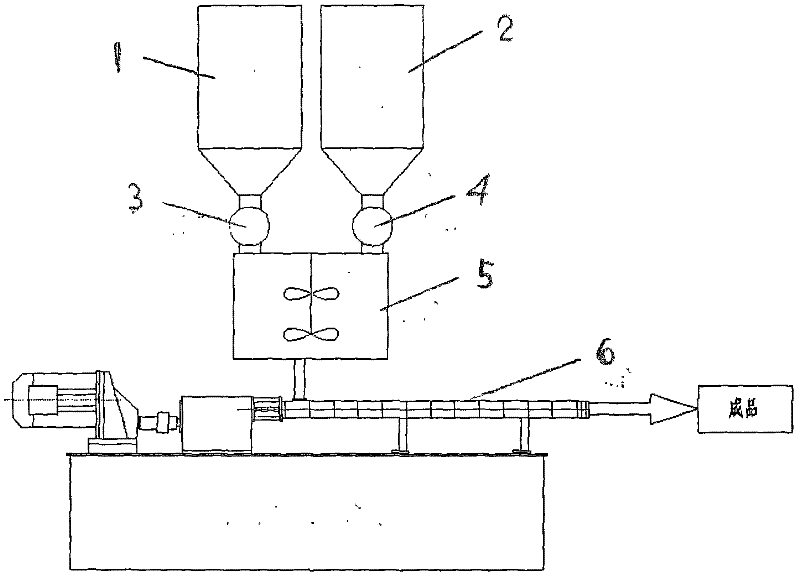

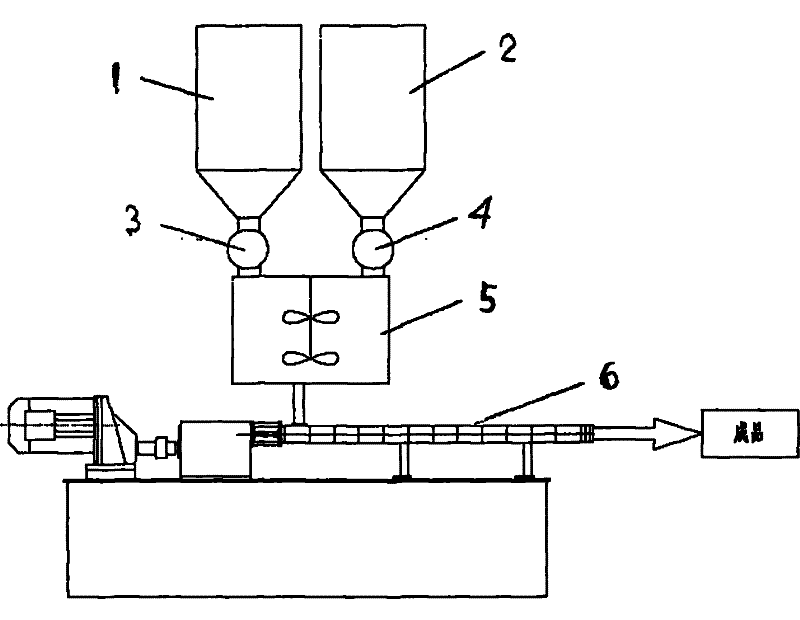

Low-alcoholysis-degree polyvinyl acetate (PVA) continuous alcoholysis process

InactiveCN102127177AReduce usageLow raw material costChemical recyclingPolyvinyl acetateRetention time

The invention discloses a novel polyvinyl acetate (PVA) continuous alcoholysis process. The process comprises the following steps of: adding polyvinyl acetate (PVAc) methanol solution and catalyst sodium hydroxide (NaOH) methanol solution into a prereactor according to a fixed amount and mixing quickly and uniformly; adding mixed solution into a reaction type double-screw extruder to perform an alcoholysis reaction; extruding from a machine head mould to obtain white granular products; and performing treatment of acid neutralization, drying and the like to obtain the final product. The process has the advantages of high reaction speed, high reaction capacity, controllable retention time of reactants, narrower retention time distribution, capability of continuous production and the like. Compared with the traditional process, the process also has the advantages of reducing the using amount of a solvent methanol and a catalyst NaOH, along with low recovery cost of the solvent and alkali and environmental friendliness. The low-alcoholysis-degree PVA product obtained by the process has narrow alcoholysis-degree distribution and stable properties.

Owner:云南煤化工应用技术研究院有限公司 +1

Double-horizontal axle concrete-mixer

InactiveCN101474825AAchieve fixationSpacing is easy to adjustCement mixing apparatusReducerScrew thread

A double-horizontal axle concrete-mixer comprises a material barrel, mixing shafts in the material barrel and mixing blades which are connected with the mixing shaft. The mixing shaft is connected with the revolving mechanism of speed reducer of main motor. Two mixing shafts are installed in parallel in the material barrel. The mixing blades on two mixing shafts have same installation form and opposite installation directions. The mixing blades are distributed with a spiral form along the axial directions of mixing shafts. The middle part of mixing shaft is connected with middle mixing blades. Two ends of mixing shafts are connected with end mixing blades. The blade surface of middle mixing blade has a sickle shape. The blade surface of end mixing blade has a kitchen knife shape. The end of knife handle is provided with screw thread. The knife handle traverses the radial preserved hole passage of mixing shaft. The screw thread at end of knife handle is connected with the nut. The double-horizontal axle concrete-mixer of the invention has advantages of stronger mixing capability, simpler structure of mixing shaft, and easy changing and regulation of mixing blade.

Owner:建研建材有限公司 +1

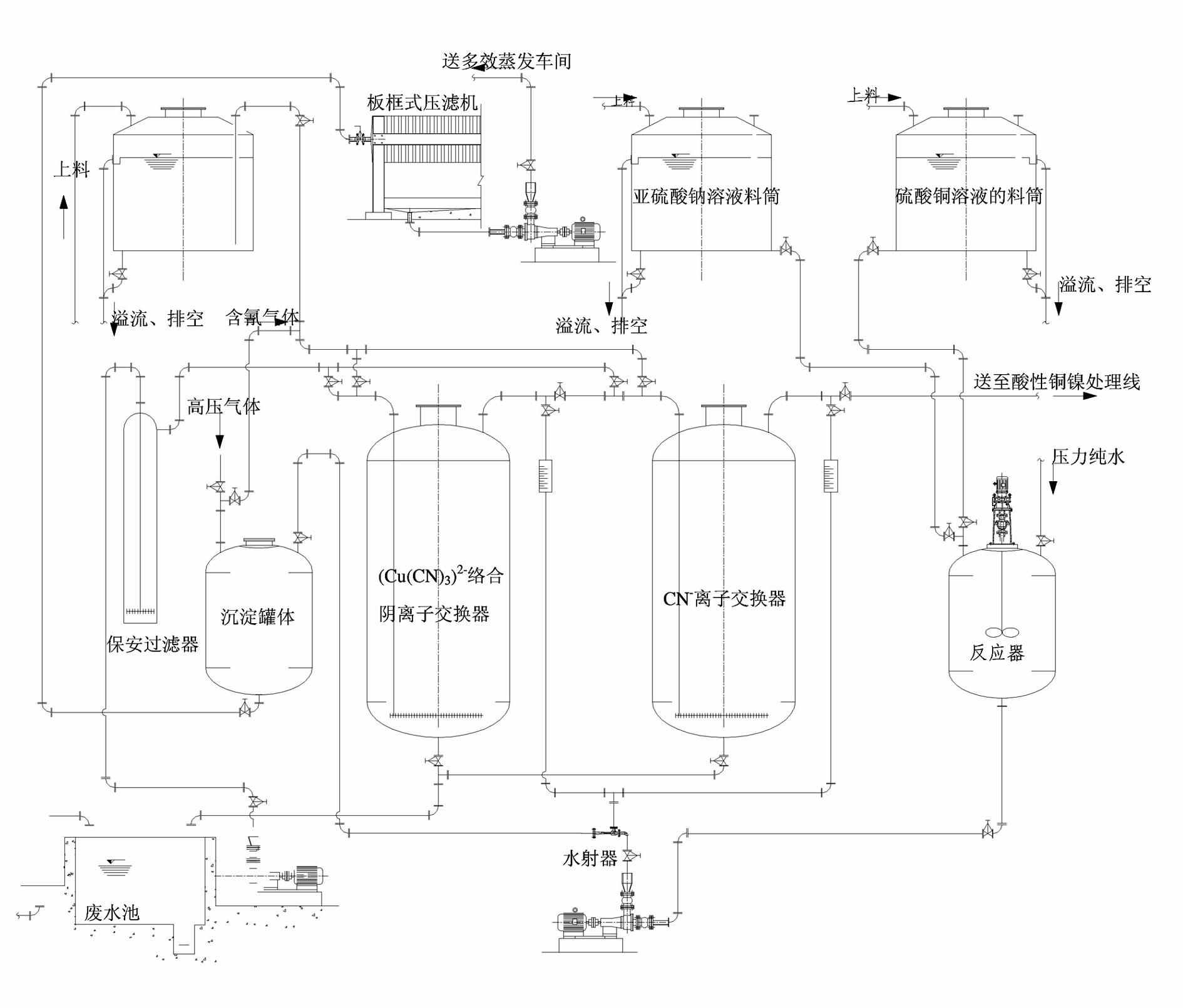

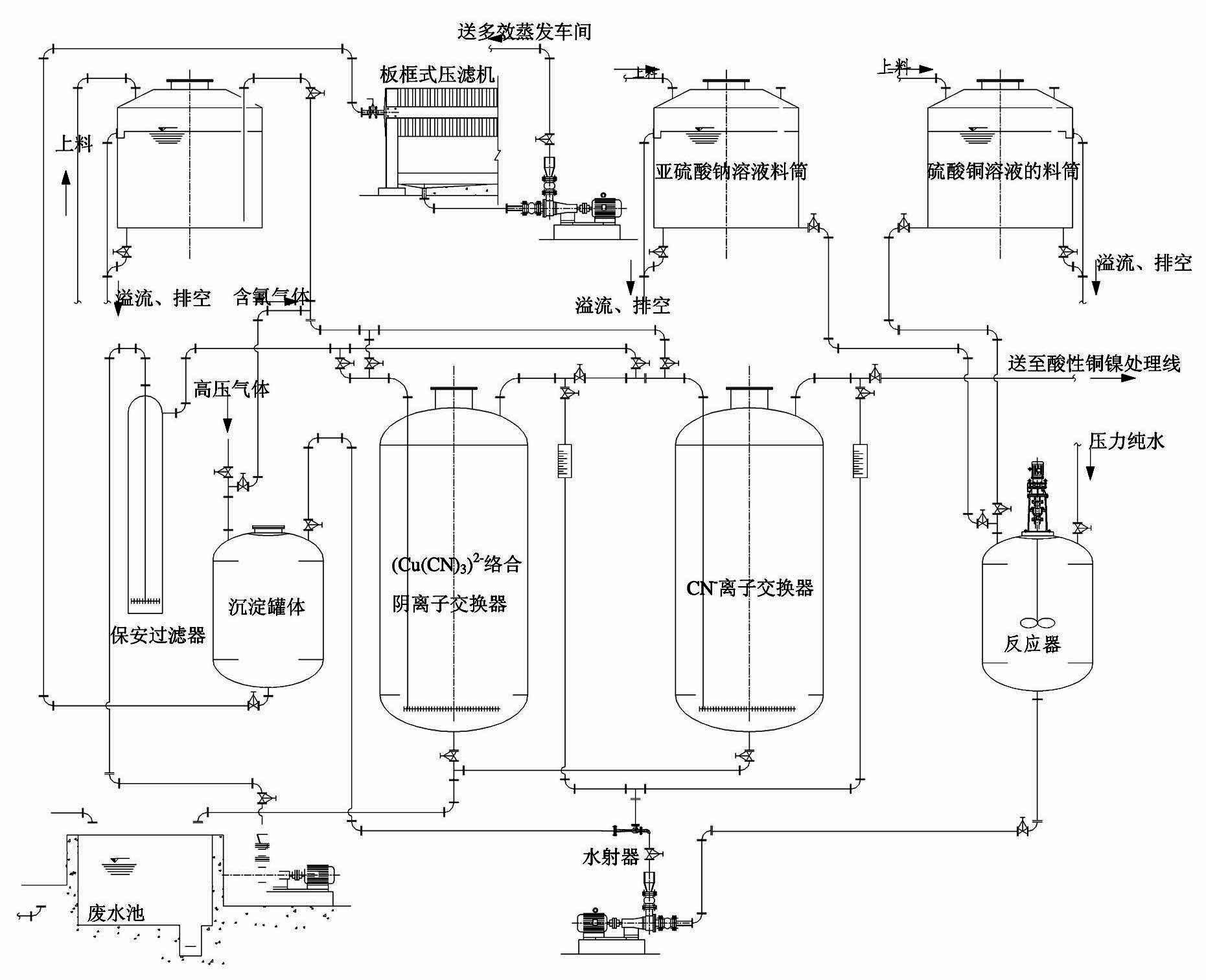

Process and equipment for treating wastewater containing cyanide ions

ActiveCN102153161ADoes not increase mineralizationReduce the impactWater contaminantsCyanic/isocyanic acidEnrichment methodsIon exchange

The invention discloses a process and equipment for treating wastewater containing cyanide ions. The equipment comprises a security filter, an ion exchanger loaded with cyanogen removal resin, a water injector and a sedimentation tank body. The process comprises the following steps of: after the wastewater is pre-filtered, adsorbing the cyanide ions by the cyanogen removal resin; after the cyanogen removal resin adsorbs the cyanide ions to be saturated, carrying out elution; sucking out hydrocyanic acid formed after elution under negative pressure formed at an outlet of the water injector; and mixing the sucked hydrocyanic acid and cuprous salt solution injected by the water injector to perform a reaction to form copper cyanide precipitates. The process has the principle that the cyanide ions in the wastewater are reduced by an enrichment method, and does not adopt a dispensing or electrolyzing mode just like the conventional method, and thus, the process does not need to consume any energy resources and is more environmental-friendly and the mineralization of water cannot be increased in the whole technological process.

Owner:江门市崖门新财富环保工业有限公司

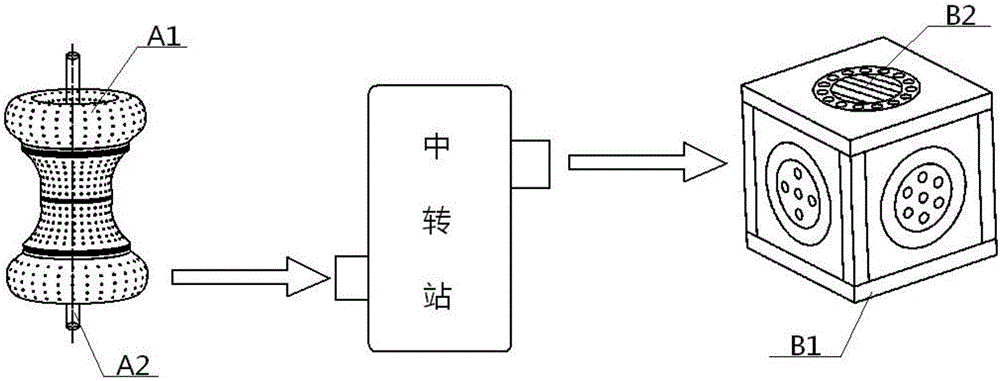

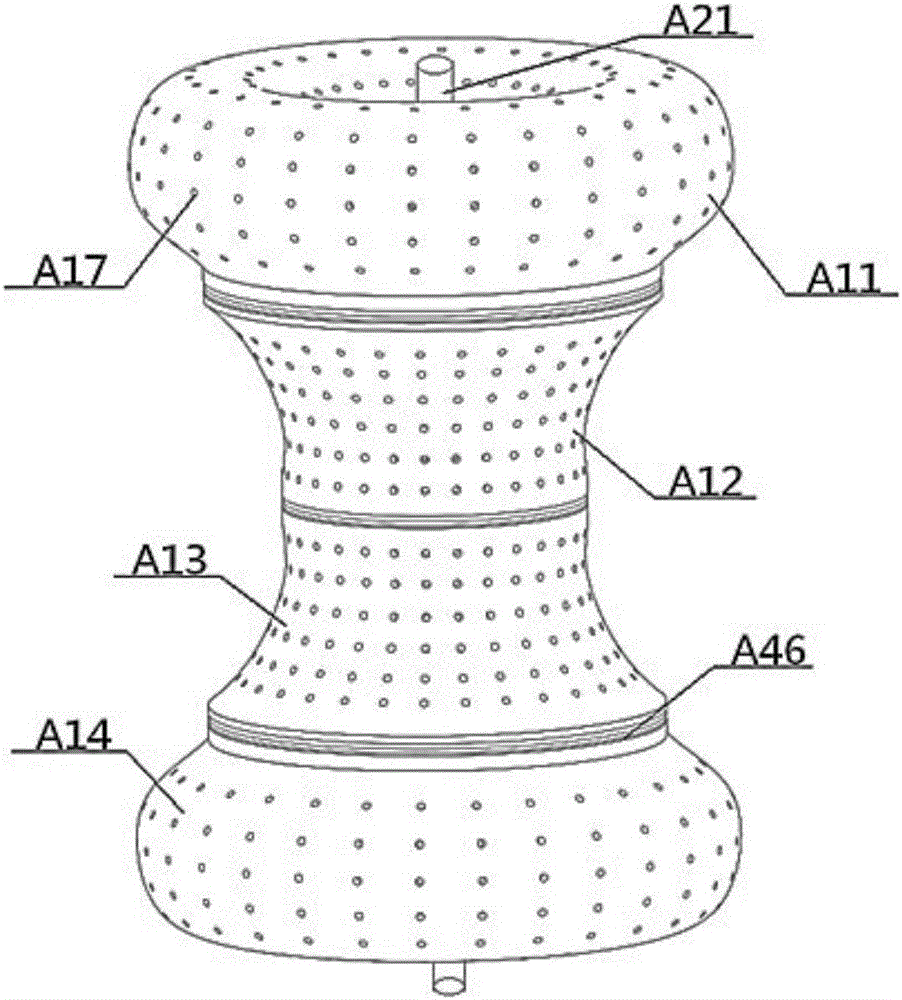

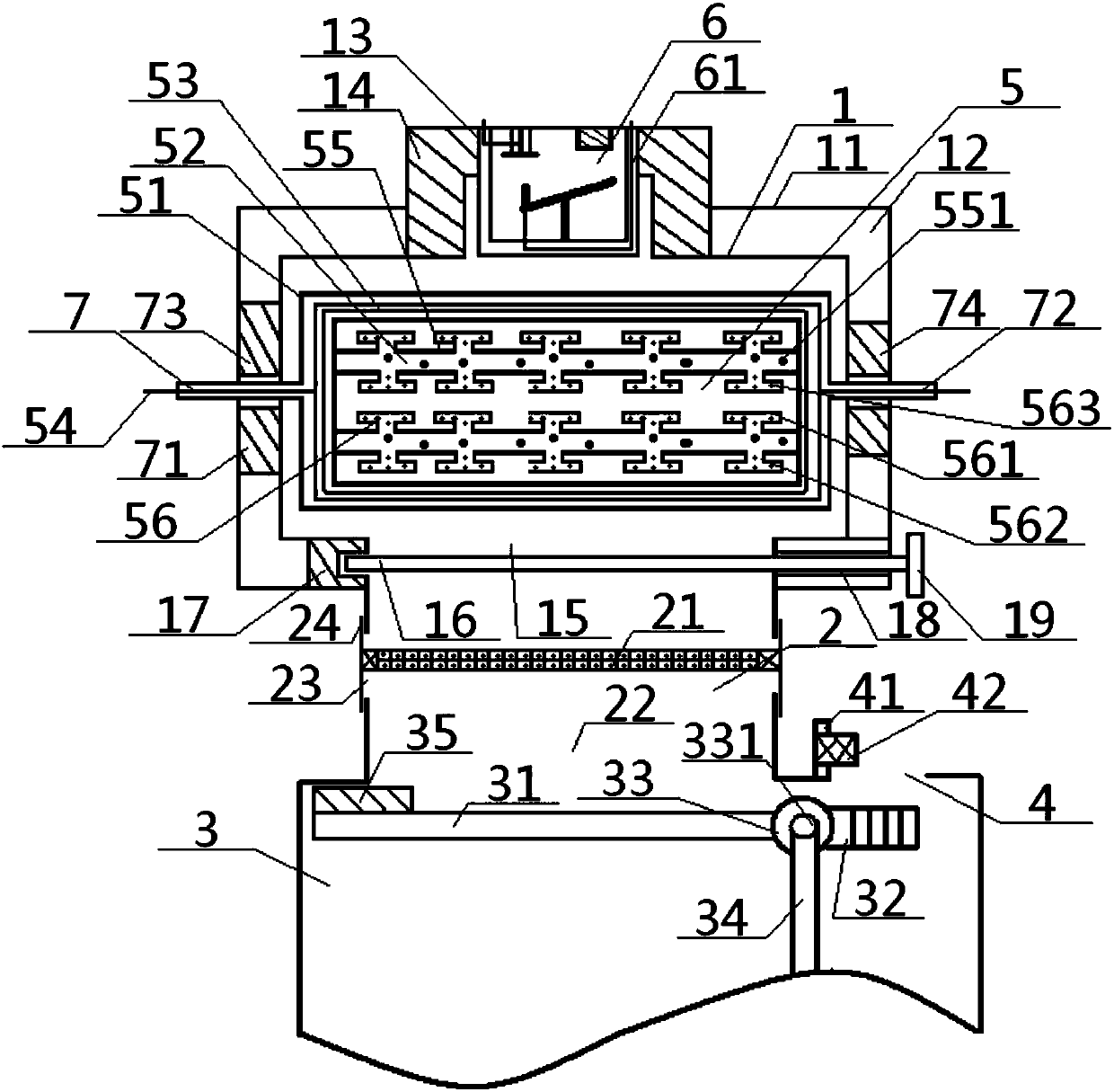

Refining and mixing system adopted in wet-process phosphoric acid refining process by solvent extraction method

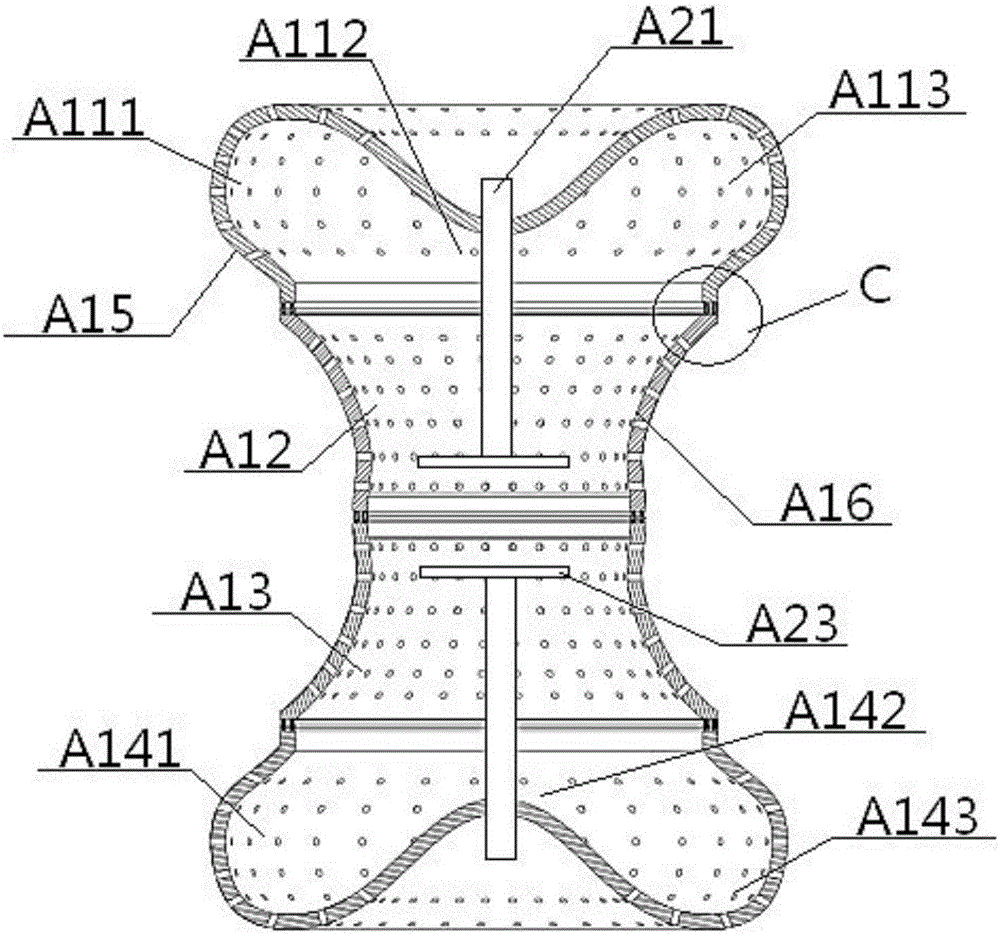

ActiveCN106379879AImprove uniformityImprove stirring effectPhosphorus compoundsPhosphoric acidLubrication

A refining and mixing system adopted in a wet-process phosphoric acid refining process by a solvent extraction method is used for liquid-liquid mixing or liquid-powder mixing and comprises an A type mixing device, a transfer station and a B type mixing device which communicate with each other successively, wherein the A type mixing device has functions including that an external containing body can rotate, a heating body can be arranged and a rotating airflow can be generated, and a stirrer has three functions of body stirring, airflow stirring and enhanced stirring; the B type mixing device has functions including that an external containing body can generate a rotating airflow, a heating body can be arranged and a module can be replaced, and a stirrer has four functions of body stirring, airflow stirring, enhanced stirring, and midway addition of raw materials. The system can eliminate a fluid stagnation zone, can heat a mixed object, has the advantages of good mixing performance and high uniformity, can achieve rotation of an external container, strong lubrication effect, various stirring functions and midway addition, and has a wide range of application.

Owner:HUAZHONG NORMAL UNIV

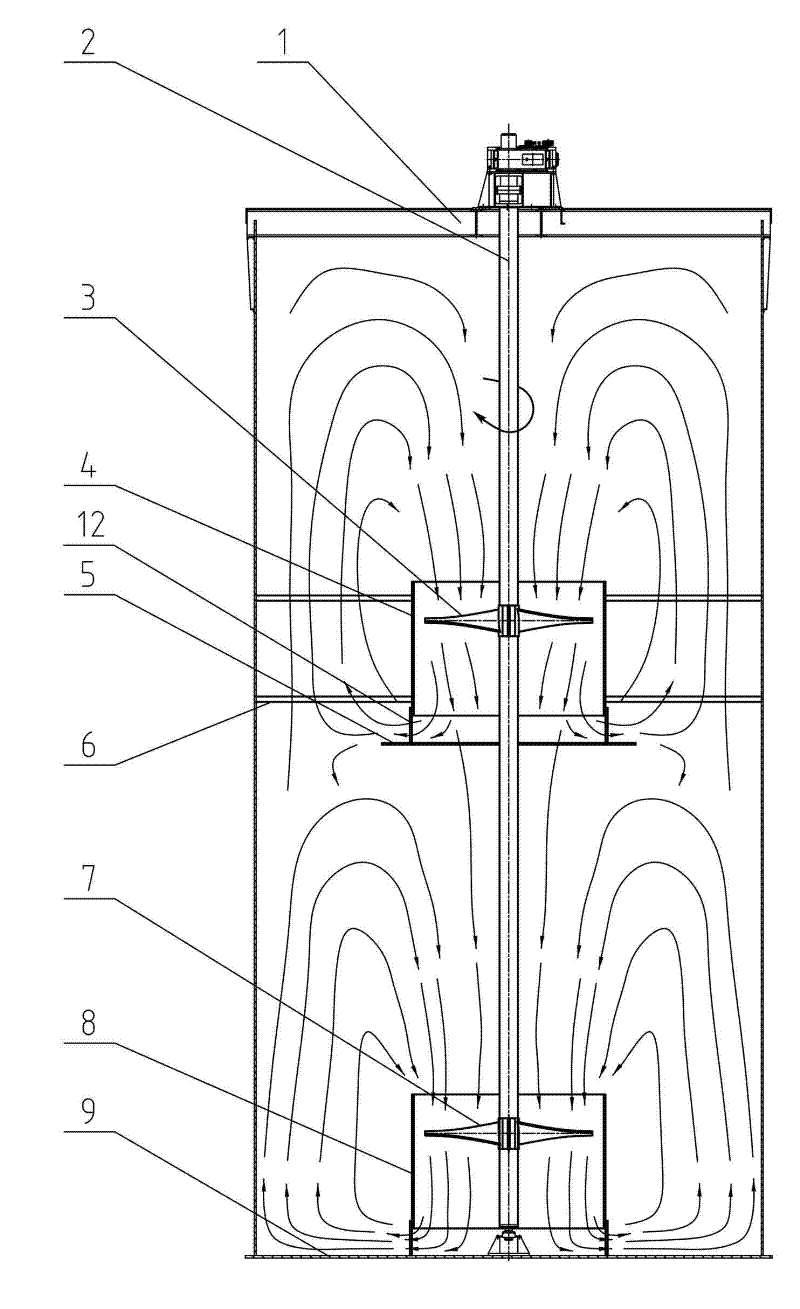

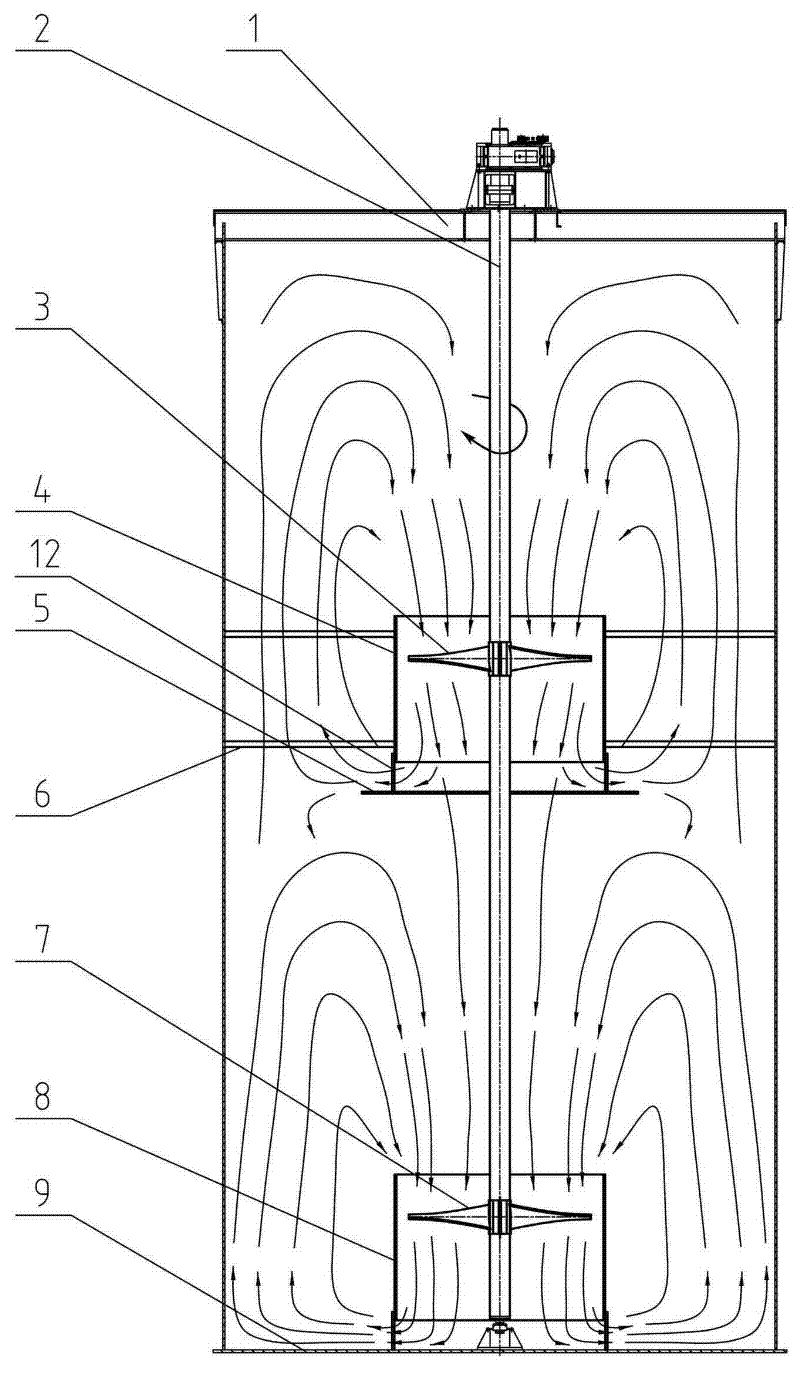

Agitating device of high-performance agitating tank

InactiveCN102527275ASignificant effective stirring rangeReduce shearRotary stirring mixersTransportation and packagingSheet steelEngineering

The invention relates to an agitating device, in particular to an agitating device of a high-performance agitating tank. The agitating device comprises an agitating paddle, wherein the agitating paddle is divided into an upper-layer paddle and a bottom-layer paddle; the outer circle of the upper-layer paddle is provided with a circle of upper-layer steel plate cylinder; a ring baffle is arranged below the upper-layer steel plate cylinder; the upper-layer steel plate cylinder is connected with the side wall of the agitating tank through a support plate; the outer circle of the bottom-layer paddle is provided with a circle of lower-layer steel plate cylinder; and the lower-layer steel plate cylinder is fixed on a bottom plate of the tank through the support plate. The invention has the following advantages: the agitating effect is better, the flow rate is accelerated, the scouring force is greatly increased, and the agitating strength is enhanced; compared with a common paddle, the energy is saved by about 40-60%; the effect on eliminating precipitates and scabs is obvious; and a common vertical baffle is canceled, so that energy consumption is reduced, and shear on liquid flows is reduced, thereby being beneficial to the growth of crystal grains in a seed precipitation tank.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

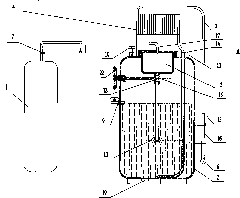

Pressure-storage premix type water mist foam fire extinguishing apparatus for ships

The invention relates to a pressure-storage premix type water mist foam fire extinguishing apparatus for ships, comprising a high-pressure tank, a storage tank, a flexible pipe, a bobbin disc and a water mist foam spray head, wherein the inner side of the top of the storage tank is provided with a foam raw liquor bottle; the foam raw liquor bottle is communicated with a high-pressure gas inlet; the high-pressure gas inlet is connected with the high-pressure tank by a high-pressure gas pipe; the outlet of the bottom of the foam raw liquor bottle is provided with a three-way valve; the downward outlet of the three-way valve is communicated with a foam raw liquor spray head by a pipe fitting; water is filled in the storage tank; the water level is arranged at the position of an overflow gap; the spray head is arranged below the liquid level in the storage tank; the rightward outlet of the three-way valve is arranged above the liquid level in the storage tank; the rightward outlet of the three-way valve is communicated with a regulating valve by the pipe fitting. The invention has compact structure, small volume and high fire extinguishing efficiency and is conveniently rapidly shifted on the ships for put out fire in initial stage and larger fire in time; foam raw liquor is sprayed to water by 360 degrees by adopting double foam raw liquor spray heads, and secondary stirring mixing is carried out on mixed liquid by subsequently sprayed high-pressure gas; matching is accurate, and mixing is evener.

Owner:UNIV OF SCI & TECH OF CHINA

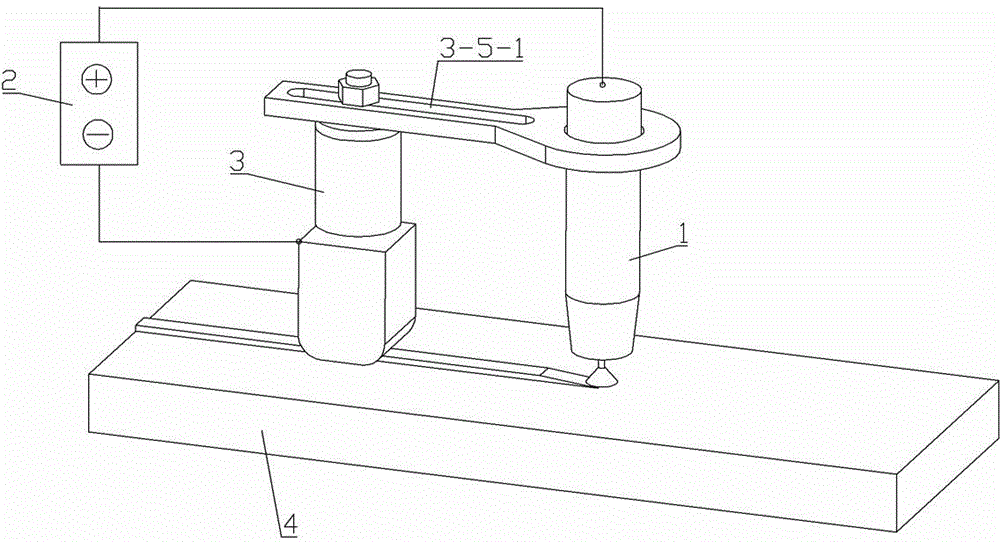

Large-area metal wall surface field patching surfacing welding method and surfacing welding device

InactiveCN104827168ASoft textureGood high temperature resistanceArc welding apparatusInstabilityEngineering

The invention provides a large-area metal wall surface field patching surfacing welding method. A synchronous moving mechanism is installed on a welding gun of a surfacing welding device, in a surfacing welding process, a graphite sliding block on the synchronous moving mechanism is always located at the back of a welding pool and tightly pressed onto a surface welding layer by an elastic pressing mechanism on the synchronous moving mechanism, the graphite sliding block moves together with the welding gun, and welding current enters into a workpiece through electric arcs from a welding wire of the welding gun and returns to the welding machine power source negative pole from the graphite sliding block. The surfacing welding device comprises the welding gun, a welding machine power source and the synchronous moving mechanism. The synchronous moving mechanism comprises an elastic pressing mechanism and an insulation connecting plate. The elastic pressing mechanism comprises a shell, a pushing plate, a spring, an end cap, the graphite sliding block and a concave disk, and in surfacing welding, the spring generates a pressing force on the graphite sliding block. According to the large-area metal wall surface field patching surfacing welding method, the graphite sliding block is used for achieving the moving type connection between welding machine ground wires and the workpiece, the backward current distribution in the welding pool is strengthened, and combined with an externally added transverse magnetic field or a longitudinal magnetic field, the problems of the welding pool instability and organizational regulation and control caused by the gravity of metal wall surface field patching surfacing welding are solved.

Owner:NANHUA UNIV

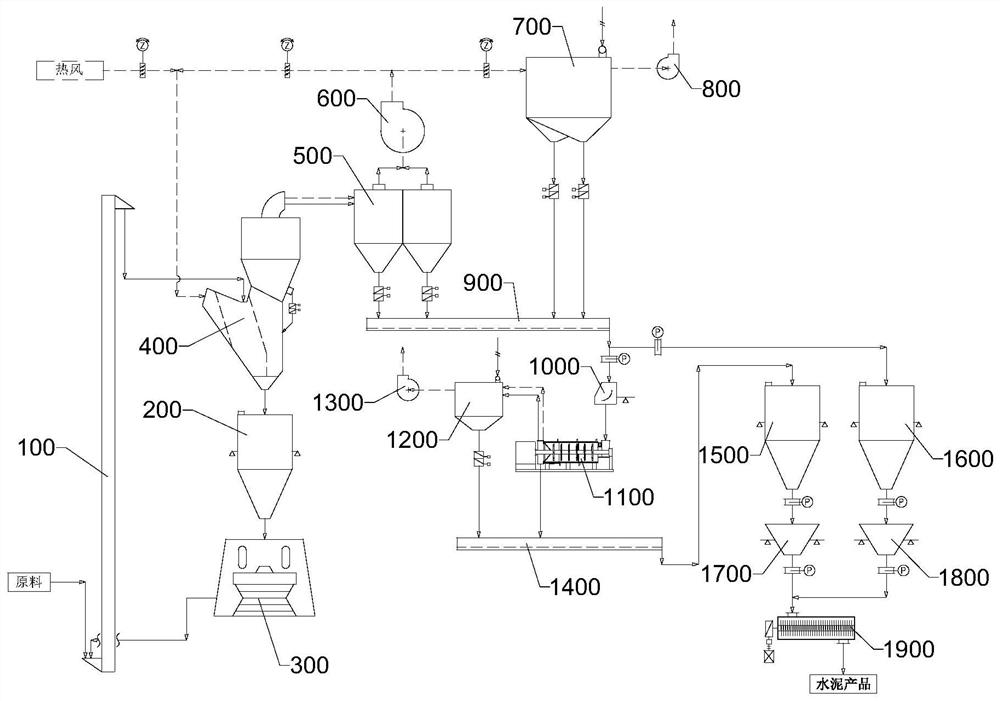

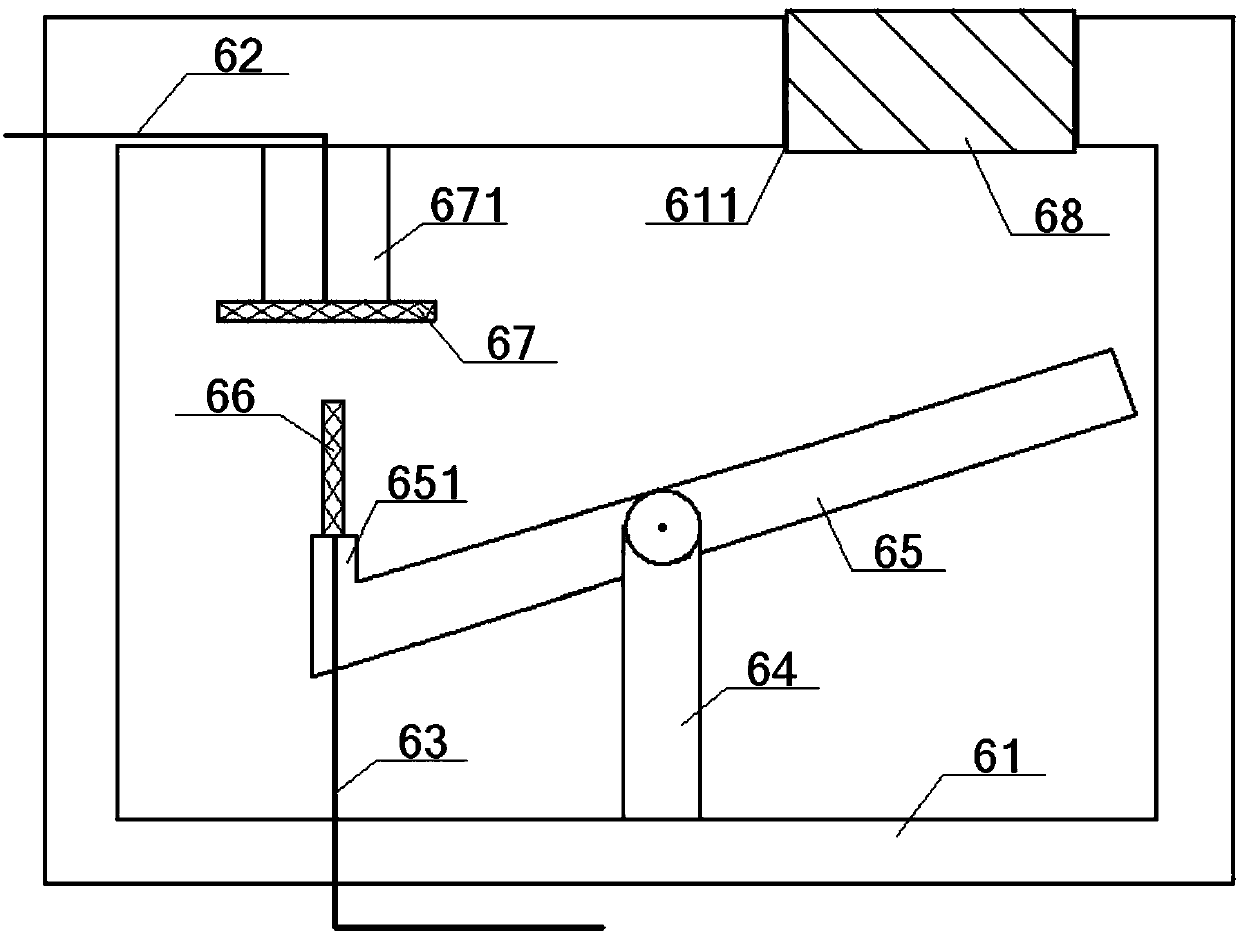

Cement external circulation vertical mill combined high-performance grinding process system

ActiveCN113976277AReduce manufacturing costImprove performanceRotary stirring mixersTransportation and packagingThermodynamicsEngineering

The invention discloses a cement external circulation vertical mill combined high-performance grinding process system, which comprises an external circulation vertical mill, a combined powder concentrator, a cyclone dust collector, a first conveying chute, a dry stirring mill, a second conveying chute, a fine powder blending bin, a coarse powder blending bin and a mixer. The external circulation vertical mill and combined powder concentrator are connected end to end, an upper discharge port of the combined powder concentrator is connected with the cyclone dust collector; a discharge port of the cyclone dust collector is connected with the first conveying chute; an outlet of the first conveying chute is divided into two paths, one path is connected with the dry stirring mill, and the other path is connected with the coarse powder blending bin; a discharge hole of the dry stirring mill is connected with the second conveying chute; an outlet of the second conveying chute is connected with the fine powder blending bin; and outlets of the fine powder blending bin and the coarse powder blending bin are connected with the mixer. The advantages of coarse grinding of the external circulation vertical mill and fine grinding of the stirring mill in the aspects of process and energy consumption are exerted, the fine powder energy consumption of the external circulation vertical mill is reduced, the particle size distribution of the final product can be flexibly adjusted according to the ratio of coarse powder to fine powder, and the cement performance is improved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

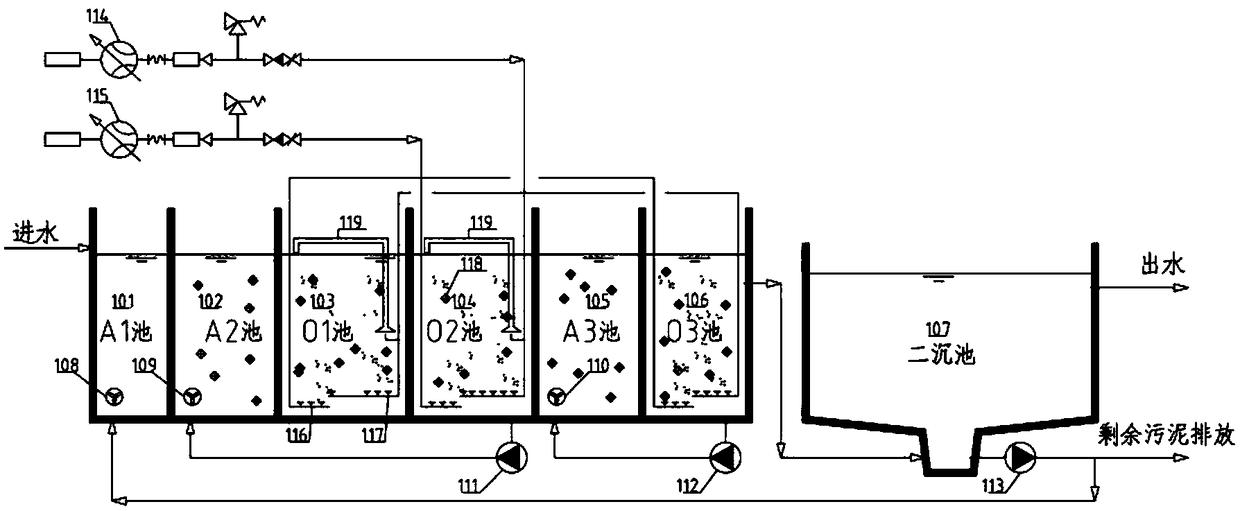

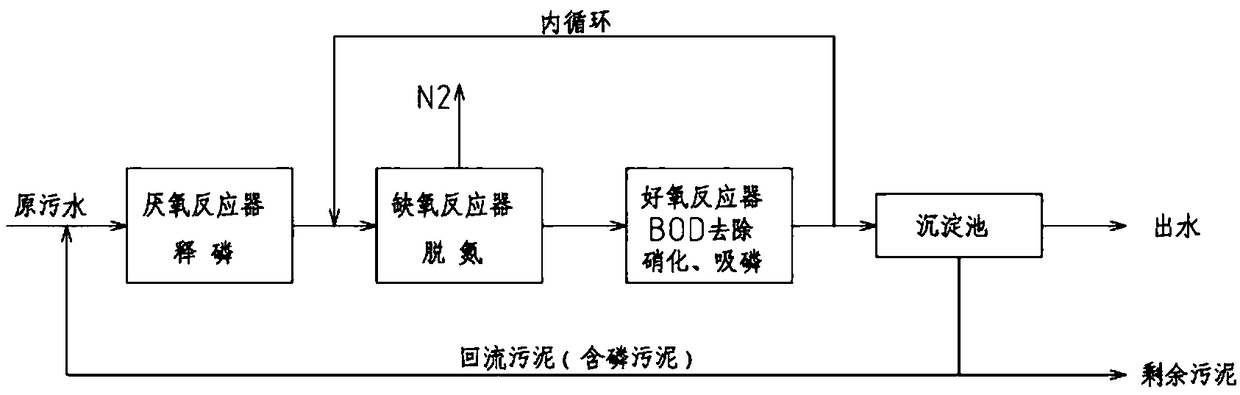

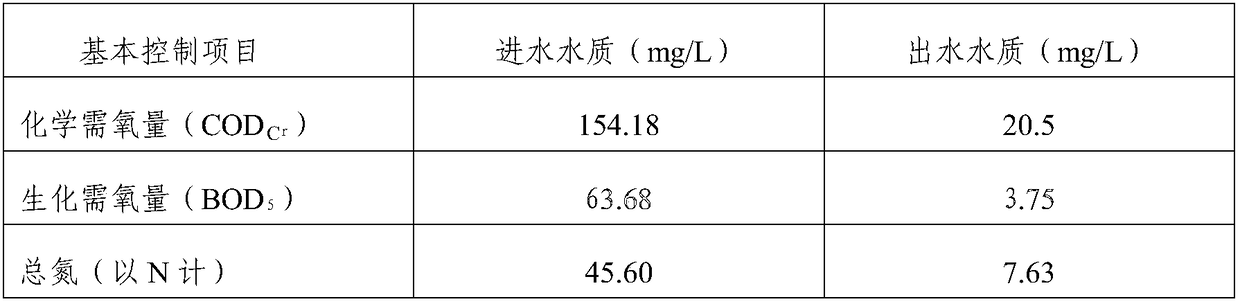

High-efficiency nitrogen removal and dephosphorization device and process method using multi-stage AO composite IFAS technology

PendingCN109279694AIncreased processing power and its performanceLow running costWater contaminantsTreatment with aerobic and anaerobic processesUpgradeSettling

The invention provides a high-efficiency nitrogen removal and dephosphorization device and process method using a multi-stage AO composite IFAS technology. The device includes an AI anaerobic tank, anAII anoxic tank, an OI aerobic tank, an OII aerobic tank, an AIII anoxic tank, an OIII aerobic tank and a secondary settling tank. The device and method can improve the efficiency of nitrogen removaland dephosphorization, correspond to existing sewage plant treatment process, get rid of the limitation of use of land, facilitate the implementation of standard upgrade speed up the process of standard upgrade of the sewage plant and greatly improve the technical level of sewage treatment.

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

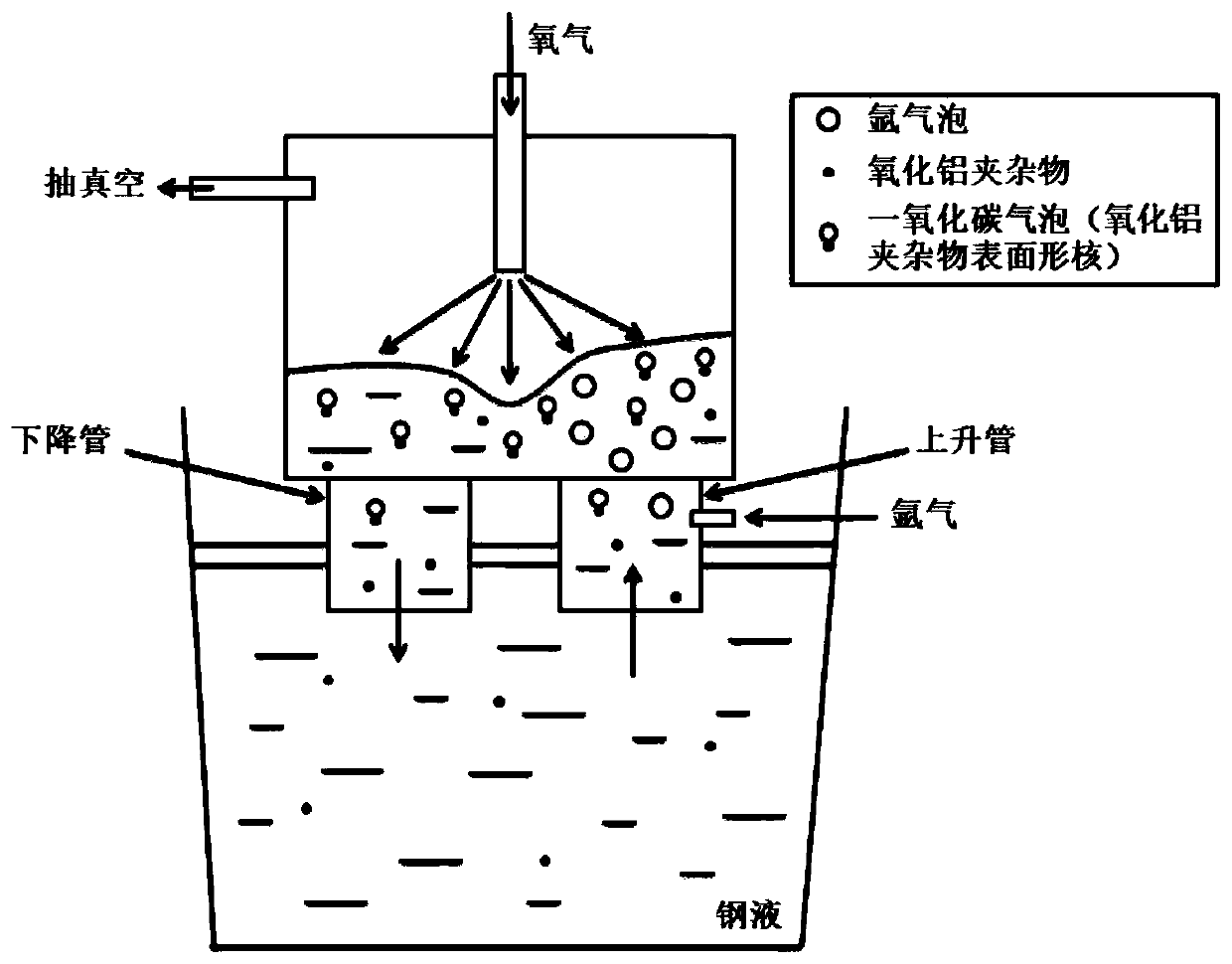

Method for promoting RH decarburization

The invention discloses a method for promoting RH decarburization. Before or during RH decarburization of ultra-low carbon steel, aluminum or aluminum alloy is added into molten steel, an aluminum oxide reaction is used for forming dispersed Al2O3 inclusions in the molten steel, wettability of the generated Al2O3 inclusions and the molten steel is poor, the wetting angle is large, the Al2O3 inclusions become a heterogeneous nucleation core of carbon monoxide bubbles generated by an RH decarburization reaction, nucleation of the carbon monoxide bubbles is promoted, the nucleation depth of the carbon monoxide bubbles in the molten steel is increased, the thickness of a reaction layer of a carbon-oxygen reaction in an RH vacuum tank is increased, and the ability of RH deep decarburization isimproved. According to the method, the RH decarbonization rate can be effectively increased, the end point carbon content is reduced by (1-10)*10<-6>. The generated carbon monoxide bubbles have smallsizes and a strong ability to catch the inclusions, the removal of the previously generated Al2O3 inclusions can be promoted without polluting the molten steel.

Owner:UNIV OF SCI & TECH BEIJING

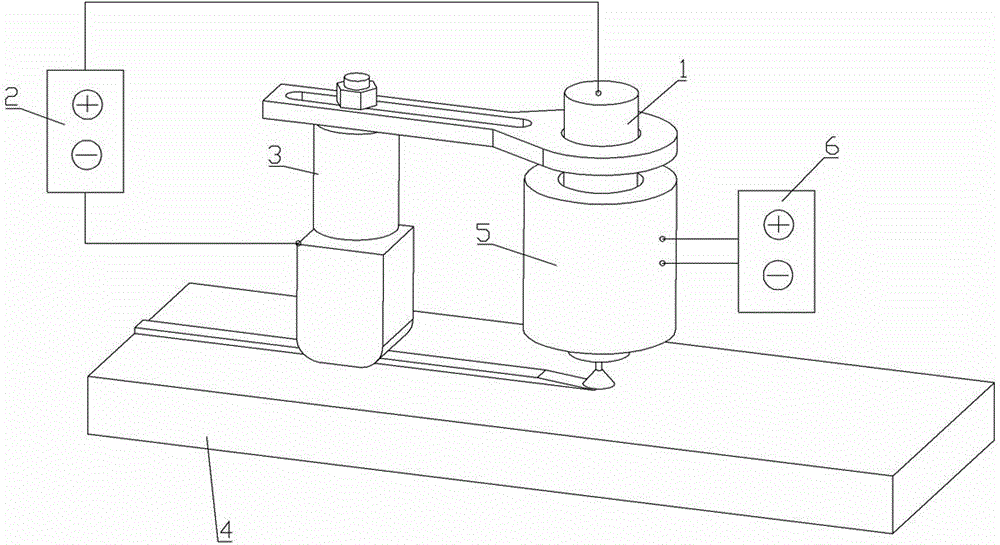

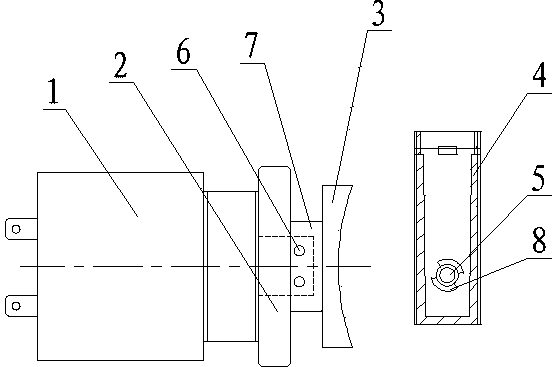

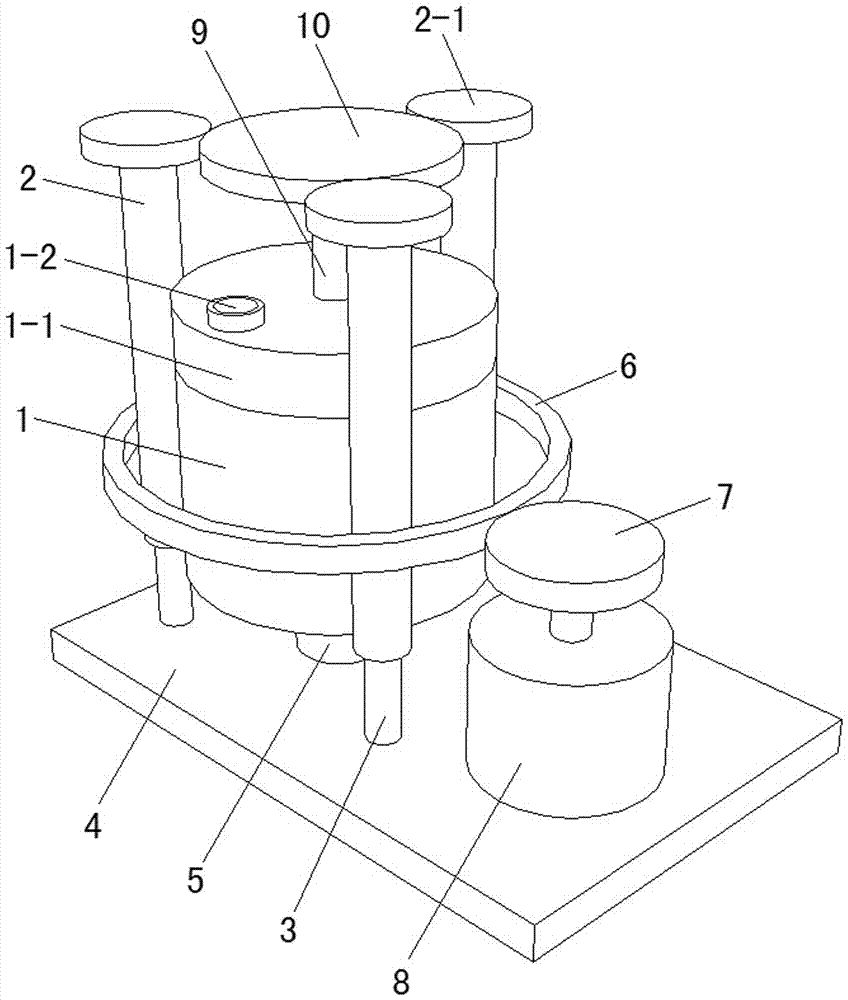

Magnetic stirring device and manufacturing method thereof

The invention relates to a magnetic stirring device and a manufacturing method thereof. The magnetic stirring device comprises a stirring motor, a mounting base, a permanent magnet, a magnetic particle and a sample box, wherein the stirring motor is fixedly installed on the mounting base, the permanent magnet is installed on an output shaft of the stirring motor, the sample box is arranged in front of the permanent magnet, and a magnetic particle used for stirring is arranged in the sample box. The magnetic stirring device has the advantages of sanitation in operation, high stirring speed and good stirring uniformity.

Owner:HUNAN OUJIE BIOTECH DEV

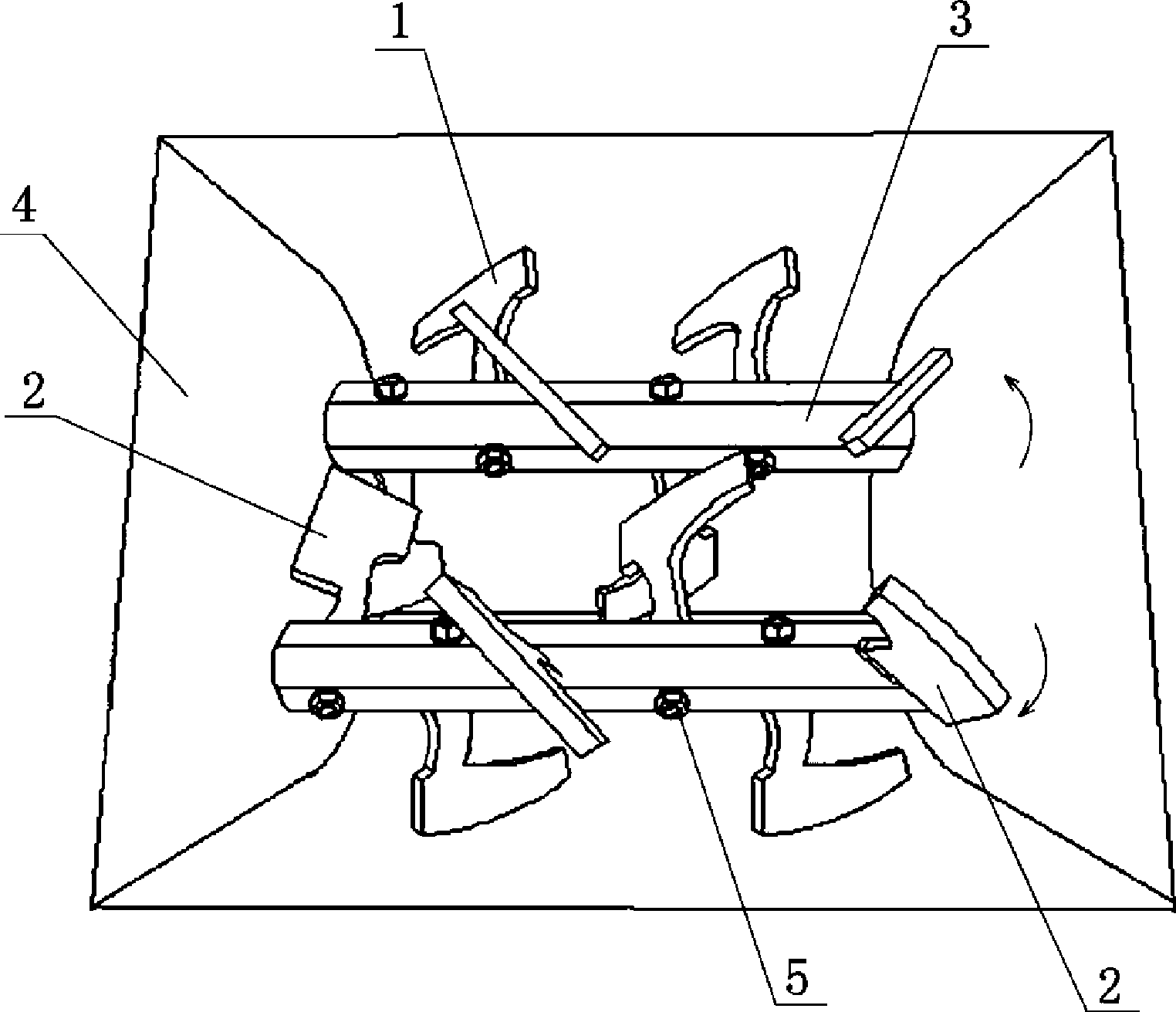

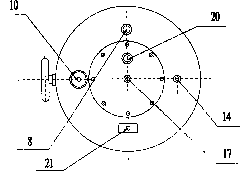

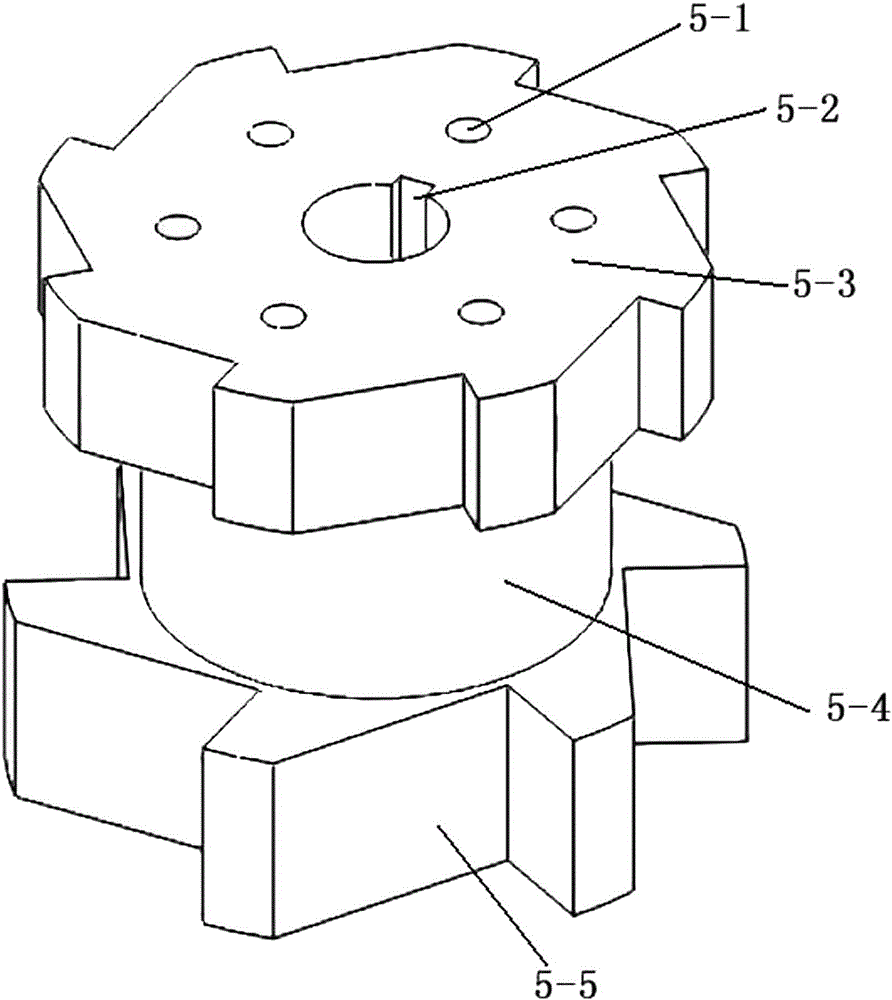

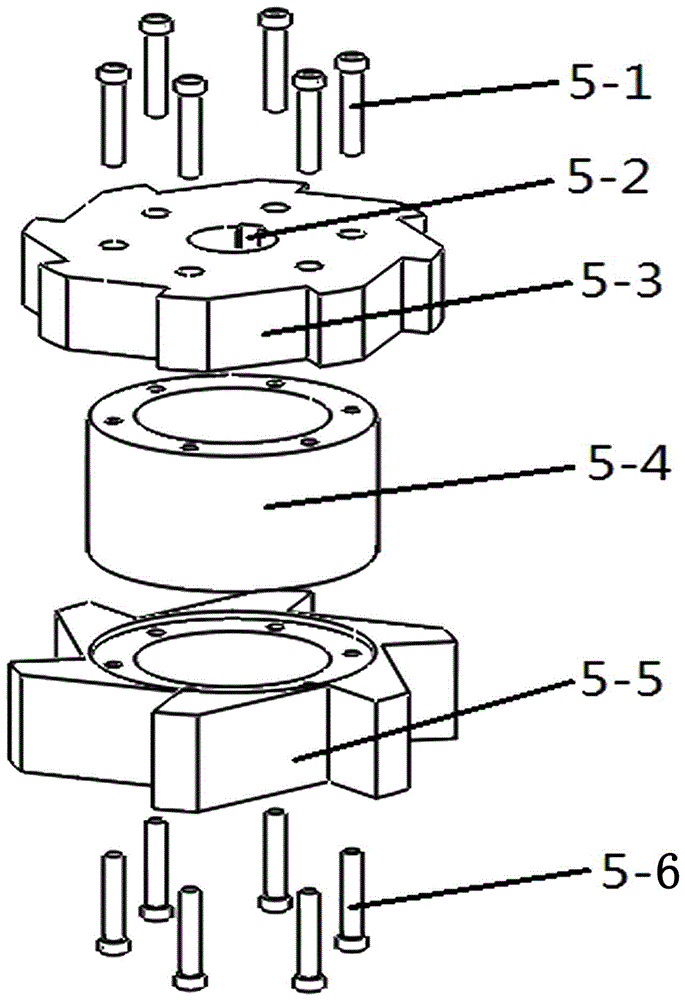

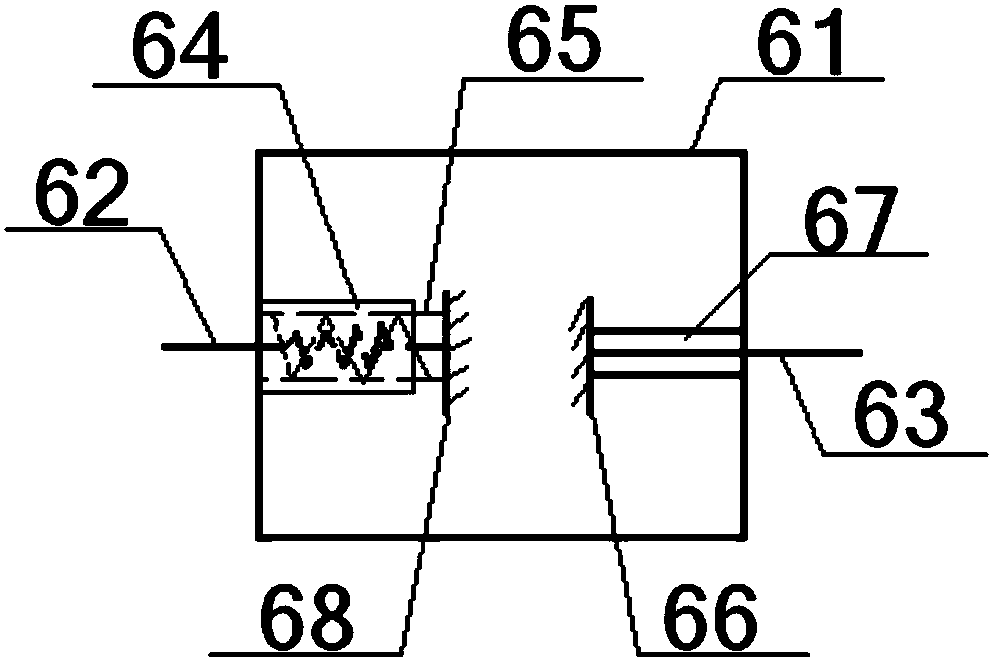

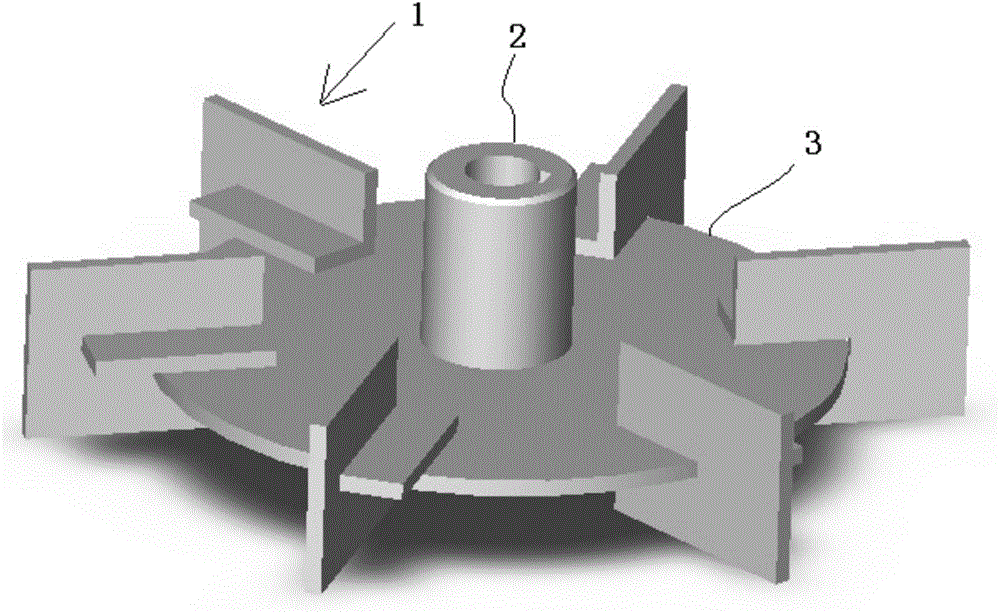

Combined impeller of rotating-type erosion test apparatus

InactiveCN106124302AThe test runs smoothlyLow costInvestigating abrasion/wear resistanceImpellerElectric machine

The invention provides a combined impeller of a rotating-type erosion test apparatus, belonging to the field of stirring equipment. The combined impeller comprises an upper blade, a connecting sleeve, a lower blade, upper screws and lower screws, wherein the upper blade is of an eight-blade tooth-shaped structure, the lower blade is of a six-blade tooth-shaped blade structure, the upper blade is fixed at the upper end of the connecting sleeve by virtue of the upper screws, the lower blade is fixed at the lower end of the connecting sleeve by virtue of the lower screws to form the combined impeller, the combined impeller is installed on a motor main shaft, and the motor main shaft is driven by a servo motor to stir slurry in a tank. Compared with an ordinary stainless steel material impeller, the weight of the impeller is remarkably reduced, the impeller and the main shaft run stably in the high-speed erosion test process, safety and reliability are realized, the service life of the motor is prolonged, and the wear resistance and corrosion resistance are relatively good. By adopting a split-type structure design, the combined impeller is convenient to repair and replace.

Owner:HENAN POLYTECHNIC UNIV

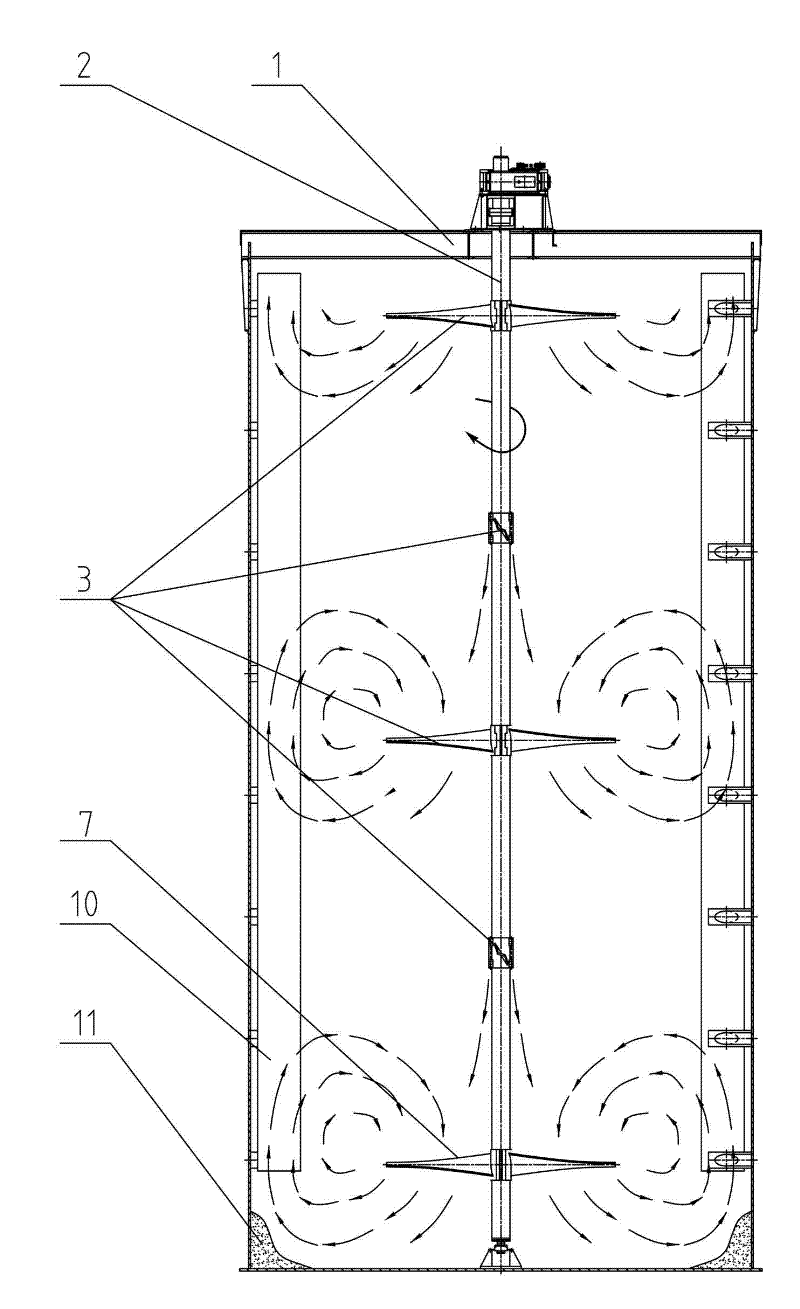

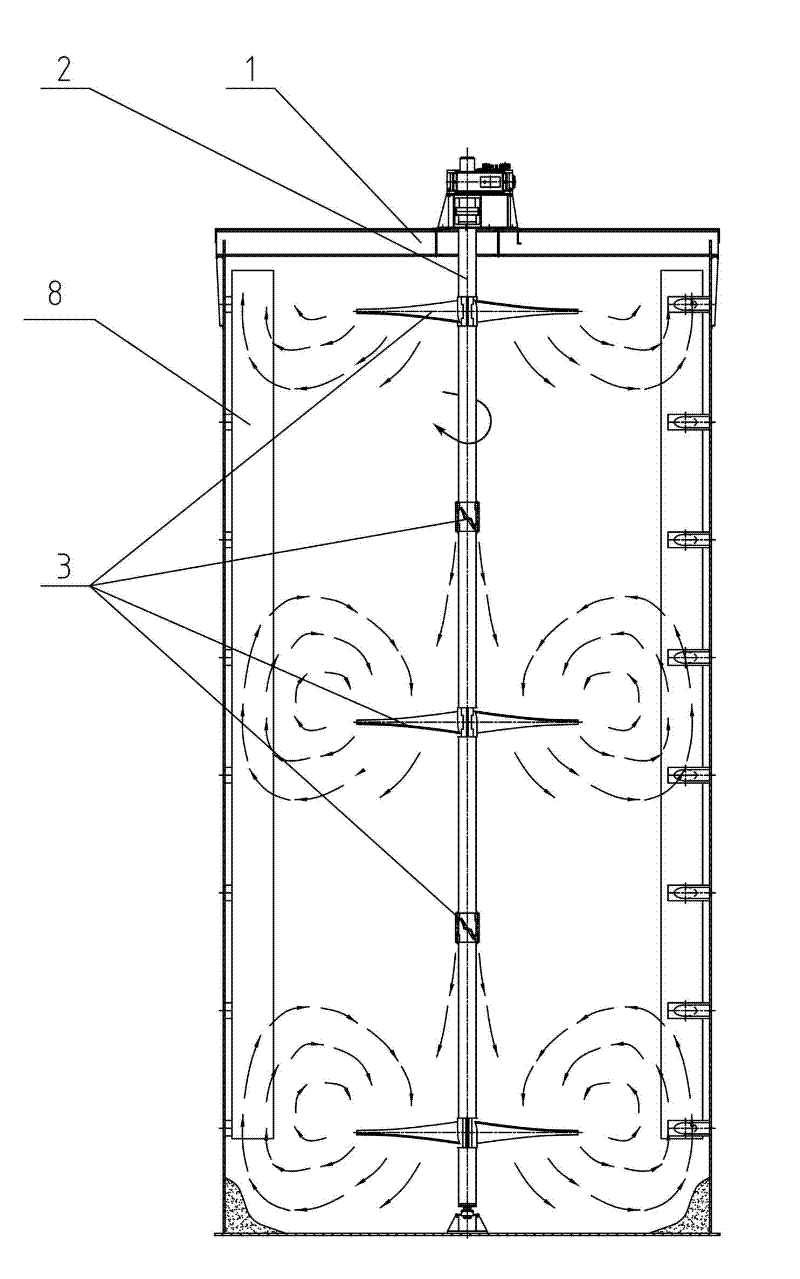

Alumina decomposition tank stirring system

InactiveCN107555456AReduce usageReduce manufacturing costRotary stirring mixersTransportation and packagingWind drivenPipe fitting

The invention discloses an alumina decomposition tank stirring system and belongs to the technical field of power stirring. The alumina decomposition tank stirring system comprises a tank body and a wind-driven stirring device, wherein the wind-driven stirring device comprises a ventilating shaft, a stirring blade and two bearings; the two bearings are respectively arranged on the top and at the bottom of the tank body and is used for supporting the ventilating shaft to rotate around the axis; one end of the ventilating shaft is opened, the other end of the ventilating shaft is provided with aclosed pipe fitting, and a side face of the ventilating shaft is connected with the stirring blade; the stirring blade comprises a blade and a ventilating pipe; the blade is of a flat cavity structure, a hole communicated with the cavity is formed in one surface of the blade, and the other opposite surface of the blade is used for driving and stirring slurry in the tank body; the ventilating pipeis used for fixedly connecting the blade and the ventilating shaft; and a pipe orifice of the ventilating shaft is communicated with the cavity of the blade. According to the stirring system, the used power energy is compressed air, different stirring strengths for different slurry layers can be realized according to process requirements, the equipment manufacturing cost is low, the operating cost is low, and the economic benefits are excellent.

Owner:广西信发铝电有限公司

Environment-friendly utilization system for producing biogas from plant wastes

InactiveCN107760558AIncrease temperatureReduce volumeBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental resistanceInverted t

An environment-friendly utilization system for plant waste to generate biogas. The main drive shaft drives the left stirring ball, the middle stirring ball, the right stirring ball, and the rotating fork to destroy and crush the plant waste to be treated in the mixing chamber to reduce the amount of plant waste. volume, and improve the mixing uniformity of plant waste and humidity. The inverted T-shaped rotating fork includes a vertical hook and a horizontal hook. The temperature in the room, the temperature sensor can monitor the temperature in the mixing room to ensure the crushing and mixing effect. This design can not only carry out reciprocating motion in the horizontal direction and switching of the crushing direction, but also has a better crushing effect, can add fermentation drugs online, and has high screening efficiency and feeding efficiency, good crushing effect, and good environmental protection effect of waste utilization .

Owner:李秀青

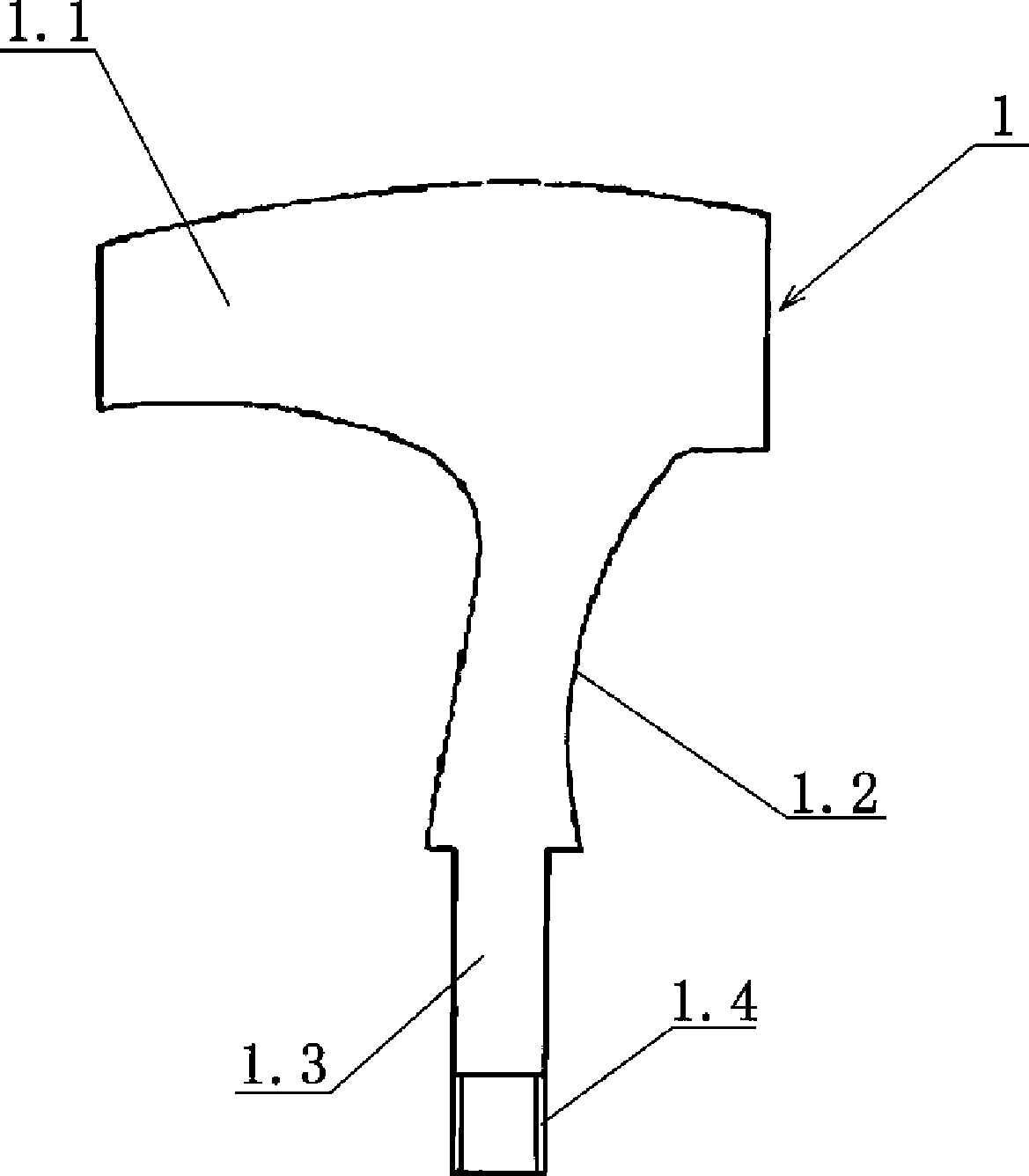

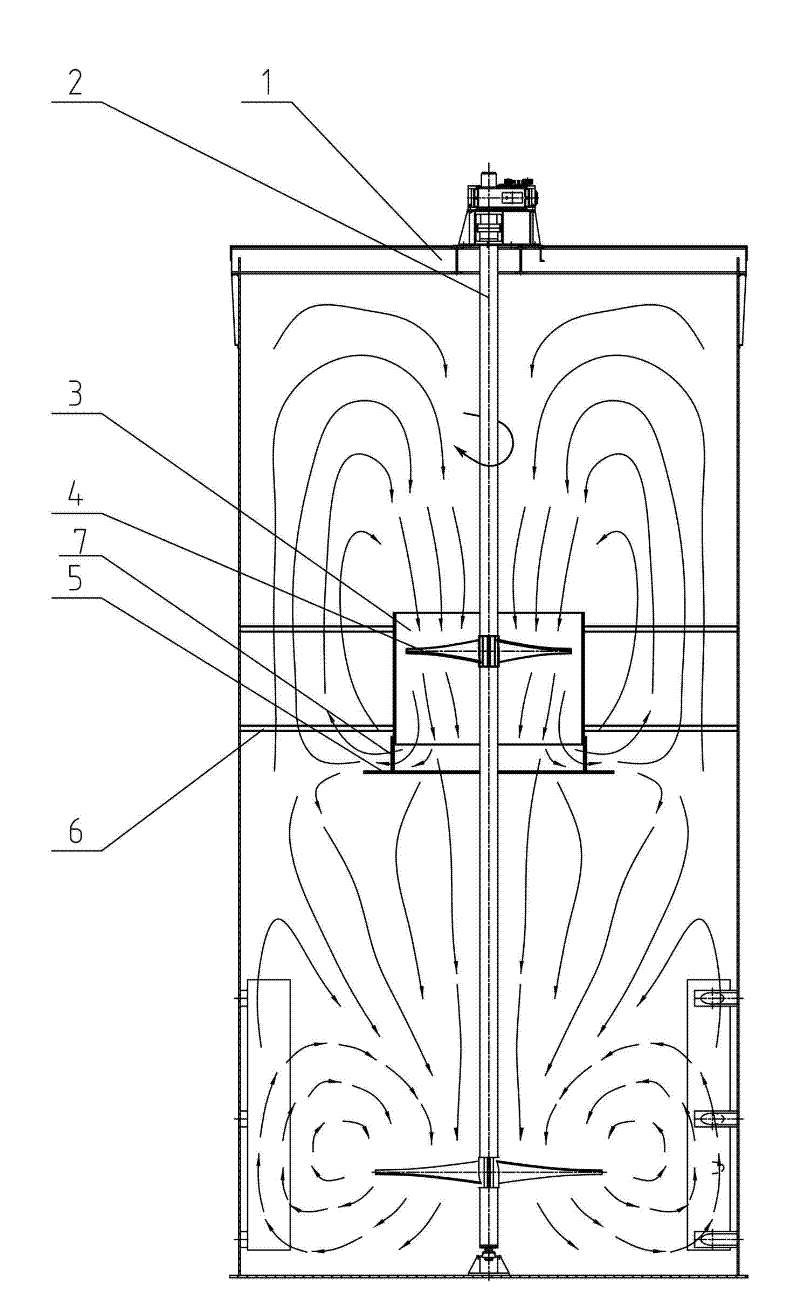

Upper-layer paddle for high-performance agitating tank

InactiveCN102527276AReduce shearImprove the mixing effectRotary stirring mixersTransportation and packagingEngineeringUltimate tensile strength

The invention relates to an upper-layer paddle, in particular to an upper-layer paddle for a high-performance agitating tank, which is suitable for agitating devices for various agitating tanks in the alumina industry. The upper-layer paddle comprises blades, wherein the outer circle of the blades is provided with a circle of upper-layer steel plate cylinder, a ring baffle is arranged below the upper-layer steel plate cylinder, and the upper-layer steel plate cylinder is connected with the side wall of the agitating tank through a support plate. The invention has the following advantages: the upper-layer paddle provided by the invention has a good agitating effect; the upper-layer steel plate cylinder forms a collector for centralizing the liquid flows generated by an agitating paddle to one direction, so that the flow rate is accelerated, the scouring force is greatly increased, and the agitating strength is enhanced; by the ring baffle below the upper-layer steel plate cylinder, the liquid flow overflowing from the lower end of the upper-layer steel plate cylinder turns upwards after being in contact with the ring baffle, so that the effective agitating range of the upper-layer paddle is greatly expanded; a fewer number of layers of blades can meet the requirement for the agitating uniformity, so that the energy consumption is lowered; and an appropriate interval is kept between the ring baffle and the lower end of the collector, so that the energy consumption can be lowered and the cutting on liquid flows can be reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Extrusion forming laser welding brazing method

ActiveCN106077862ASpread evenlyEasy to overflowSoldering apparatusWelding/soldering/cutting articlesMelting tankLaser beams

The invention provides an extrusion forming laser welding brazing method. The extrusion forming laser welding brazing method comprises the steps that (1) a solder powder strip is paved in a to-be-welded position of a lower welding block in advance; (2) a first end of an upper welding block is placed in the position, close to the solder powder strip, on the lower welding block, and a 0 to 60-degree included angle space is formed between the upper welding block and the lower welding block; (3) laser beams obliquely shoot from the included angle space, and the laser beams are focused on the solder powder strip to form a strip-shaped brazing molten pool; (4) a second end of the upper welding block is pressed downwards, the strip-shaped brazing molten pool is pushed to be spread on a welding surface between the upper welding block and the lower welding block, and the upper welding block completely fits the lower welding block; and (5) solder is solidified to form a welding connector. According to the extrusion forming laser welding brazing method, the laser beams are utilized to melt solder to form the strip-shaped brazing molten pool, the liquid solder is pushed to be spread on a to-be-welded surface through extrusion, bubbles in the molten pool are released, the metallurgy reaction of a welding brazing connector is sufficient, the technological quality of the welding brazing connector is good, and the mechanical property is high.

Owner:苏州奥钦商贸有限公司

Chemical reactor tool having mixing function

ActiveCN107262015AIncrease speedSimple structureRotating receptacle mixersTransportation and packagingCircular discChemical reactor

The invention relates to a chemical reactor tool having a mixing function, which relates to the chemical reactor tool. According to the invention, a lower end of a mixer shaft passes through a mixer shaft through hole of a cover to rotate and is inserted into an agitator tank, a spiral stirring blade is fixed on the mixer shaft, spiral stirring sheets are fixed at the inner side wall of the agitator tank, a support cylinder is used for connecting the agitator tank and a bottom plate in a rotation mode, teeth can be arranged at the outer side wall of the agitator tank, the teeth can be arranged on the outer side walls of three transmission vertical rods and engaged with the teeth of the agitator tank, the transmission vertical rods are connected with the bottom plate through the locating shaft rods, the upper ends of the transmission vertical rods are respectively and fixedly connected with the gears 2, a transmission disc is fixedly connected with the upper end of the mixer shaft, the teeth can be arranged at the outer side wall of the transmission disc and engaged with three gears 2, the teeth at the inner side wall of a tooth ring and the teeth of three transmission vertical rods are engaged, a gear 1 and the teeth of the outer side wall of a tooth ring are engaged, and a motor for driving the gear 1 is fixed on the bottom plate. The chemical reactor tool is capable of increasing the rotation speed of the agitator tank and the mixer shaft, and can form bidirectional active cycle stirring flow while stirring.

Owner:CHINA BULE STAR HARBIN PETROCHEM

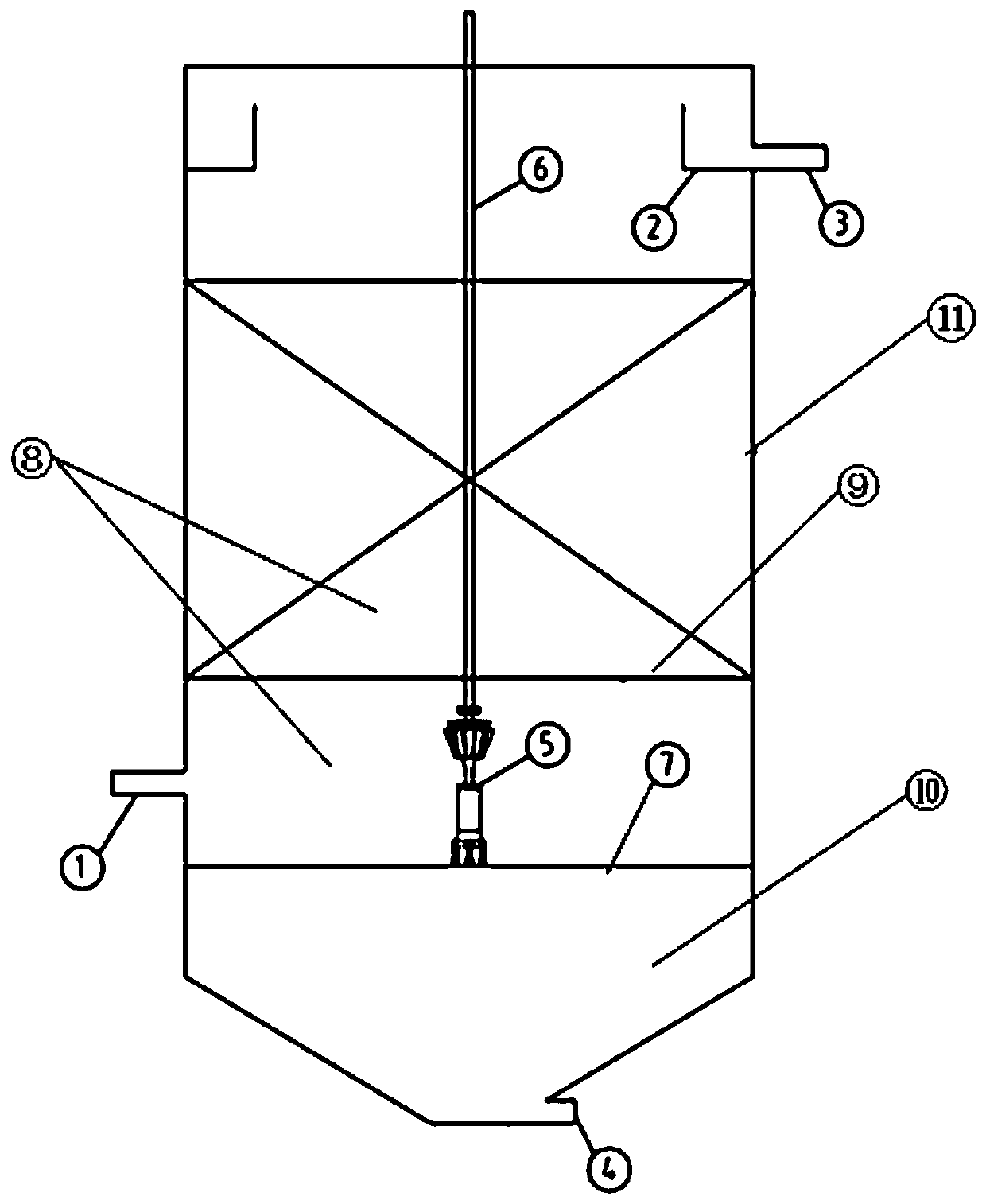

Anaerobic mud bed reactor

ActiveCN1715209ASmall volumeLess investmentTreatment with anaerobic digestion processesVolume loadAnaerobic sludge

The present invention discloses a kind of anaerobic mud bed reactor for treating organic waste water. The anaerobic mud bed reactor has rectangular or circular horizontal cross section, is provided with inflow devices homogeneously distributed in the inflow end and outflow device in the far end to the inflow end, and may form the reasonable distribution of type-A mud grains in the front part and type-B and type-C mud grains in the back part. The present invention has organic waste water treating capacity higher than UASB reactor, COD volume load in unit reactor as high as several kg or even decades kg, and lower investment.

Owner:SICHUAN YIBIN WULIANGYE GROUP

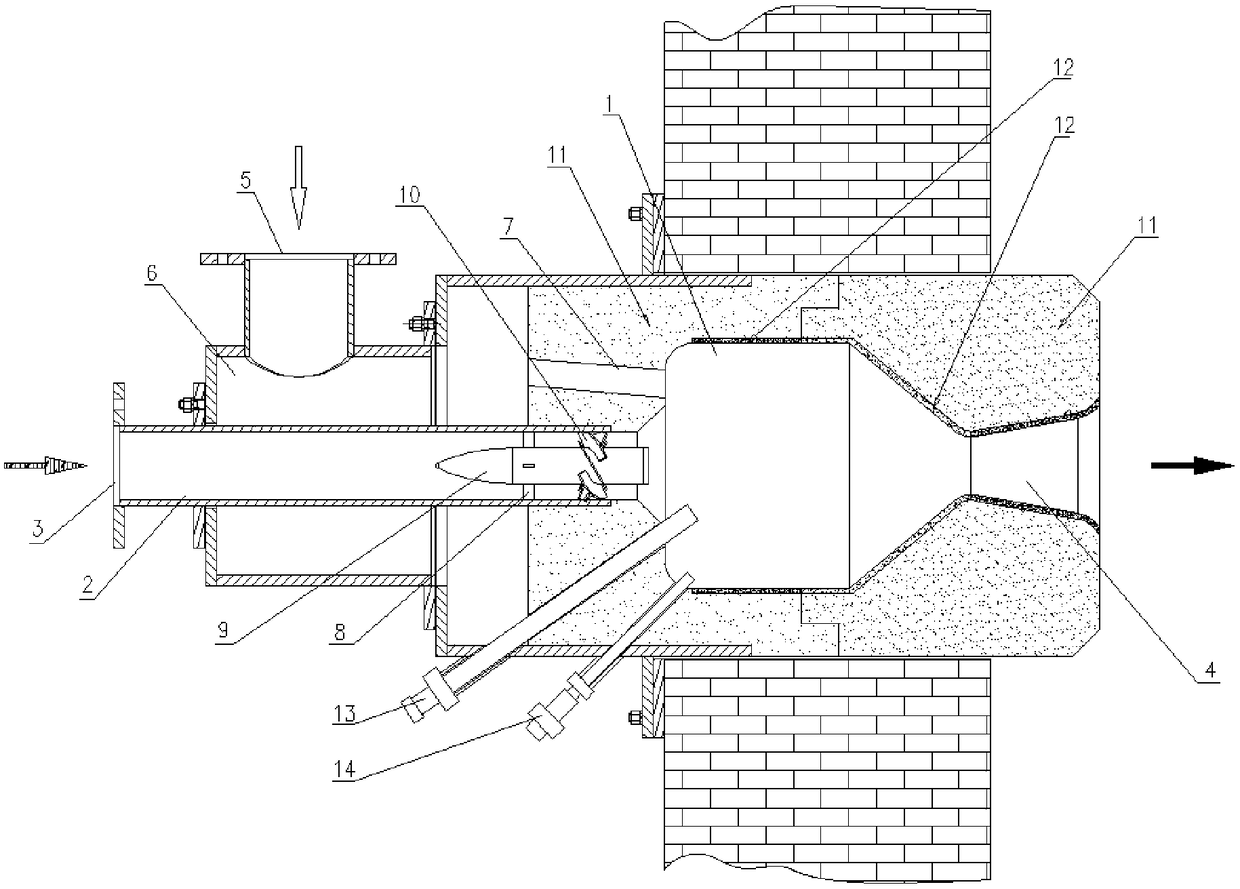

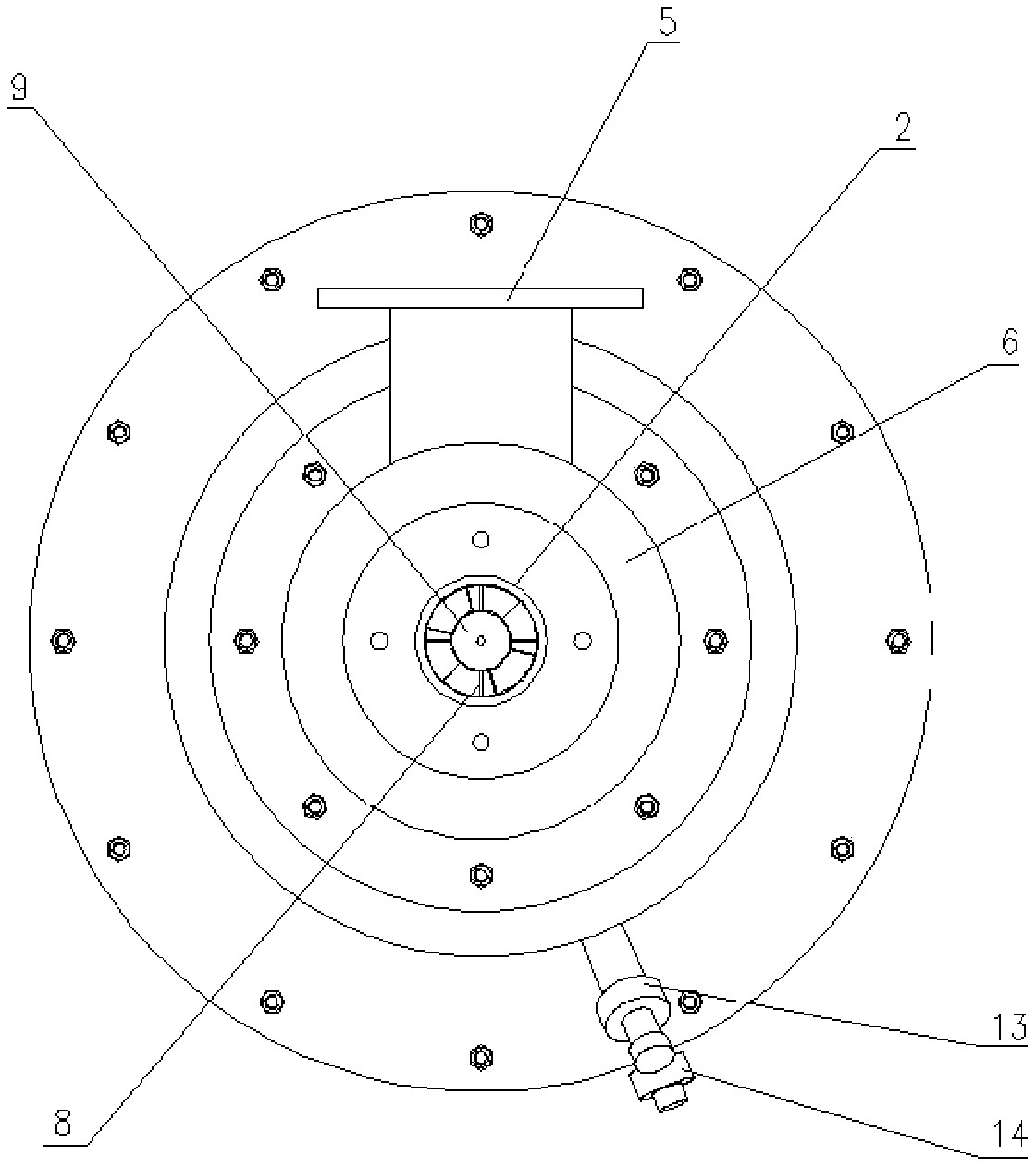

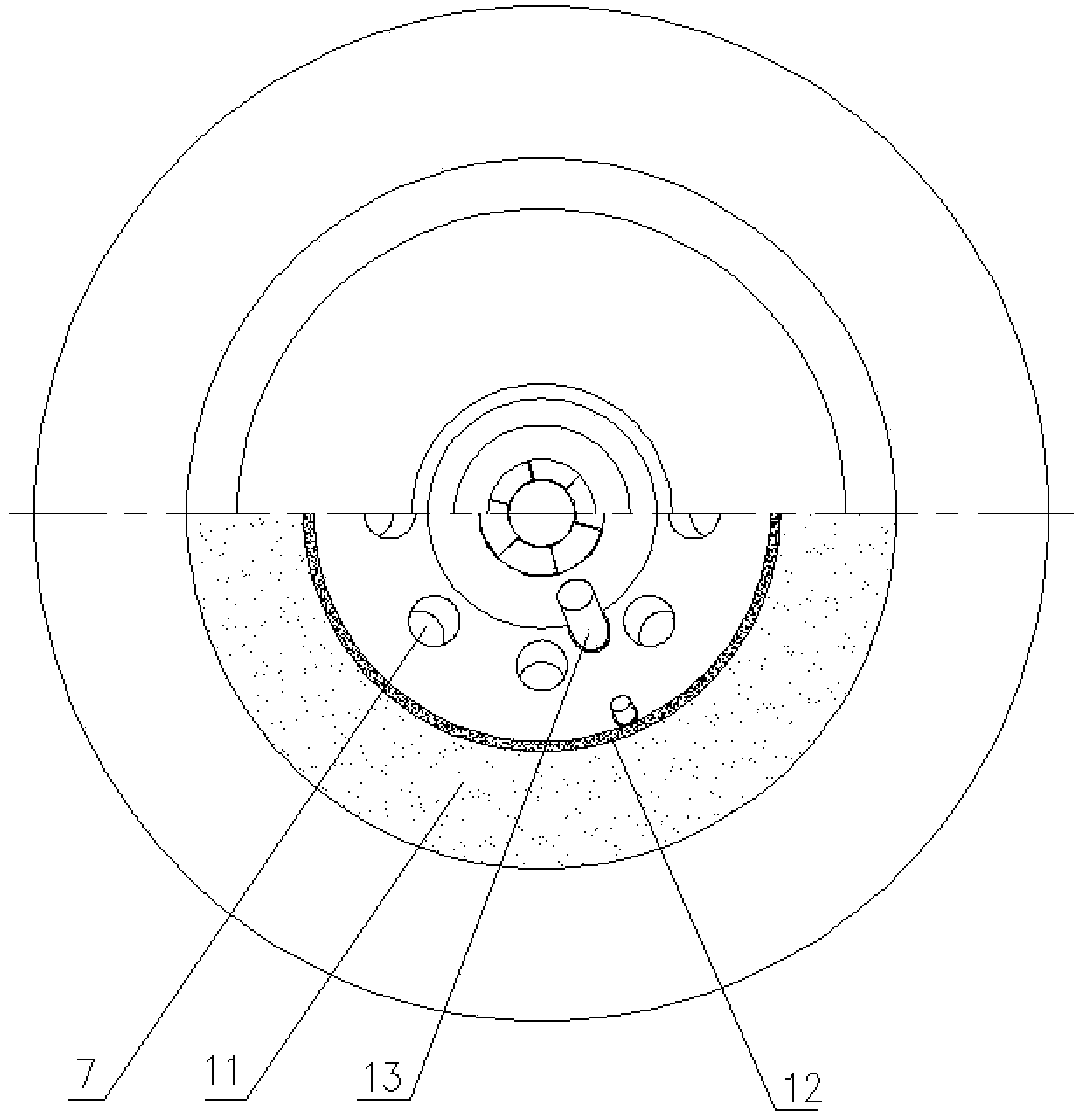

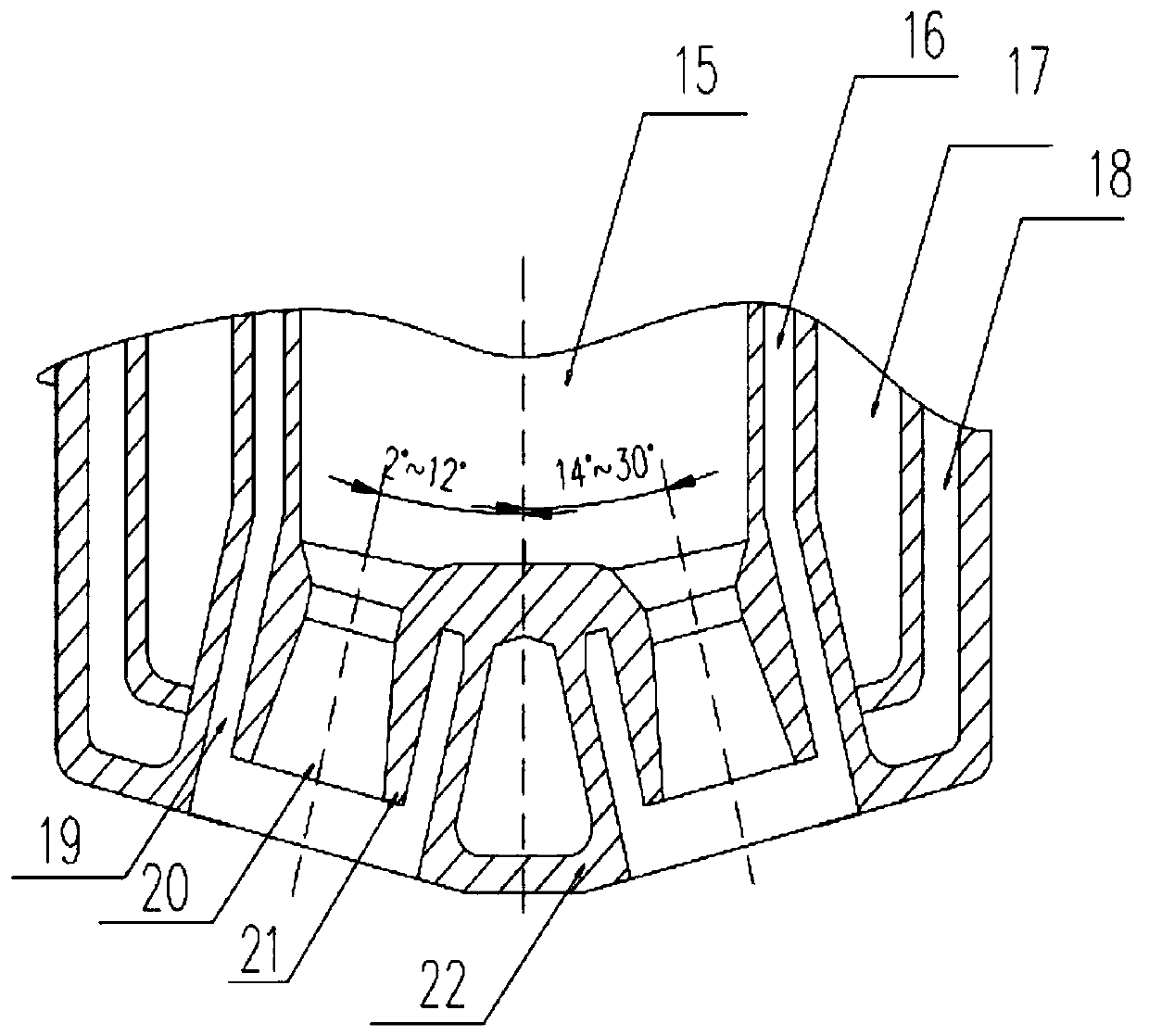

Low NOx emission combustor

PendingCN109489035ASmall volumeCompact structureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention discloses a low NOx emission combustor. The low NOx emission combustor comprises a combustion chamber; the front end of the combustion chamber is provided with a fuel gas inlet through afuel gas channel, a flue gas nozzle is arranged at the rear end of the combustion chamber, an air channel with an air inlet is formed in the outer side of the fuel gas channel, and the air channel isin communication with the combustion chamber through air nozzles arranged in the air channel; and the rear end of the fuel gas channel is provided with a gas guide cone through a supporting rod. Thedevice is simple and compact in structure, small in occupied space and easy to install and maintain, the volume of the combustion chamber is smaller than that of a heating furnace hearth of a common combustor, and the volume heat strength is large and can reach 6*10<8> kJ / m3.h; the width of the adjusting range can reach 1:50, while the common combustor is only 1:10, and automatic regulation and control are easy; and in addition, the air can be preheated by high-temperature, high combustion temperature can be obtained with low-heating-value fuel gas, the combustion temperature of the combustionchamber is high and close to 2000 DEG C, and therefore the combustor can be applied to most industrial furnaces.

Owner:中冶京诚(扬州)冶金科技产业有限公司

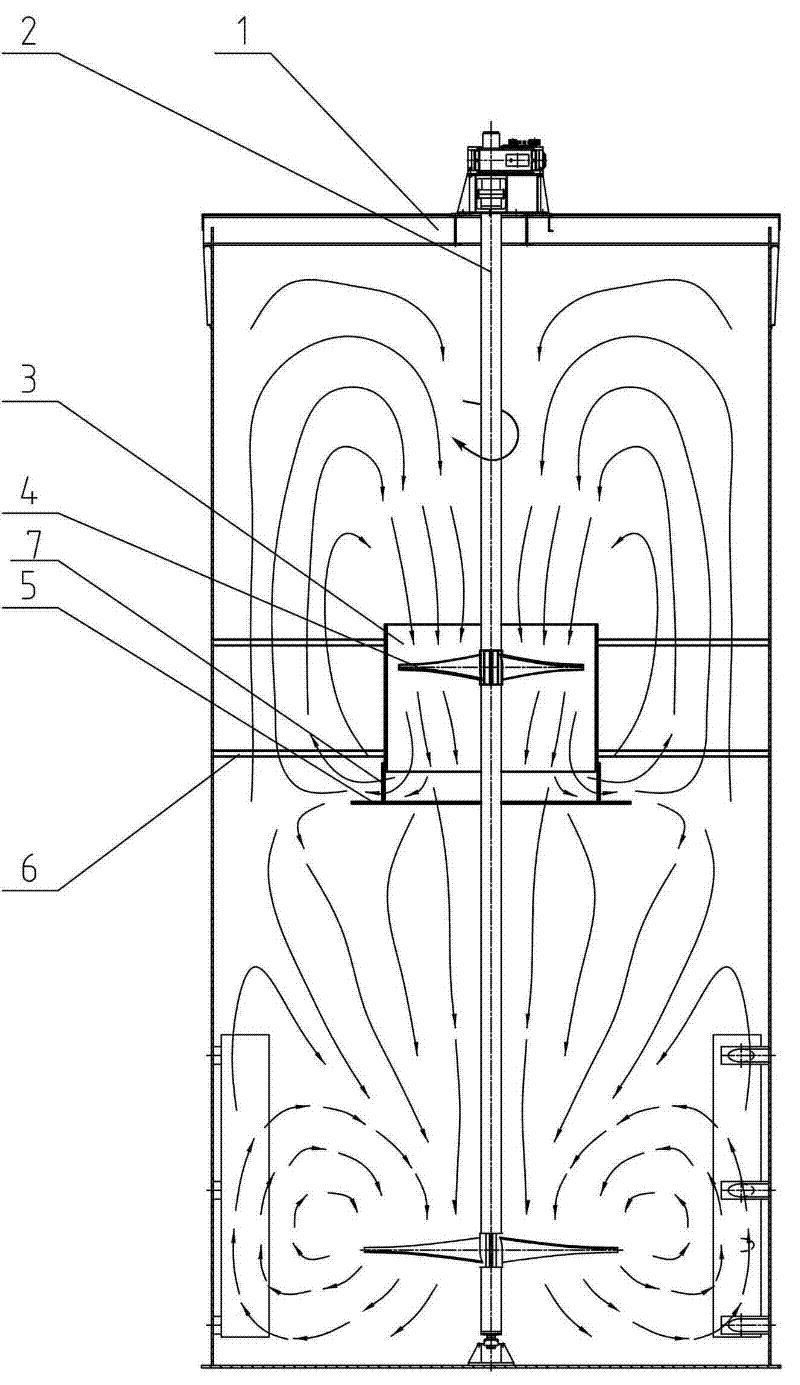

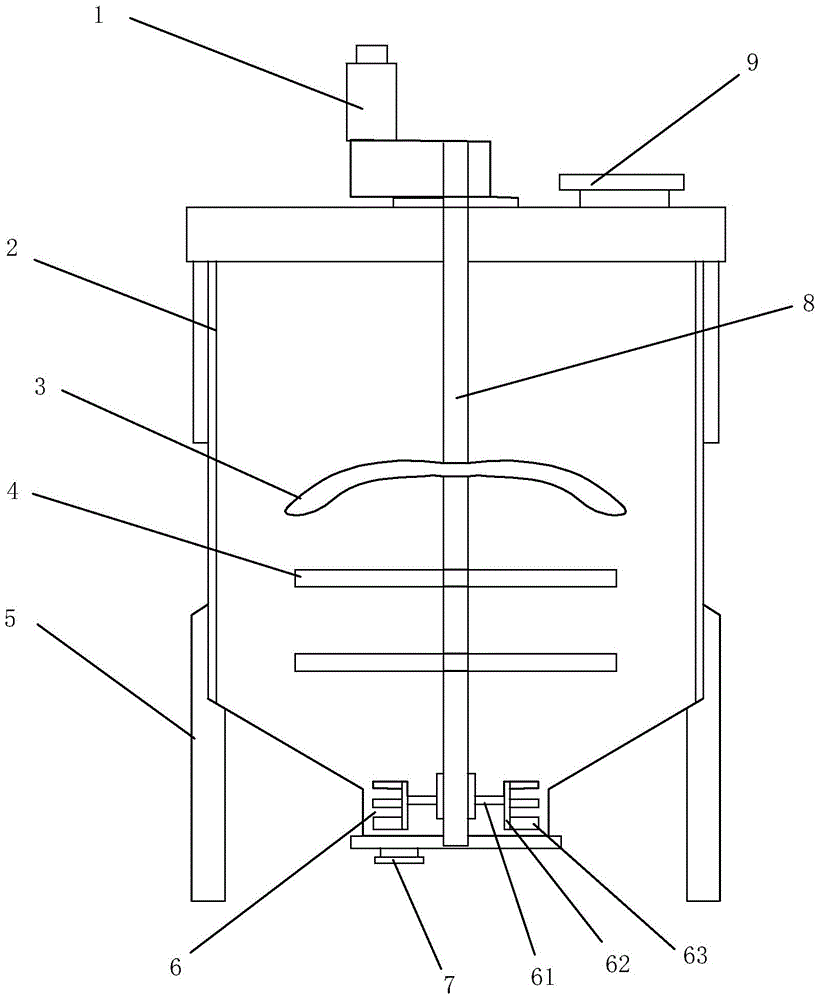

Agitation tank

InactiveCN104826531AStir wellImprove stirring performanceRotary stirring mixersBiochemical engineering

The invention provides an agitation tank comprising a sealed tank body. The bottom of the tank body is conical while the top is cylindrical, a feed inlet and a discharge outlet are arranged in the top end and the bottom end of the tank body respectively, supporting legs used for supporting the tank body are arranged on the side wall of the tank body, a rotating shaft is vertically arranged at internal center of the tank body, the top end of the rotating shaft extends out of the tank body and is driven to rotate via a motor at the top end of the tank body, the bottom end of the rotating shaft extends to the inner bottom of the tank body, a powerful agitating paddle is mounted to the bottom end of the rotating shaft, a stirring agitating paddle is mounted to the middle of the rotating shaft, and common agitating paddles are mounted on the rotating shaft between the powerful agitating paddle and the stirring agitating paddle. The agitating paddles of multiple types are used in combination, so that agitation performance of the agitation tank can be improved effectively.

Owner:张松波

Biogas raw material generating device

InactiveCN107723220AReduce volumePromote fragmentationBioreactor/fermenter combinationsBiological substance pretreatmentsLowering plantsMixing effect

The invention discloses a biogas raw material generating device. The biogas raw material generating device has the advantages that an outer frame, inner supports and mixing branches can be driven by astirring shaft to destroy and smash to-be-treated plant waste in a cutting assembly, so that the volume of the plant waste can be reduced, and the plant waste and moisture mixing uniformity can be improved; the mixing branches comprise horizontal pipes and perpendicular pipes, fermentation medicines can be provided by support medicine outlet holes and pipe medicine outlet holes in an online manner, the internal temperature of the cutting assembly can be increased by a heat supply cavity, heat sources can be additionally provided by an auxiliary heating device, the internal temperature of thecutting assembly can be monitored by a temperature measuring sensor, and accordingly smashing and mixing effects can be guaranteed; the biogas raw material generating device has a powerful smashing function, excellent smashing effects can be realized by the biogas raw material generating device, and the fermentation medicines can be added in an online manner; the biogas raw material generating device is high in screening efficiency, feeding efficiency and heating uniformity, and good waste utilization environmental protection effects can be realized by the biogas raw material generating device.

Owner:李秀青

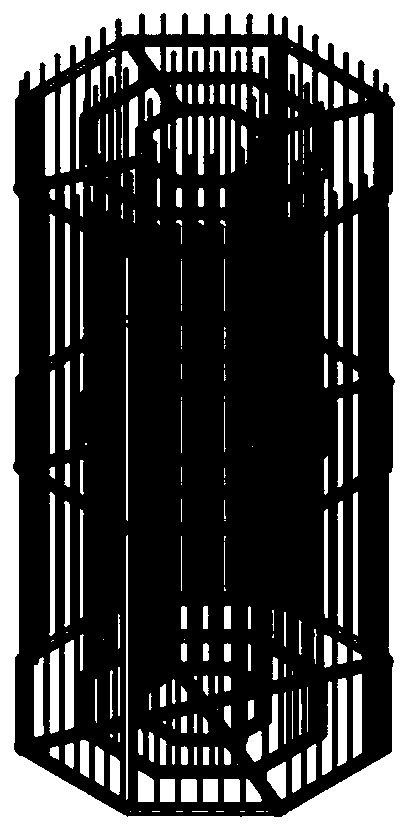

Wastewater preprocessing catalytic reduction reactor and wastewater preprocessing system and technology thereof

PendingCN110981044ASolving Recycling ProblemsAvoid production stoppage troublesWater contaminantsWater/sewage treatmentPtru catalystHazardous substance

The invention discloses a wastewater preprocessing catalytic reduction reactor and a wastewater preprocessing system and technology thereof. The reactor comprises a reactor body, a rotary-cut mixed flow aerator, a rolled iron-aluminum mixture, and a catalyst framework. The reactor body comprises a reaction area and a sludge precipitation area. The sludge precipitation area is arranged on the bottom of the reactor body. The lower part of the reaction area is provided with a raw water inlet. The upper part of the reaction area is provided with a water outlet. The catalyst framework is arranged in the reaction area. The rolled iron-aluminum mixture is arranged in the catalyst framework. The rotary-cut mixed flow aerator is arranged on the bottom of the reaction area. The air inlet pipe of therotary-cut mixed flow aerator penetrates the catalyst framework and is connected to an air supply device. The bottom of the sludge precipitation area is provided with a mud discharge pipe. The provided catalytic reduction reactor can still convert degradation-resistant, macromolecular, harmful, and toxic substances in wastewater into easily degradable, micromolecular, nontoxic, and harmless substances even if the pH value is high; the heavy metal ions are reduced and removed, and the wastewater can be better biochemically processed.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

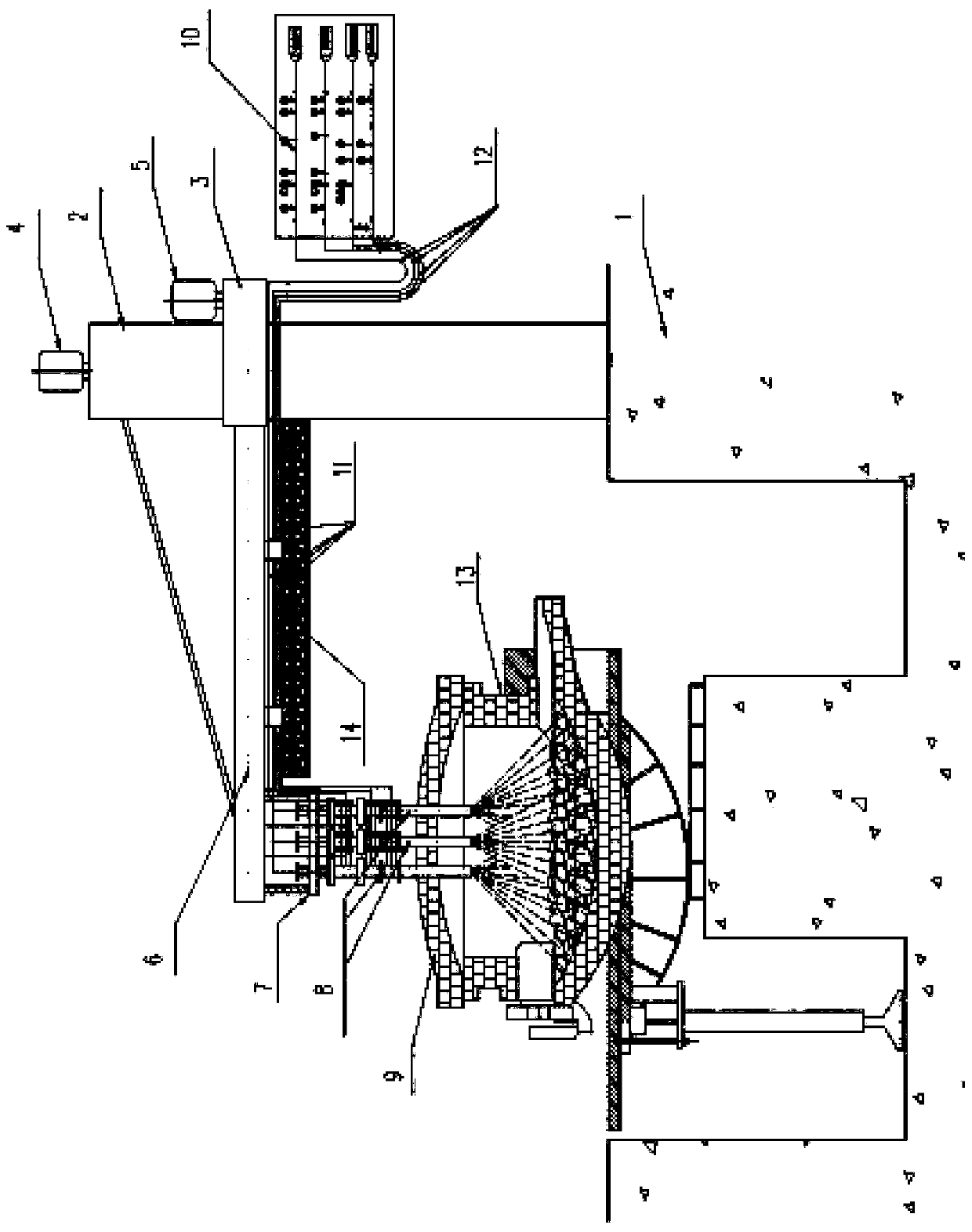

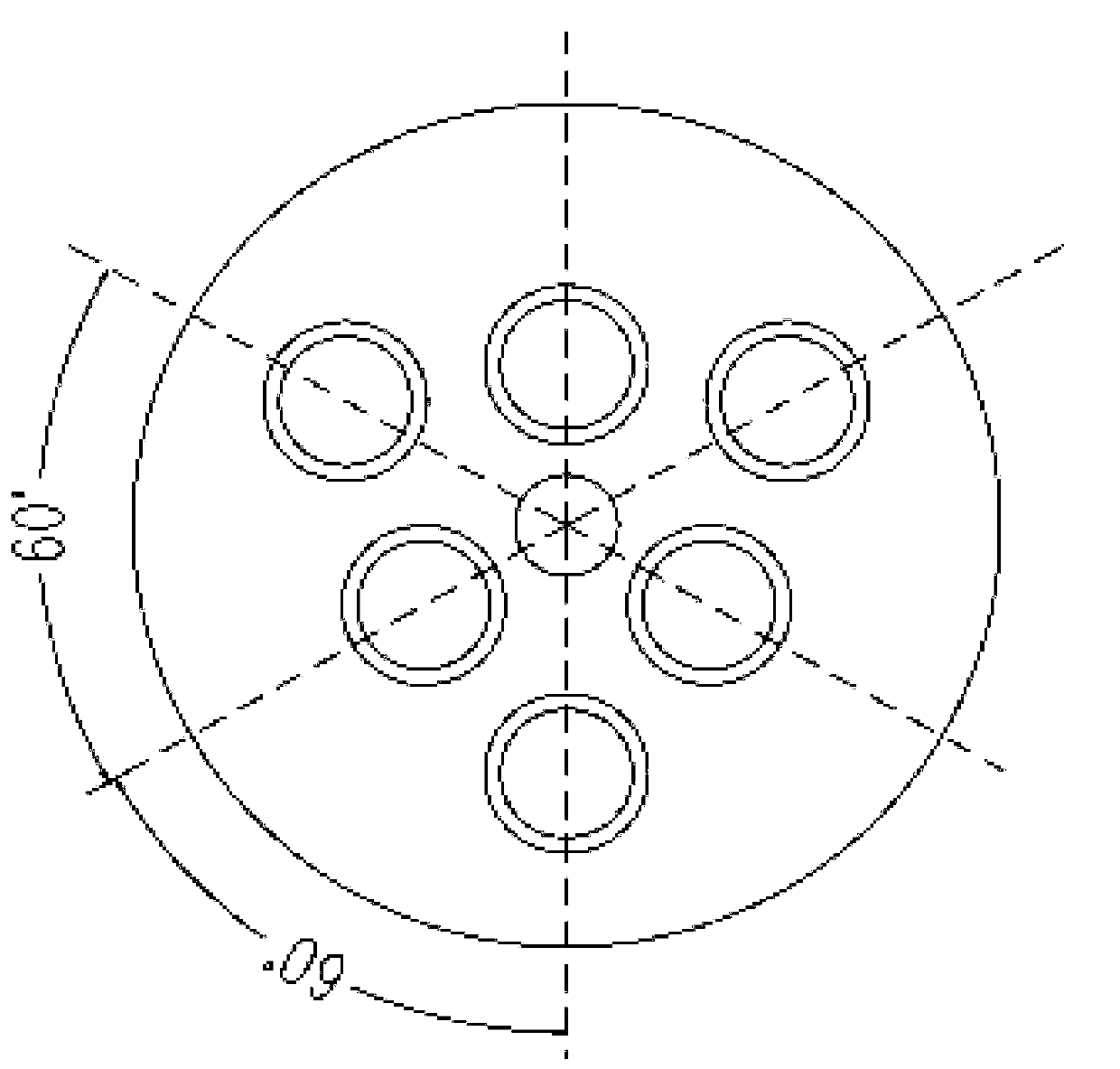

Equipment and method for electric arc furnace steelmaking by using oxygen combustion guns

PendingCN111378809AReduce consumptionReduce the cost per ton of steelProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention discloses equipment and method for electric arc furnace steelmaking by using oxygen combustion guns, and belongs to the technical field of electric arc furnace steelmaking. The equipmentis mainly characterized in that the oxygen combustion guns are inserted into a furnace from electrode holes of an electric furnace cover, and high-temperature and high-energy flames produced by the combustion of oxygen and gas which are sprayed by the oxygen combustion guns are utilized to heat and melt scrap steel in the electric furnace; and after the scrap steel is melted to form a molten pool, the molten pool is blown with the oxygen combustion guns for temperature rise, carbon reduction and slagging operation. The oxygen spray pipes of the 6-hole oxygen combustion guns of the equipment are each of a Laval type spray pipe structure, and have the dual functions of combustion heating and oxygen blowing for carbon reduction. According to the electric furnace, the three oxygen combustionguns are inserted into the electric arc furnace for steelmaking, the electric power for the electric arc furnace can be saved by 20-50%, the electrode consumption of the electric arc furnace can be reduced by 70-90%, and the cost per ton of steel can be reduced by 10-35%.

Owner:江苏必瑞驰科技有限公司

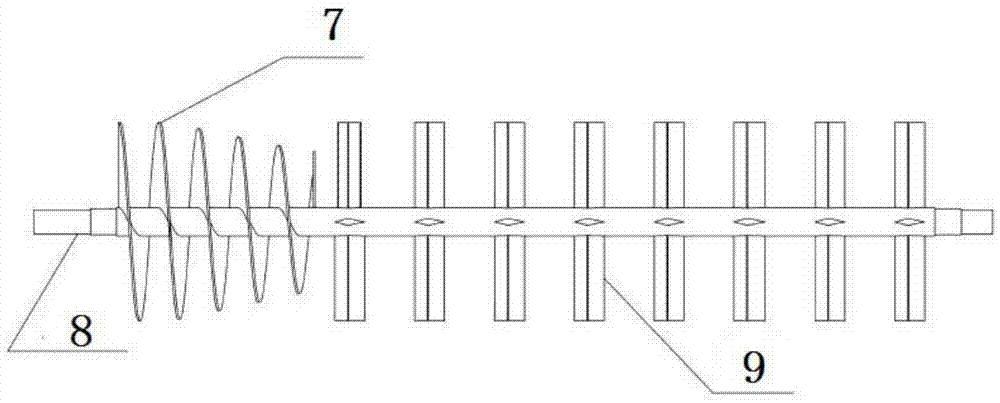

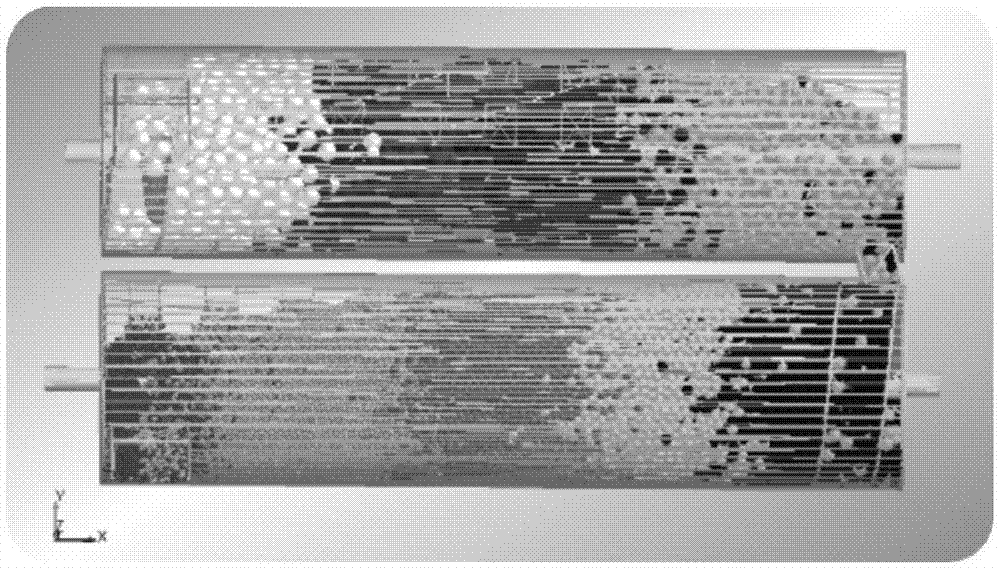

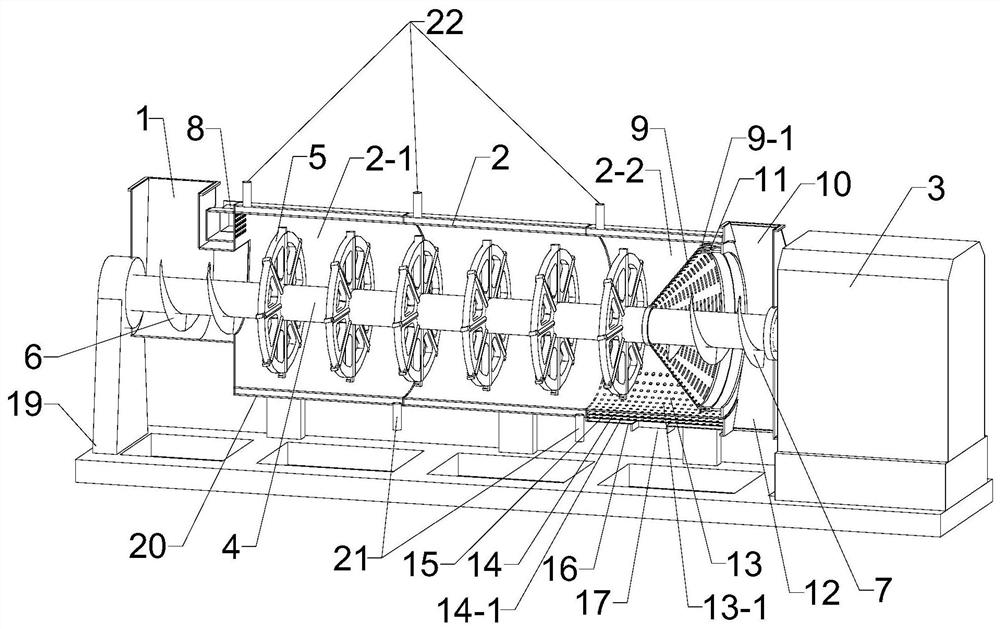

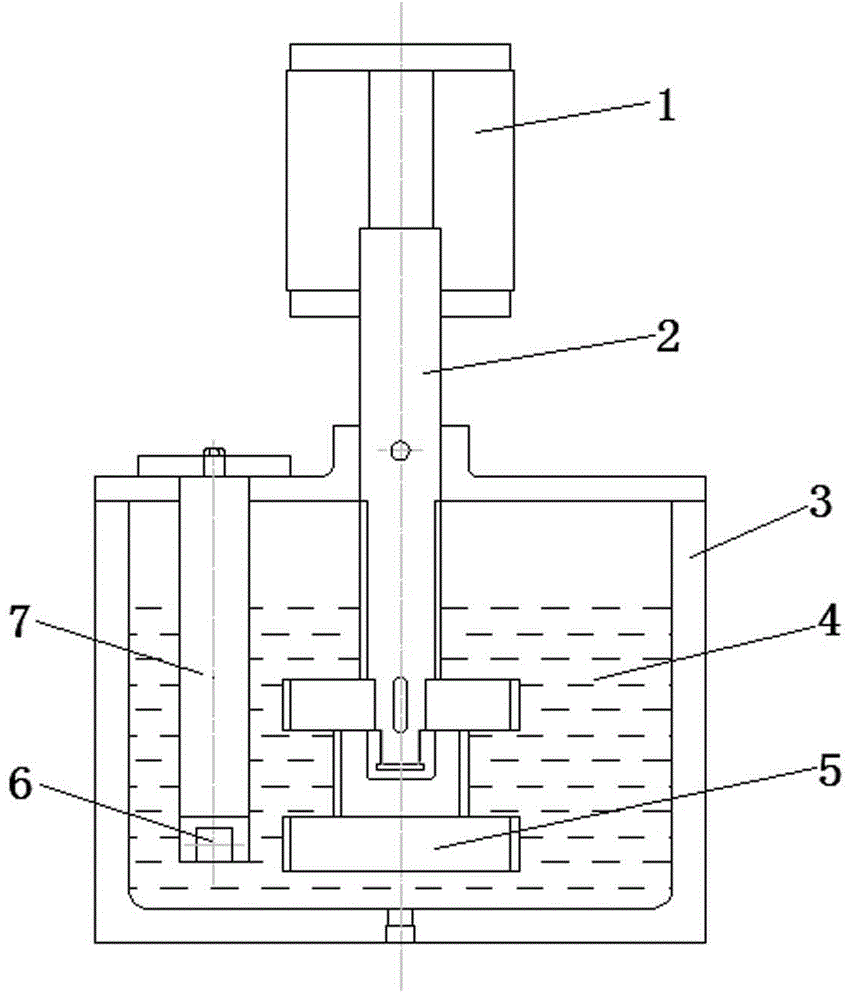

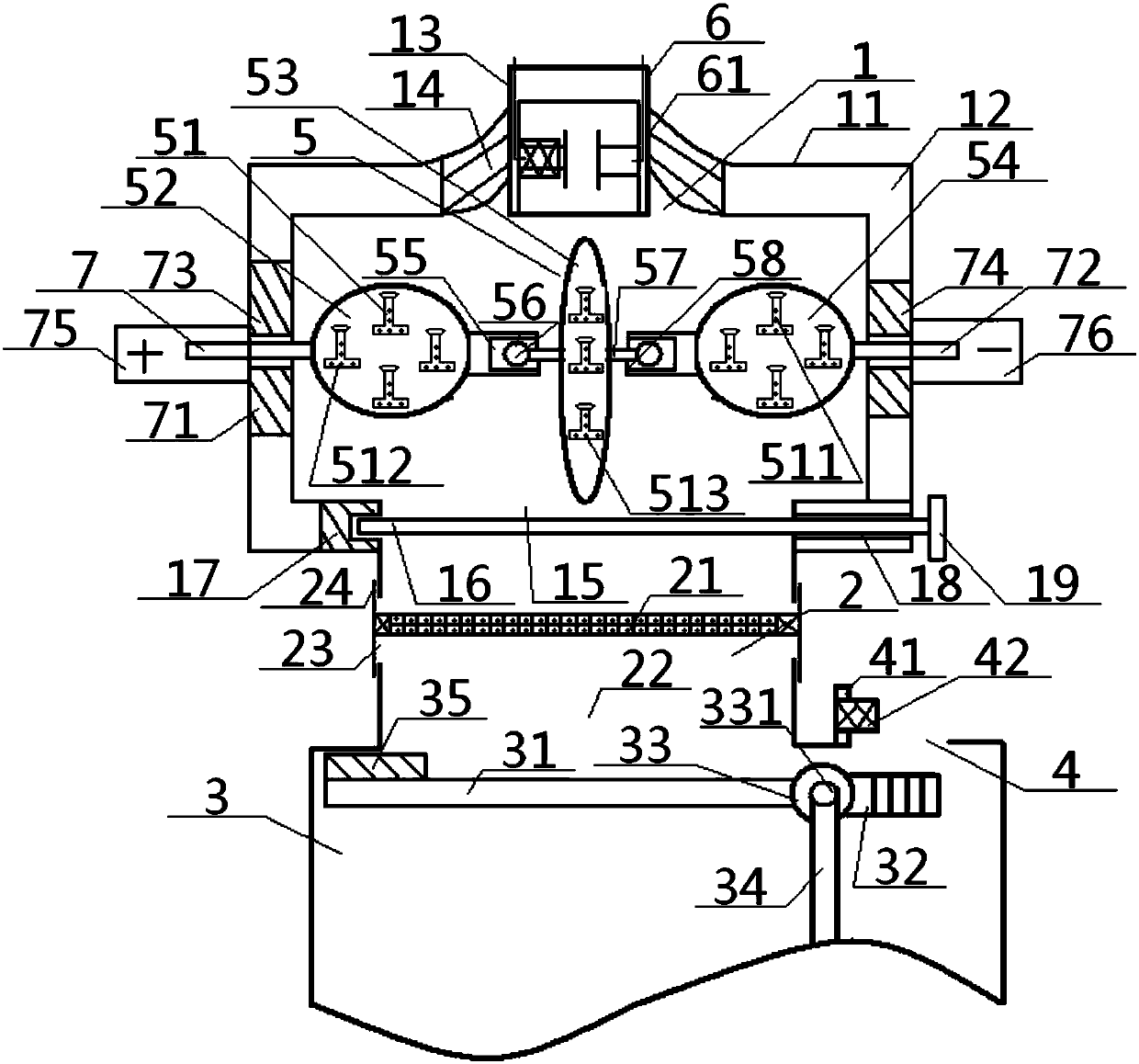

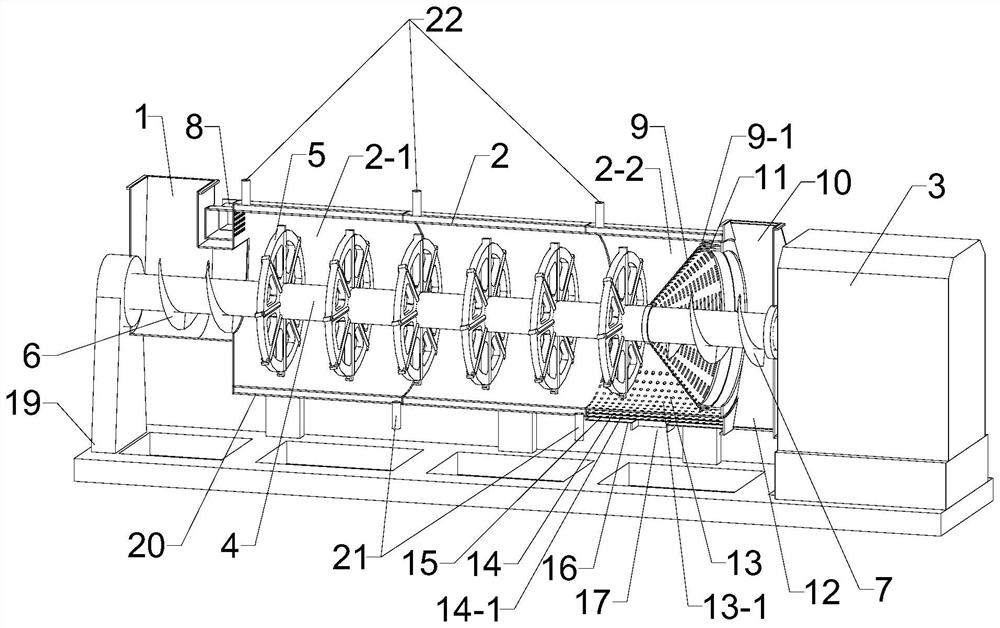

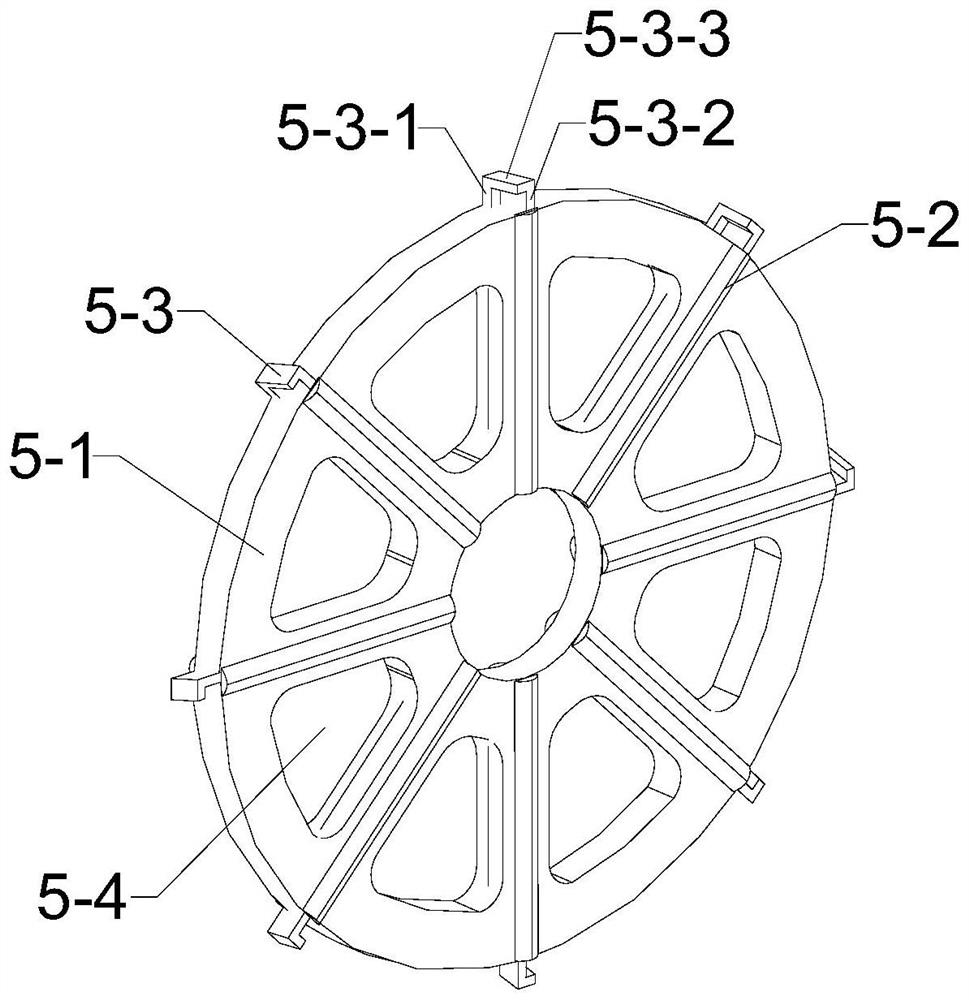

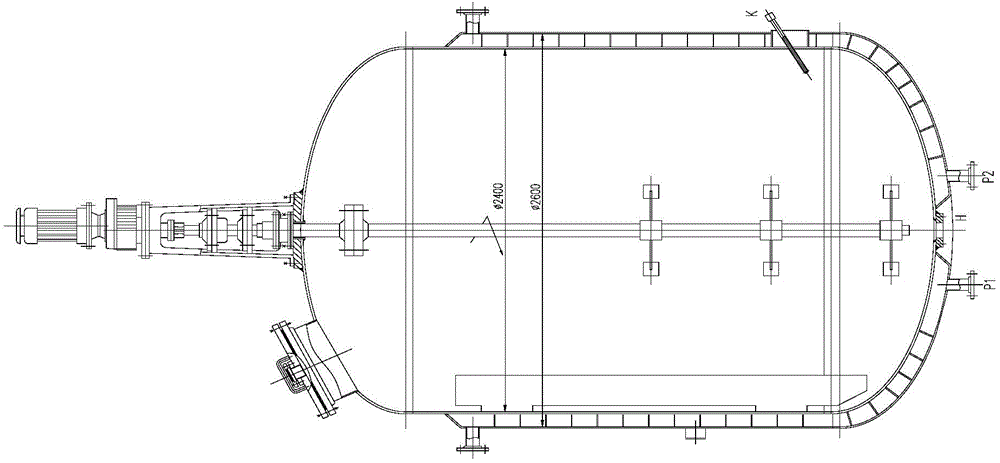

Dry stirring mill and operation method thereof

ActiveCN113953029AIncrease working areaImprove stirring performanceGrain treatmentsEngineeringMechanical engineering

The invention discloses a dry stirring mill and an operation method thereof. The dry stirring mill comprises a grinding cylinder, a feeding opening, a discharging opening, a mill air inlet, a mill air outlet, a main shaft, a driving device, stirrers, a separating device and a grading air supply device; the grinding cylinder is horizontally arranged, one end of the grinding cylinder is provided with the feeding opening and the mill air inlet, and the other end of the grinding cylinder is provided with the discharging opening and the mill air outlet; the interior of the grinding cylinder is divided into a grinding area and a grinding grading area, and the grinding area is close to one side of the feeding opening; the main shaft is located in the grinding cylinder and penetrates through the center of the grinding cylinder, one end of the main shaft is connected with the driving device, and the other end of the main shaft is supported by a bearing installed on a foundation and a support; stirrers are arranged at the position, in the grinding area, of the main shaft, and the other stirrers and the separating device are arranged at the position, in the grinding grading area, of the main shaft; a trepanning area is arranged at the bottom of the portion, in the grinding grading area, of the grinding cylinder; and the position, in the trepanning area, of the grinding cylinder is connected with the grading air supply device. Grinding efficiency is greatly improved, timely separation of materials from grinding media is guaranteed, and reliability and stability of the mill are improved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

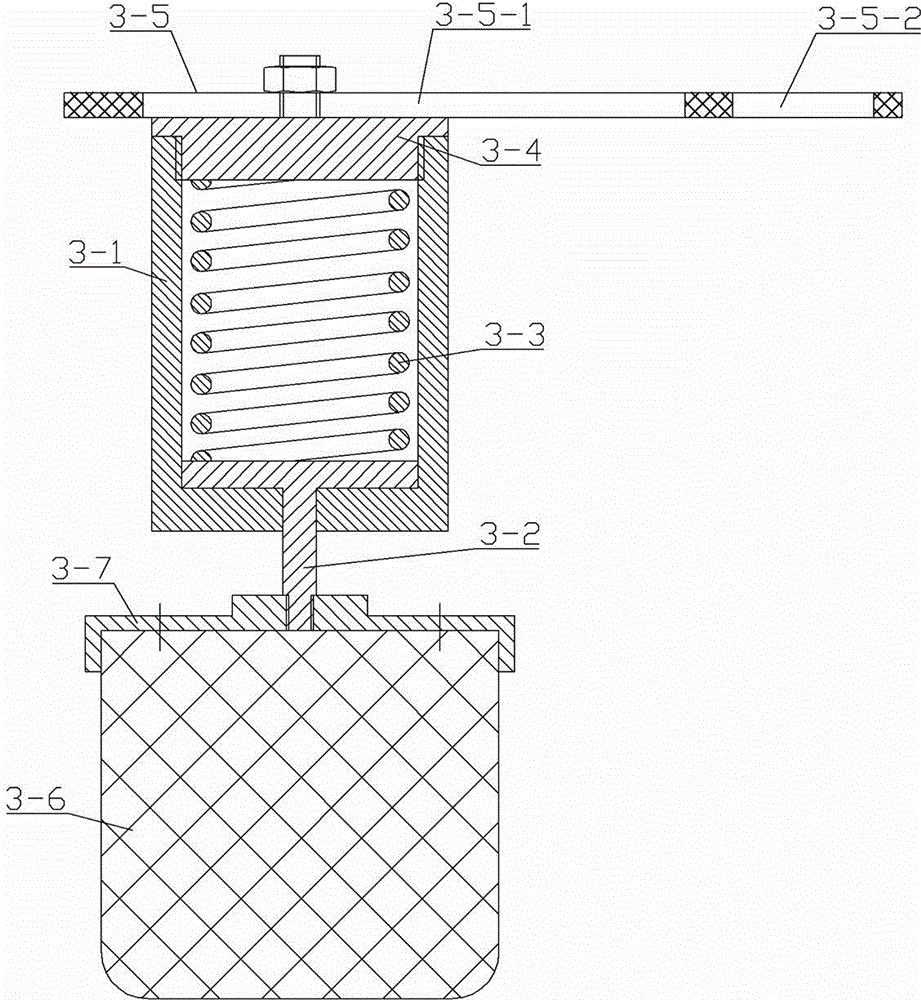

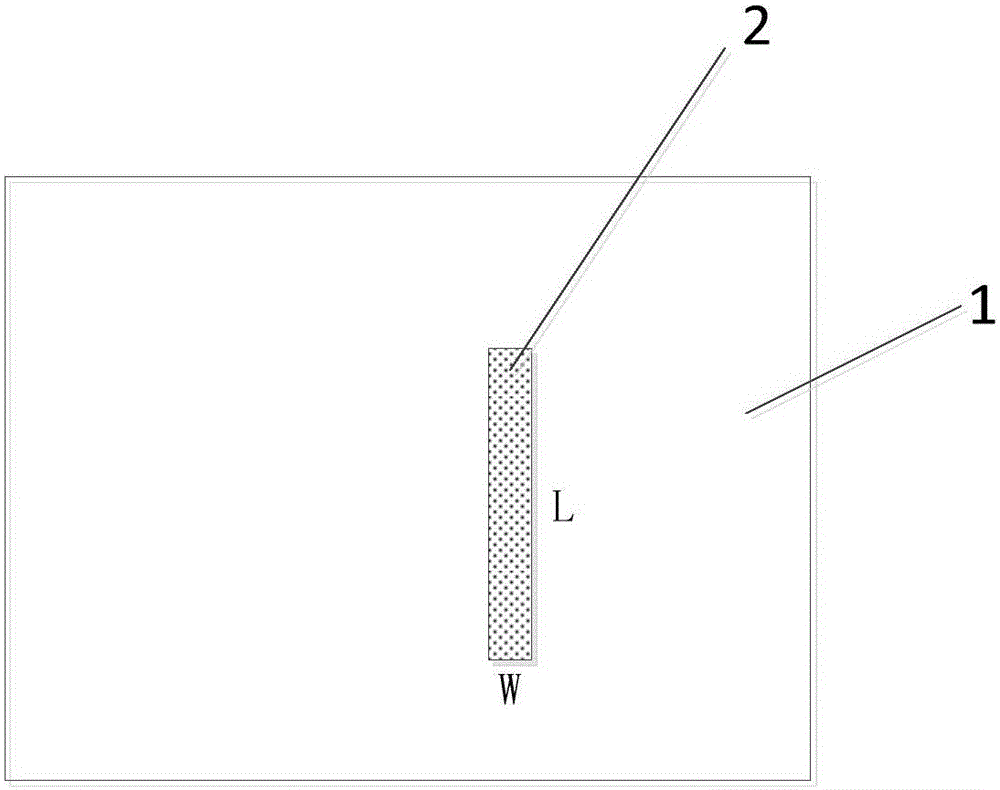

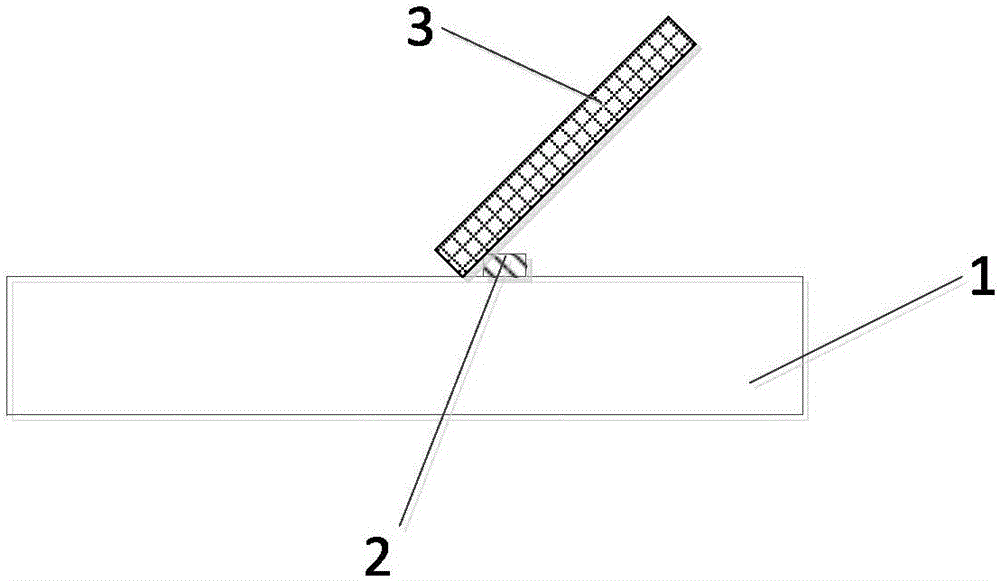

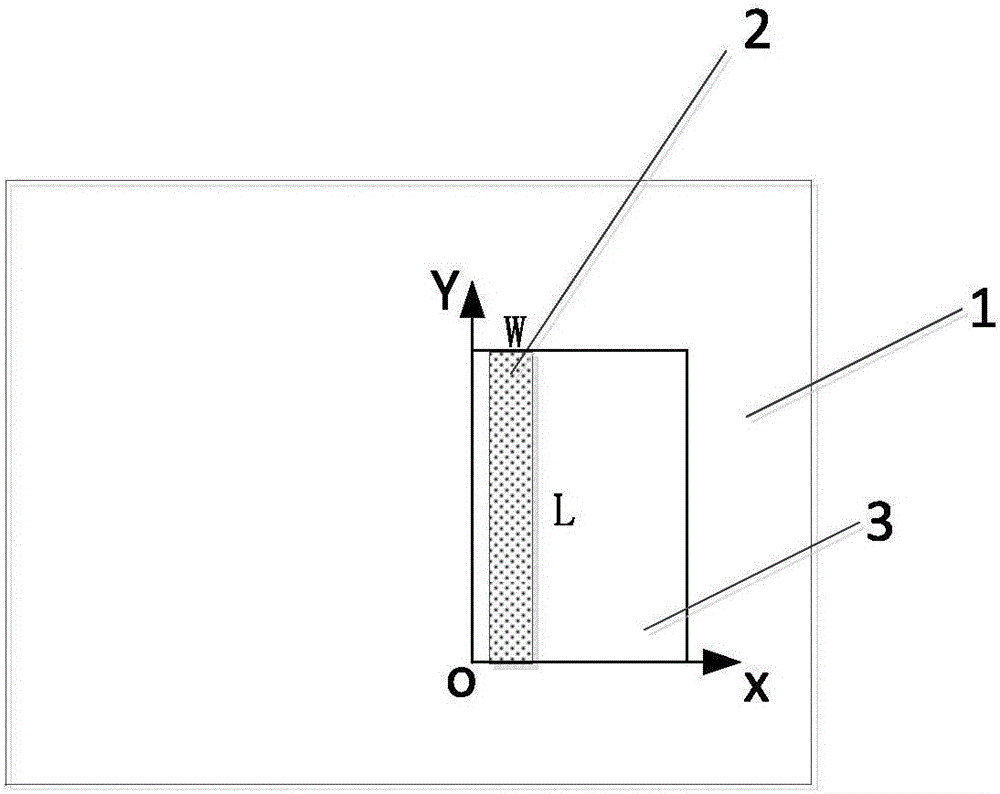

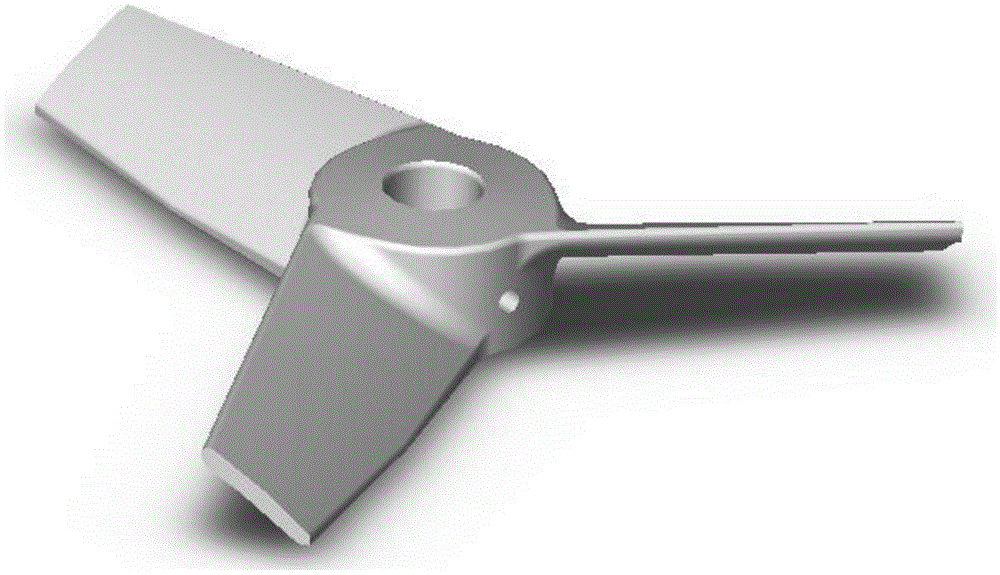

Stirring reactor and application thereof in condensation reaction of Grignard reagent

InactiveCN104607113AEnhanced Liquid RenewalImprove stirring performanceCarboxylic acid nitrile preparationOrganic compound preparationGrignard reagentEngineering

The invention discloses a stirring reactor and application thereof in condensation reaction of a Grignard reagent. The reactor comprises a kettle body, a stirring device, a cooling device and a feeding device, wherein the stirring device comprises a stirring shaft, a driving mechanism for driving the stirring shaft and a stirring paddle fixedly connected with the stirring shaft; the stirring paddle is formed by at least one blade group; the blade group comprises a hub in the center of which a through hole is formed, a disk which is fixedly connected onto the periphery of the hub and a plurality of blades which are uniformly connected onto the disk; the hub is mounted on the stirring shaft through the through hole in a sleeving manner; the root and the end part of each blade form a torsion angle of 5 to 90 DEG; and the included angle between the edge of the root of each blade and the plane perpendicular to the stirring shaft is 5 to 90 DEG. Through the stirring reactor, the mixing effect is excellent, no mixing dead zone can be generated, and materials can be distributed uniformly, so that the stirring reactor is particularly suitable for the condensation reaction.

Owner:ZHEJIANG APELOA JIAYUAN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com