Method for promoting RH decarburization

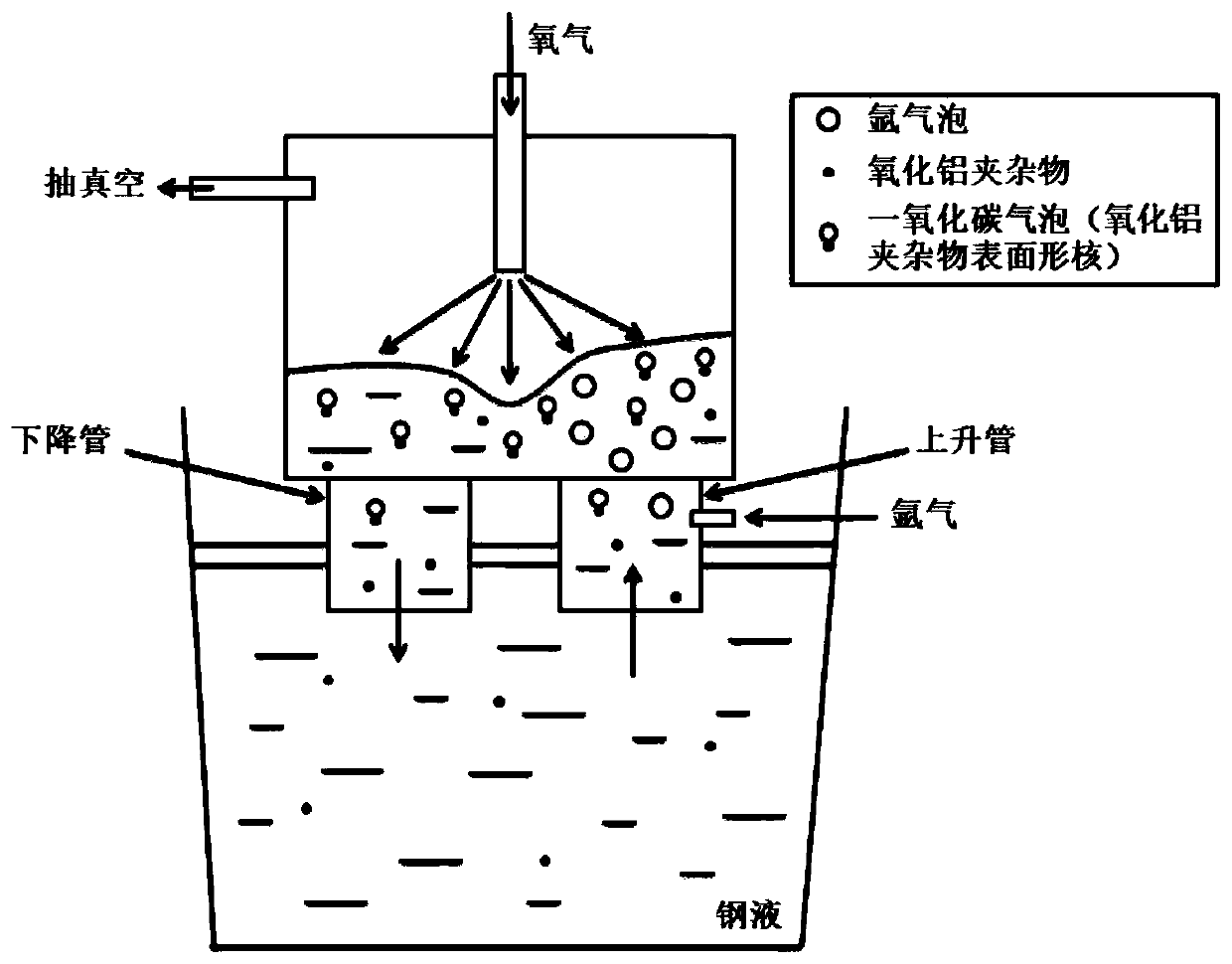

A decarburization and carbon monoxide technology, applied in the field of metallurgy, can solve the problems of influence, equipment modification, treatment process, and difficult operation, and achieve the effect of promoting aggregation and growth, improving RH decarburization rate, and good removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The BOF-LF-RH-CC process is adopted to produce IF steel with a converter capacity of 300t. The final oxygen content of the converter is 612×10 -6 , Then the ladle is moved to the RH station, and the carbon concentration in the steel is determined to be 300×10 -6 . When this patented technology is not used, after RH vacuum decarburization for 15 minutes, the mass concentration of carbon in the steel is determined to be 16×10 -6 .

[0035] When using this patented technology, the dissolved oxygen content in the steel before adding aluminum particles is 612×10 -6 . During the tapping process, aluminum particles are added to the steel, the addition amount is 210kg, the ladle is moved to the RH station, and the oxygen mass concentration in the steel before the RH vacuum treatment is determined to be 300×10 -6 , The carbon mass concentration is 300×10 -6 . RH refining starts, after vacuuming for 2 minutes, the pressure in the vacuum tank drops to 8000Pa, and the top gun is used...

Embodiment 2

[0037] The BOF-LF-RH-CC process is used to produce IF steel with a converter capacity of 120t. After the converter is tapped, the ladle is moved to the RH station, and the dissolved oxygen content in the steel is determined to be 485×10 -6 , The carbon mass concentration is 250×10 -6 . When this patented technology is not used, after RH vacuum decarburization for 10 minutes, the mass concentration of carbon in the steel is determined to be 15×10 -6 .

[0038] When this patented technology is used, aluminum particles are added to the steel before the RH treatment, the added amount is 44kg, and the dissolved oxygen content in the steel before the aluminum particles is 485×10 -6 . The mass concentration of oxygen in steel measured before RH vacuum treatment is 321×10 -6 , The carbon mass concentration is 250×10 -6 . RH refining starts, after vacuuming for 2 minutes, the pressure in the vacuum tank drops to 7500Pa, and the top gun is used to blow oxygen into the molten steel with a ...

Embodiment 3

[0040] The BOF-LF-RH-CC process is used to produce DX56D+Z steel with a converter capacity of 150t. After tapping, the ladle is moved to the RH station, and the dissolved oxygen content in the steel is determined to be 680×10 -6 , The carbon mass concentration is 400×10 -6 . When this patented technology is not used, after RH vacuum decarburization for 14 minutes, the mass concentration of carbon in the steel is determined to be 12×10 -6 .

[0041] When using this patented technology, aluminum particles are added to the steel in the early stage of the RH vacuum treatment, the addition amount is 54kg, and the dissolved oxygen content in the steel before the aluminum particles is 680×10 -6 . After adding aluminum particles, the oxygen mass concentration in steel is determined to be 520×10 -6 , The carbon mass concentration is 400×10 -6 . RH refining starts, after vacuuming for 2 minutes, the pressure in the vacuum tank drops to 8600Pa. A top gun is used to blow a large flow of oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com