Environment-friendly utilization system for producing biogas from plant wastes

A waste and plant-based technology, which is applied to the fermentation system of plant waste materials and the field of environment-friendly utilization systems, can solve the problems of weak stirring ability and poor crushing effect, and achieve the effect of strong stirring ability and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

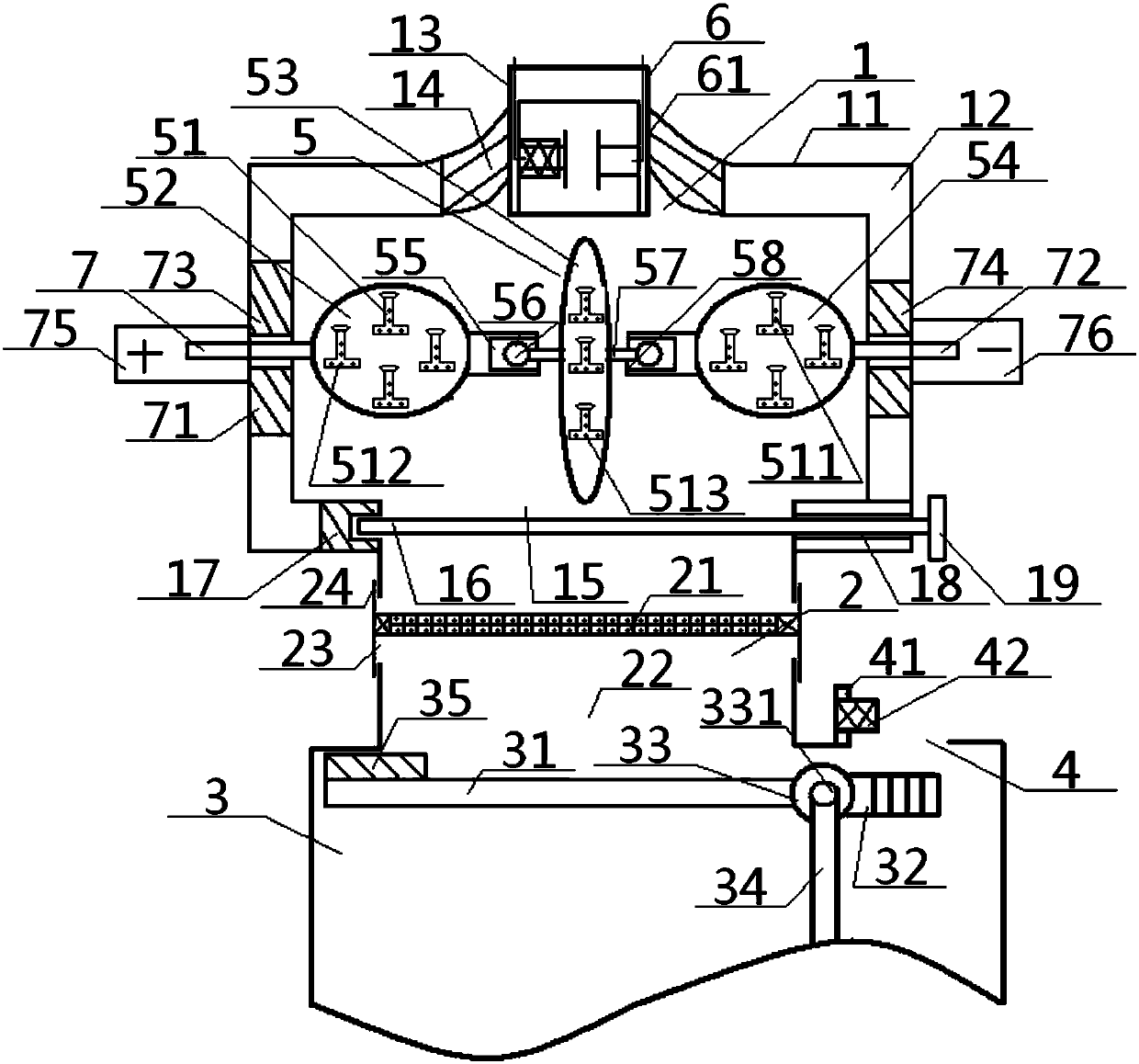

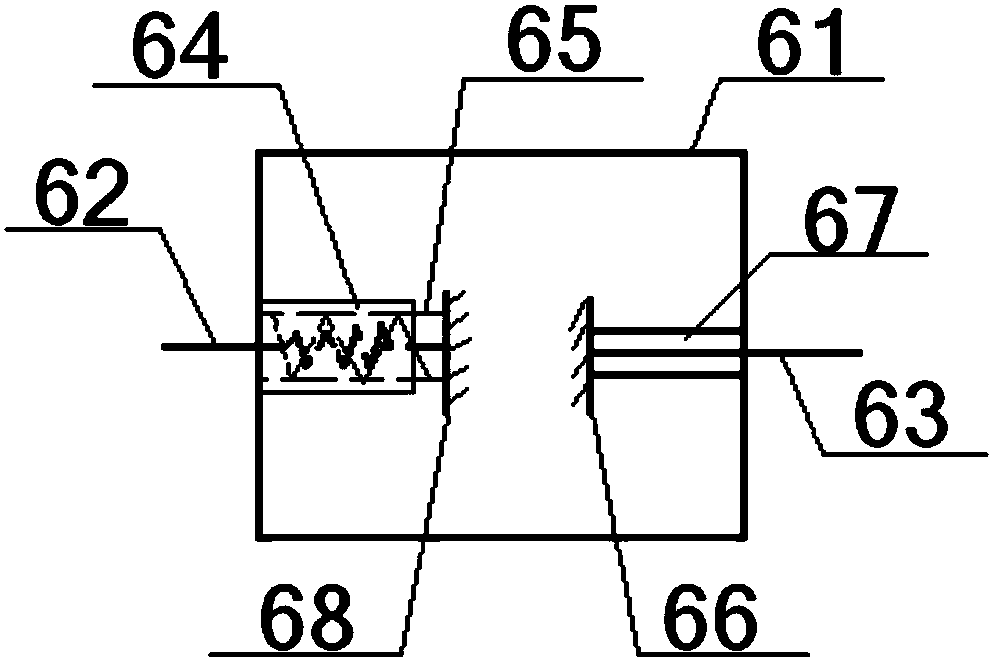

[0027] see Figure 1 to Figure 2, an environment-friendly utilization system for generating biogas from plant waste, comprising a mixing chamber 1, a material selection chamber 2 and a feeding chamber 3, the bottom of the mixing chamber 1 communicates with the top of the feeding chamber 3 through the material selection chamber 2 , the inside of the stirring chamber 1 is provided with a stirring device 5, the inside of the stirring device 5 passes through a main drive shaft 7, and the left and right ends of the main drive shaft 7 pass through the left and right side walls of the stirring chamber 1 respectively. Pass;

[0028] The side wall of the stirring chamber 1 is wrapped with a stirring shell 11, and a heating chamber 12 is sandwiched between the stirring shell 11 and the stirring chamber 1, and a left agitating chamber 12 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com