Dry stirring mill and operation method thereof

A stirring mill and grinding machine technology, applied in grain processing, etc., can solve the problems of poor separation between qualified materials and grinding media, low grinding efficiency of dry stirring mill, and difficulty in heat dissipation, so as to promote disordered movement and improve grinding efficiency , the effect of large working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

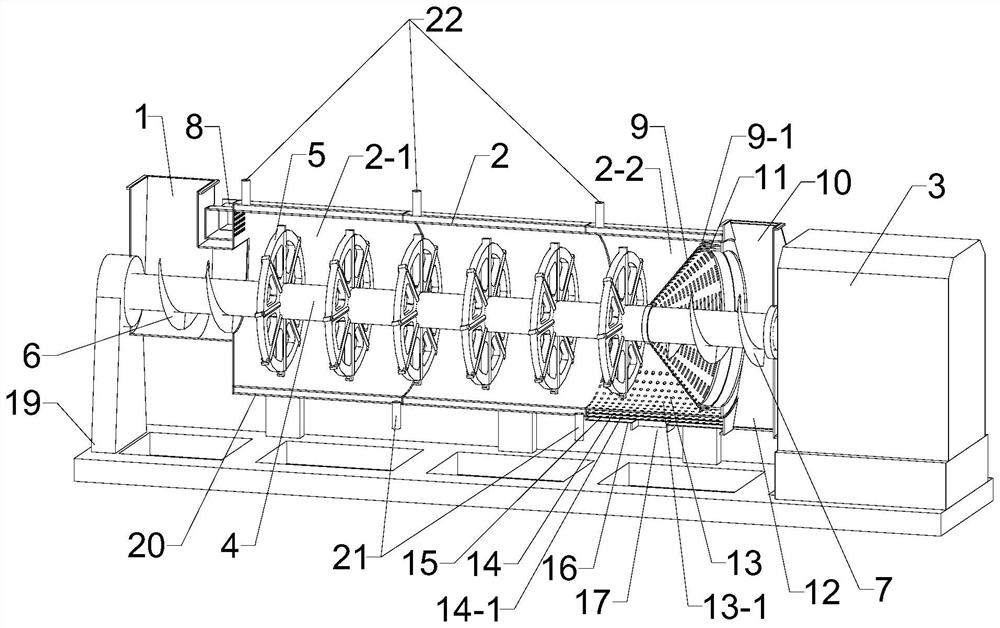

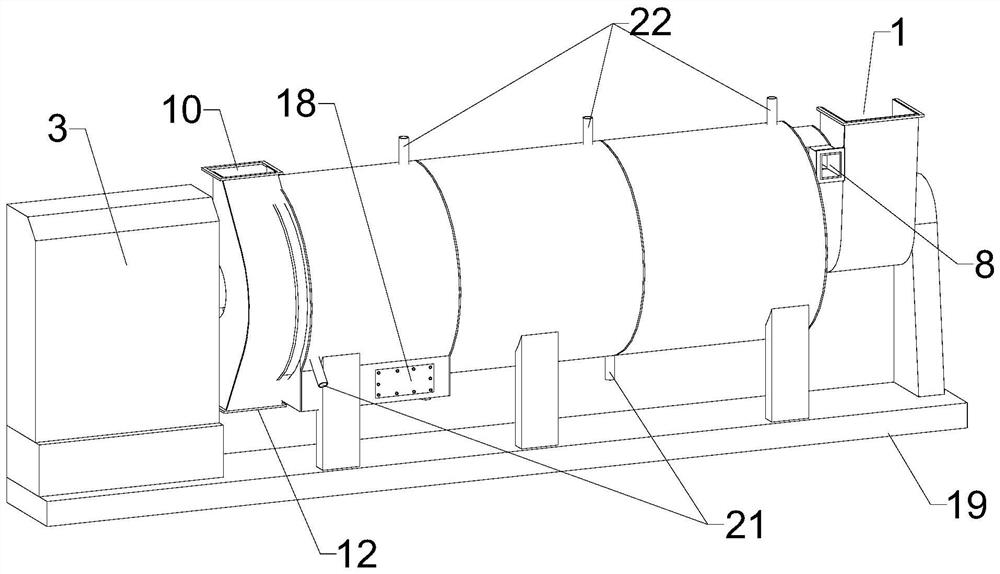

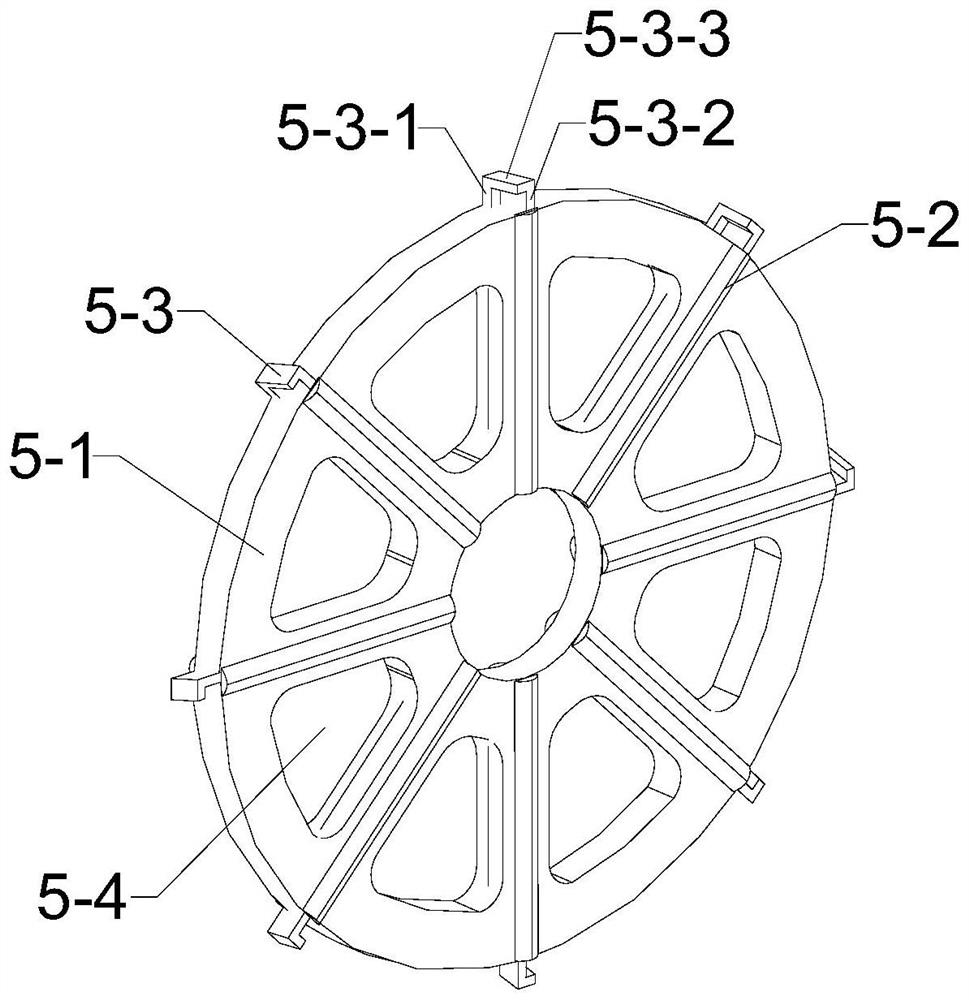

[0058] see Figure 1-7 , the present embodiment provides a dry stirring mill, the mill comprises a grinding cylinder 2, a feed port 1, a discharge port 12, a mill air inlet 8, a mill air outlet 10, a main shaft 4, a driving device 3, Stirrer 5, separating device 9, grading air supply device and cooling device.

[0059] The grinding cylinder 2 is cylindrical, arranged horizontally, supported and fixed by the foundation and the bracket 19, one end of the grinding cylinder 2 is provided with a feeding port 1 and a mill air inlet 8, and the other end is provided with a discharge port 12 and a mill air outlet 10, Grinding barrel 2 is filled with spherical grinding media with a diameter of 2 to 15 mm, and the filling rate of grinding media is 60% to 85%. Grinding barrel 2 is divided into grinding area 2-1 and grinding and grading area 2-2 according to functions. The area 2-1 is close to the side of the feeding port 1; the length of the grinding area 2-1 is 0.6-0.9 times the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com