Patents

Literature

48results about How to "Effective collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

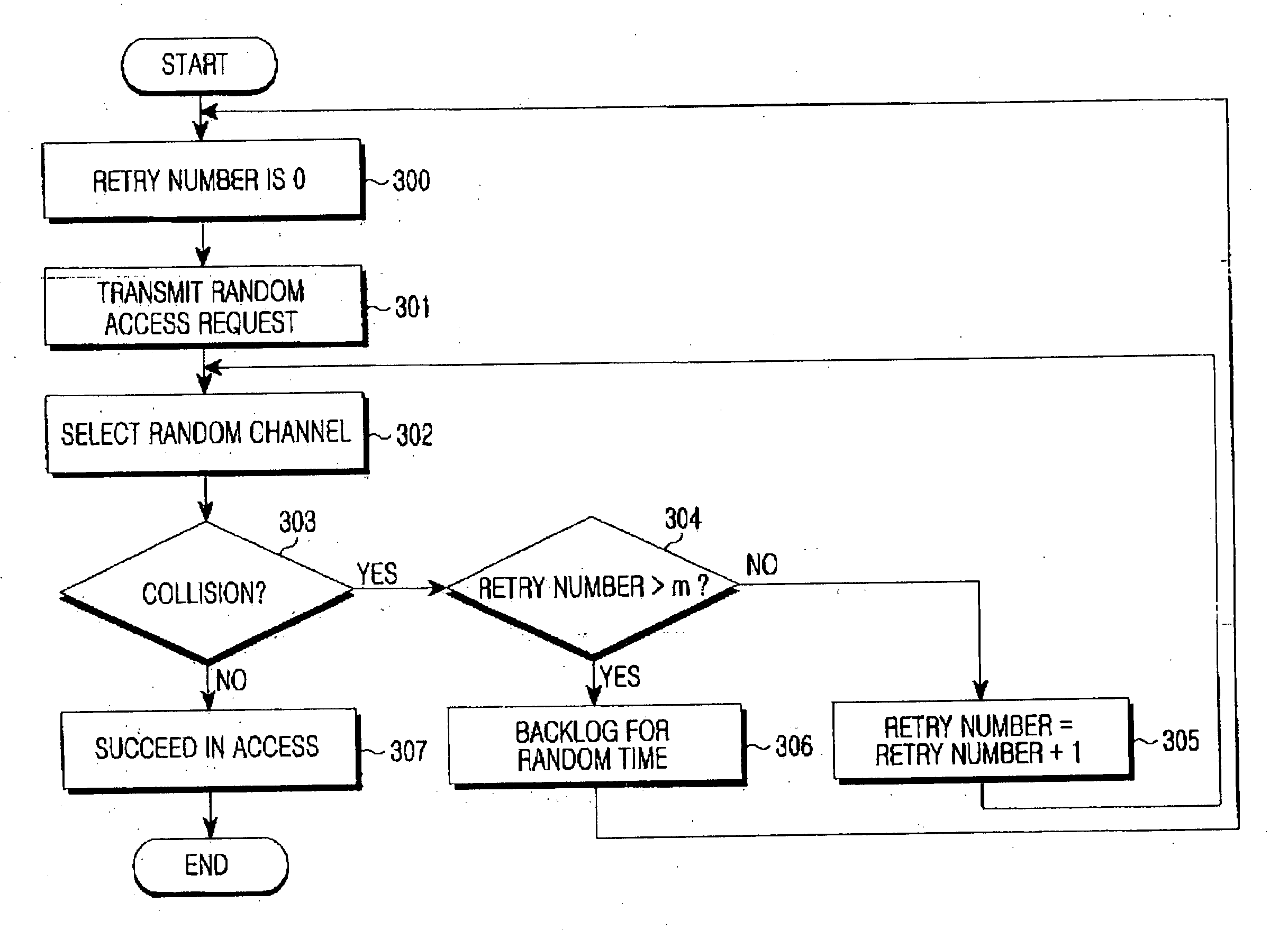

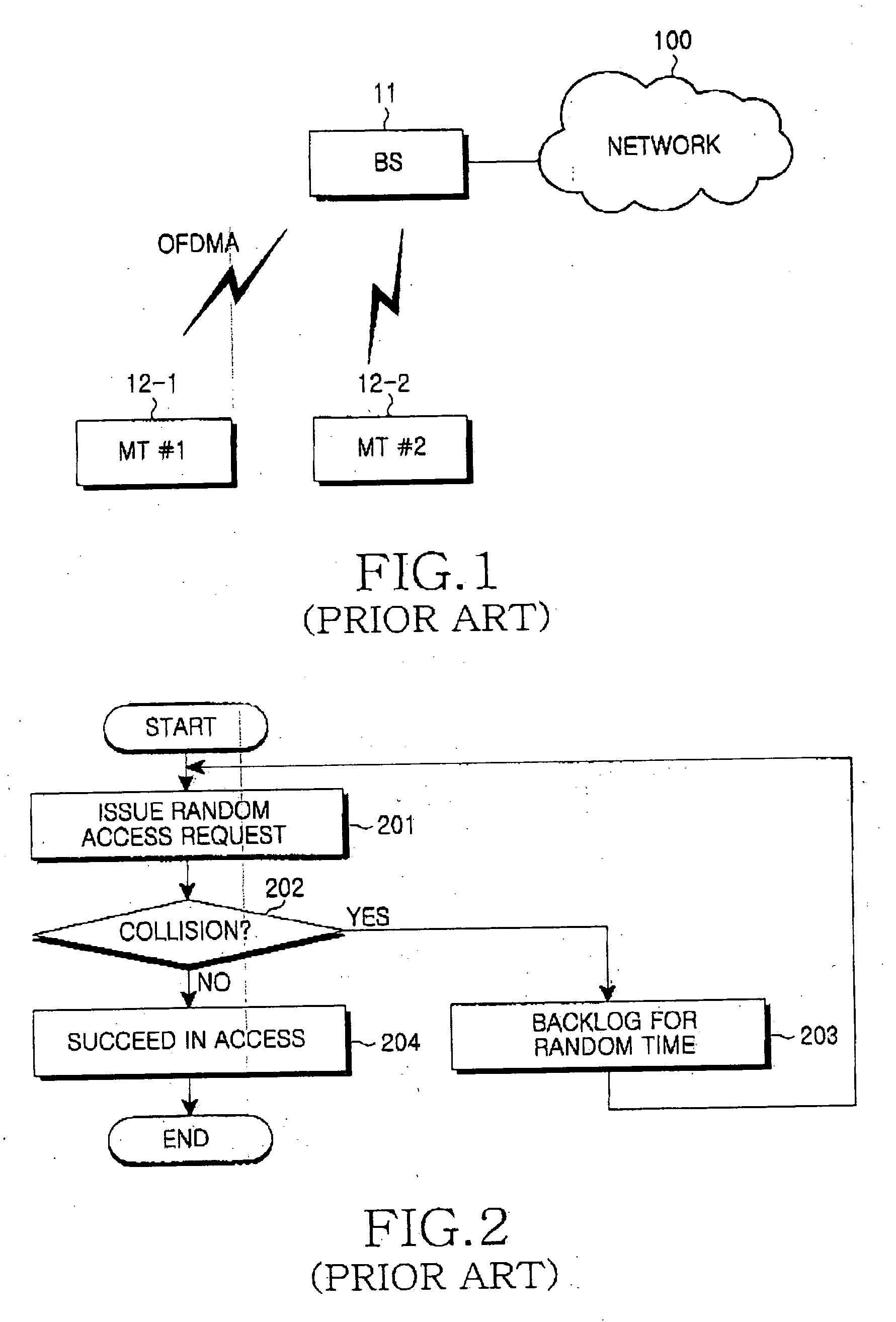

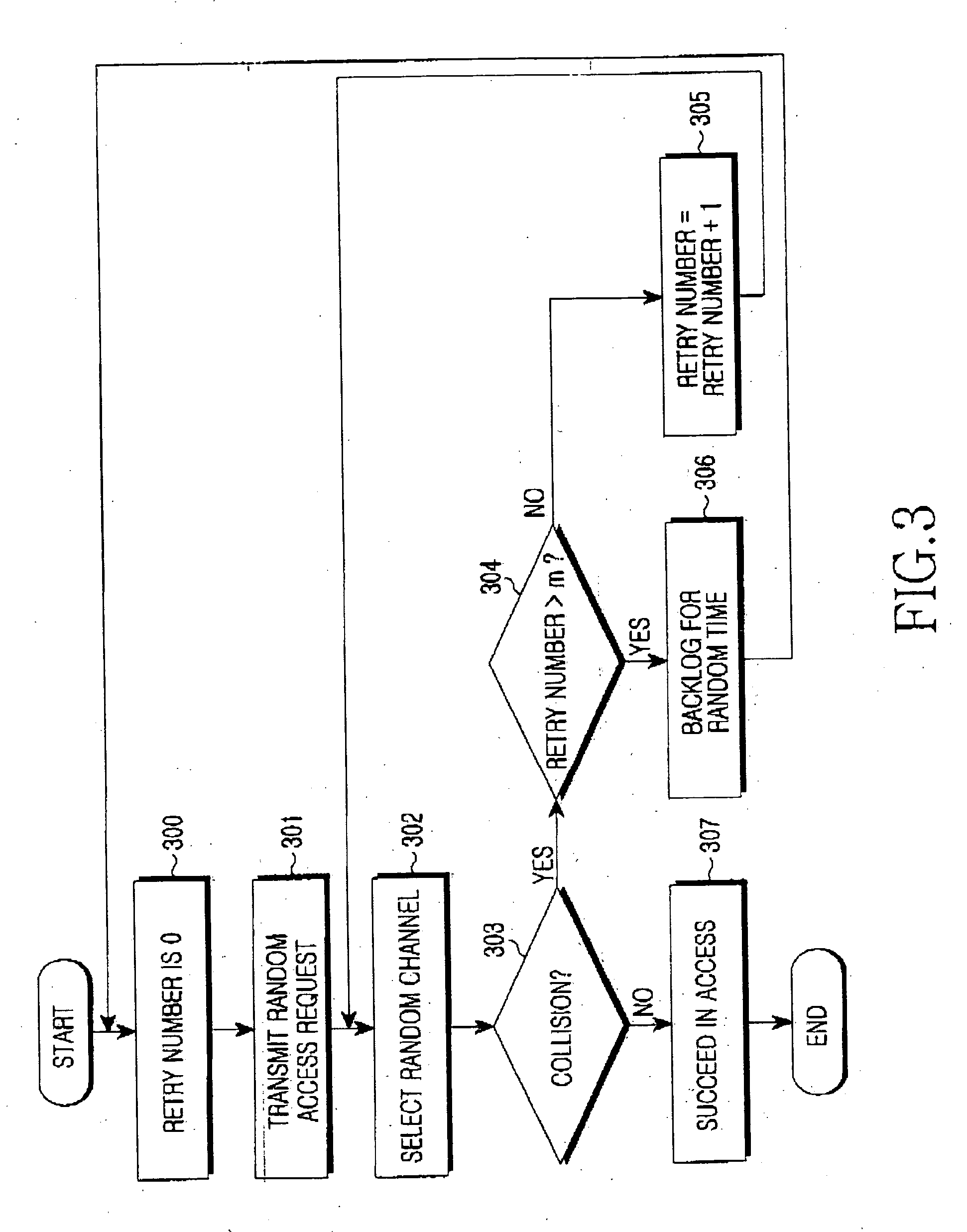

Random access method in multi-cell OFDMA networks

InactiveUS20060045047A1Easy to useEffective collisionTransmission path divisionSignal allocationTelecommunicationsAccess method

Disclosed is an upstream access method in an Orthogonal Frequency Division Multiple Access (OFDMA)-based mobile communication system in which a random access method in an OFDMA network includes randomly selecting, by each subscriber device, one of a plurality uplink random access channels, if a random access request to the OFDMA network is transmitted by each subscriber device, accessing through the selected channel if a collision has not occurred in the selected channel, randomly selecting one of the uplink random access channels, if a collision has occurred in the selected channel, and if the number of retries for channel selection is less than a predetermined value, and determining whether a has collision has occurred, accessing through a finally selected channel, if it is determined that a collision has occurred; and randomly selecting one of the uplink random access channels if it is determined that a collision has occurred.

Owner:SAMSUNG ELECTRONICS CO LTD +1

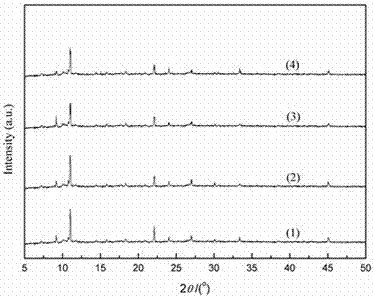

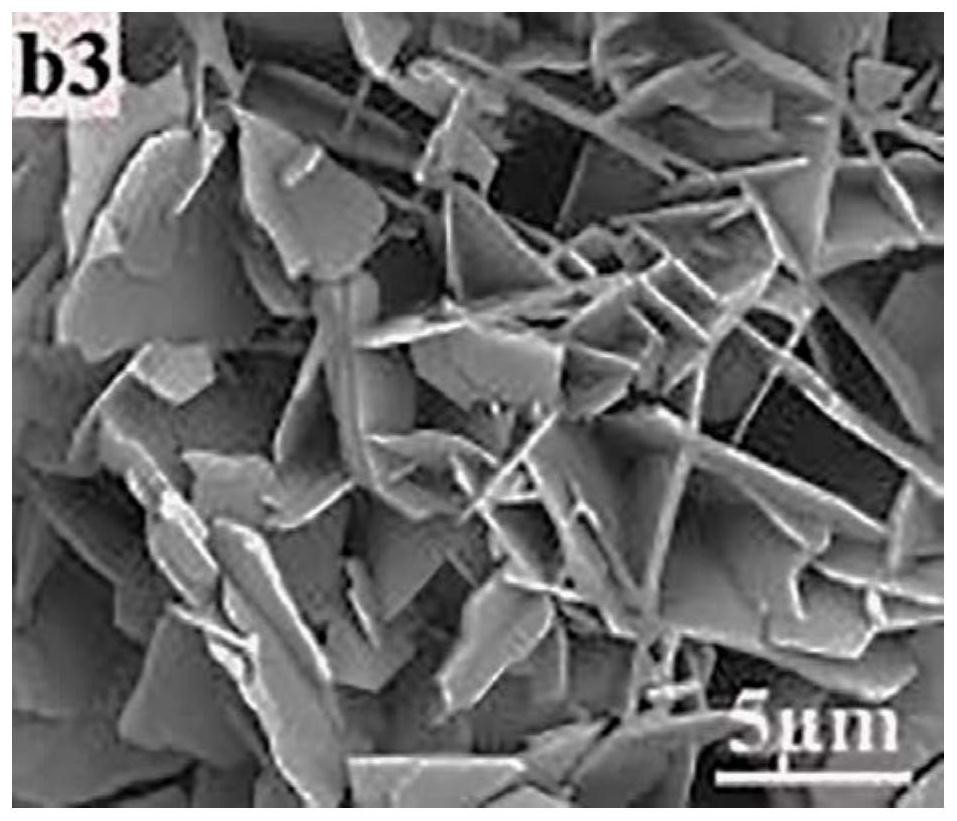

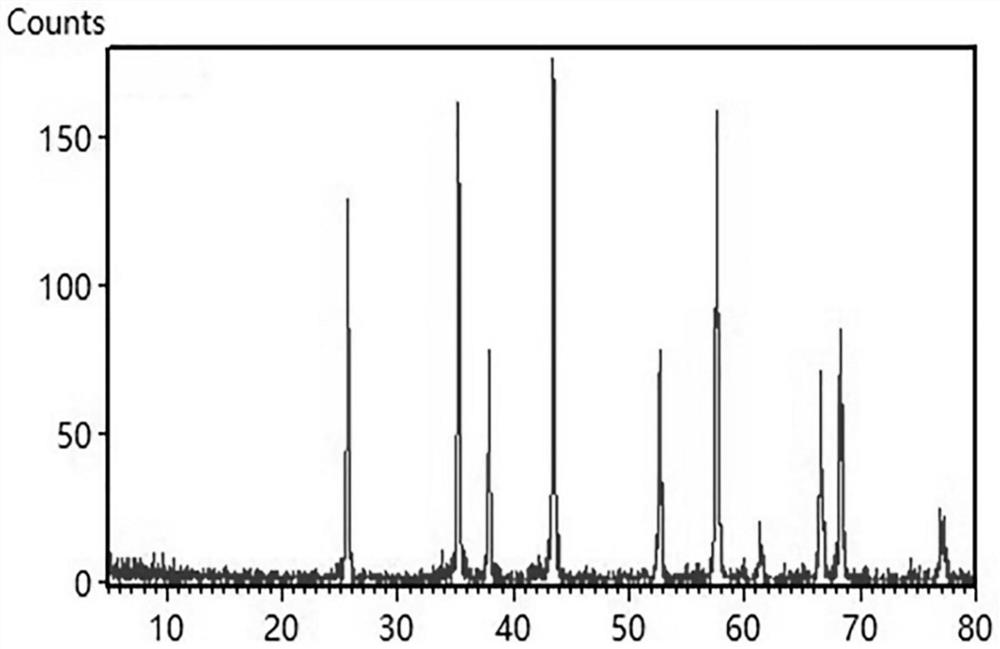

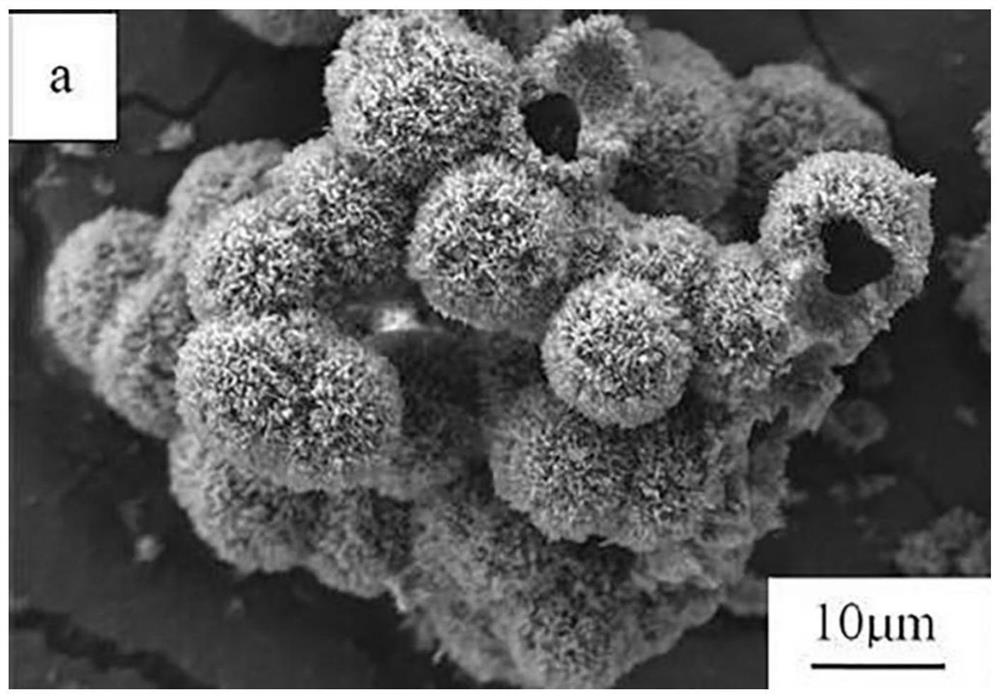

Method for synthesizing metal-organic framework material Co-MOF-71

InactiveCN107099038AUniform grain sizeImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionReactive siteMetal-organic framework

The invention relates to successful preparation of a Co-MOF-71 nano-material. According to the invention, preparation process conditions are optimized; the prepared Co-MOF-71 nano-material is uniform in crystal grain size and has good stability; and when Co utilizes the acidic catalysis reaction of MOF framework metal ions, the metal ions are active sites and the supporting points of a framework, and metal ions undergo coordination in the process of catalysis. The prepared Co-MOF-71 material has high metal content and completely exposed metal sites; more Lewis acid site Co-MOF-71 materials can be provided; and the material is beneficial for total activation of reactant molecules and has good catalytic activity.

Owner:NINGXIA UNIVERSITY

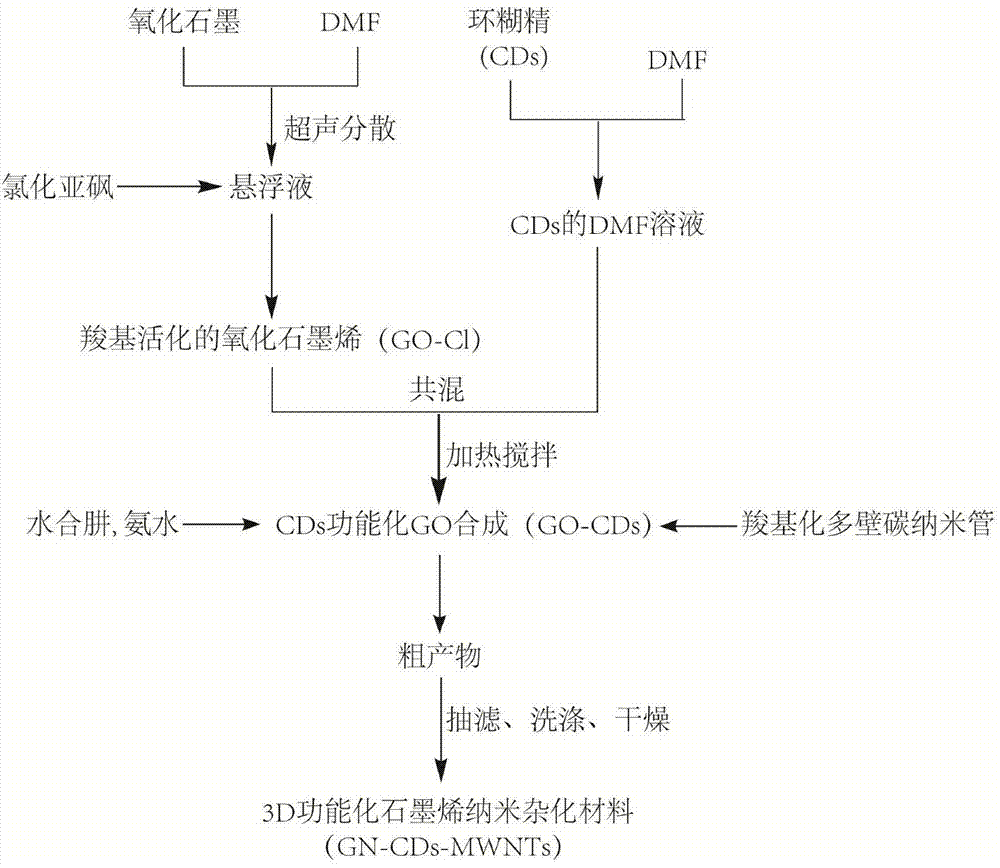

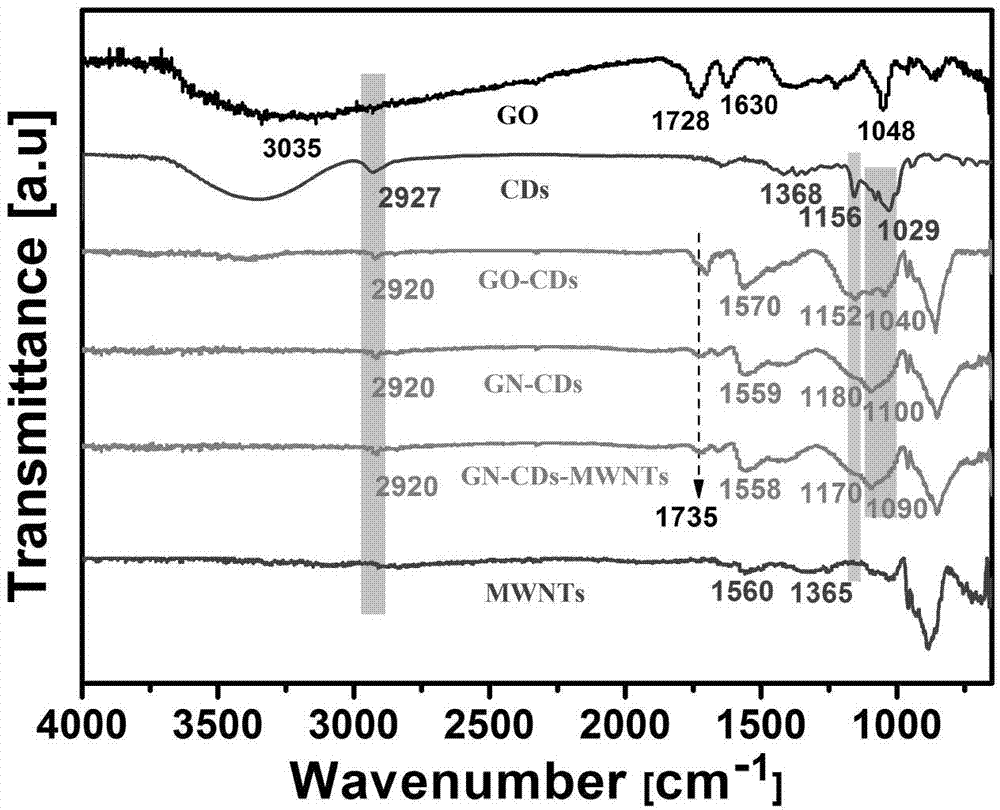

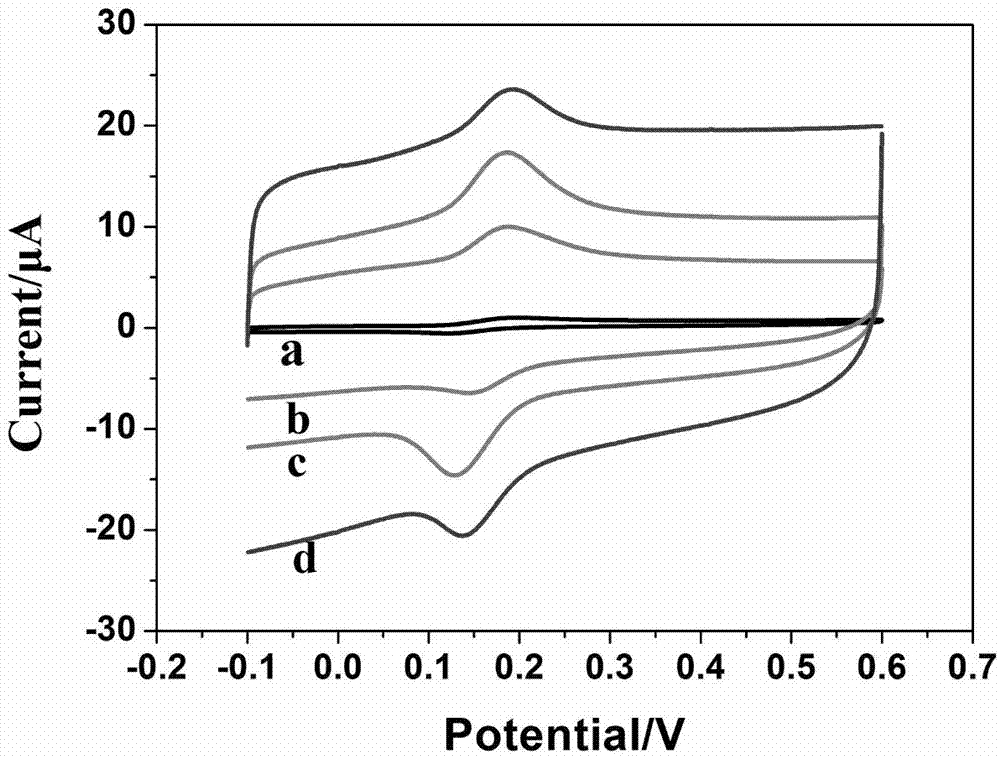

Multi-wall carbon nano-tube bridged 3D graphene conductive network and preparation method thereof

InactiveCN104730121AImprove conductivityEffective collisionMaterial nanotechnologyNanomedicineAfter treatmentCyclodextrin

The invention discloses a carboxylation multi-wall carbon nano-tube bridged 3D graphene conductive network and a preparation method thereof. The method comprises the steps of preparing graphite oxide, preparing cyclodextrin functionalized graphene and preparing the carboxylated multi-wall carbon nano-tube bridged 3D graphene conductive network. The covalence organic decoration technology and the non-covalence organic decoration technology are scientifically combined, a nano hybridized material responding to electrochemical promotion of dopamine, ascorbic acid, purine trione and tryptophan is established, and the electrochemical performance of a nano material is adjusted by changing the type of cyclodextrin and the content of the carboxylated multi-wall nano-tube; the 3D functionalized nano material is simple in synthesis step, efficient, simple in after-treatment and easy for mass preparation; moreover, by adopting the 3D functionalized nano material, DA, AA, UA and Trp can be sensitively detected in a complicated environment in the presence of other interference substances; the defect that CDs is likely to drop can be effectively solved, and the conductivity of the system and the CDs selectivity can be remarkably improved by virtue of the non-covalence bridging of the carboxylated carbon nano-tube.

Owner:NANJING UNIV OF SCI & TECH

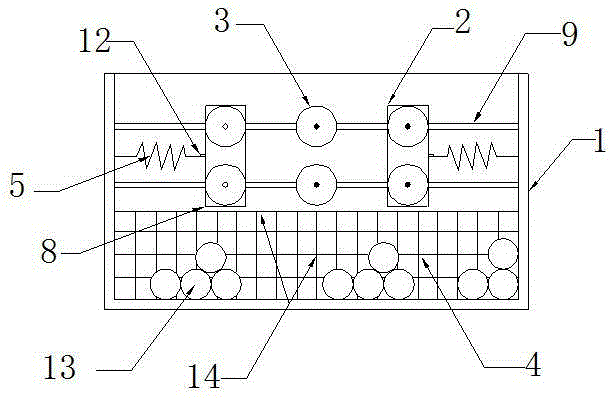

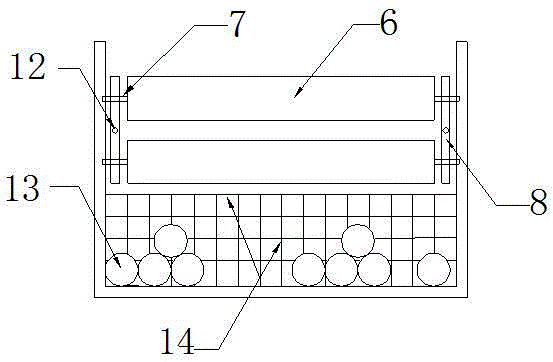

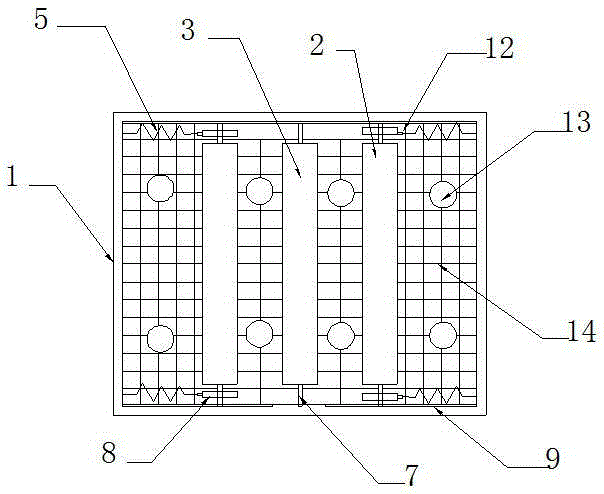

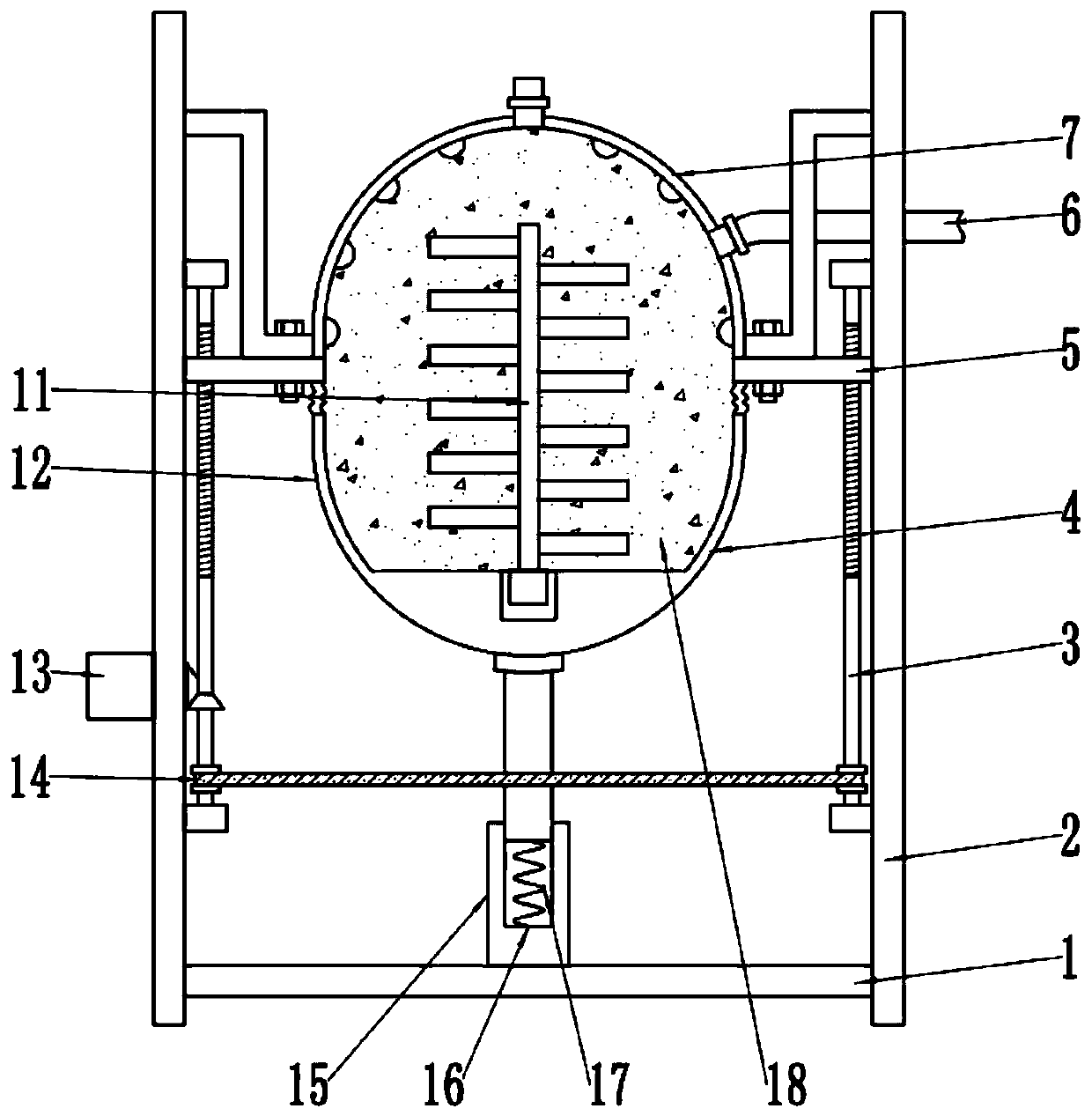

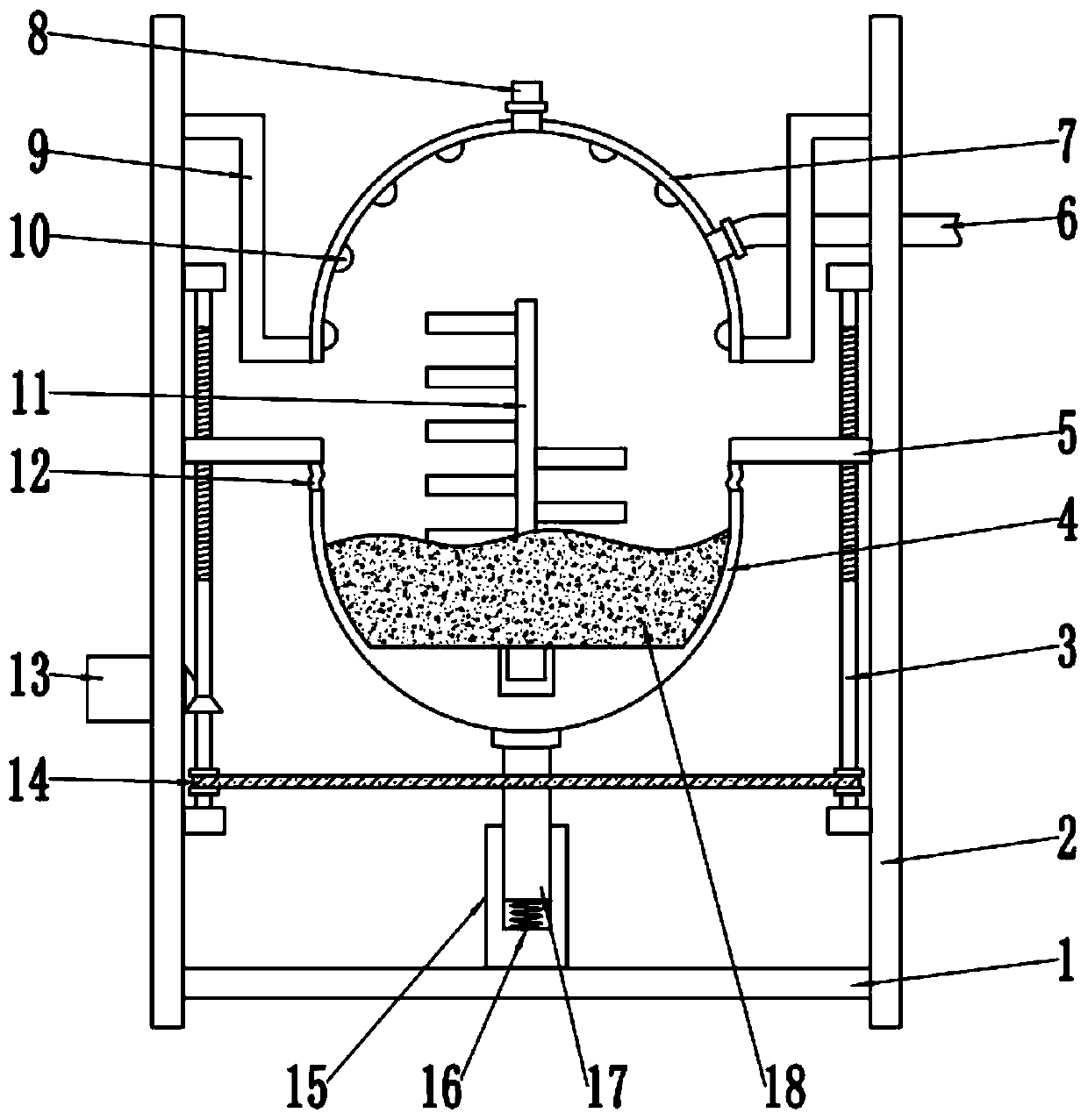

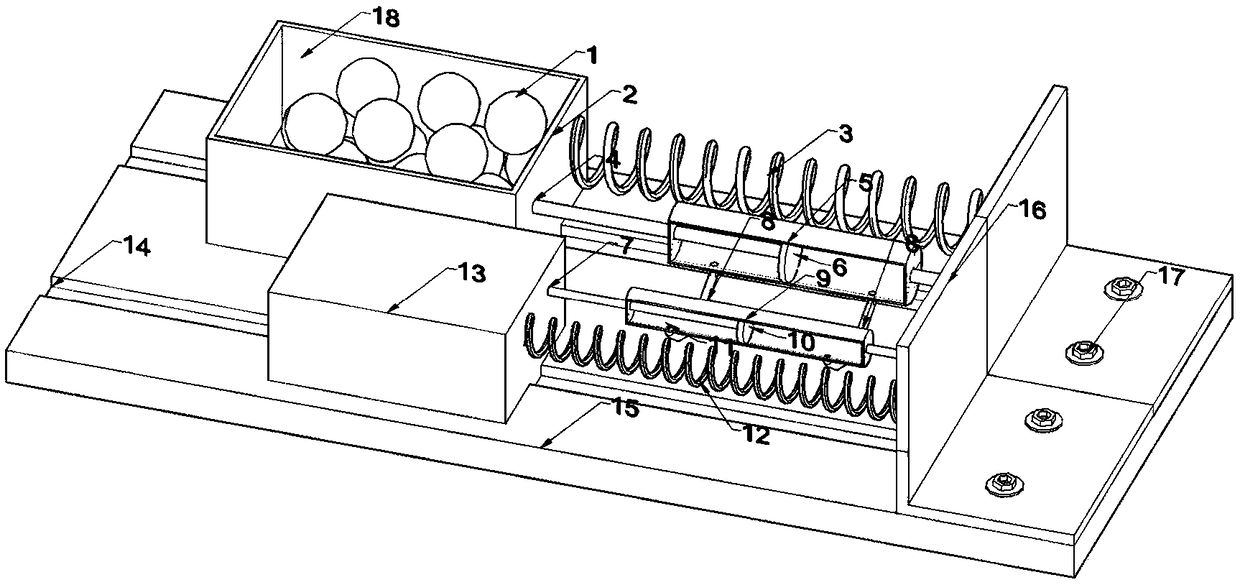

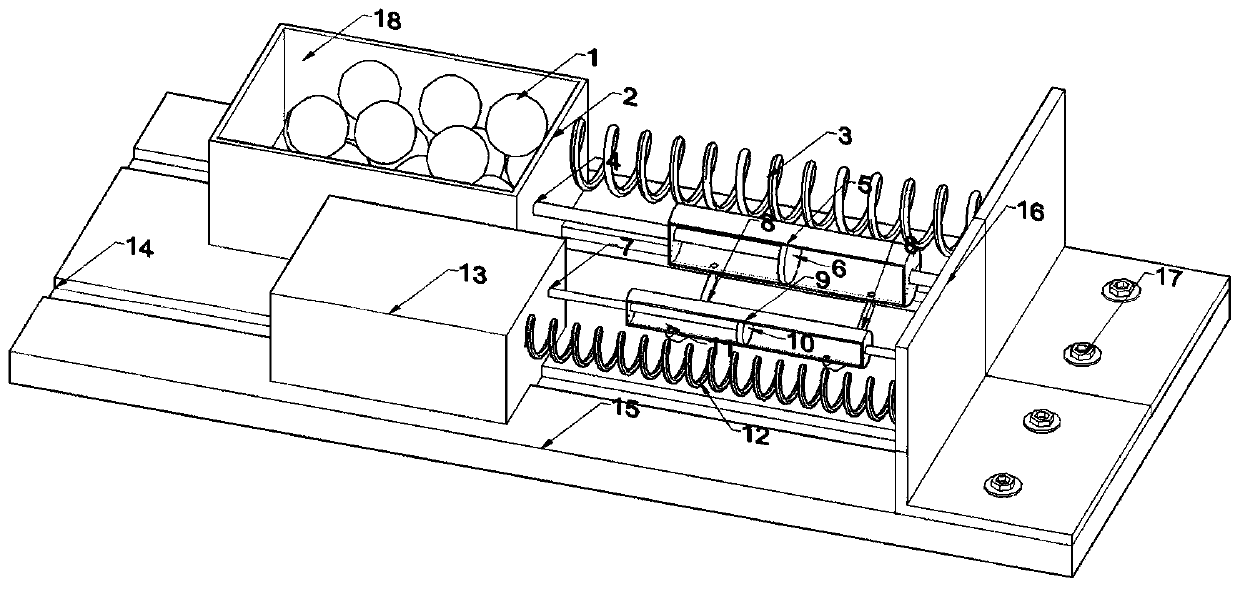

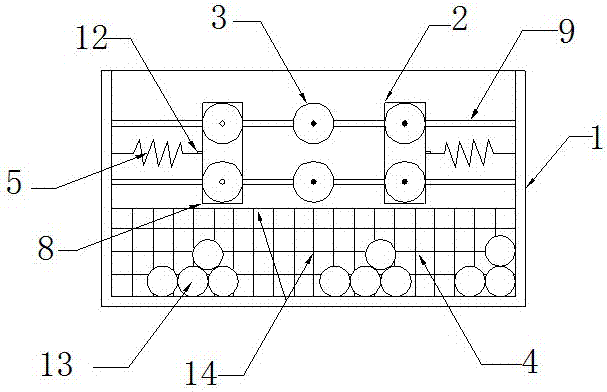

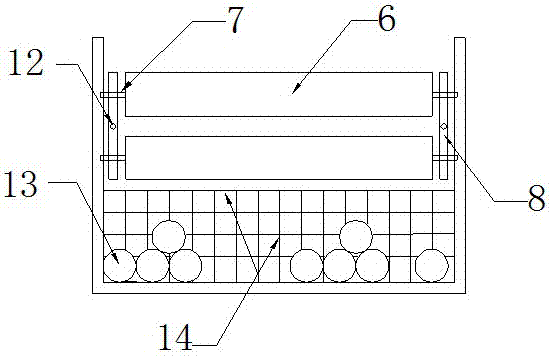

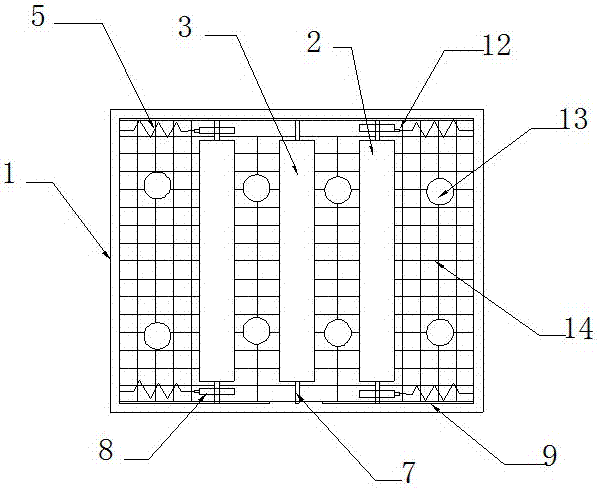

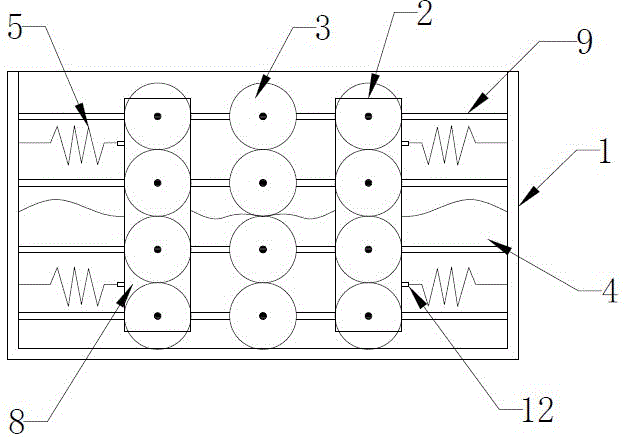

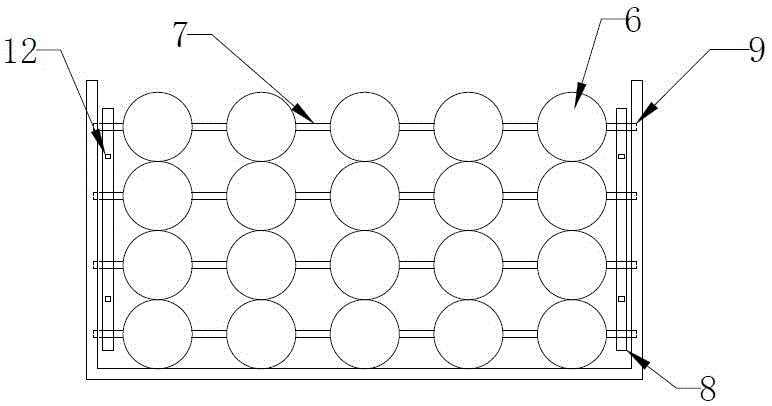

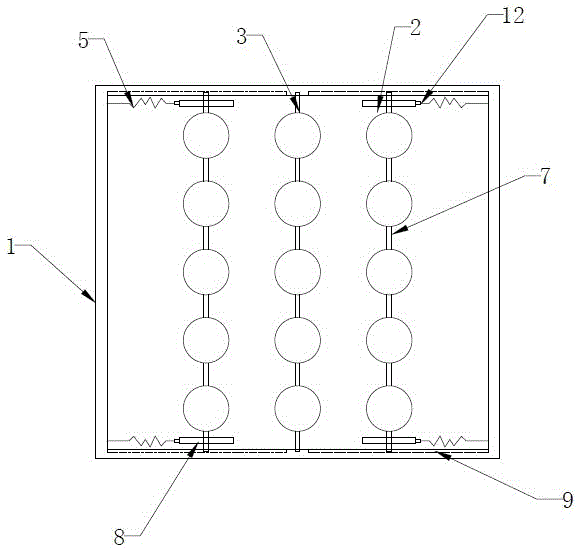

Combined multi-phase vibration-reduction device

InactiveCN105297940AClear structureVibration reduction and energy consumptionShock proofingViscous liquidEarthquake resistance

The invention discloses a combined multi-phase vibration-reduction device. The combined multi-phase vibration-reduction device comprises a container, particle systems, viscosity liquid, elastic systems and a screen. The particle systems are formed by spherical particles, bearing rods, fixing rods and built-in transverse cylinders in a two-way arrangement mode, the viscosity liquid is formed by mixing one or more kinds of liquid and located inside the container, and the spherical particles are located inside the viscosity liquid or float or settle at the bottom of the liquid. The viscosity liquid can vibrate inside the container, and the spherical particle systems collide with each other and rub each other inside the screen to consume energy. The viscosity liquid and the particle systems collide with each other and rub each other to consume energy, and the particles and the screen collide with each other and rub each other to consume energy. Advantages of a tuned liquid damper, a viscous damper, a tuned mass damper and a particle damper are combined, energy consumption is performed through the combination of a liquid phase and a solid phase, the vibration-reduction effect is good, and the combined multi-phase vibration-reduction device is widely applied to the fields of constructional engineering earthquake resistance and wind resistance.

Owner:TONGJI UNIV

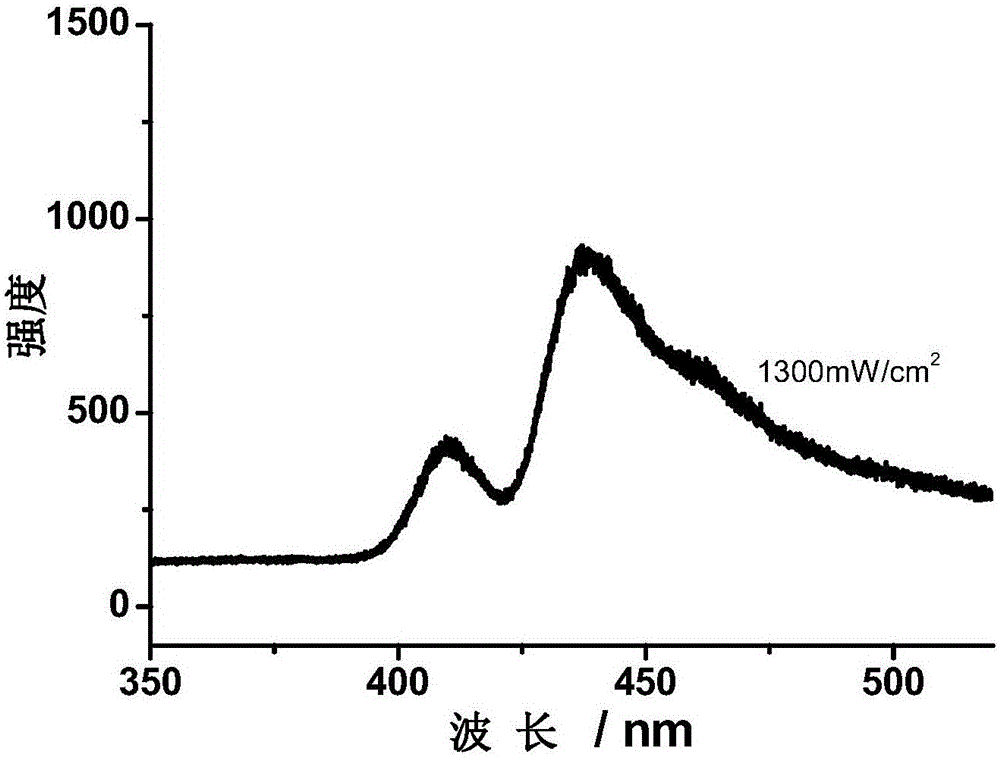

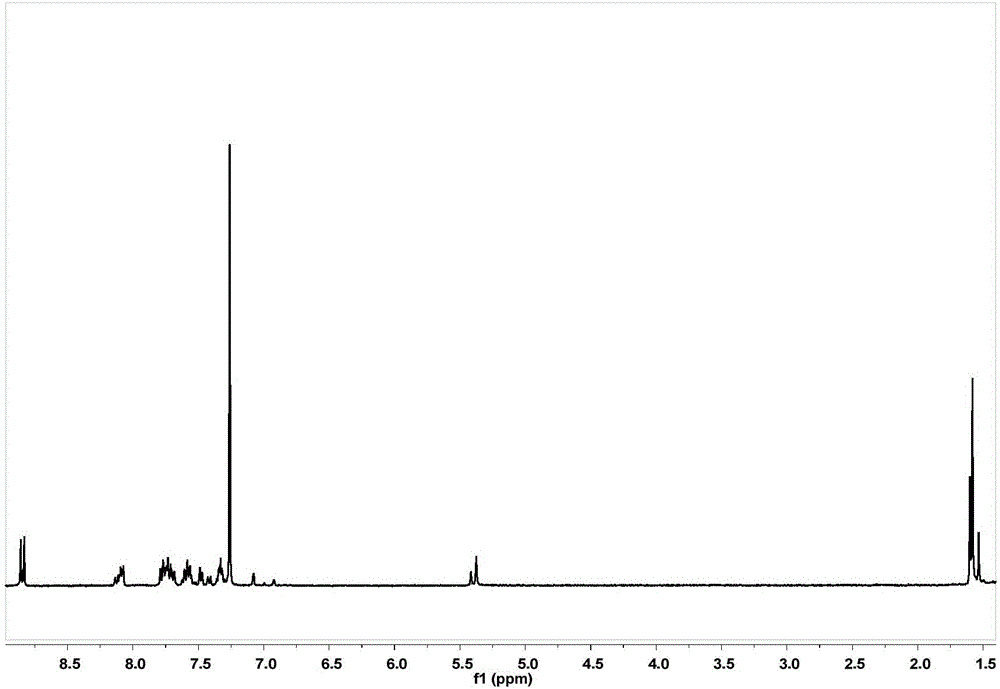

Dendritic polymer structure based triplet-triplet annihilation upconversion luminescent material

ActiveCN105969336ARegular structureGood compatibilityLuminescent compositionsTriplet stateCovalent modification

The invention discloses a dendritic polymer structure based triplet-triplet annihilation upconversion luminescent material, and relates to the technical field of photon upconversion. The upconversion luminescent material comprises a dendrite structure based annihilation agent formed by covalent modification of 9, 10-diphenylanthracene (DPA) on the periphery of an aromatic ether dendrite polymer. The upconversion luminescent material provided by the invention can realize the upconversion luminescence under the condition of low excitation light power density in a solution and solid, and is a novel upconversion luminescent material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

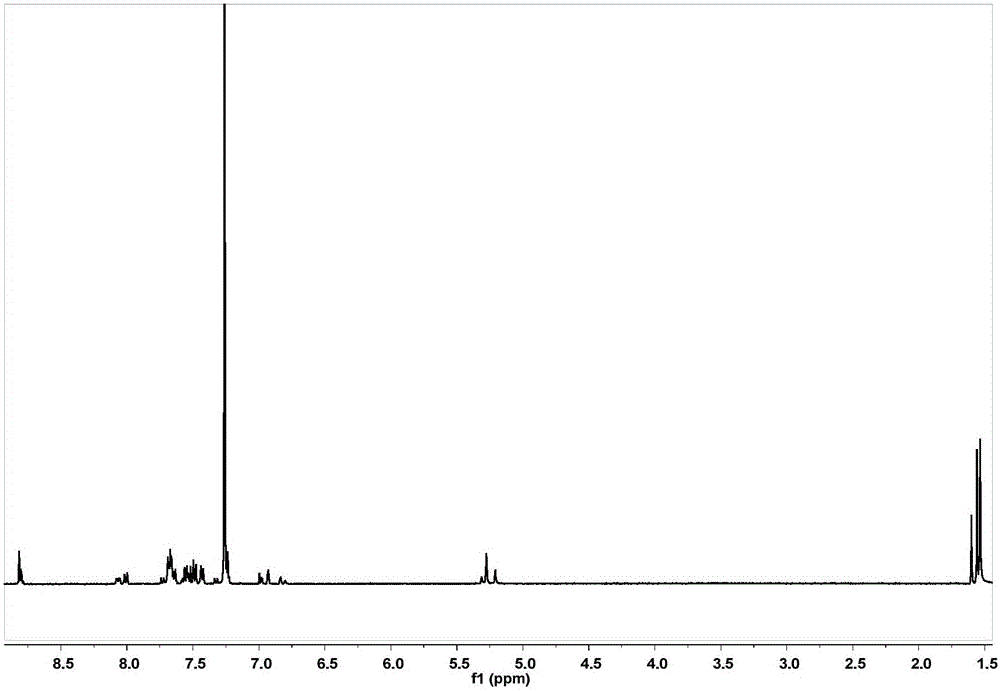

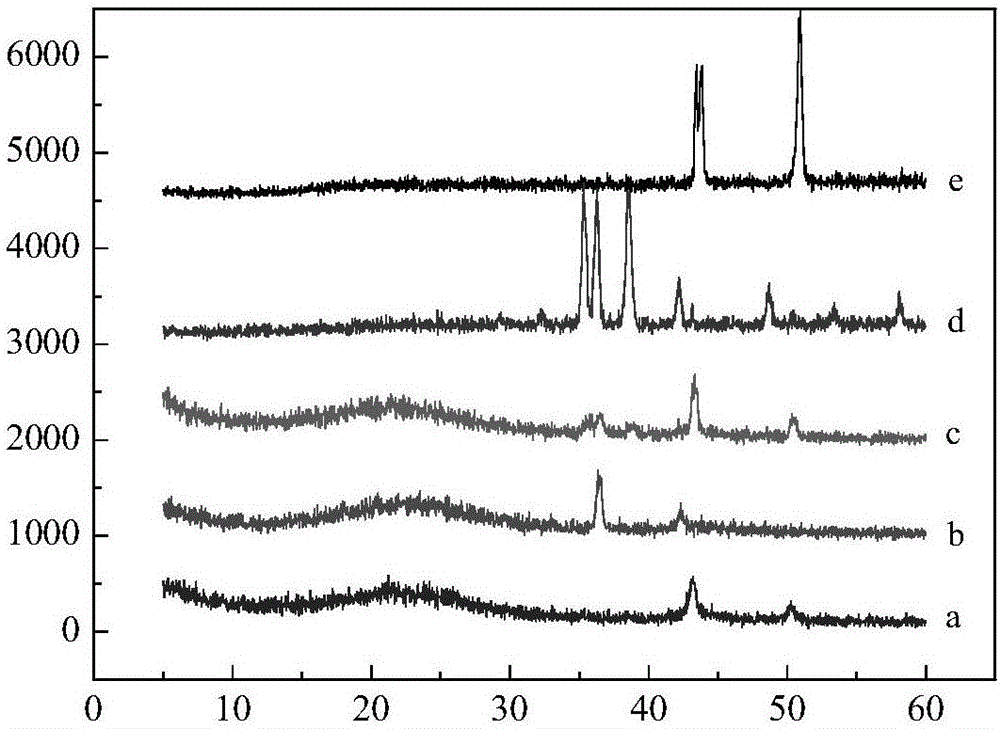

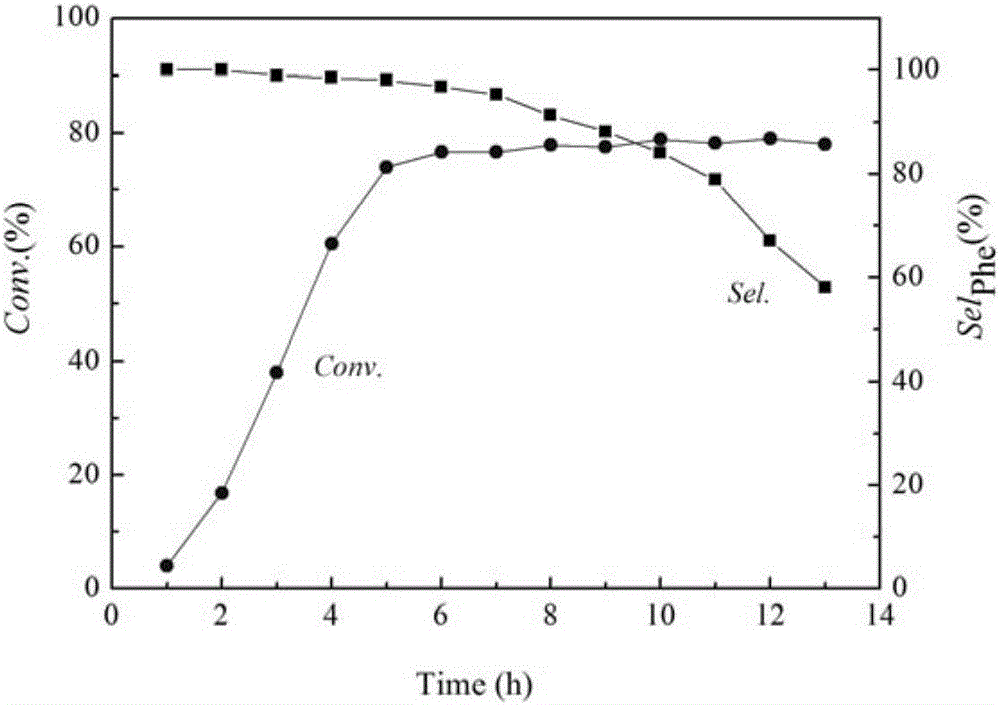

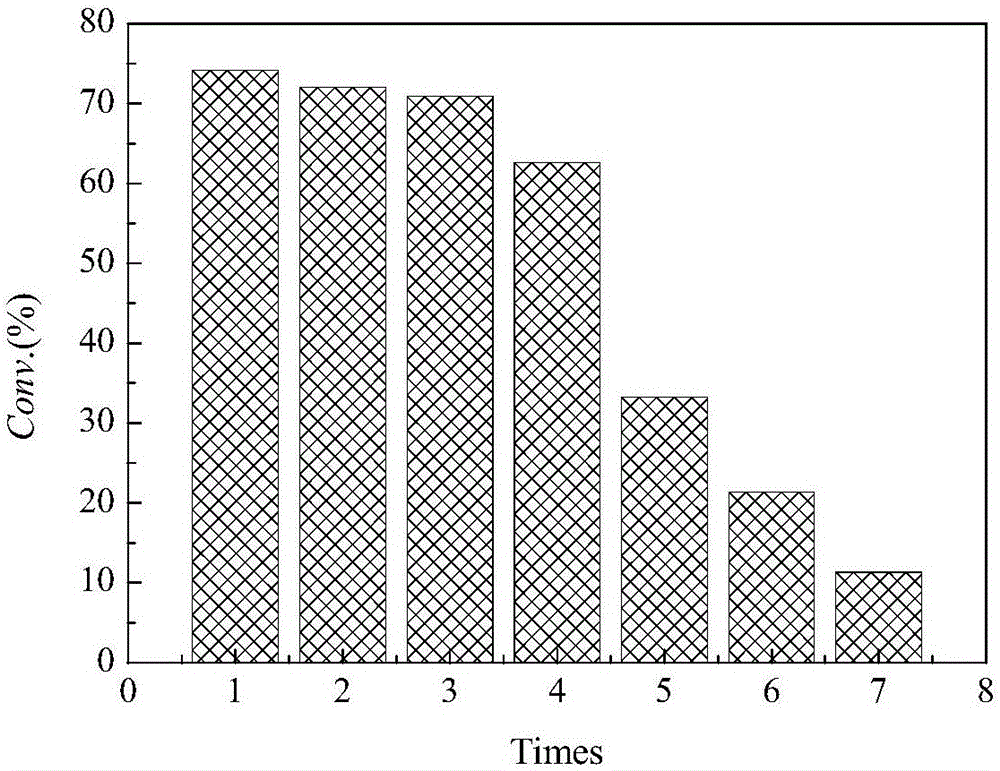

Copper-loaded mesoporous carbon catalyst for benzene hydroxylation and preparation method thereof

InactiveCN106582644ARich attachment sitesEvenly dispersedOrganic chemistryOrganic compound preparationCupric nitratePhenol

The invention discloses a copper-loaded mesoporous carbon catalyst for benzene hydroxylation and a preparation method thereof. The preparation method comprises the following steps: dissolving hydroxypropyl-beta-cyclodextrin in a dilute sulphuric acid water solution; then adding tetraethyl orthosilicate and cupric nitrate; uniformly stirring, and then distilling to obtain a gel substance; placing the gel substance in an open container for aging; then drying; carbonizing under the protection of an inert gas; soaking a carbide in an HF solution; then filtering; sequentially washing with absolute ethyl alcohol and deionized water; and drying to obtain the copper-loaded mesoporous carbon catalyst for benzene hydroxylation. The copper-loaded mesoporous carbon catalyst shows a certain catalytic activity and high selectivity for directly preparing phenol through benzene hydroxylation, and has the benzene conversion ratio of 74% and the phenol selectivity of 98%.

Owner:QINGHAI NORMAL UNIV

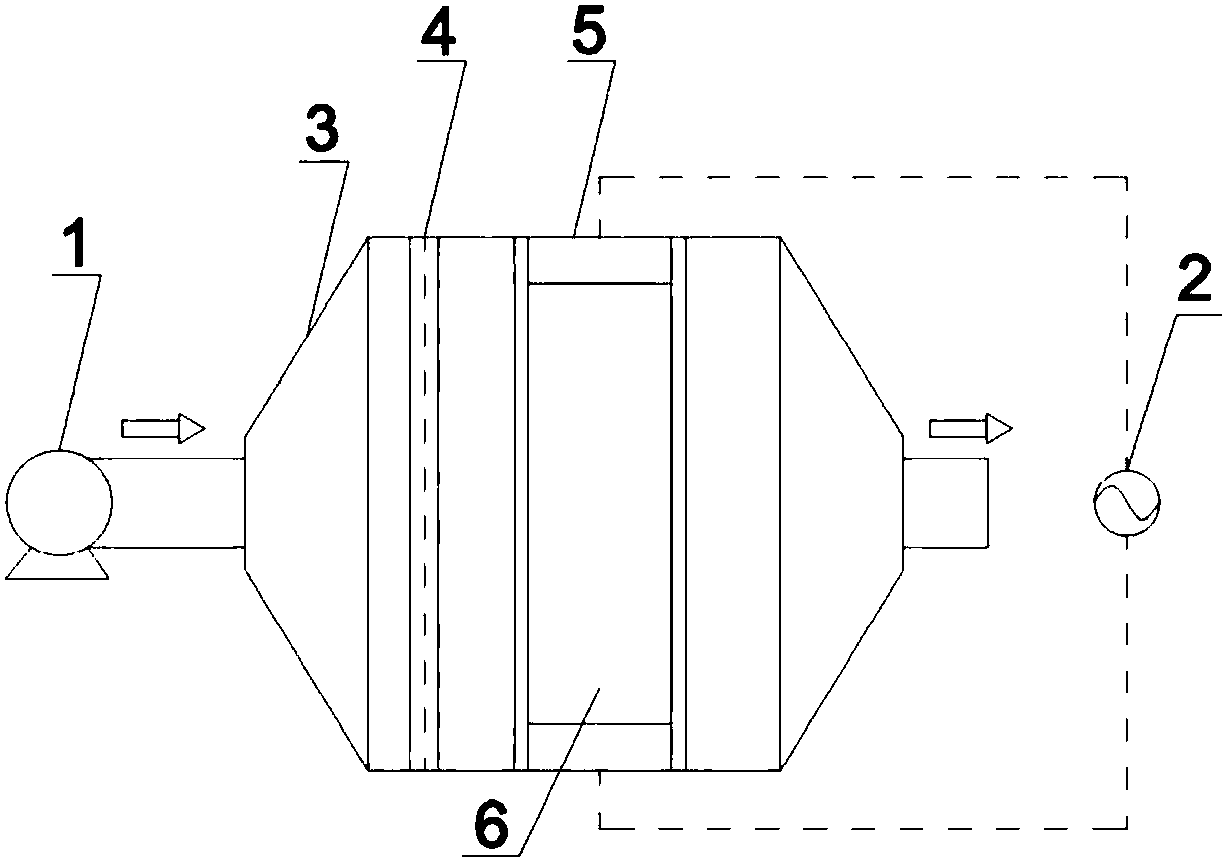

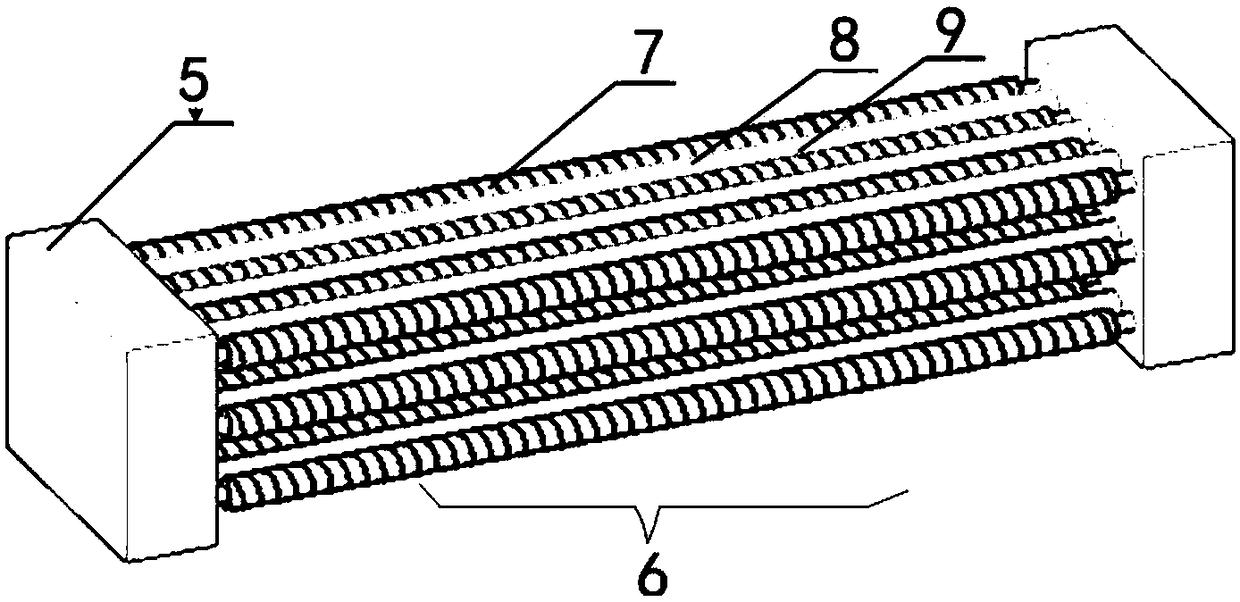

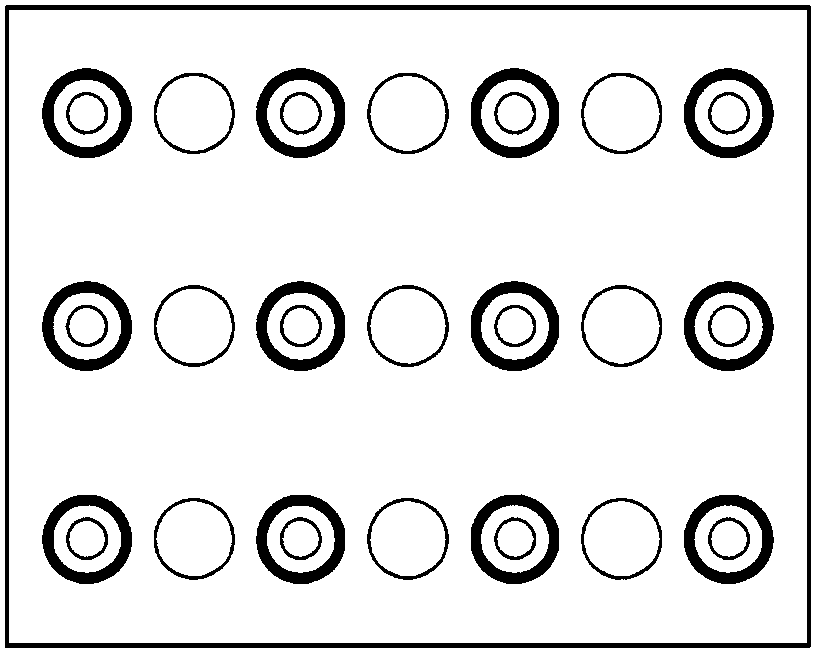

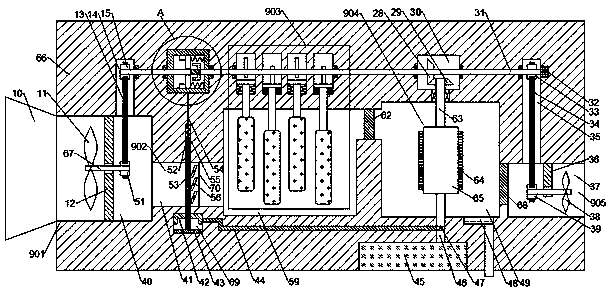

Device and method for processing VOCs through asymmetrical single-medium barrier discharge

PendingCN108554136AReduce cleaning frequencyReduce replacement frequencyGas treatmentDispersed particle separationHigh densityConductive materials

The invention belongs to the technical field of VOCs processing devices, and relates to a device and method for processing VOCs through asymmetrical single-medium barrier discharge. The device comprises a draught fan, a power supply and a box body. A flow equalizing plate, an electrode fixing plate and a discharging unit are arranged in the box body. The discharging unit is of an asymmetrical discharging electrode structure, and comprises a metal electrode and an insulating medium pipe. The metal electrode is prepared from a metal rod with threads and fins. A medium internal electrode preparedfrom a conductive material is arranged in the insulating medium pipe. Gas containing VOCs enters the device from the inlet, is equalized by the flow equalizing plate and then enters a high-density strong plasma discharging area to collide and react with high-activity particles produced by discharging for degradation, coking substances produced in the discharging process are collected by a groovein the metal electrode, and the discharging stability and the high processing effect and efficiency are kept. The device has the advantages of being long in cleaning cycle, high in VOCs processing efficiency and the like, and is suitable for processing VOCs pollution in related industries.

Owner:DALIAN UNIV OF TECH

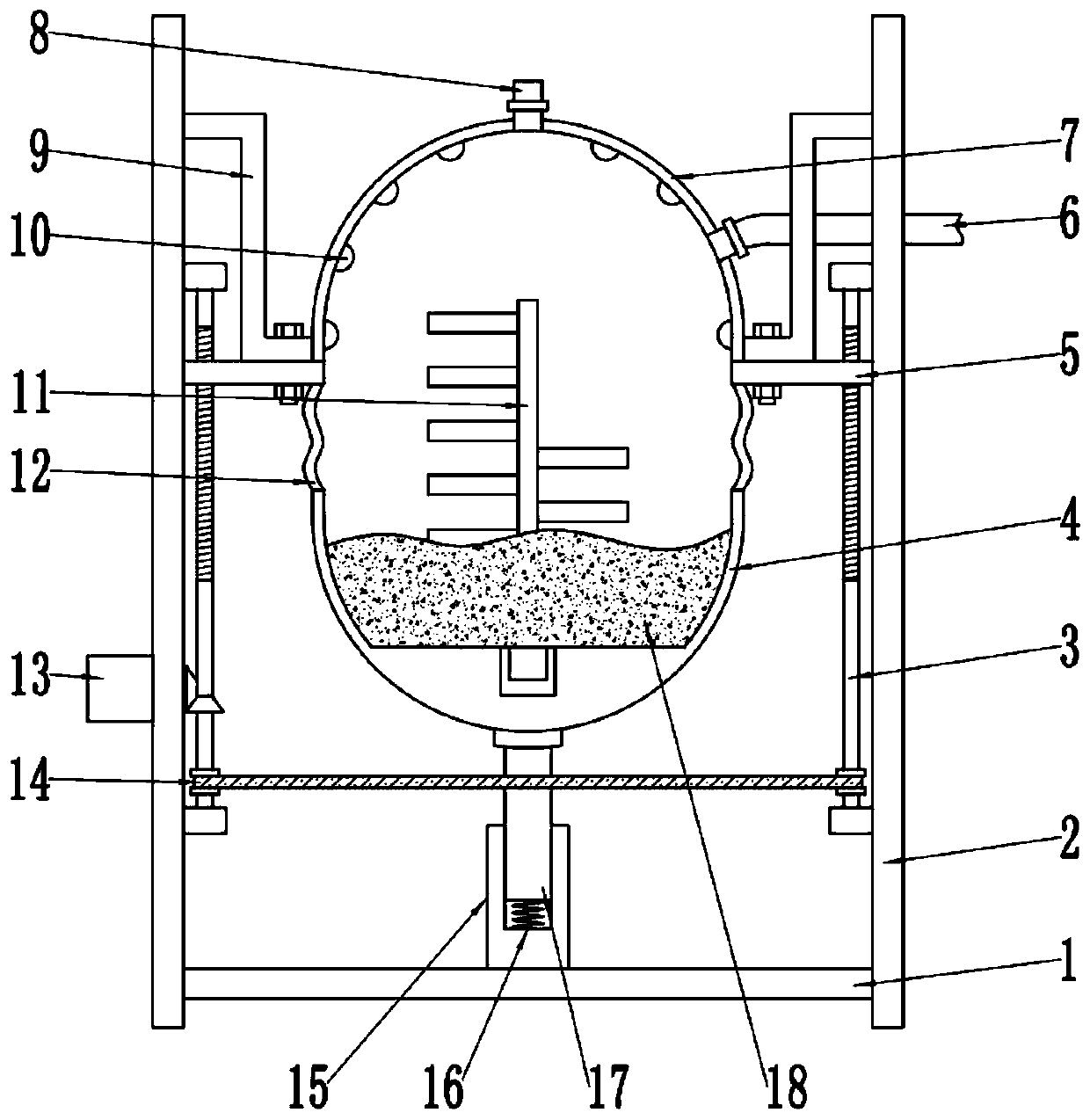

Multi-position adjustable flue gas purification environmental-protection equipment

ActiveCN110207142APurify thoroughlyImprove purification effectLighting and heating apparatusFlue gasEngineering

The invention relates to the technical field of flue gas purification, in particular to multi-position adjustable flue gas purification environmental-protection equipment which comprises a bottom plate, a lower ball body and an upper ball body. Two side plates are symmetrically and fixedly arranged on the left side and the right side of the bottom plate; the left side and the right side of the upper ball body are fixedly connected with the two side plates through two supports; the lower ball body is movably arranged right under the upper ball body; a connecting piece is arranged between the upper ball body and the lower ball body; the lower ball body, the upper ball body and the connecting piece are spliced to form a purification chamber for flue gas treatment; the connecting piece is of an elastic telescopic structure; and multiple active carbon granules are stored in the lower ball body. According to the multi-position adjustable flue gas purification environmental-protection equipment provided by the invention, flue gas and the active carbon granules have a certain initial velocity, a purification effect of the active carbon granules can be improved during the collision of the flue gas and the active carbon granules, the adsorbability of the active carbon granules is fully utilized, the use effect of the active carbon granules is improved, and the flue gas can be purified thoroughly.

Owner:泰州鼎恒环保科技有限公司

Dust settling water bag for blasting demolition of buildings

InactiveCN102527689AWith sticky dust covering effectIncrease in sizeFouling preventionDetonatorAlcohol

The invention discloses a dust settling water bag for blasting demolition of buildings, which consists of slurry, a blasting device and a blasting-proof water bag. Raw materials of the slurry include, by weight, 96-98kg of water and 2-4kg of dust adhesive. Raw materials of the dust adhesive include, by weight, 1.0-2.2 kg of cohesive soil, 0.3-0.5kg of binder, 0.3-0.5kg of sodium alcohol ether sulphate and 0.4-0.8 kg of table salt. The production steps of the dust settling water bag for blasting demolition of buildings include of preparing the dust adhesive by mixing the cohesive soil, the binder, the sodium alcohol ether sulphate and the table salt, preparing the slurry by adding water into the dust adhesive and uniformly stirring the same, producing the blasting device by inserting a detonator into 75-100g waterproof stick explosive, pouring 50-80kg of the slurry into the blasting-proof water bag, arranging the blasting device into the center of the blasting-proof water bag, thereby producing the dust settling water bag for blasting demolition of buildings. The dust settling water bag effectively solves the difficult problem that dust generated in blasting demolition of buildings flies anywhere in air, is low in cost and convenient in product and use and has the dust settling efficiency higher than 95%.

Owner:ANHUI UNIV OF SCI & TECH

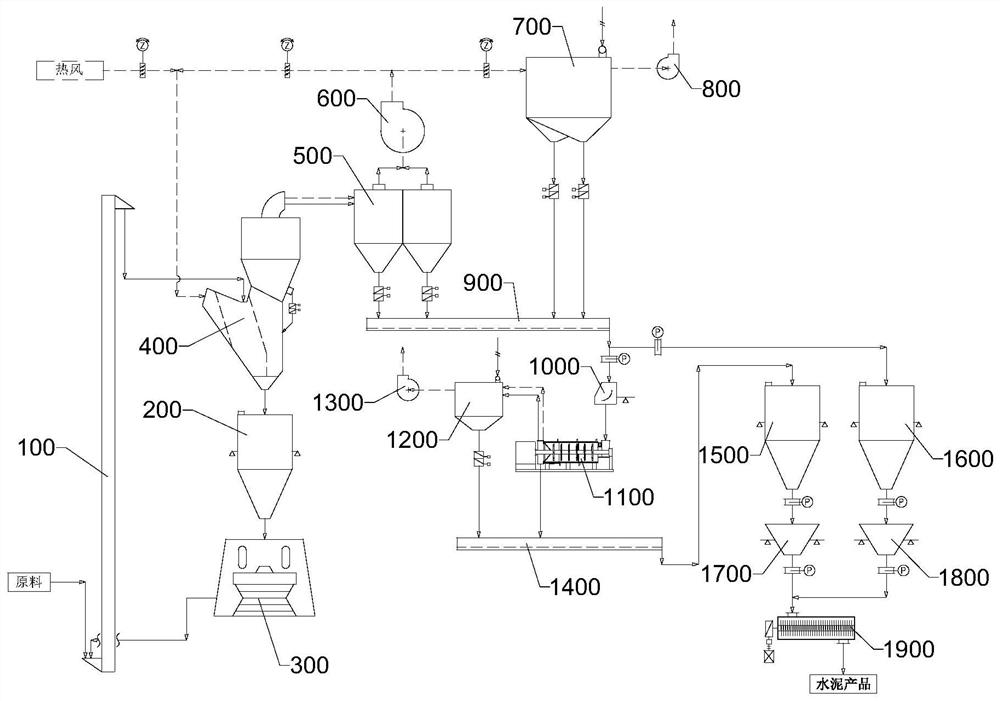

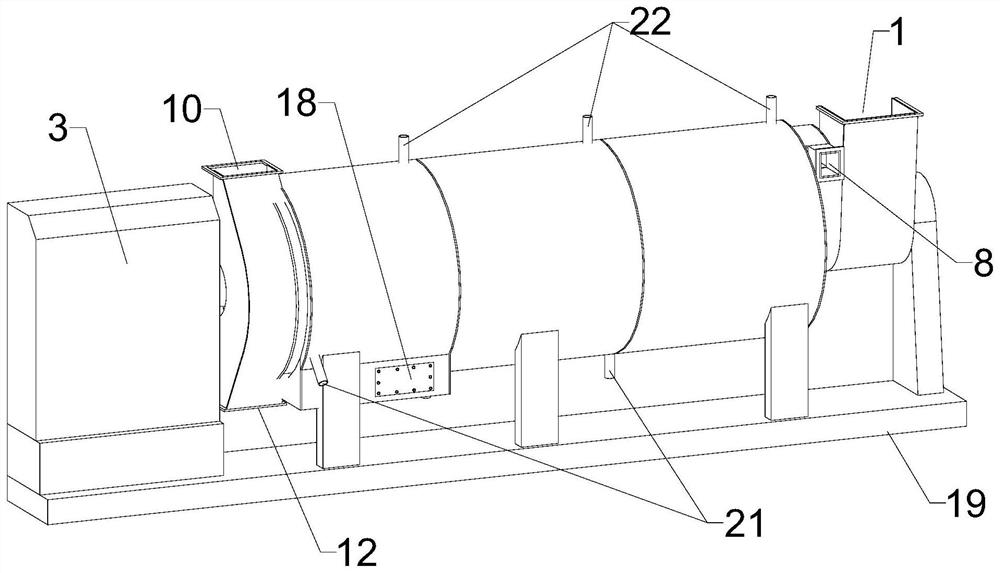

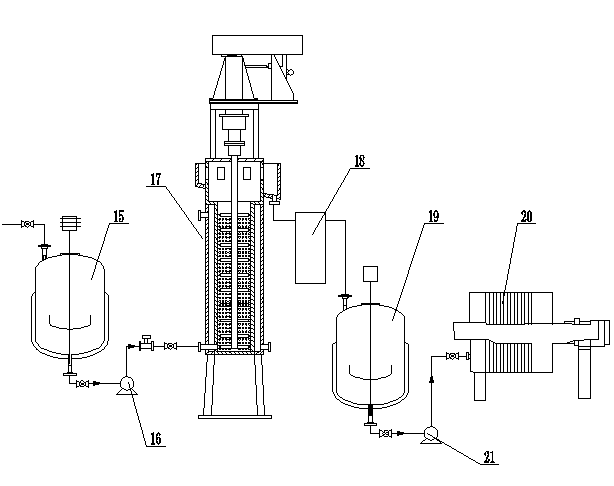

Cement external circulation vertical mill combined high-performance grinding process system

ActiveCN113976277AReduce manufacturing costImprove performanceRotary stirring mixersTransportation and packagingThermodynamicsEngineering

The invention discloses a cement external circulation vertical mill combined high-performance grinding process system, which comprises an external circulation vertical mill, a combined powder concentrator, a cyclone dust collector, a first conveying chute, a dry stirring mill, a second conveying chute, a fine powder blending bin, a coarse powder blending bin and a mixer. The external circulation vertical mill and combined powder concentrator are connected end to end, an upper discharge port of the combined powder concentrator is connected with the cyclone dust collector; a discharge port of the cyclone dust collector is connected with the first conveying chute; an outlet of the first conveying chute is divided into two paths, one path is connected with the dry stirring mill, and the other path is connected with the coarse powder blending bin; a discharge hole of the dry stirring mill is connected with the second conveying chute; an outlet of the second conveying chute is connected with the fine powder blending bin; and outlets of the fine powder blending bin and the coarse powder blending bin are connected with the mixer. The advantages of coarse grinding of the external circulation vertical mill and fine grinding of the stirring mill in the aspects of process and energy consumption are exerted, the fine powder energy consumption of the external circulation vertical mill is reduced, the particle size distribution of the final product can be flexibly adjusted according to the ratio of coarse powder to fine powder, and the cement performance is improved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

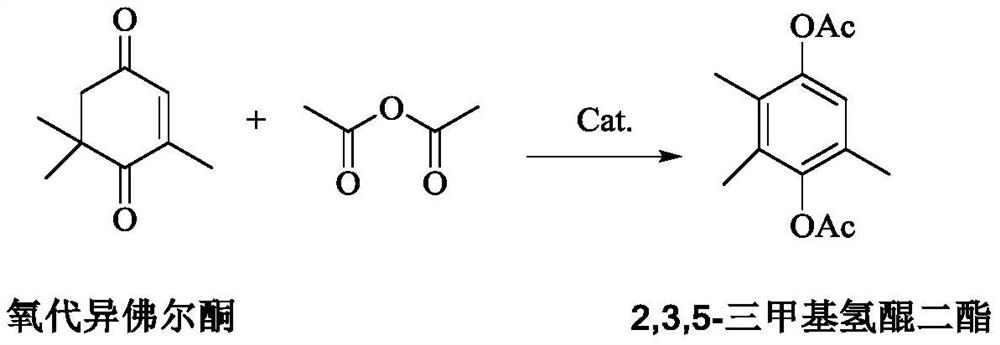

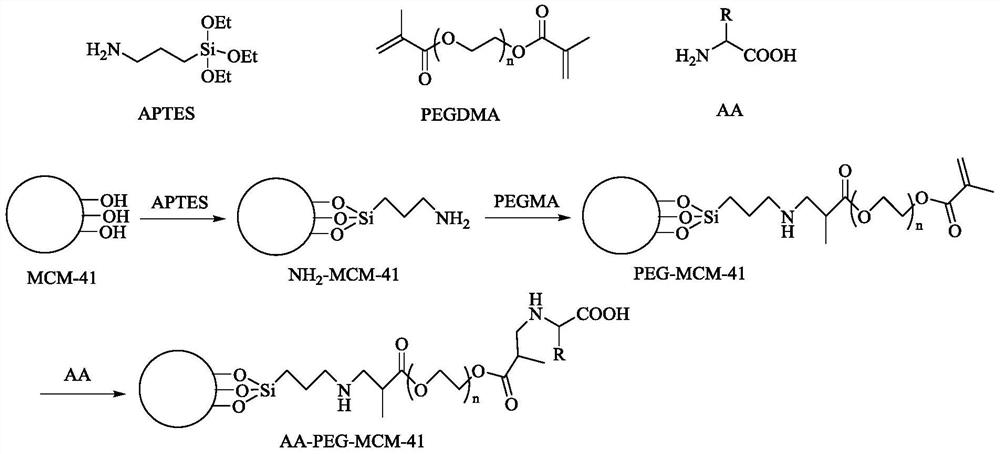

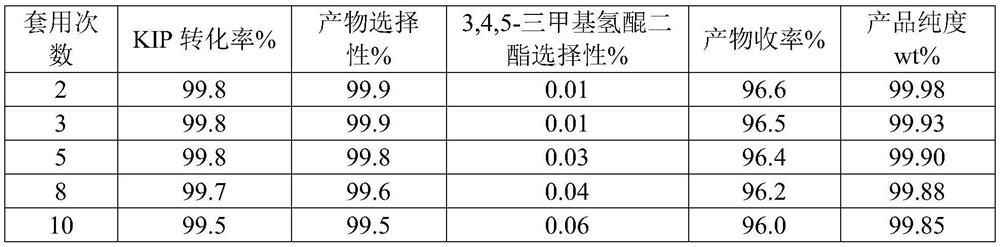

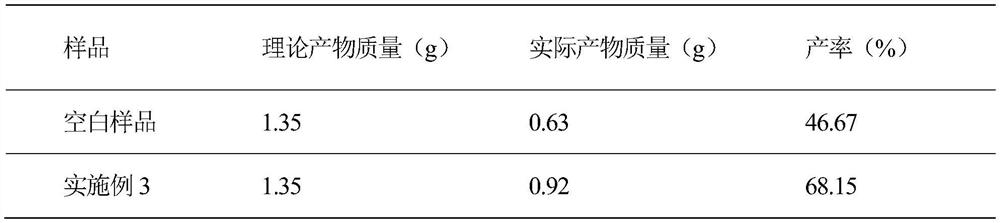

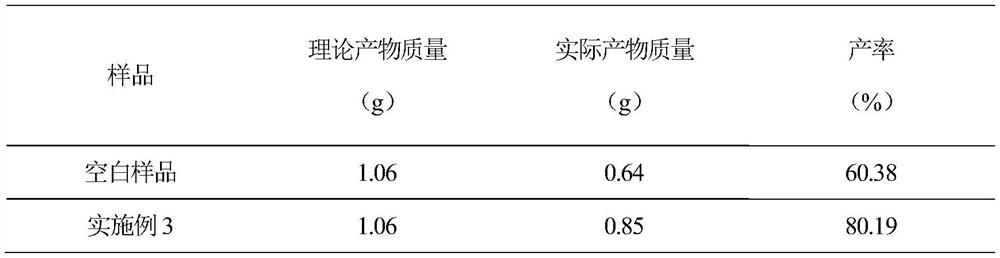

Method for preparing 2,3,5-trimethylhydroquinone diester

ActiveCN111675612AStrong loadIncrease the number of recyclingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveAcetic anhydride

The invention discloses a method for preparing 2,3,5-trimethylhydroquinone diester. The method comprises the following steps: carrying out rearrangement reaction on oxoisophorone and acetic anhydrideunder the catalysis of amino acid and polyethylene glycol modified mesoporous molecular sieve loaded solid acid to prepare the 2,3,5-trimethylhydroquinone diester. The method adopts amino acid and polyethylene glycol modified mesoporous molecular sieve loaded solid acid as the catalyst, has the advantages of high oxoisophorone conversion rate, high product selectivity, small environmental pollution and recyclability of the catalyst, and can overcome the defects of complex operation, serious equipment corrosion and the like in an existing process.

Owner:WANHUA CHEM GRP CO LTD

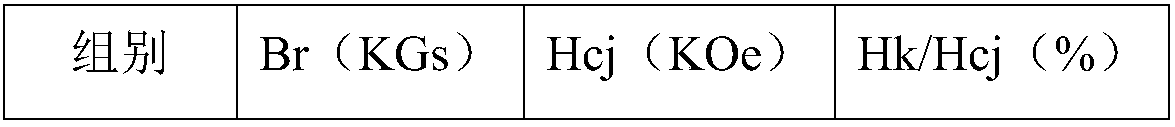

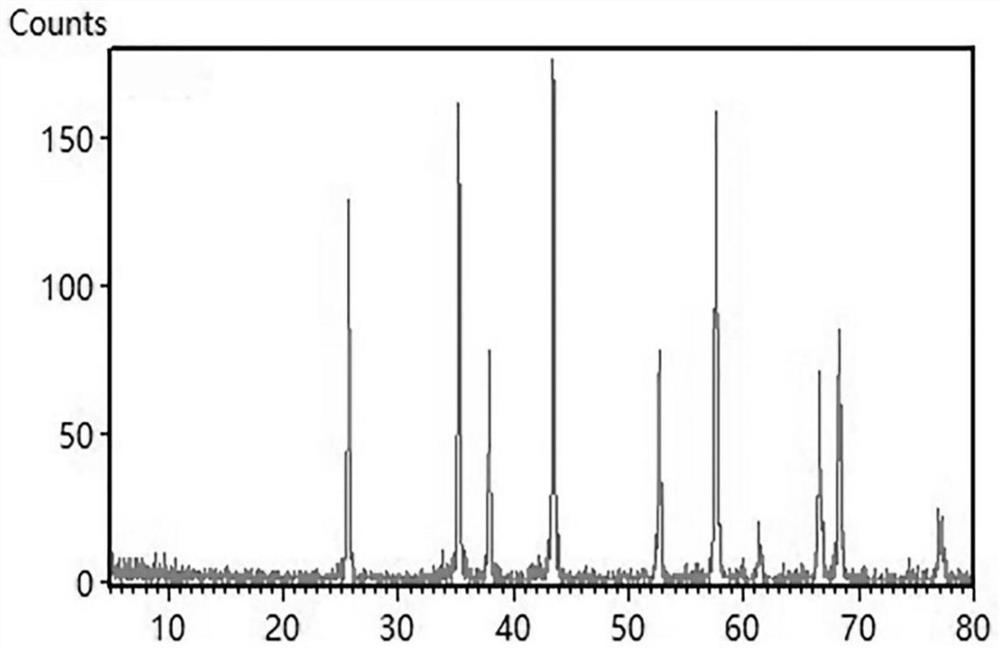

Preparation method of composite magnetic powder

ActiveCN111230127AStability is not affectedHigh saturation magnetizationInductances/transformers/magnets manufactureIngotHigh saturation magnetization

The invention discloses a preparation method of composite magnetic powder. The preparation method comprises the following steps that an alloy ingot is smelted according to the nominal composition MnxBi100-x (mole fraction x = 45, 50, 55), and the alloy ingot is coarsely crushed. According to the preparation method, the prepared MnxBi100-x alloy ingot fragments are put into a mortar to be coarselyground, screening is conducted through a 100-mesh grid sieve after grinding is completed, and the obtained MnxBi100-x alloy powder is subjected to low-energy ball milling compositing; a proper amountof the prepared MnxBi100-x alloy powder is put into a ball milling tank, meanwhile, alpha-Fe micron powder which is 5% of the mass of the MnxBi100-x alloy powder is put, then a proper amount of ethanol and non-magnetic steel balls with proper sizes are added, the ethanol is taken as a ball milling medium, the ratio of the mass of the steel balls to the mass of the MnxBi100-x alloy powder is 10:1,and finally the powder is put into a planetary ball mill; and after the powder is put into the planetary ball mill, the ball milling time is set to be 1-6 hours, the ball milling rotating speed is 256revolutions per minute, and the clockwise / anticlockwise rotating alternating time is 6 minutes, so that the high-saturation magnetization alpha-Fe / MnBi composite magnetic powder is obtained. The process is simple and easy to operate, and the production cost of the high-performance permanent magnet is reduced.

Owner:CHINA JILIANG UNIV

Continuous grinding method for brominated flame retardant and grinding machine for realizing method

InactiveCN103071568AReduce the effect of colorAvoid corrosionGrain treatmentsPulp and paper industryReducing agent

The invention discloses a continuous grinding method for a brominated flame retardant, which comprises the following steps: (1) after uniformly mixing the brominated flame retardant, a reducing agent, a pH regulator and process water, obtaining mixed feed liquid; (2) continuously feeding the mixed feed liquid into a grinding machine for grinding through the bottom of the grinding machine, controlling a feeding speed, and causing the later mixed feed liquid entering into the grinding machine to drive the earlier mixed feed liquid entering into the grinding machine to move upward till flowing out of an overflow port at the top of the grinding machine, wherein the liquid continuously flowing from the overflow port is overflow feed liquid; and (3) after removing ferromagnetic materials from the overflow feed liquid through an iron-removing machine, performing solid-liquid separation, washing the obtained solid material with water and drying, and then obtaining the powdered brominated flame retardant with the grain size in a preset scope. The obtained product has the advantages of good color and luster, uniform grain size of the product, small size distribution scope and stable quality.

Owner:SHANDONG TIANYI CHEM

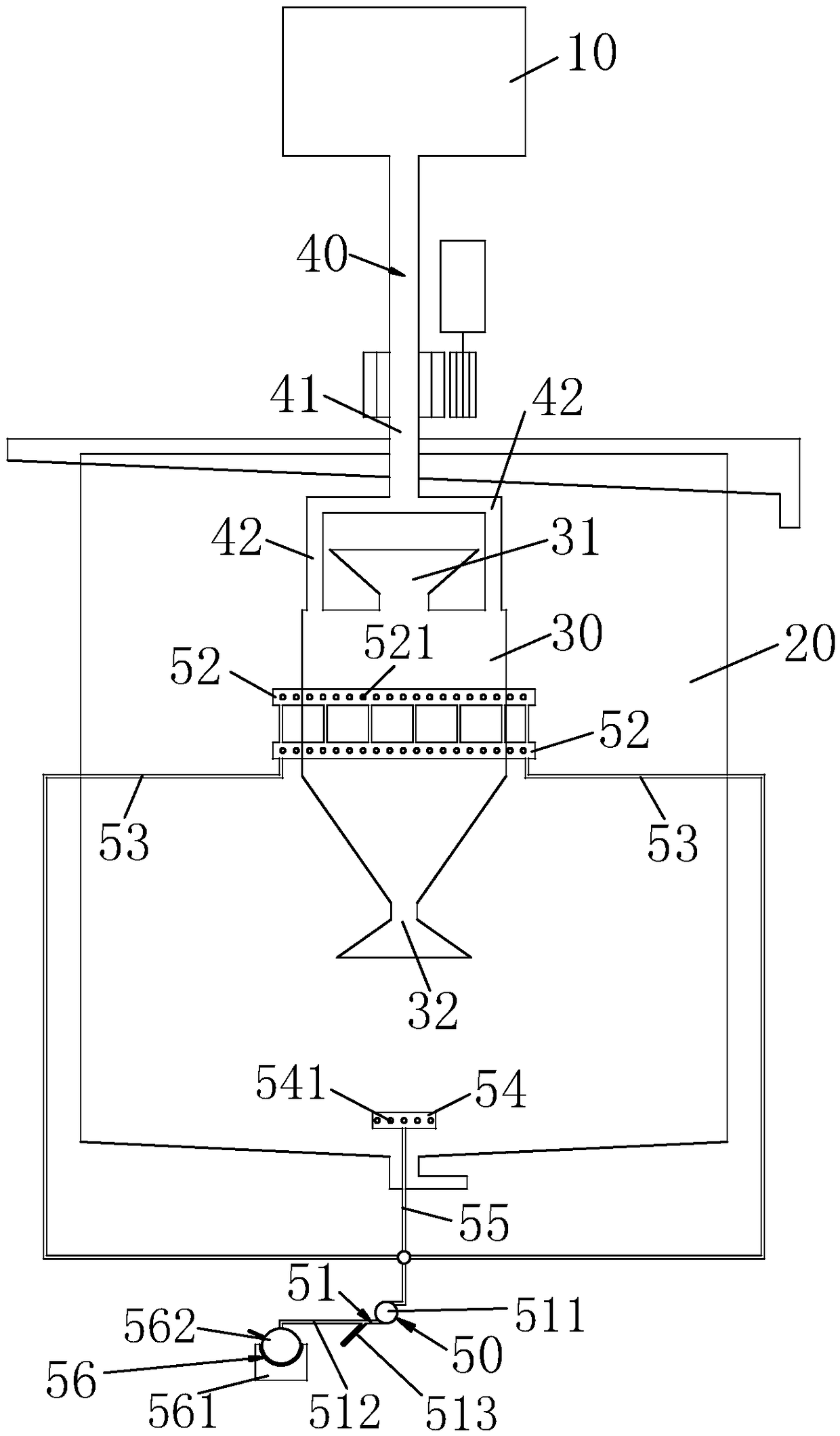

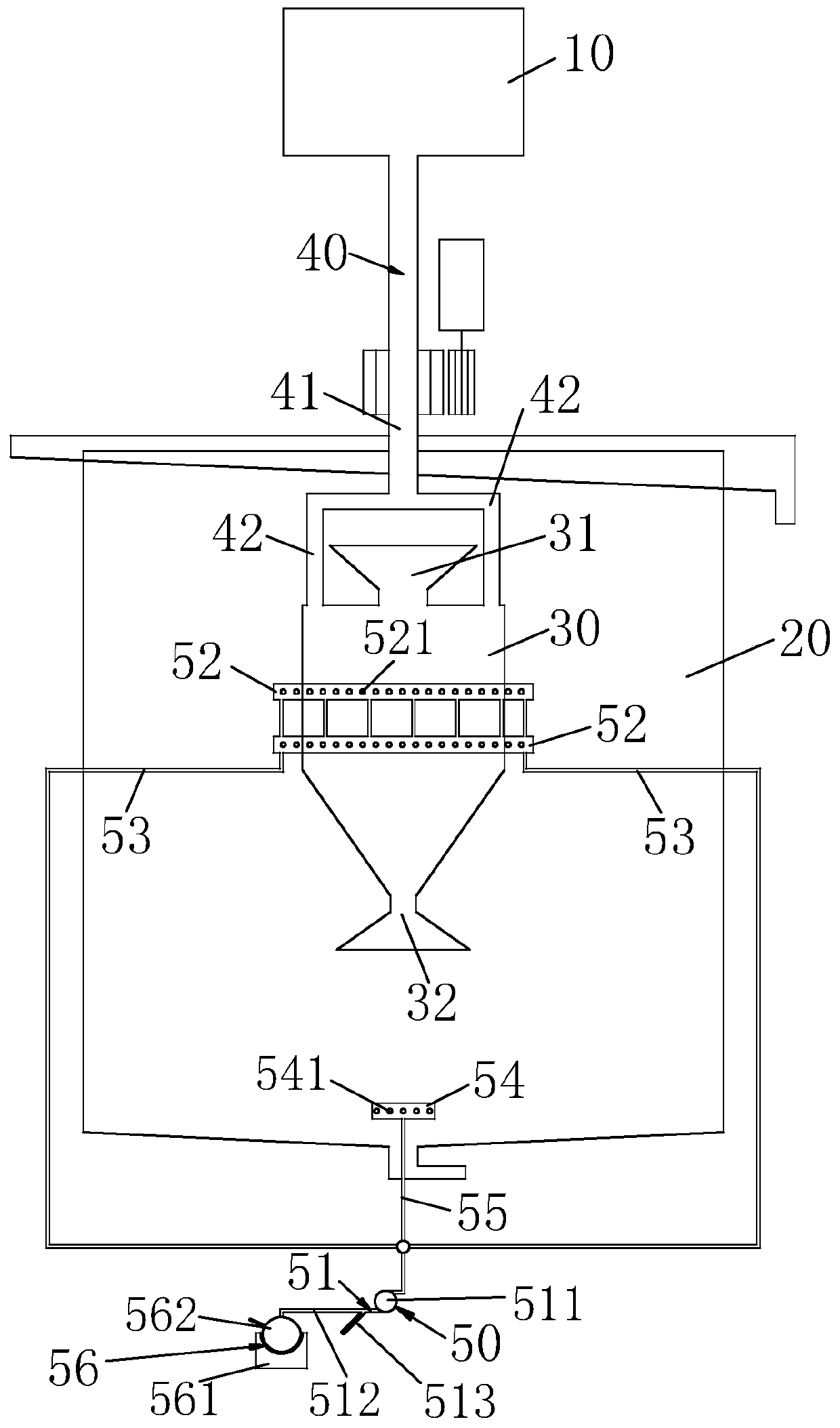

Mineral flotation system

ActiveCN109046793AReduce the difficulty of collisionIncrease the probability of collisionFlotationMaceralEngineering

The invention belongs to the technical field of mineral flotation, and particularly relates to a mineral flotation system. The device comprises a rotatable ore pulp barrel, a flotation groove communicated with the ore pulp barrel, a rotating barrel capable of rotating is arranged in the flotation groove in a sleeved mode, the rotating barrel is communicated with the ore pulp barrel through a pipeline, one end, connected with the rotating barrel, of the pipeline is located at the upper end of the barrel wall of the rotating barrel or close to the barrel wall of the rotating barrel, the rotatingbarrel and the ore pulp barrel rotate synchronously, the lower part of the rotating barrel is of a cone structure and is in a reduced diameter shape from top to bottom, an upper overflow port and a lower underflow port are formed in the upper end and the lower end of the rotating barrel respectively, the flotation groove is communicated with the ore pulp barrel through the rotating barrel and thepipeline; the system further comprises a bubble generation device, and the bubble generation device is communicated with the flotation groove. According to the mineral flotation system, the effectivecollision rate of the bubbles can be improved when the mineral flotation work is carried out, so that the collision probability between the bubbles and the mineral particles to be recovered is increased, and then the flotation efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

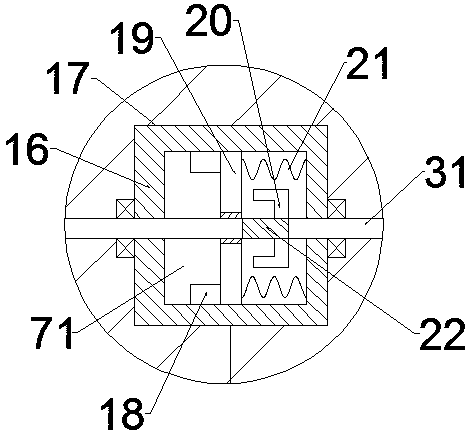

Double-tuned inertance system

ActiveCN109138567AIncreased bandwidthImprove energy absorptionProtective buildings/sheltersShock proofingFrequency bandEnergy infrastructure

The invention relates to a double-tuned inertance system in the civil engineering and energy infrastructure field. The system comprises a first-grade collision friction type tuning mass unit, a second-grade tuning mass unit, a liquid inertance damping unit and an installation unit. In the invention, a double damping tuning mechanism is established to adjust a system frequency and carry out dampingcontrol, and the frequency bandwidth of the effective damping control of the damping system is increased. The two grade tuning mass units and the liquid inertance unit are used to store energy. The nonlinear collision of a collision friction block and a liquid inertance damping dissipation structure are used to vibrate energy. Based on the quality synergy effect of the liquid inertance unit, additional mass required for the first-grade collision friction type tuning mass unit is greatly reduced, and a light-weight tuning damping device is provided. In addition, the inertance unit effectivelycontrols the deformation of the entire first-grade collision friction type tuning mass unit, the installation space of the device is saved, the efficiency of the internal damping energy consumption of collision friction block damping is improved, and the system has a wide application prospect.

Owner:TONGJI UNIV

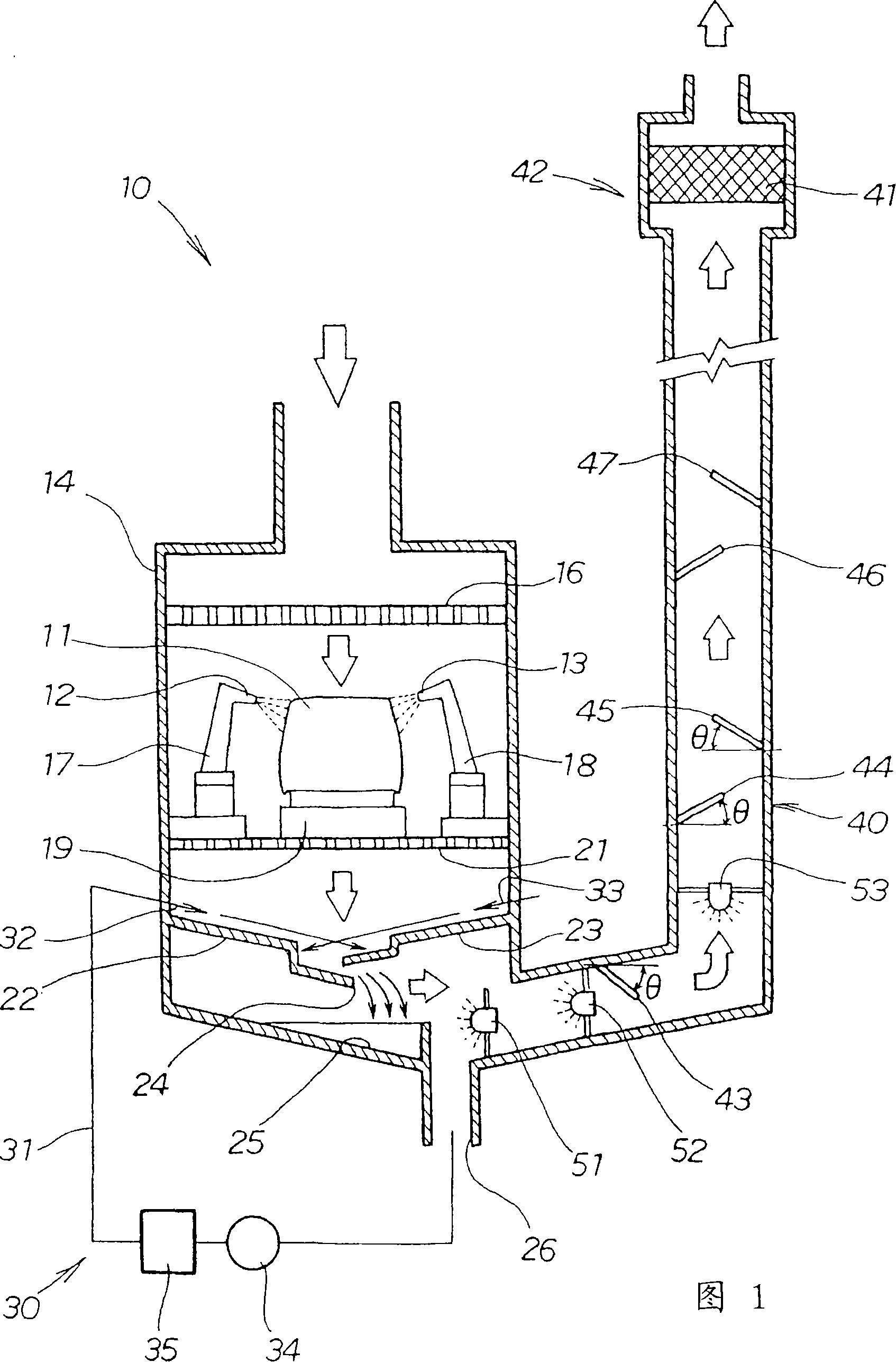

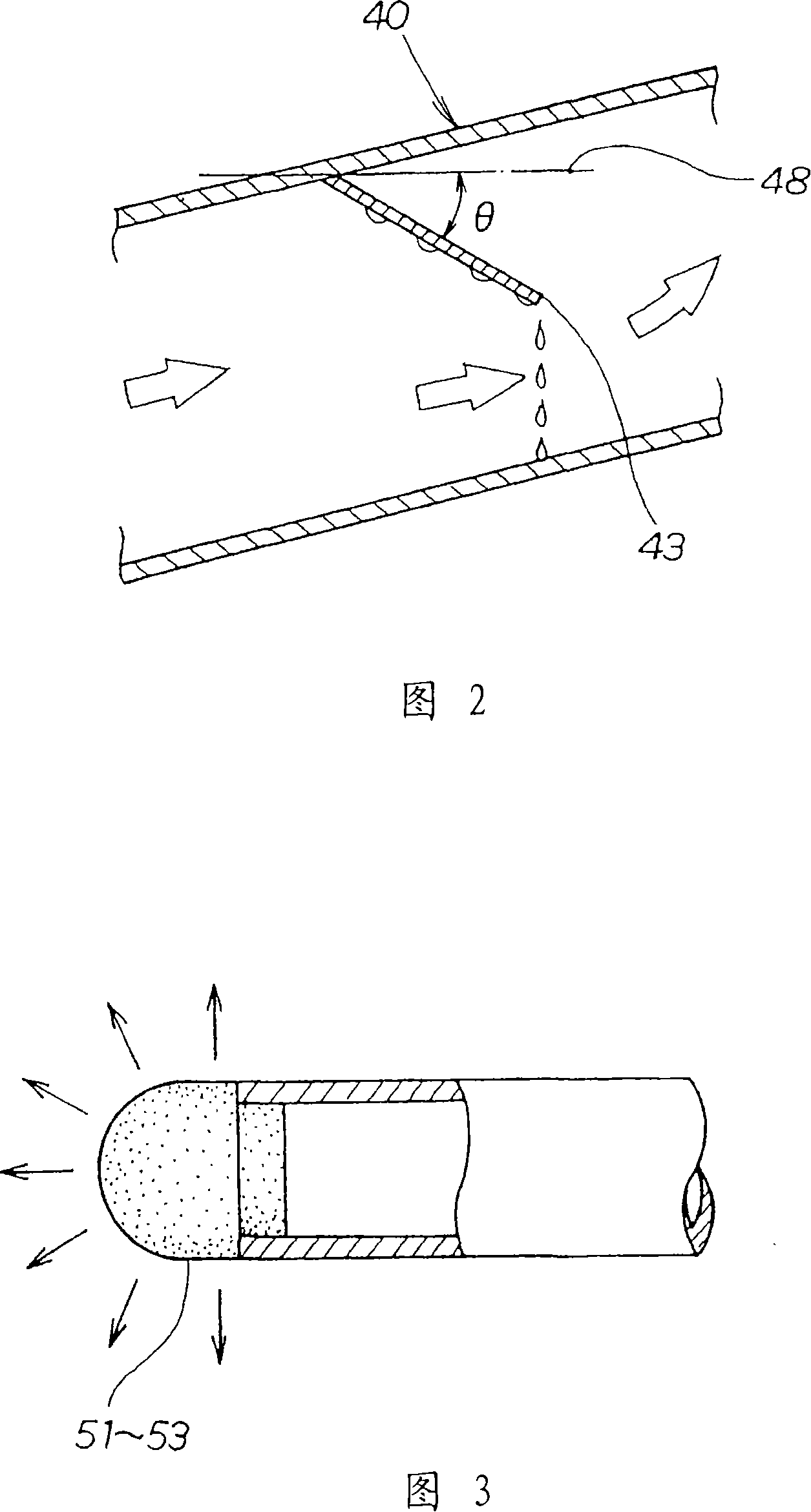

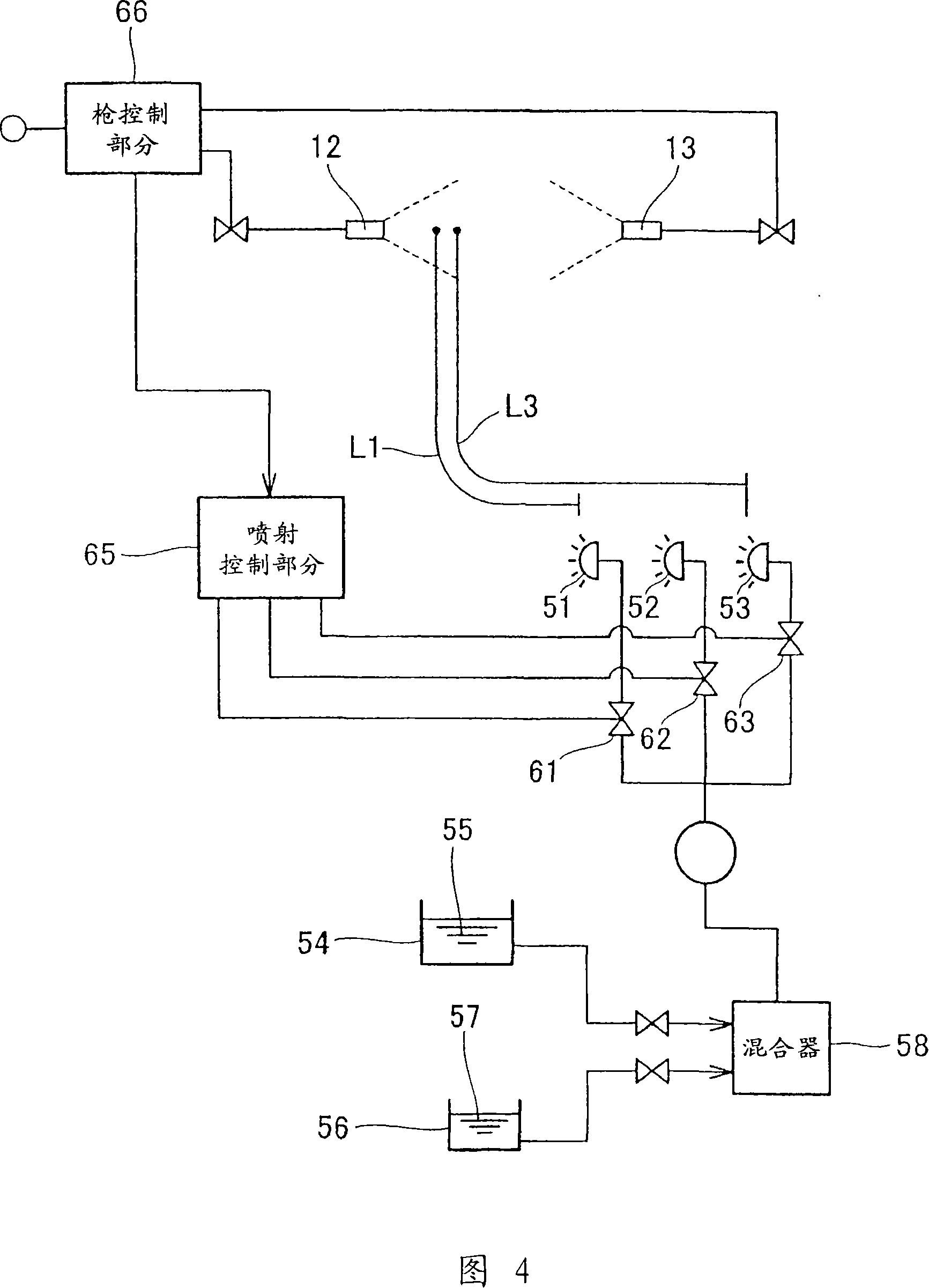

Painting equipment with air purifying means

InactiveCN101142031AJet stopLow costLiquid surface applicatorsGas treatmentAir cleaningEnvironmental engineering

Water is sprayed from a water nozzle (32, 33) of a water-washing device to wash polluted air in a painting booth (14), and then, a liquid polymer substance (57) having a character to adsorb a VOC is spayed from an adsorbent spraying nozzle (51 - 53) to remove the VOC from the air. Baffle (43 - 47) is provided in a discharge duct to prevent the VOC-contained mixed liquid mist from moving with the air. Namely, by causing the air to hit the baffle, the VOC-contained mist turns into drops. Through the water-washing by the water-washing device, VOC adsorption by the mixed liquid and mixed liquid mist removal by the baffle, the polluted air can be sufficiently purified.

Owner:HONDA MOTOR CO LTD

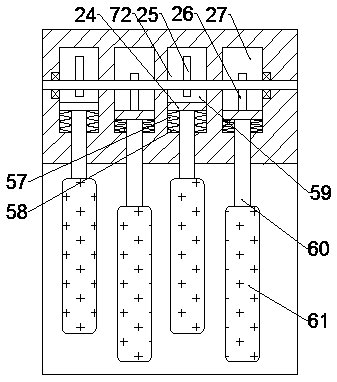

Vibration filtration multistage dust removal equipment for building dust removal

ActiveCN111437685AEfficient and effective preliminary dust removalEasy to removeCombination devicesGas treatmentDust controlStructural engineering

The invention discloses vibration filtration multistage dust removal equipment for building dust removal. The vibration filtration multistage dust removal equipment comprises a machine body; a power rotating box rotating block for power transmission is arranged on the upper side of the machine body; a capturing cover for collecting building dust is arranged on the left side wall body of the machine body; an air inlet fan cavity used for sucking dust in is formed in the portion, on the right side of the capturing cover, of the machine body, and fixing rods are fixedly arranged on the upper sidewall body and the lower side wall body of the air inlet fan cavity. An inertial dust removal device is arranged, and efficient and effective preliminary dust removal can be carried out through a simple mechanical mechanism; by arranging a vibration dust removal device, the dust can be in vibration contact with a filtering device through mechanical vibration and effectively collides with the filtering device, so that the dust can be removed by the filtering device more efficiently; by arranging a water mist dust removal device, water mist sprayed out in a rotating mode can make full contact with the dust in air, and therefore the effective dust removal effect is achieved.

Owner:聊城九洲建设集团有限公司

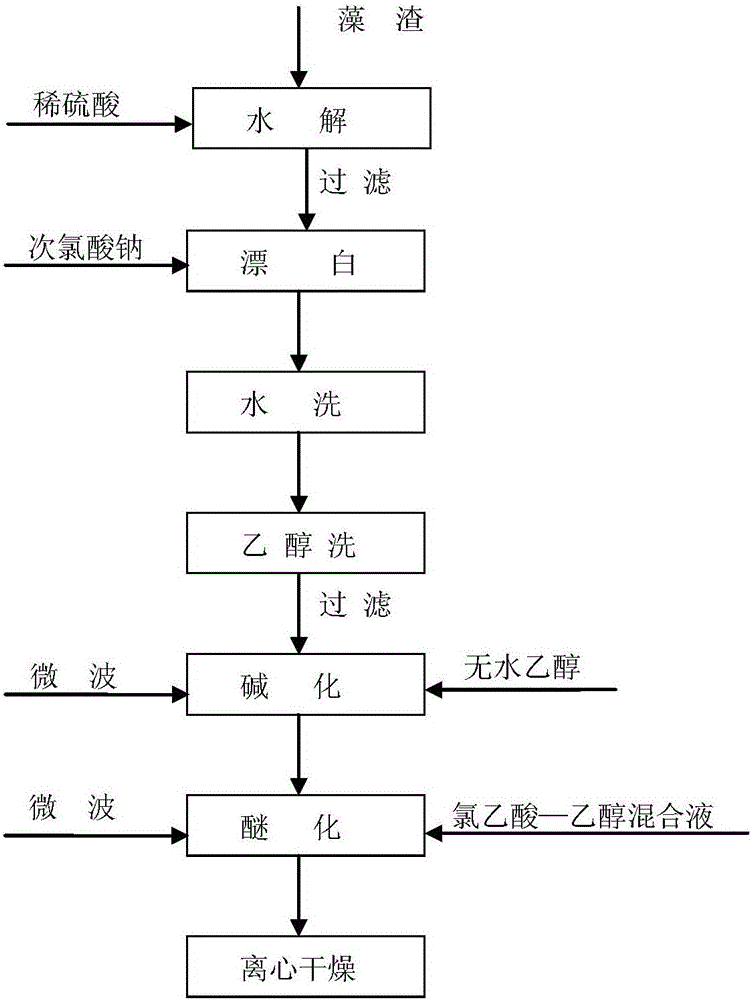

Method for preparing sodium carboxymethyl cellulose by utilizing degummed seaweed residues

The invention discloses a method for preparing sodium carboxymethyl cellulose by utilizing degummed seaweed residues. The method comprises the following steps: firstly adding a certain amount of degummed seaweed residues to a dilute sulfuric acid solution, heating the materials, carrying out hydrolysis and filtration under the condition of boiling and collecting the seaweed residues; obtaining white granular seaweed residues after the steps of bleaching, washing and ethanol washing in sequence; fully mixing the white granular seaweed residues with absolute ethyl alcohol, adding a sodium hydroxide solution to the mixture to obtain mixed liquor I, fully stirring the mixed liquor I and then sending the mixed liquor I into a microwave generator, then pumping the mixed liquor I into an alkalization tank and stirring the mixed liquor I to react; adding chloroacetic acid-ethanol mixed liquor to the alkalized mixed liquor I to obtain mixed liquor II, sending the mixed liquor II into the microwave generator to be treated, then pumping the mixed liquor II into an etherification tank and stirring the mixed liquor II to react; adding glacial acetic acid to regulate the pH value of the mixed liquor II to be neutral after etherification is completed and obtaining a white or faint yellow fibrous crude product after separation with a centrifuge. The method has the advantages that the degree of substitution of the final product can be increased through two-time microwave treatment and microwave treatment is easy to control.

Owner:青岛聚大洋藻业集团有限公司

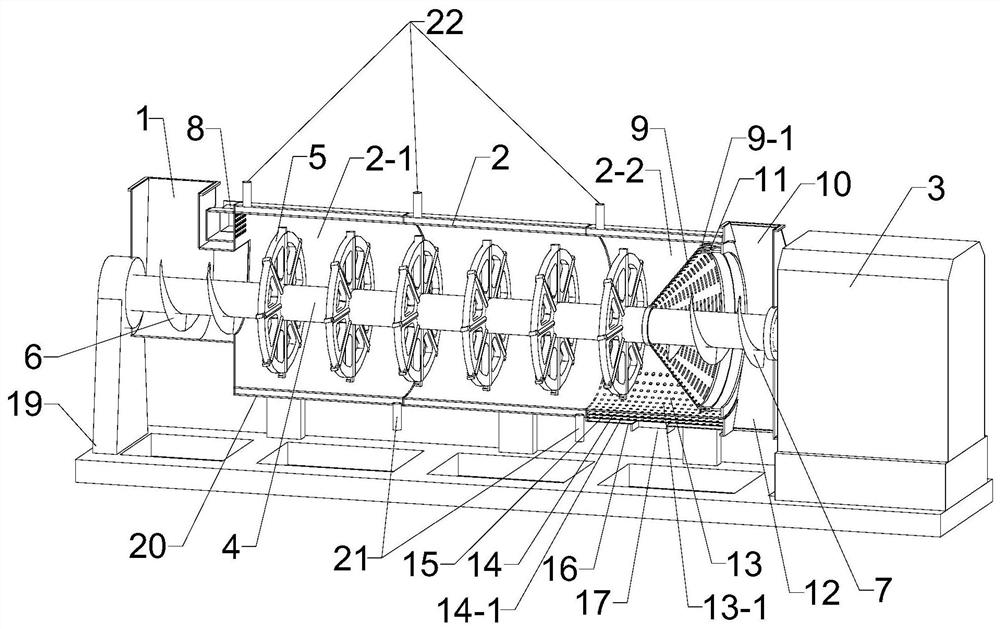

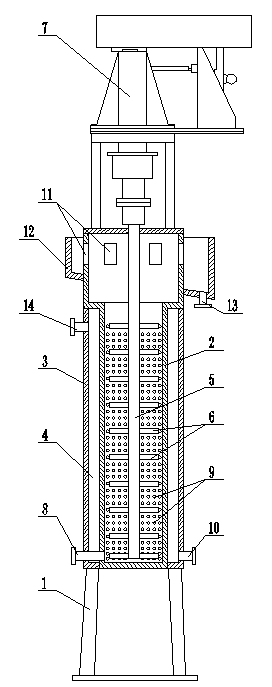

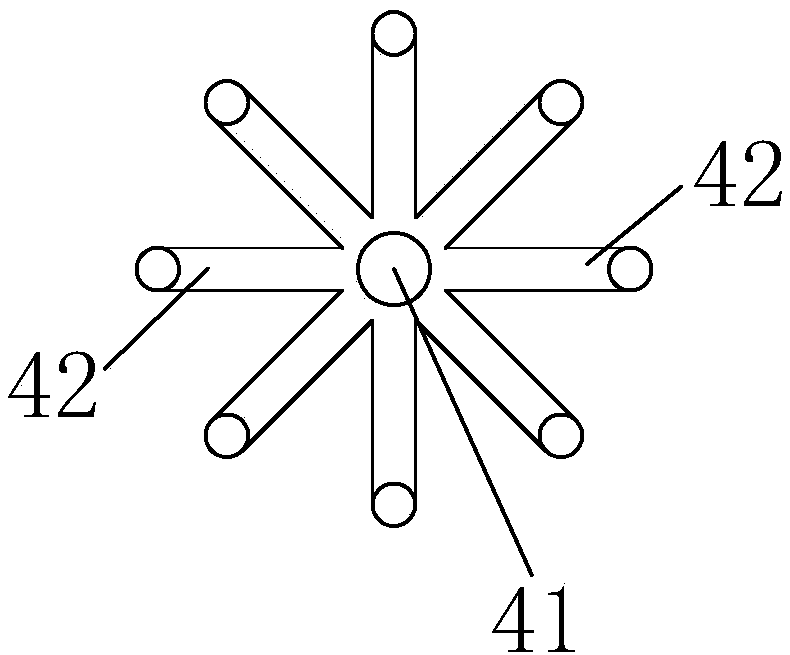

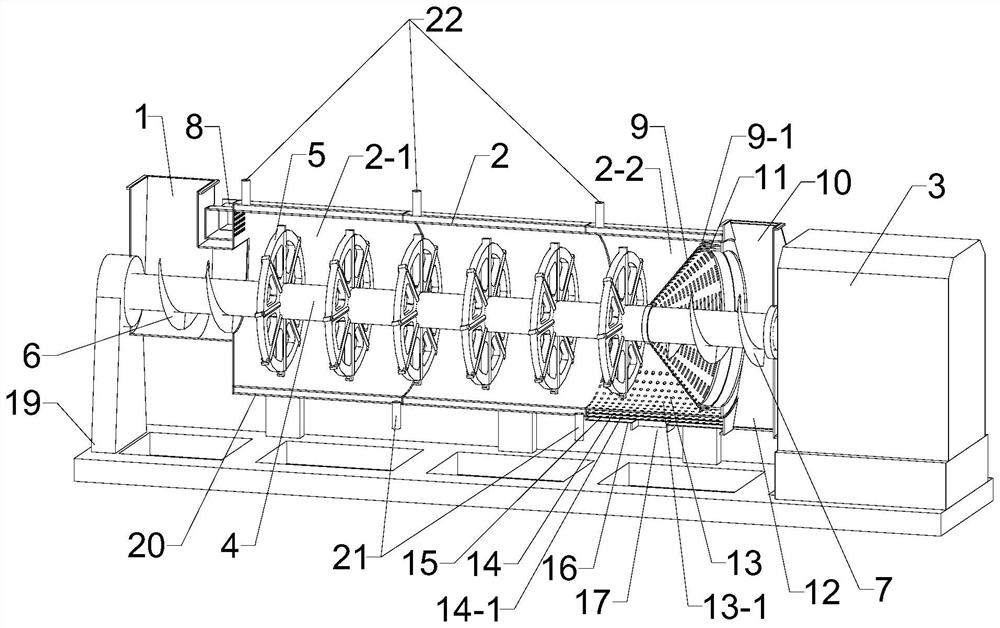

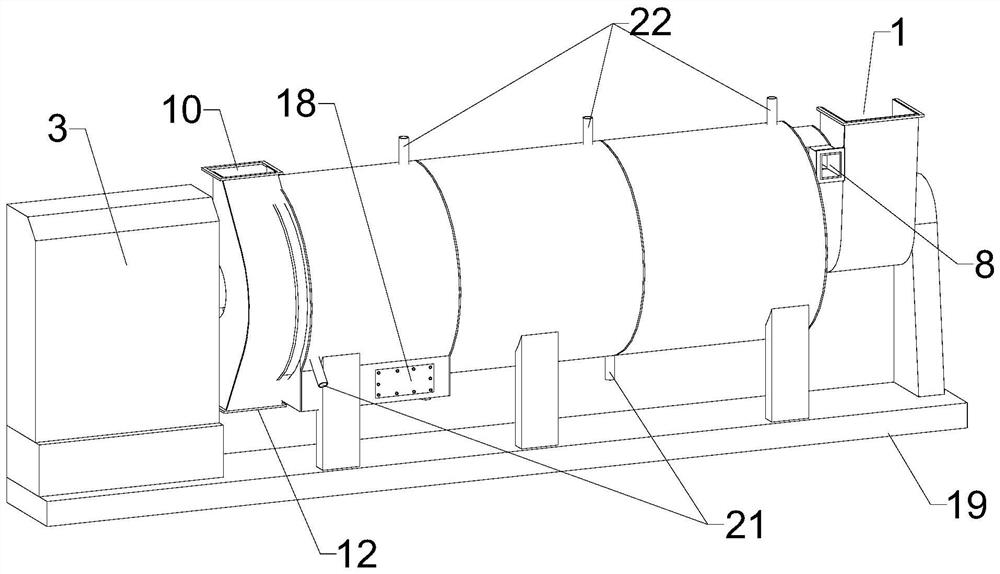

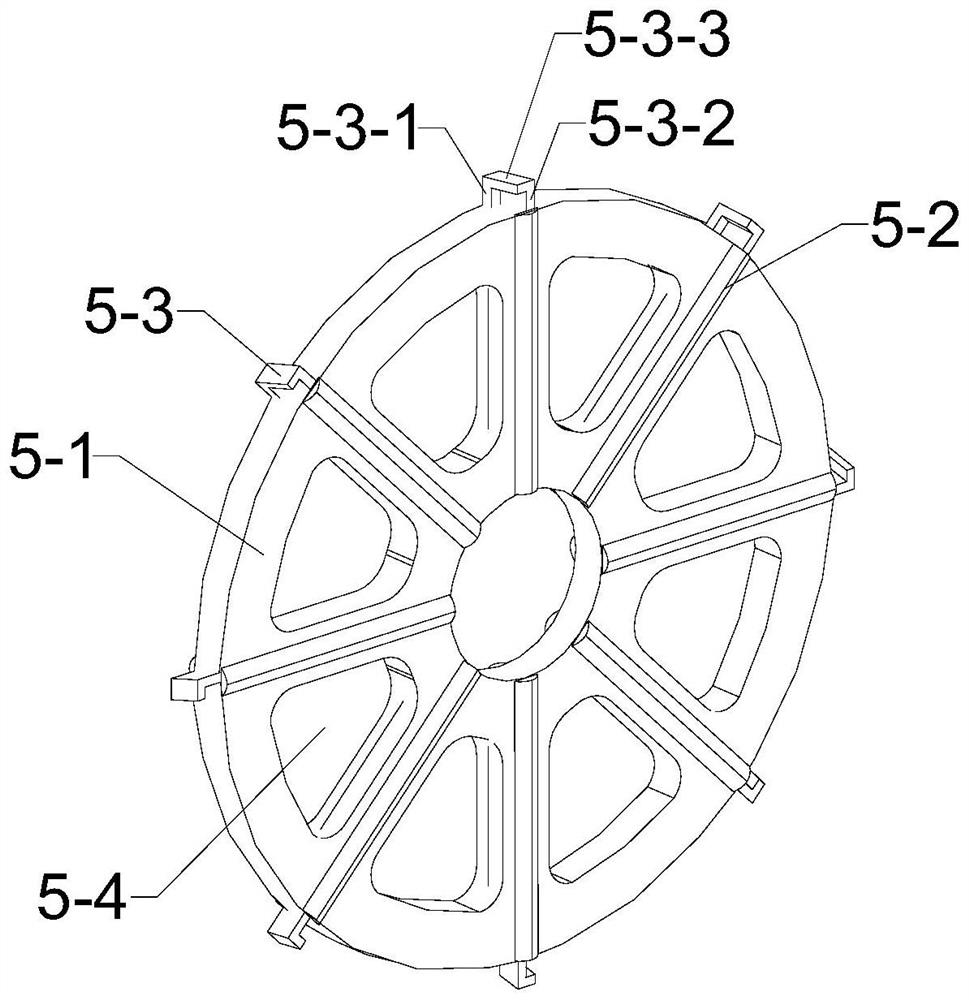

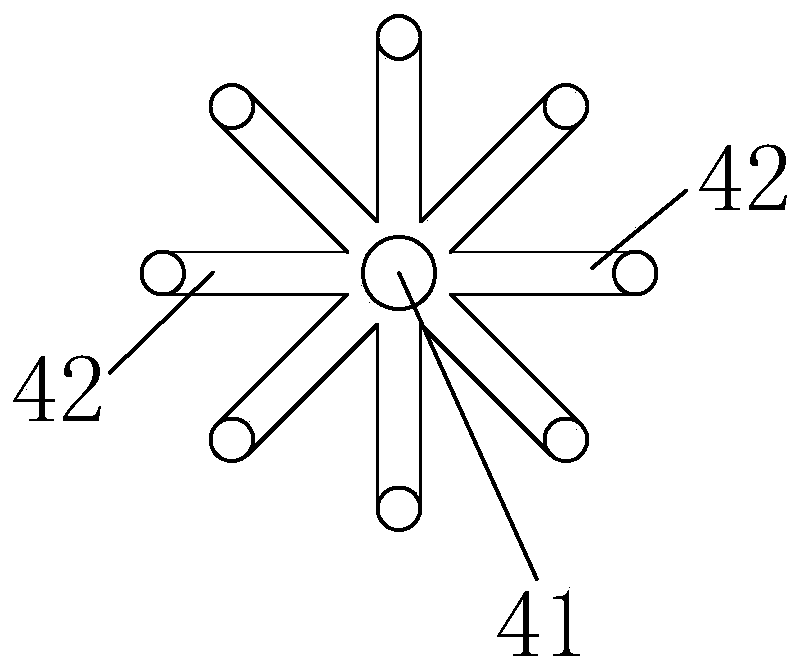

Dry stirring mill and operation method thereof

ActiveCN113953029AIncrease working areaImprove stirring performanceGrain treatmentsEngineeringMechanical engineering

The invention discloses a dry stirring mill and an operation method thereof. The dry stirring mill comprises a grinding cylinder, a feeding opening, a discharging opening, a mill air inlet, a mill air outlet, a main shaft, a driving device, stirrers, a separating device and a grading air supply device; the grinding cylinder is horizontally arranged, one end of the grinding cylinder is provided with the feeding opening and the mill air inlet, and the other end of the grinding cylinder is provided with the discharging opening and the mill air outlet; the interior of the grinding cylinder is divided into a grinding area and a grinding grading area, and the grinding area is close to one side of the feeding opening; the main shaft is located in the grinding cylinder and penetrates through the center of the grinding cylinder, one end of the main shaft is connected with the driving device, and the other end of the main shaft is supported by a bearing installed on a foundation and a support; stirrers are arranged at the position, in the grinding area, of the main shaft, and the other stirrers and the separating device are arranged at the position, in the grinding grading area, of the main shaft; a trepanning area is arranged at the bottom of the portion, in the grinding grading area, of the grinding cylinder; and the position, in the trepanning area, of the grinding cylinder is connected with the grading air supply device. Grinding efficiency is greatly improved, timely separation of materials from grinding media is guaranteed, and reliability and stability of the mill are improved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

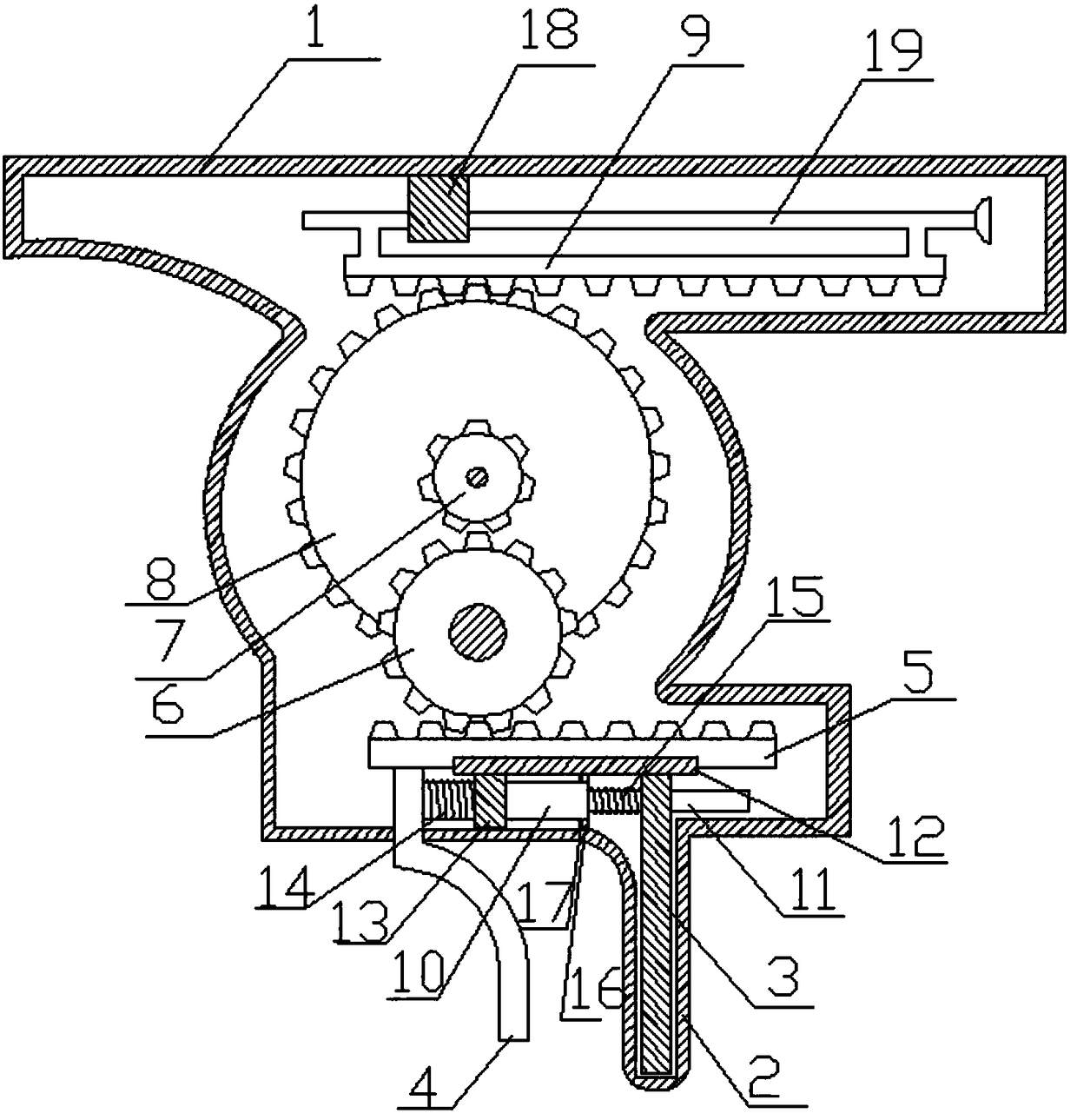

Brake device for ink application for color printing equipment

PendingCN108327395AHigh speedImprove convenienceInking apparatusPrinting press partsColor printingEngineering

The invention discloses a brake device, and particularly discloses a brake device for ink application for color printing equipment. The invention aims at solving the problems of complex operation, high speciality and low operability of an ink application device for a color printing machine in the prior art. The brake device disclosed by the invention comprises a shell body, wherein a hollow handleis arranged at the lower end of the shell body; a handgrip sleeves into the handle; a through hole is formed in the upper end of the handgrip; a pull buckle is arranged at one side of the handle; a movable rod group capable of horizontally moving is connected to the pull buckle; a first tooth plate is further arranged at one end connected with the movable rod group, of the pull buckle; a first gear engaged with the first tooth plate is arranged above the first tooth plate; a second gear engaged with the first gear is arranged above the first gear; a third gear coaxially rotating with the second gear is arranged at the centre of the second gear; and a second tooth plate engaged with the third gear is arranged above the third gear. The brake device disclosed by the invention is simple to operate, applicable to common users, capable of being repeatedly used, environment-friendly, and practical.

Owner:郑州华美彩印纸品有限公司

Double tuned inertial system

ActiveCN109138567BIncreased bandwidthImprove energy absorptionProtective buildings/sheltersShock proofingEnergy infrastructureEngineering

The invention relates to a double-tuned inertance system in the civil engineering and energy infrastructure field. The system comprises a first-grade collision friction type tuning mass unit, a second-grade tuning mass unit, a liquid inertance damping unit and an installation unit. In the invention, a double damping tuning mechanism is established to adjust a system frequency and carry out dampingcontrol, and the frequency bandwidth of the effective damping control of the damping system is increased. The two grade tuning mass units and the liquid inertance unit are used to store energy. The nonlinear collision of a collision friction block and a liquid inertance damping dissipation structure are used to vibrate energy. Based on the quality synergy effect of the liquid inertance unit, additional mass required for the first-grade collision friction type tuning mass unit is greatly reduced, and a light-weight tuning damping device is provided. In addition, the inertance unit effectivelycontrols the deformation of the entire first-grade collision friction type tuning mass unit, the installation space of the device is saved, the efficiency of the internal damping energy consumption of collision friction block damping is improved, and the system has a wide application prospect.

Owner:TONGJI UNIV

Combined multi-phase vibration damping device

InactiveCN105297940BClear structureVibration reduction and energy consumptionShock proofingViscous liquidParticulates

The invention discloses a combined multi-phase damping device, which includes a container, a particle system, a viscous liquid, an elastic system and a screen, wherein the particle system is composed of spherical particles, bearing rods, fixed rods and built-in horizontal cylinders arranged bidirectionally, The viscous liquid is formed by mixing one or more liquids, the viscous liquid is located inside the container, and the spherical particles are located in the viscous liquid, or float or sink to the bottom of the liquid. The viscous liquid can vibrate in the container, and the spherical particle system collides with each other in the screen, and the friction energy is consumed; the viscous liquid and the particle system collide with each other, and the friction energy is consumed between the particles and the screen. The invention combines the advantages of a tuned liquid damper, a viscous damper, a tuned mass damper and a particle damper, consumes energy through the combination of liquid phase and solid phase, and has a good vibration damping effect. It has wide applicability.

Owner:TONGJI UNIV

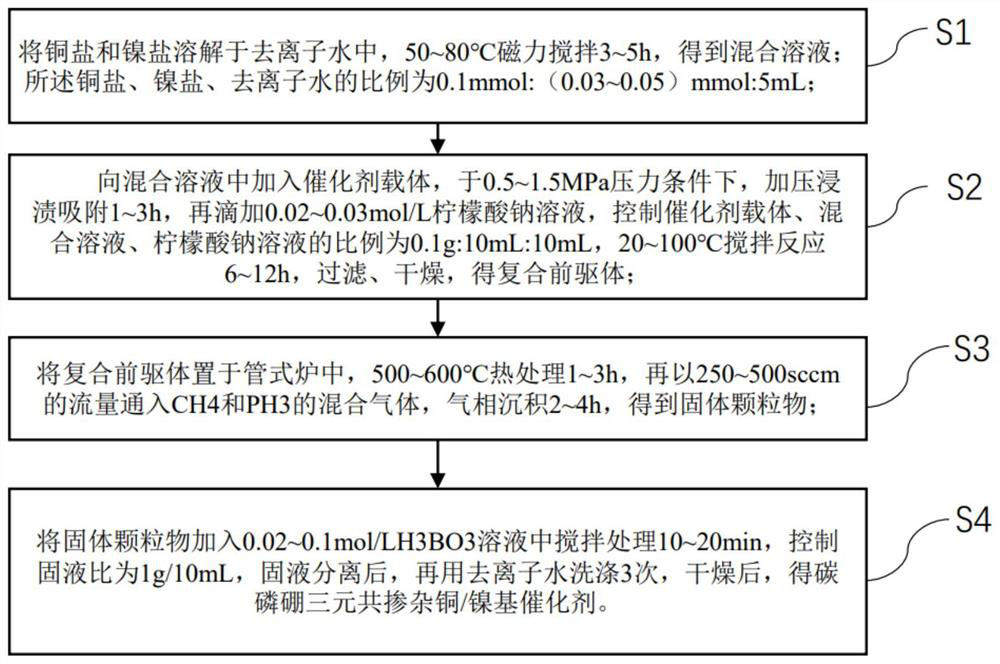

Preparation method and application of carbon-phosphorus-boron ternary co-doped copper/nickel-based catalyst

InactiveCN113457728AImprove doping stabilityIncrease forceMolecular sieve catalystsOrganic compound preparationNickel saltPtru catalyst

The invention discloses a preparation method and application of a carbon-phosphorus-boron ternary co-doped copper / nickel-based catalyst, and the preparation method comprises the following steps: S1, dissolving a copper salt and a nickel salt in deionized water, and magnetically stirring at 50-80 DEG C for 3-5 hours to obtain a mixed solution; s2, adding a catalyst carrier into the mixed solution, performing pressurized impregnation adsorption for 1-3 hours under the pressure condition of 0.5-1.5 MPa, then dropwise adding a 0.02-0.03 mol / L sodium citrate solution, performing stirring reaction for 6-12 hours at the temperature of 20-100 DEG C, filtering, and drying to obtain a composite precursor; s3, placing the composite precursor in a tubular furnace, carrying out heat treatment at 500-600 DEG C for 1-3 hours, then introducing mixed gas of CH4 and PH3 at a flow rate of 250-500 sccm, and carrying out vapor deposition for 2-4 hours to obtain solid particles; and S4, adding the solid particles into a 0.02-0.1 mol / L H3BO3 solution, stirring for 10-20 minutes, controlling the solid-to-liquid ratio to be 1g / 10mL, carrying out solid-liquid separation, washing with deionized water for 3 times, and drying, so as to obtain the carbon-phosphorus-boron ternary co-doped copper / nickel-based catalyst. The ZSM-5 molecular sieve is used as a carrier, sodium citrate is used as a metal complexing agent, Cu < 2 + > and Ni < 2 + > grow in situ, non-metallic elements of carbon, phosphorus and boron are deposited, and the selectivity and catalytic activity of the catalyst are improved.

Owner:哈尔滨领昇生物医药科技有限公司

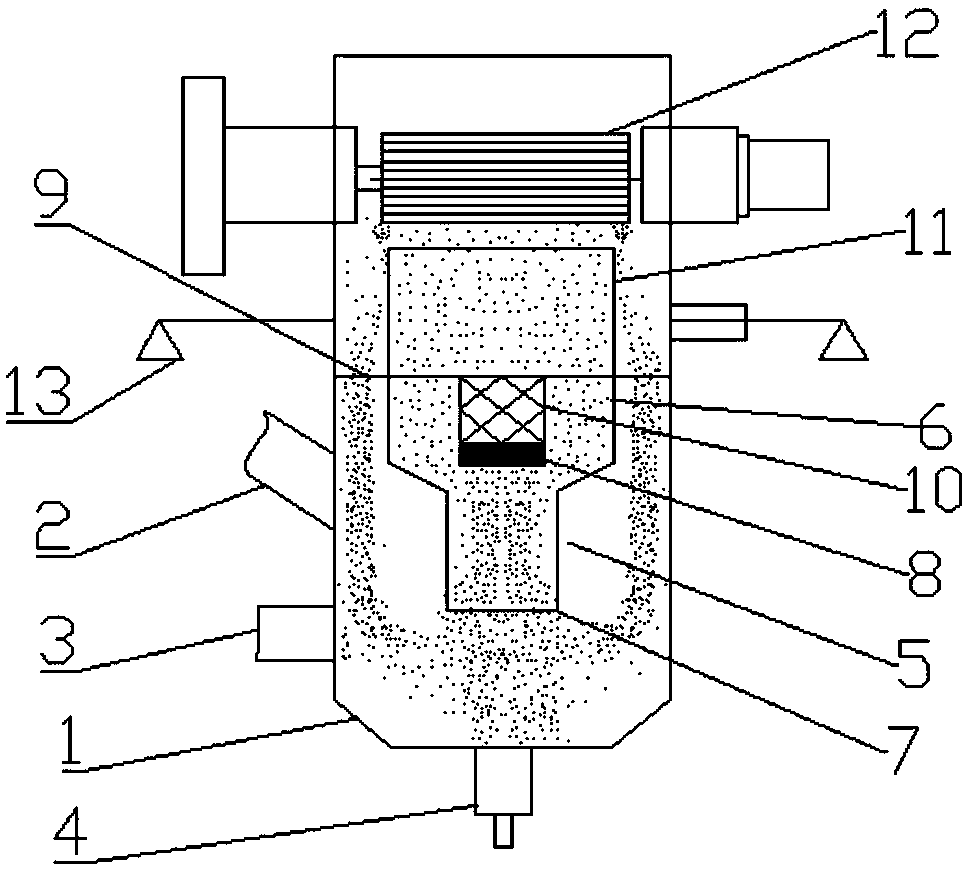

Target airflow mill and method for preparing economical sintered neodymium iron boron blank

ActiveCN108597846AUniform particle sizeImprove magnetismInductances/transformers/magnets manufactureEngineeringAlloy

The invention discloses a target airflow mill, comprising: a housing vertically arranged, the lower part of the side wall of the housing being provided with a downward inclined feed opening and at least one horizontal dispersed nitrogen flow inlet, and the center of the bottom of the housing being provided with a pulverized nitrogen flow inlet; and an impact path pipe coaxially fixed in the housing, the impact path pipe comprising a thick pipe section and a thin pipe section integrally formed and connected from top to bottom, and an alloy target being coaxially fixed in the thick pipe section.Also provided is a method for preparing an economical sintered neodymium iron boron blank, comprising the steps of: crushing a neodymium iron boron alloy casting piece to obtain coarse powder; feeding the coarse powder into the housing, introducing dispersed nitrogen and crushed nitrogen, and crushing and screening the coarse powder to obtain target powder; and preparing a blank from the target powder. The method can prepare small-sized and uniform neodymium iron boron powder and a blank with good magnetic properties, and can save raw materials and reduce the production cost.

Owner:京磁材料科技股份有限公司

A hybrid energy dissipation vibration damping device

ActiveCN104453004BClear structureVibration reduction and energy consumptionShock proofingViscous liquidEngineering

The invention relates to a mixed energy dissipation and vibration reduction damping device with a more perfect energy consumption effect. The device comprises a container, particle systems and viscous liquid and a spring system, wherein the particle systems consist of solid particles, bearing rods and fixing plates. The device integrates the advantages of a particle damper and a tuning liquid damper; when the damping device moves, liquid sloshes to consume energy; holes among the particles improve sloshing energy consumption capacity of the liquid; at the same time, the liquid sloshes to drive the movable particle systems to move; and the movable particle systems impact the fixed particle system on the inner side to consume the energy during reciprocating motion. Due to various mixed energy consumption mechanisms such as the liquid phase friction energy consumption and solid phase collision and friction energy consumption, the device has a greater advantage compared with the traditional vibration reduction damper with a single energy consumption principle.

Owner:TONGJI UNIV

Method for preparing flaky aluminum oxide with high radius-thickness ratio by taking lotus root as template

ActiveCN112978775AImprove precipitation efficiencyHigh purityAluminium oxide/hydroxide preparationAluminium chlorideAluminum fluoride

The invention discloses a method for preparing flaky aluminum oxide with a high radius-thickness ratio by taking lotus roots as a template. The method comprises the following steps: adding malonyl urea and polyaluminum chloride sol into a diluted hydrochloric acid solution to obtain a solution A; drying fresh lotus roots, cutting the lotus roots into blocks, washing the lotus roots, and immersing the lotus roots into a glucose solution for filling to obtain a lotus root precursor B; dropwise adding a melamine solution into the solution A, then dropwise adding a dilute sodium hydroxide solution until the pH value is 7.5-8.5, and adding the lotus root precursor B for soaking to obtain a mixed solution C; transferring the mixed solution C into a microwave ultrasonic hydrothermal synthesizer for reaction, and collecting to obtain a mixed solution D; pouring an upper-layer turbid solution of the mixed solution D, washing, dehydrating and drying the obtained product, and collecting to obtain a solid E; uniformly mixing the solid E, potassium aluminum fluoride and silicon dioxide in proportion, sintering, cooling, collecting a product, washing and drying to obtain the high-radius-thickness-ratio flaky aluminum oxide. The method is simple, low in cost, high in product purity and good in orientation, and the preparation efficiency of the product is effectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

A mineral flotation system

ActiveCN109046793BReduce the difficulty of collisionEfficient ConcentrationFlotationMining engineeringMineral flotation

The invention belongs to the technical field of mineral flotation, and particularly relates to a mineral flotation system. The device comprises a rotatable ore pulp barrel, a flotation groove communicated with the ore pulp barrel, a rotating barrel capable of rotating is arranged in the flotation groove in a sleeved mode, the rotating barrel is communicated with the ore pulp barrel through a pipeline, one end, connected with the rotating barrel, of the pipeline is located at the upper end of the barrel wall of the rotating barrel or close to the barrel wall of the rotating barrel, the rotatingbarrel and the ore pulp barrel rotate synchronously, the lower part of the rotating barrel is of a cone structure and is in a reduced diameter shape from top to bottom, an upper overflow port and a lower underflow port are formed in the upper end and the lower end of the rotating barrel respectively, the flotation groove is communicated with the ore pulp barrel through the rotating barrel and thepipeline; the system further comprises a bubble generation device, and the bubble generation device is communicated with the flotation groove. According to the mineral flotation system, the effectivecollision rate of the bubbles can be improved when the mineral flotation work is carried out, so that the collision probability between the bubbles and the mineral particles to be recovered is increased, and then the flotation efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

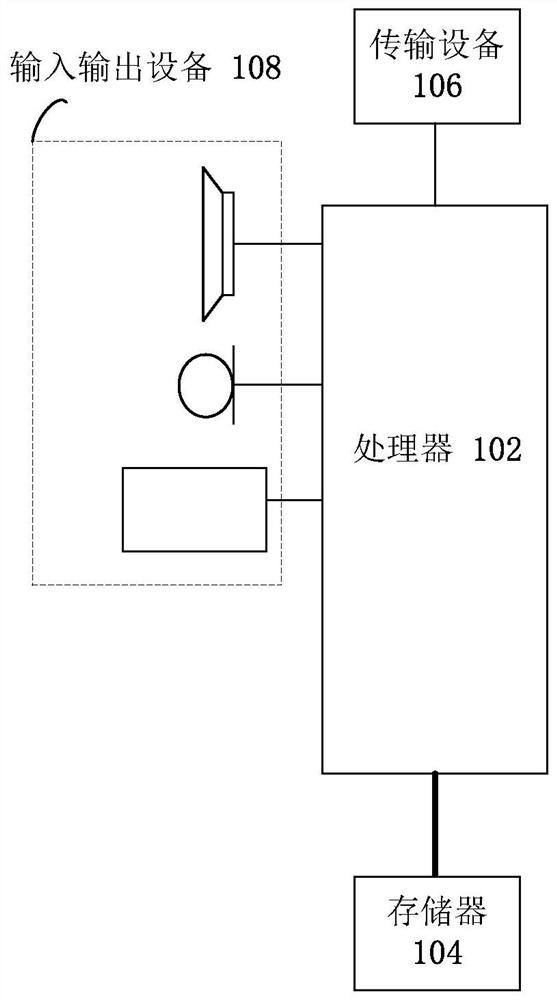

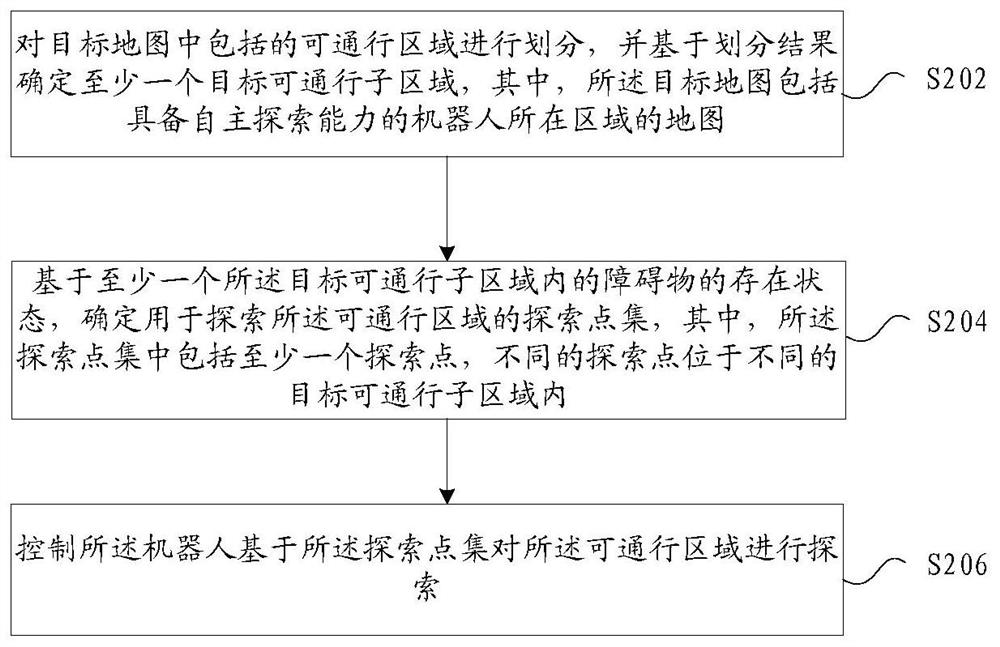

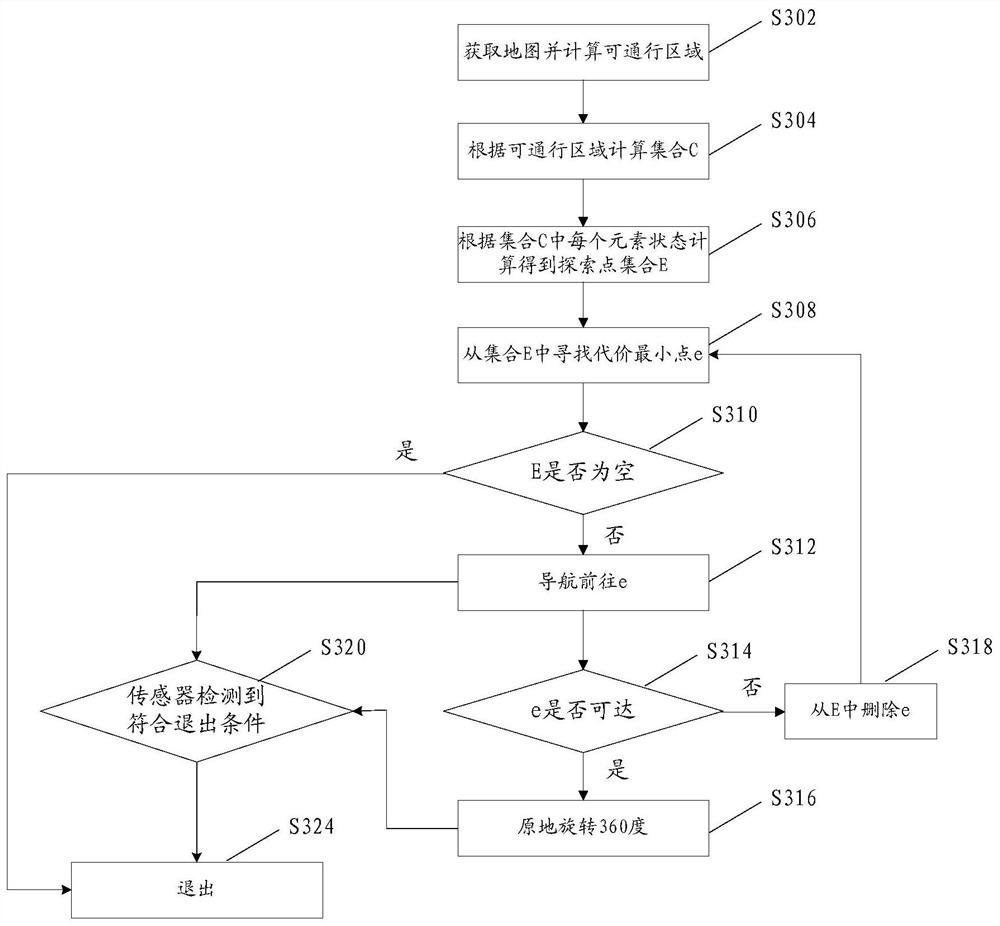

Exploration method and device of passable area, storage medium and electronic device

ActiveCN114543802AEffectively avoidReduce the number of collisionsNavigational calculation instrumentsPosition/course control in two dimensionsEngineeringData mining

The embodiment of the invention provides a passable area exploration method and device, a storage medium and an electronic device.The method comprises the steps that a passable area included in a target map is divided, and at least one target passable sub-area is determined based on the division result, the target map comprises a map of an area where the robot with autonomous exploration capability is located; based on the existence state of the obstacle in the at least one target passable sub-area, determining an exploration point set for exploring the passable area; and controlling the robot to explore the passable area based on the exploration point set. Through the method and the device, the problems of excessive collision, high exploration time consumption and low success rate when the robot explores the passable area in the prior art are solved, the collision times when the robot explores the passable area are reduced, the safety of the robot and the surrounding environment thereof is ensured, meanwhile, the exploration time is shortened, and the exploration efficiency is improved. And the success rate of exploration is improved.

Owner:DREAM INNOVATION TECH (SUZHOU) CO LTD

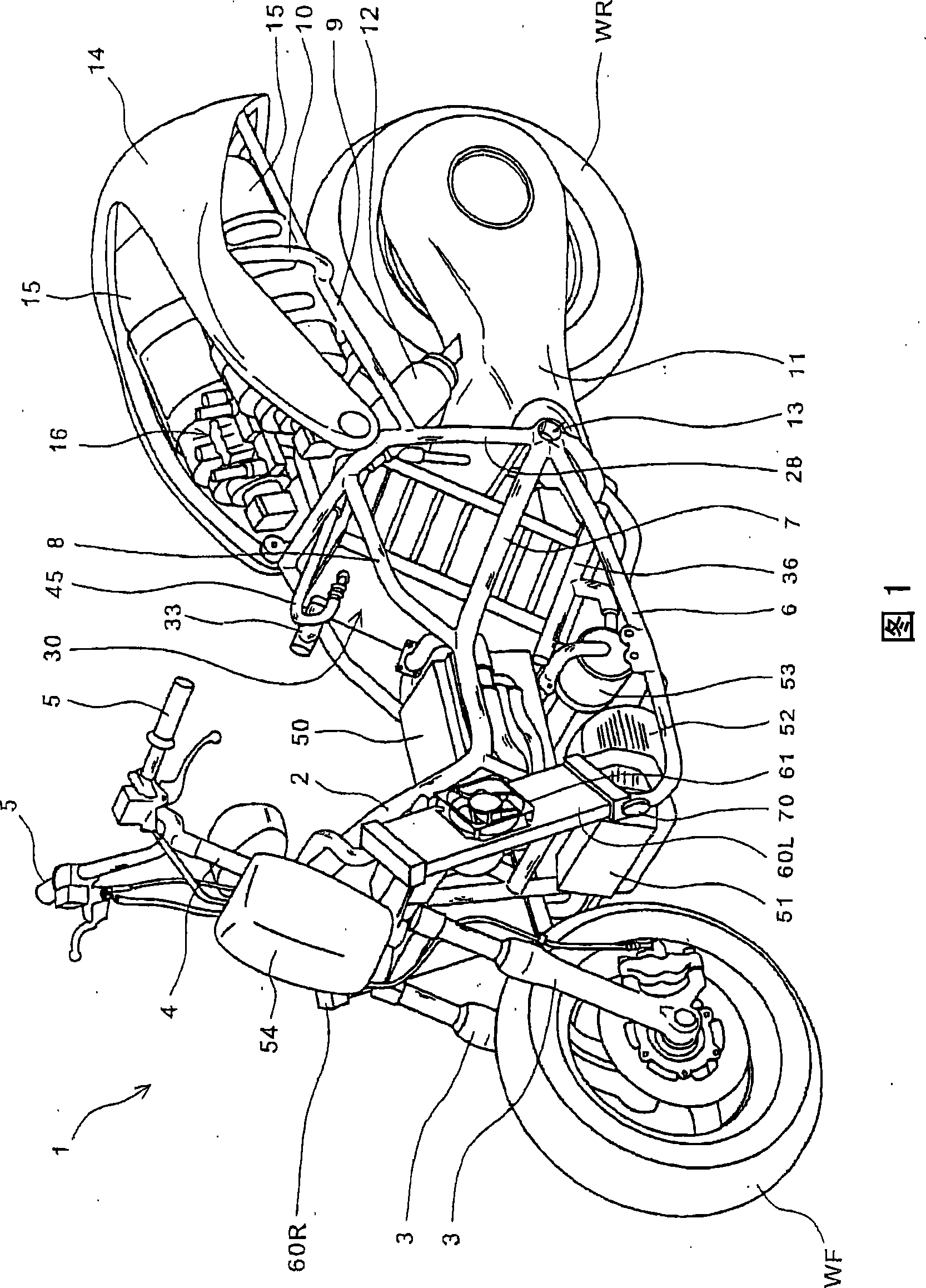

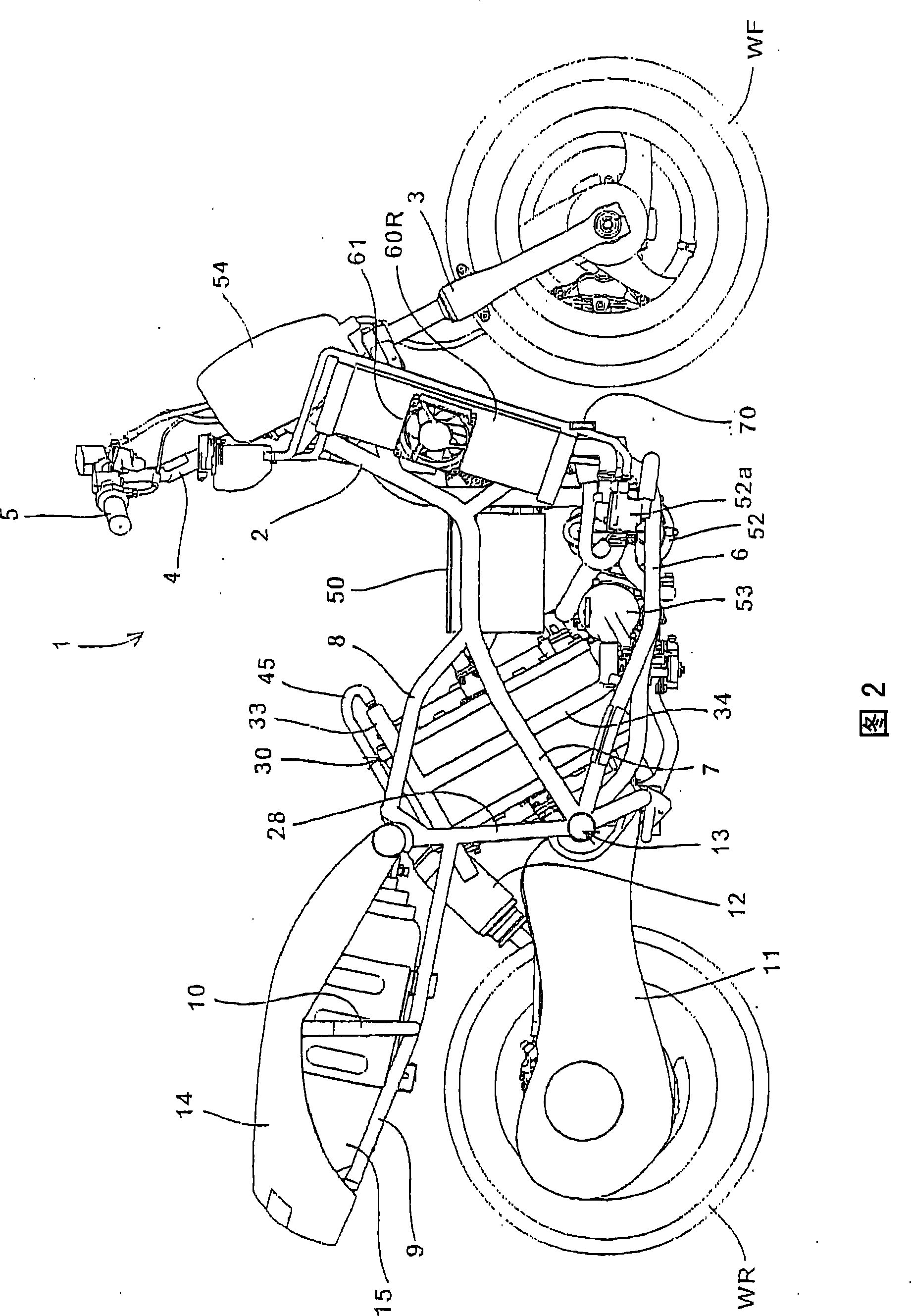

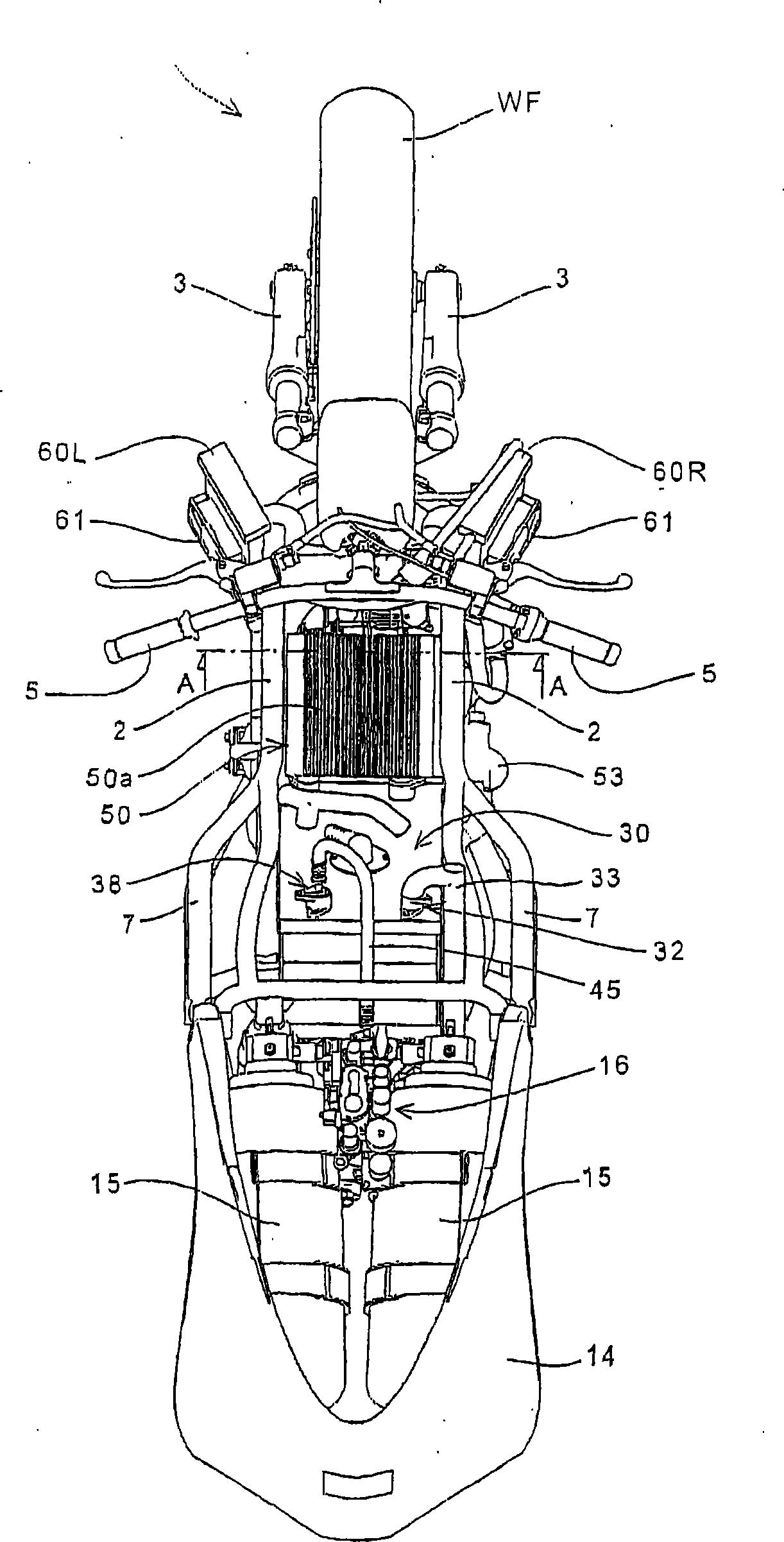

Saddle ride, fuel cell powered vehicle

InactiveCN101274652BImprove cooling effectSmall sizeCycle equipmentsPower to auxillary motorsVoltage converterFuel cells

A fuel cell powered vehicle includes radiators disposed on left and right sides on the skew rear side of a front wheel in relation to the vehicle body front-rear direction. A secondary battery is disposed between the left and right radiators. A thin plate-shaped inner cowl is disposed between the secondary battery and the front wheel. Duct mechanisms surrounding the radiators are provided on the left and right sides of the inner cowl and inside a cowling. Each duct mechanism includes introduction ports for a running airflow, and a discharge port that is fitted with variable-type louvers. A voltage converter unit is accommodated in a straddled part of the vehicle. Radiating fins of the voltage converter include plate-like members erected in the vehicle body front-rear direction that are directed toward the upper side of the vehicle body and are exposed to the exterior of the vehicle body.

Owner:HONDA MOTOR CO LTD

Method for preparing self-assembled hollow alumina microspheres by taking sesbania gum as template

PendingCN112960681ARaw materials are easy to getLow costAluminium oxide/hydroxide preparationMicrosphereFreeze-drying

The invention discloses a method for preparing self-assembled hollow alumina microspheres by taking sesbania gum as a template. The method comprises the following steps: 1, adding aluminum sulfate octadecahydrate, dicyandiamide and methyl pyrrolidone into deionized water, and carrying out ultrasonic dispersion to obtain a clear solution A; 2, gradually dropwise adding a sesbania gum solution into the solution A, adjusting the pH value to 8.2-9.2, and performing magnetic stirring to obtain a solution B; 3, transferring the solution B into a rotary micro-polymerization reactor for micro-polymerization reaction, and collecting a product to obtain a solid C; 4, washing the solid C for multiple times, performing vacuum freeze drying, and performing collecting to obtain a white powdery solid D; 5, mixing the solid D with potassium aluminum fluoride, transferring the mixture into a muffle furnace, preserving heat, and performing cooling, washing and drying to obtain the self-assembled hollow aluminum oxide microspheres. A micro-nano spherical space structure naturally formed in the sesbania gum is used as a growth template of alumina seed crystals, the obtained alumina crystal grains are good in orientation and uniform, the production and manufacturing cost is lower, and the production process is simple.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com