Combined multi-phase vibration damping device

A combined and subtractive technology, applied in the direction of building components, shockproof, etc., can solve the problems of viscous damper viscous material aging, particle damper response lag, poor low cycle fatigue performance, etc., to increase the vibration reduction frequency band , Improve the efficiency of vibration reduction and energy consumption, and increase the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

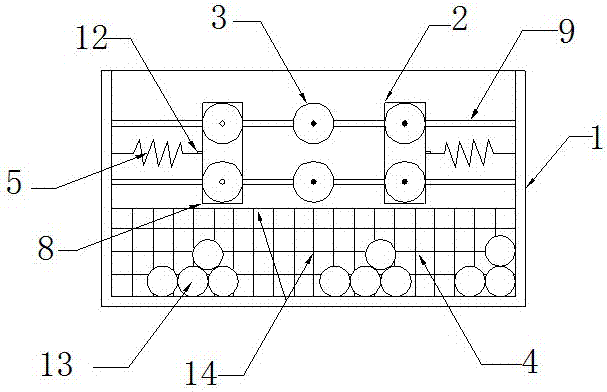

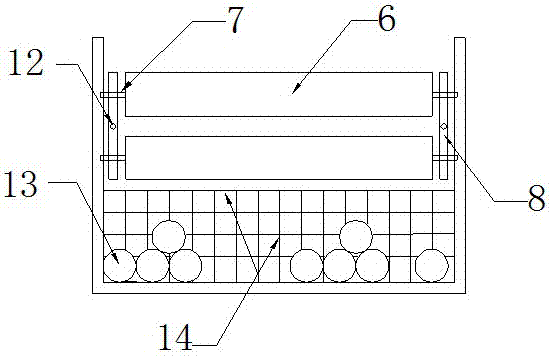

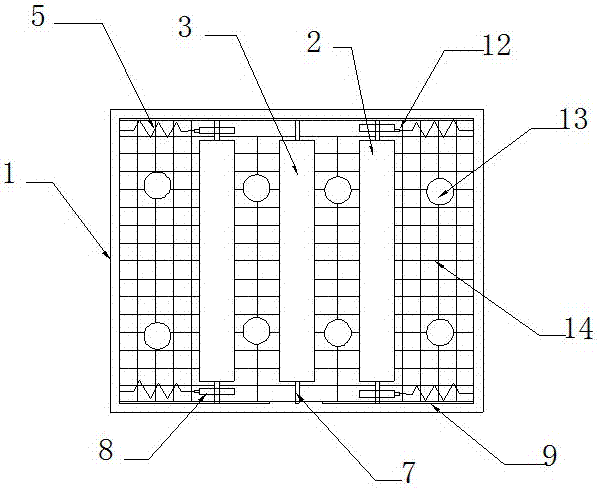

[0033] Example 1: See figure 1 , figure 2 , image 3 It is a schematic diagram of views in various directions of the overall structure of the experimental device of the present invention.

[0034] Container 1 is a cuboid, containing all energy-consuming substances. The movable particle system 2 consists of one or more spherical particles 13 made of one or more materials, bearing rods 7 and inner transverse cylinders 6 . The fixed particle system 3 consists of one or more bearing rods 7 made of one or more materials and an inner transverse cylinder 6 . Viscous liquid 4 consists of one or more stable liquids that can be layered or mixed. Its physical properties require heat resistance, non-volatile, non-flammable, stable chemical substances, and the viscosity coefficient depends on the energy consumption capacity required by the controlled structure. If it is mixed with multiple liquids, it is required that no excessive chemical reaction occurs, preferably no chemical reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com