Device and method for processing VOCs through asymmetrical single-medium barrier discharge

A single-dielectric barrier and asymmetric technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of easily generating spark discharge or arc discharge, reducing mineralization rate and pollutant removal rate, reducing discharge intensity and Energy utilization rate and other issues to achieve the effect of improving mineralization rate and power utilization rate, reducing operation and maintenance costs, and reducing cleaning and replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

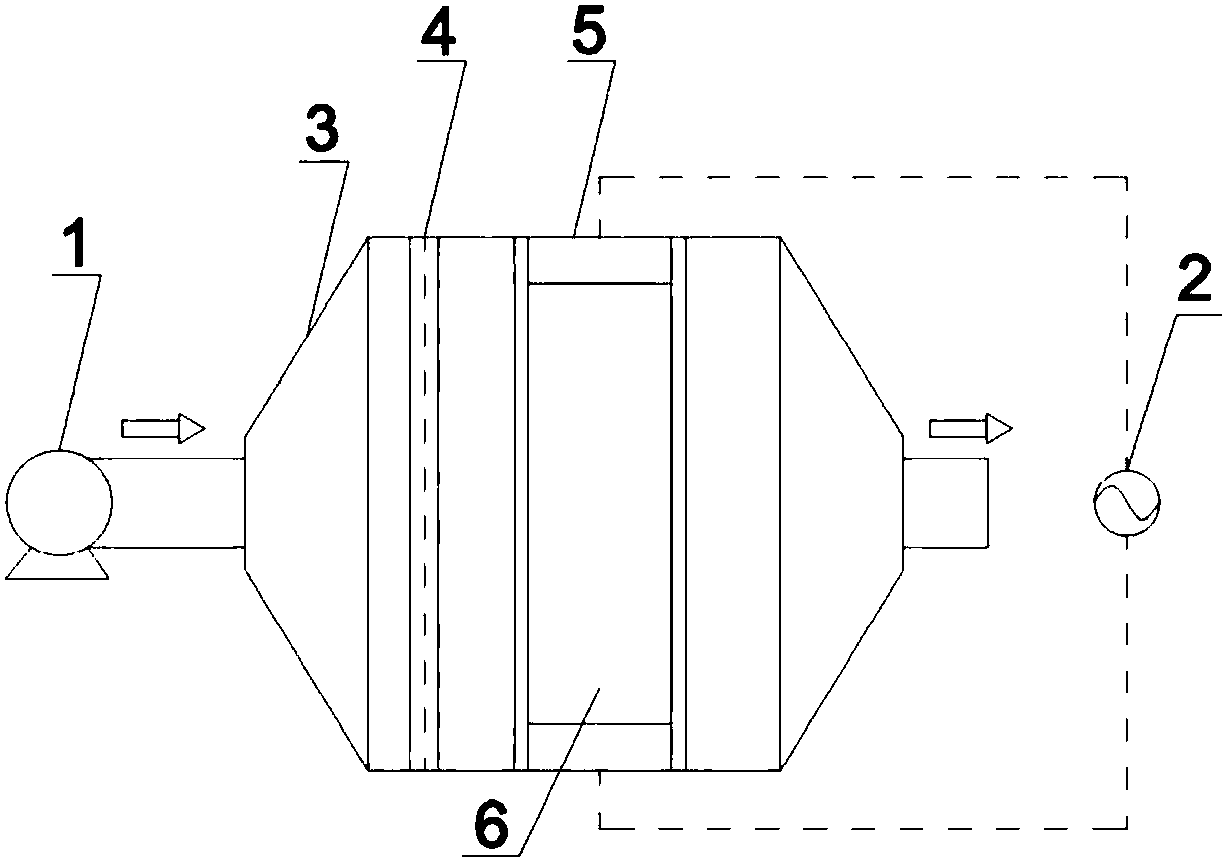

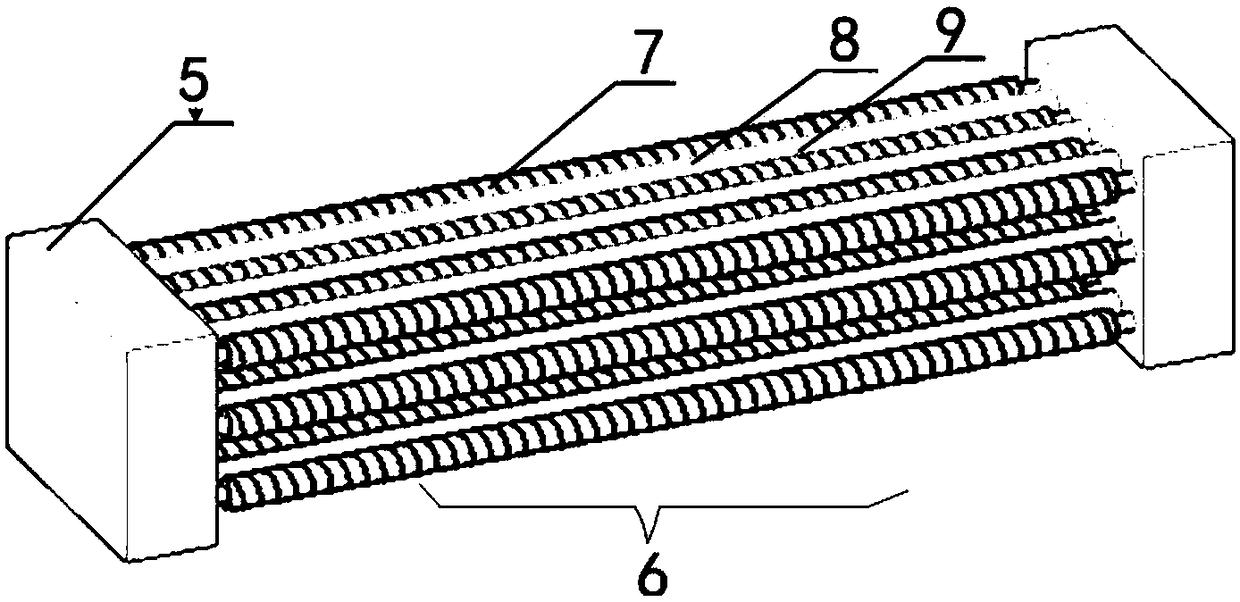

[0033] Such as figure 1 As shown, the device for treating VOCs with asymmetric single-dielectric barrier discharge in this embodiment includes a fan 1, a power supply 2, a box body 3, an equalizer plate 4, an electrode fixing plate 5 and a discharge unit 6, and the box body 3 is two The end is provided with waste gas inlet and waste gas outlet; described fan 1 is arranged at the waste gas inlet of box body 3 (blast form) or waste gas outlet (inducted wind form), is used for sending waste gas into or drawing out box body 3; The box body 3 is provided with a flow equalizer 4, an electrode fixing plate 5 and a discharge unit 6; the flow equalizer 4 is located in the box body 3 near the exhaust gas inlet, and is made of a quartz plate, which is covered with etc. The spaced channels make the airflow evenly pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com