Target airflow mill and method for preparing economical sintered neodymium iron boron blank

A jet mill, NdFeB technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems that powder cannot be used directly, the particle size fluctuates greatly, and the production cost increases. Small particle size, improved magnetic properties, and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

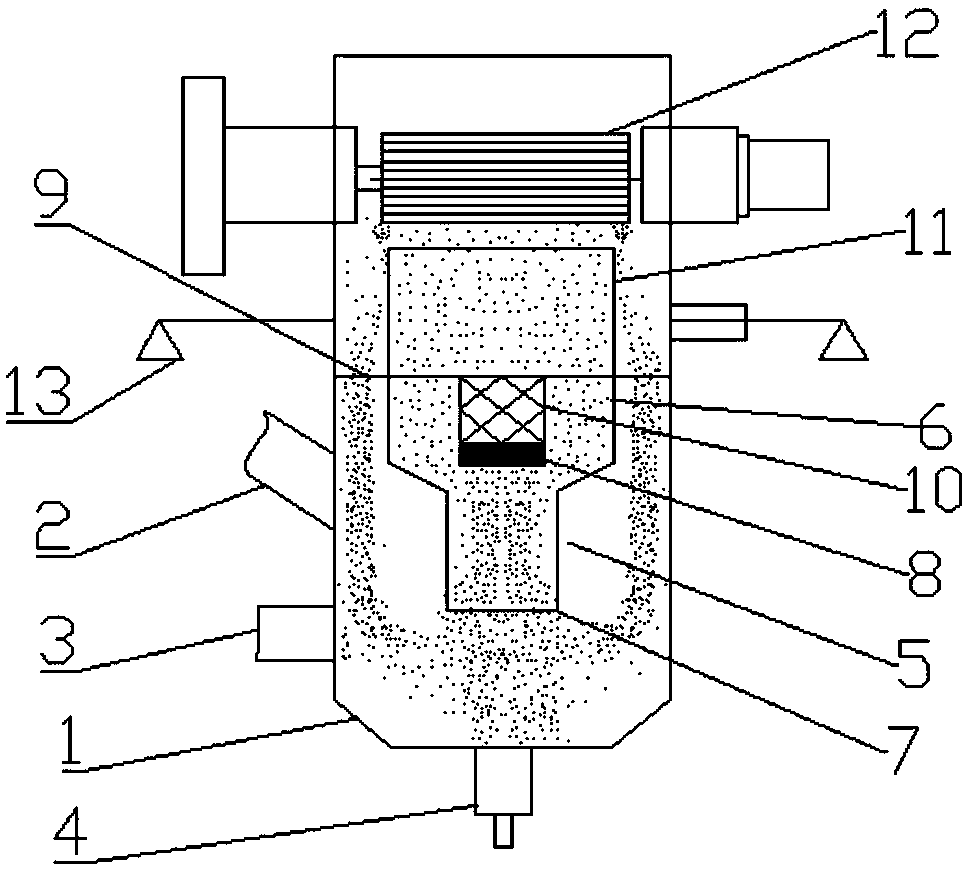

Method used

Image

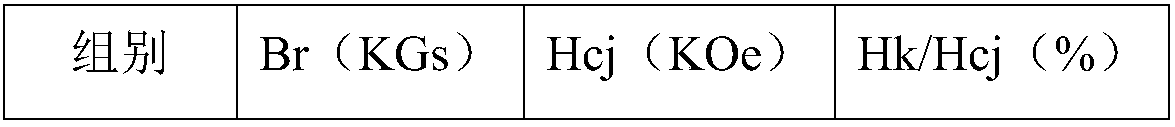

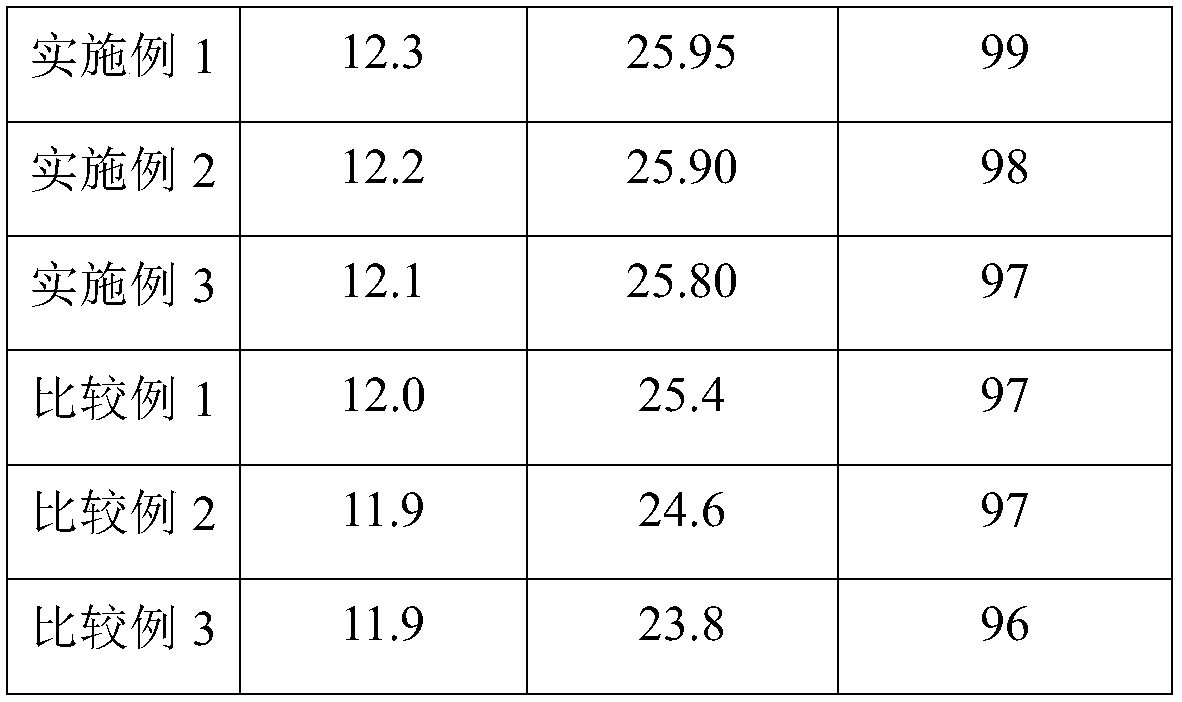

Examples

Embodiment 1

[0044] The method for preparing economical sintered NdFeB blanks based on the target jet mill includes: after hydrogen absorption and crushing of NdFeB alloy castings, adding a mixture of zinc stearate and n-hexane, and then mixing them evenly through a powder mixer , to get coarse powder, wherein the total addition of zinc stearate and n-hexane mixture is 1‰ of the quality of the NdFeB alloy casting sheet, and the mass fraction of zinc stearate is 70%; The feed inlet is fed into the housing, and then dispersed nitrogen gas with a pressure of 0.3 MPa is introduced into the dispersed nitrogen flow inlet, and crushed nitrogen gas with a pressure of 0.8 MPa is fed into the crushed nitrogen flow inlet at the same time. After the coarse powder is crushed, first After being screened by the turbine classifier, a fine powder with a particle size of less than 4.5 μm is obtained, and then the fine powder is screened by a cyclone separator to obtain a target powder with a particle size of...

Embodiment 2

[0046] The method for preparing economical sintered NdFeB blanks based on the target jet mill includes: after hydrogen absorption and crushing of NdFeB alloy castings, adding a mixture of zinc stearate and n-hexane, and then mixing them evenly through a powder mixer , to get coarse powder, wherein the total addition of zinc stearate and n-hexane mixture is 0.5‰ of the quality of the NdFeB alloy casting sheet, and the mass fraction of zinc stearate is 50%; The feed inlet is fed into the housing, and then the dispersed nitrogen gas with a pressure of 0.2MPa is fed into the dispersed nitrogen flow inlet, and the pulverized nitrogen gas with a pressure of 0.6MPa is fed into the pulverized nitrogen gas flow inlet at the same time. After the coarse powder is crushed, first After being screened by the turbine classifier, a fine powder with a particle size of less than 4.5 μm is obtained, and then the fine powder is screened by a cyclone separator to obtain a target powder with a parti...

Embodiment 3

[0048] The method for preparing economical sintered NdFeB blanks based on the target jet mill includes: after hydrogen absorption and crushing of NdFeB alloy castings, adding a mixture of zinc stearate and n-hexane, and then mixing them evenly through a powder mixer , to get coarse powder, wherein, the total addition of zinc stearate and n-hexane mixture is 0.3‰ of the quality of the NdFeB alloy casting sheet, and the mass fraction of zinc stearate is 30%; The feed inlet is fed into the housing, and then dispersed nitrogen gas with a pressure of 0.1MPa is introduced into the dispersed nitrogen flow inlet, and crushed nitrogen gas with a pressure of 0.4MPa is fed into the crushed nitrogen flow inlet at the same time. After the coarse powder is crushed, first After being screened by the turbine classifier, a fine powder with a particle size of less than 4.5 μm is obtained, and then the fine powder is screened by a cyclone separator to obtain a target powder with a particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com