Cement external circulation vertical mill combined high-performance grinding process system

A process system and external circulation technology, which is applied in the field of cement external circulation vertical mill combined with high-performance grinding process system, can solve the problems of reducing equipment stability, over-grinding of local materials, and consuming huge energy, so as to improve reliability and efficiency. Stability, ensure timely separation, and promote the effect of effective collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

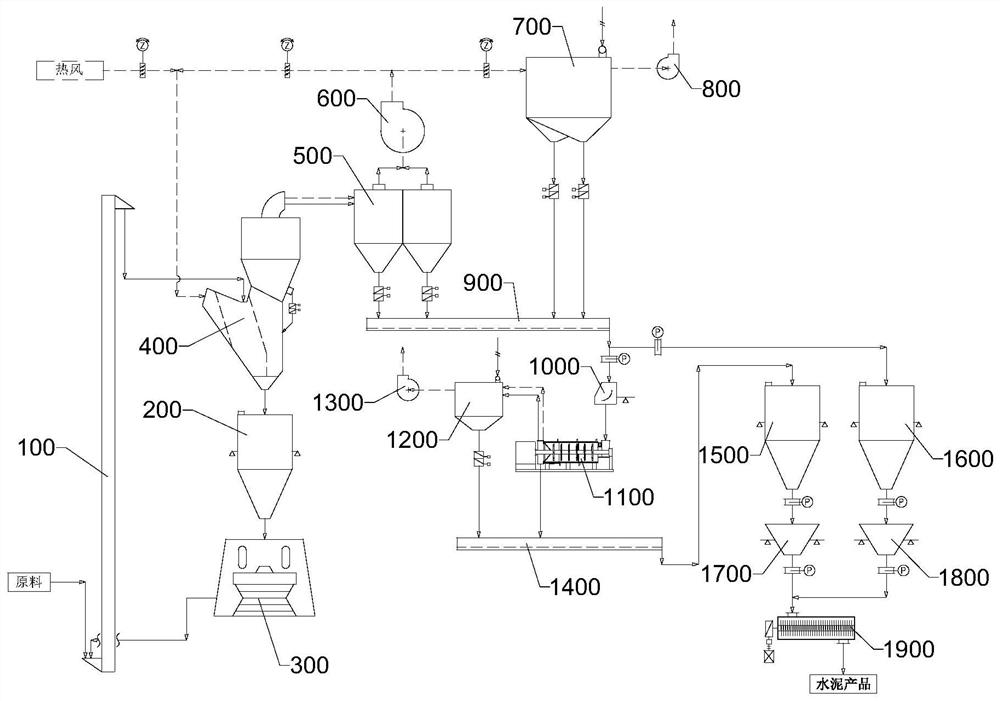

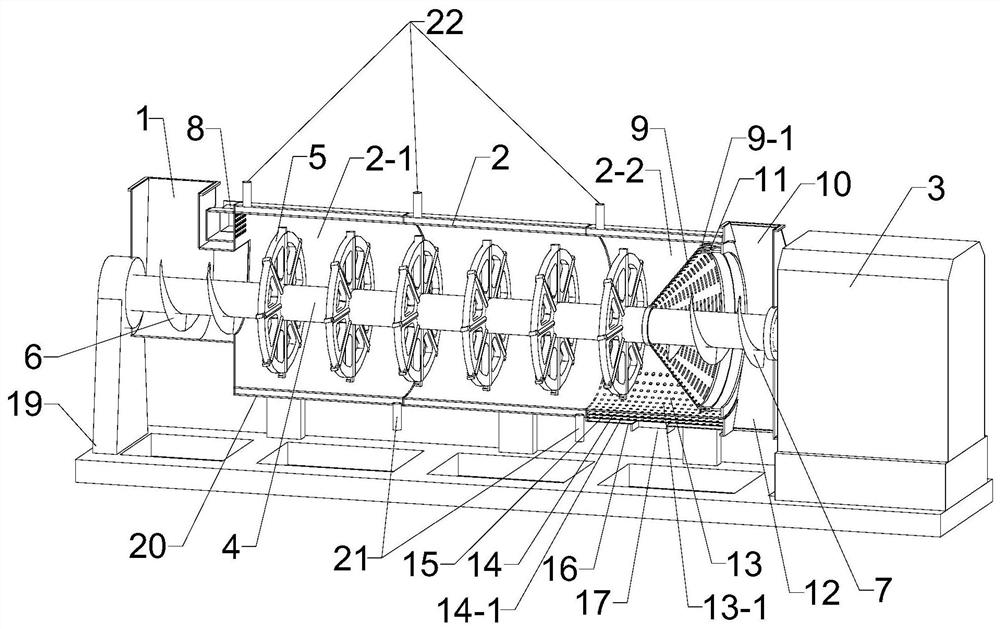

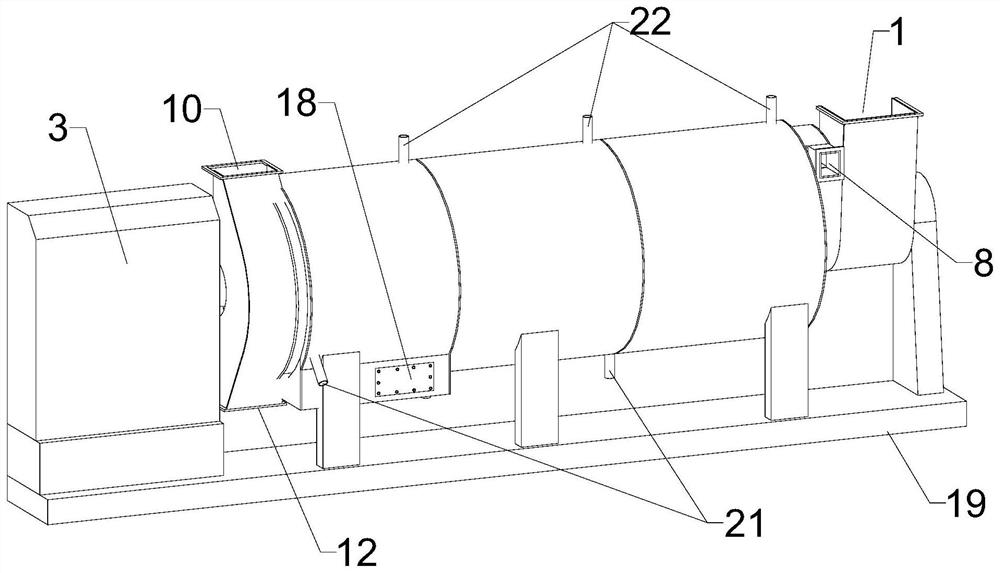

[0050] see Figure 1-8 , this embodiment provides a cement external circulation vertical mill combined with a high-performance grinding process system, including a hoist 100, a raw material bin 200, an external circulation vertical mill 300, a combined powder separator 400, a cyclone dust collector 500, and a circulating fan 600, dust collector 1 700, exhaust fan 1 800, conveying chute 900, solid flow meter 1000, dry stirring mill 1100, dust collector 2 1200, exhaust fan 2 1300, conveying chute 2 1400, Fine powder blending bin 1500, coarse powder blending bin 1600, fine powder measuring hopper 1700, coarse powder measuring hopper 1800, mixer 1900.

[0051] The discharge port of the external circulation vertical mill 300 is connected to the feed port of the combined powder separator 400 through the hoist 100, and the bottom discharge port of the combined powder separator 400 is connected to the external circulation vertical mill through the raw material bin 200. 300 feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com