Method for synthesizing metal-organic framework material Co-MOF-71

A metal-organic framework, co-mof-71 technology, applied in the field of synthesis of organic framework materials, can solve the problems of few reports and achieve the effect of high selectivity, strong operability, and highly dispersed metal sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

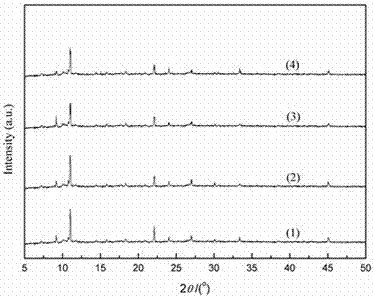

[0018] Mix the raw materials cobalt nitrate, terephthalic acid, solvent N,N-dimethylformamide, and absolute ethanol in a molar ratio of 1:1.5:95.5:31.3, place it in a Shrek tube, seal it and raise the temperature to 120°C to keep 10h, then filtered while hot, washed three times with anhydrous methanol solution with the same volume as the solvent in the ingredients, and finally dried in air at 100°C for 6h to obtain Co-MOF-71 metal organic framework material. The XRD pattern of the sample is shown as figure 1 As shown in (1), the specific surface area, micropore pore volume, and cobalt mass percentage are listed in Table 1, respectively.

Embodiment 2

[0020] Mix the raw materials cobalt nitrate, terephthalic acid, solvent N,N-dimethylformamide, and absolute ethanol in a molar ratio of 1:1.5:191.0:62.6, place it in a Shrek tube, seal it and raise the temperature to 110°C to keep 15h, then filtered while hot, washed three times with anhydrous methanol solution with the same volume as the solvent in the ingredients, and finally dried in air at 80°C for 10h to obtain Co-MOF-71 metal organic framework material. The XRD pattern of the sample is shown as figure 1 As shown in (1), the specific surface area, micropore pore volume, and cobalt mass percentage are listed in Table 1, respectively.

Embodiment 3

[0022] Mix the raw materials cobalt nitrate, terephthalic acid, solvent N,N-dimethylformamide, and absolute ethanol in a molar ratio of 1:1.5:191.0:31.3, place it in a Shrek tube, seal it and raise the temperature to 110°C to keep 15h, then filtered while hot, washed three times with anhydrous methanol solution with the same volume as the solvent in the ingredients, and finally dried in air at 100°C for 6h to obtain Co-MOF-71 metal organic framework material. The XRD pattern of the sample is shown as figure 1 As shown in (1), the specific surface area, micropore pore volume, and cobalt mass percentage are listed in Table 1, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com