Synthesis method of ultralow-sodium high-silicon nano ZSM-5 molecular sieve

A technology of ZSM-5 and synthesis method, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable industrial production and high cost of silica-alumina glue, and achieve the reduction of synthesis cost, silicon The effect of high aluminum ratio, reduction of production cost and discharge of ammonia nitrogen sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

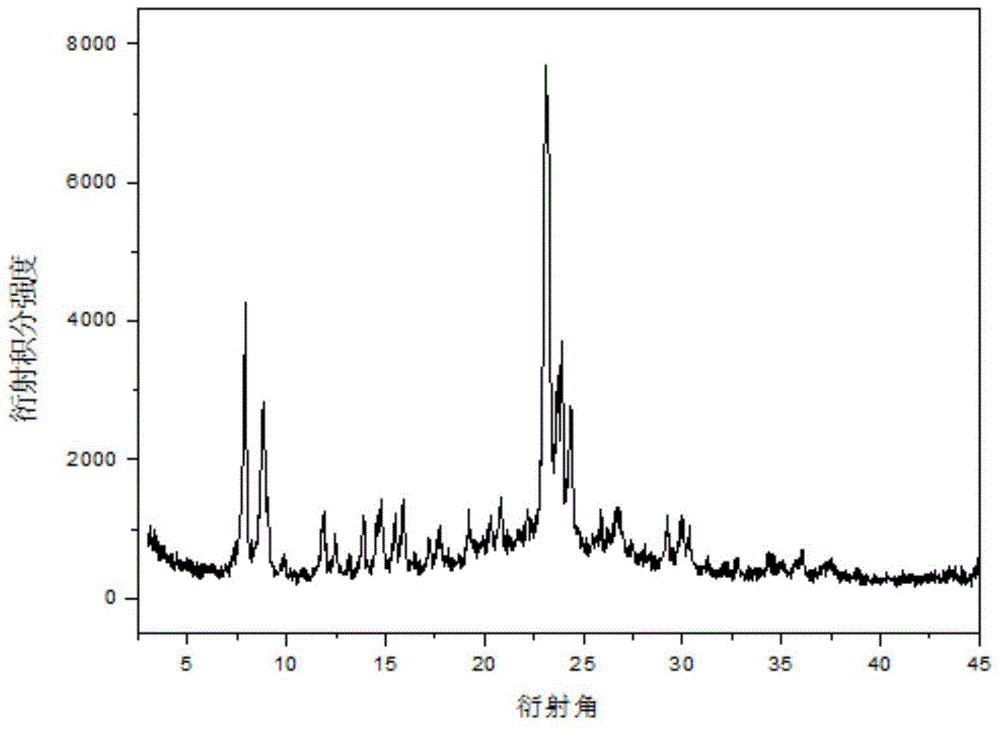

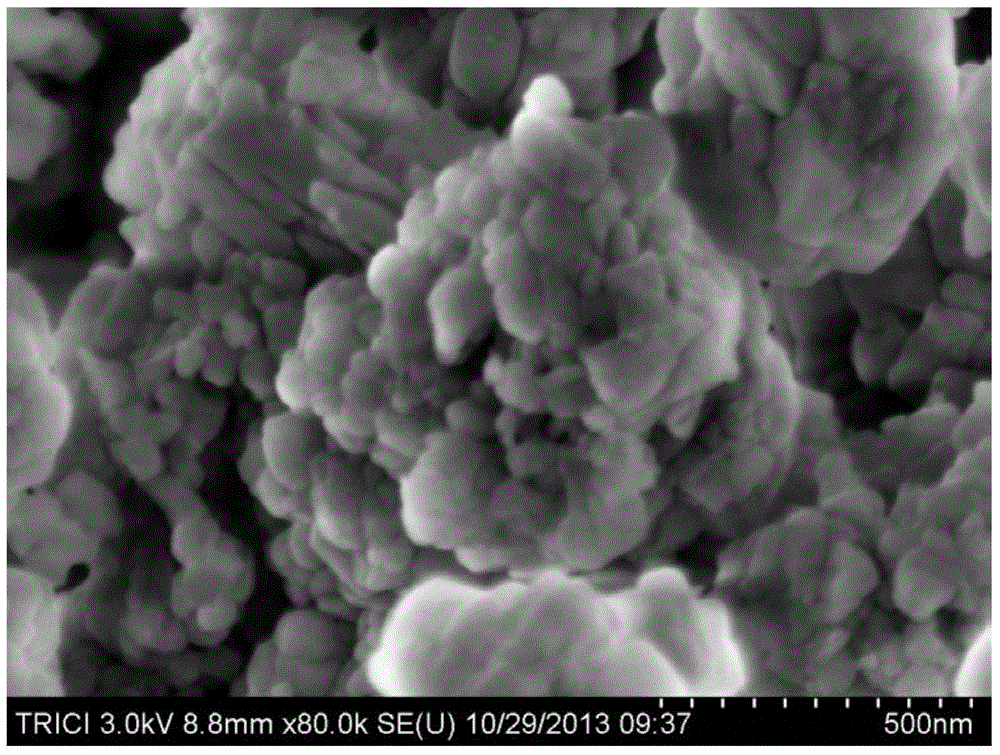

Embodiment 1

[0025] Weigh 18g of NaOH solid and dissolve it in 1160g of deionized water, slowly add 520g of acidic silica sol under mechanical stirring, and continue stirring to form a sol. Add 25.8g of template agent TEAC, stir evenly, slowly add 7.8g of aluminum sulfate under stirring, mechanically stir continuously during the adding process, so that the reactant is latex-like. After aging at room temperature for 8 hours, the latex-like reactant was added to a dynamic stirring reactor for programmed temperature hydrothermal crystallization. The heating rate of the reactor was 2°C / min. The crystallization temperature is 180°C and the crystallization time is 48h. The resulting product is filtered and washed until the filtrate is neutral, and after drying and roasting, 175g of ZSM-5 type zeolite molecular sieve is obtained. Through XRF analysis, SiO 2 / Al 2 o 3 =133.69, Na 2 The O content is 0.0485%, and the average crystal grain diameter is 50nm.

Embodiment 2

[0027] Weigh 22g of NaOH solid and dissolve it in 1160g of deionized water, slowly add 520g of acidic silica sol under mechanical stirring, and continue stirring to form a sol. Add 25.8g of template agent TEAC, stir evenly, slowly add 11.4g of aluminum sulfate under stirring, mechanically stir continuously during the addition process, so that the reactant is latex-like. After aging at room temperature for 8 hours, the latex-like reactant was added to a dynamic stirring reactor for programmed temperature hydrothermal crystallization. The heating rate of the reactor was 2°C / min. The crystallization temperature is 180°C and the crystallization time is 48h. The resulting product is filtered and washed until the filtrate is neutral, dried and roasted to obtain 170 g of ZSM-5 type zeolite molecular sieve, which is analyzed by XRF, and SiO 2 / Al 2 o 3 =98.86,Na 2 The O content is 0.0694%, and the average crystal grain diameter is 55nm.

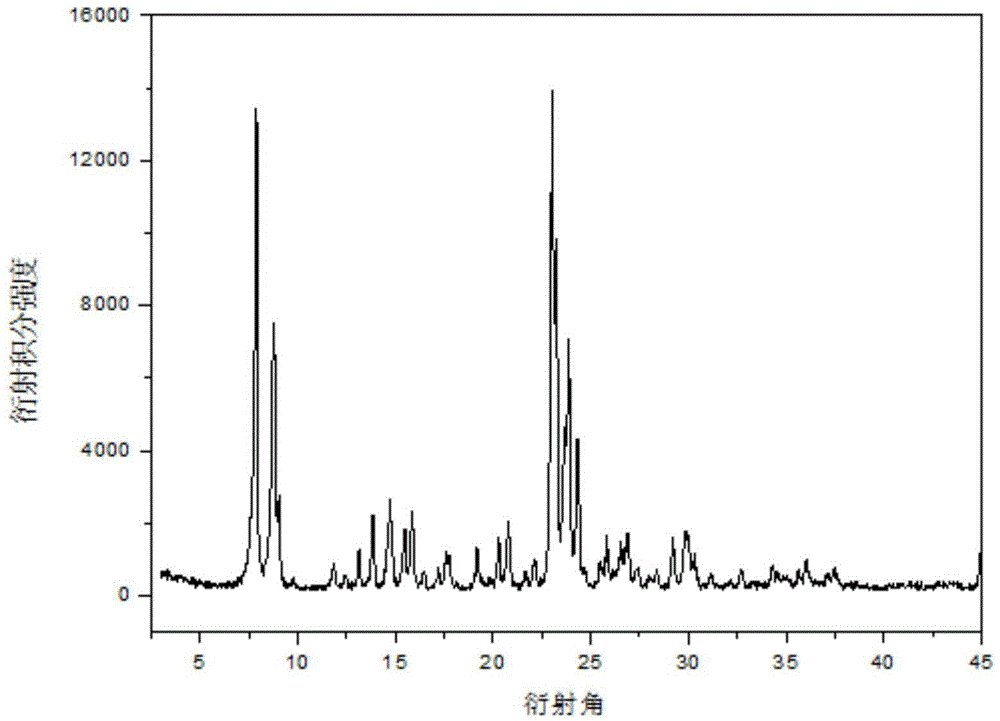

Embodiment 3

[0029] Weigh 24g of NaOH solid and dissolve it in 1160g of deionized water, slowly add 520g of acidic silica sol under mechanical stirring, and continue stirring to form a sol. Add 25.8g of template agent TEAC, stir evenly, slowly add 11.4g of aluminum sulfate under stirring, mechanically stir continuously during the addition process, so that the reactant is latex-like. After aging at room temperature for 8 hours, the latex-like reactant was added to a dynamic stirring reactor for programmed temperature hydrothermal crystallization. The heating rate of the reactor was 2°C / min. The crystallization temperature is 180°C and the crystallization time is 48h. The resulting product is filtered and washed until the filtrate is neutral, and after drying and roasting, 175g of ZSM-5 type zeolite molecular sieve is obtained. Through XRF analysis, SiO 2 / Al 2 o 3 =101.27,Na 2 The O content is 0.114%, and the average crystal grain diameter is 53nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com