High purity NiPt alloy target material and preparation method thereof

An alloy target and high-purity technology, which is applied in the field of high-purity NiPt alloy sputtering target and its preparation, can solve the problems of large loss of NiPt alloy target material and achieve the effect of fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

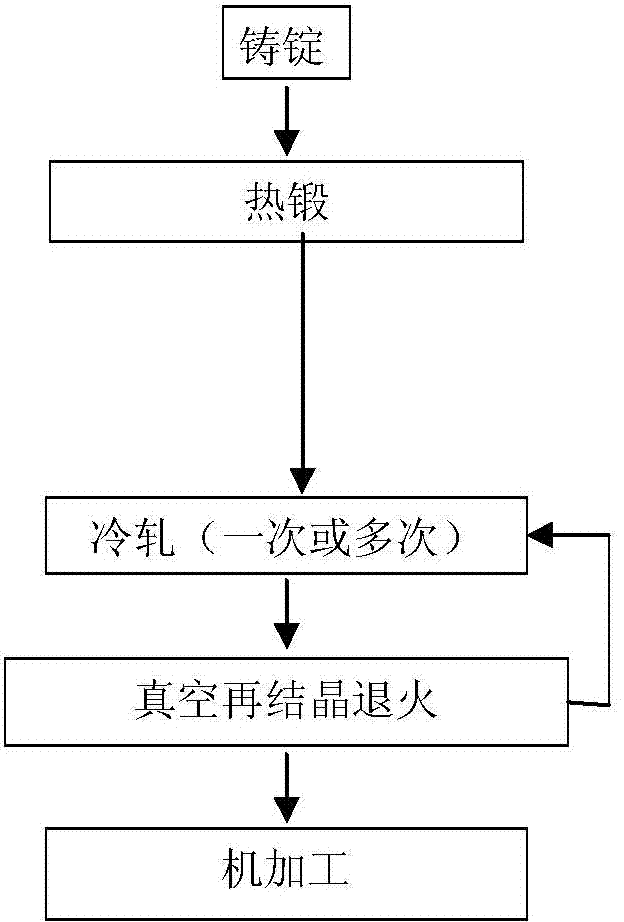

Method used

Image

Examples

Embodiment 1

[0032] A 3N5 NiPt ingot with a Ni:Pt mass ratio of 95:5 is heated and forged at 900-1000°C to form a billet of the desired shape. Broken as-cast structure.

[0033] The billet is rolled by a rolling mill, and the rolling method is cross rolling. The pass deformation is 5%-35%, the initial rolling deformation is 10%, and when the final thickness is close to the desired billet thickness, the pass deformation is 35%, and the total deformation reaches 95%.

[0034] The billet after rolling is subjected to vacuum heat treatment, and the heat treatment temperature is 800°C.

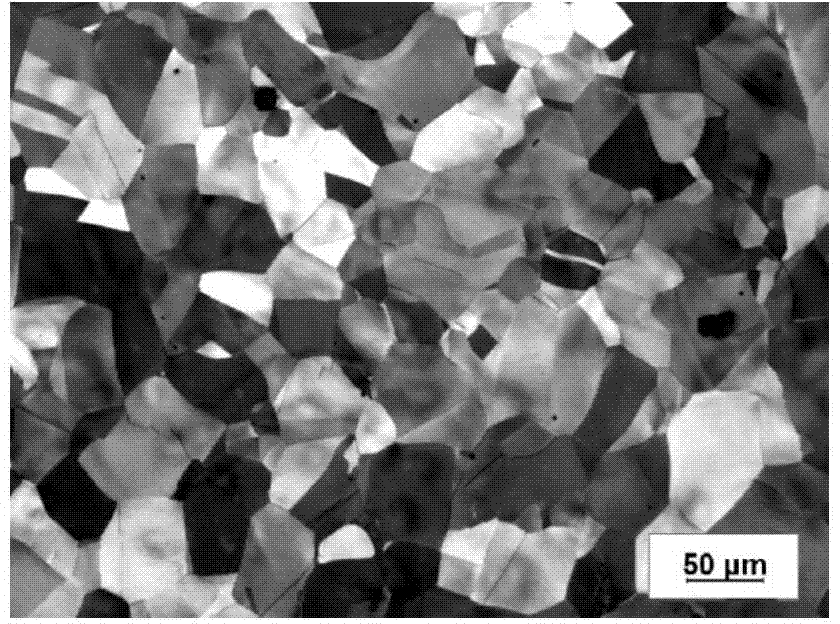

[0035] The metallographic structure of the resulting finished blank is shown in figure 2 , the grain size is about 30 μm.

Embodiment 2

[0037] A 3N5 NiPt ingot with a Ni:Pt mass ratio of 85:15 was heated and forged at 1150°C to form a billet of the desired shape. Broken as-cast structure.

[0038] The billet is rolled by a rolling mill, and the rolling method is cross rolling. The deformation of each pass is maintained at 10%-20%, and the total deformation reaches 80%.

[0039] The billet after rolling is subjected to vacuum heat treatment, and the heat treatment temperature is 900°C.

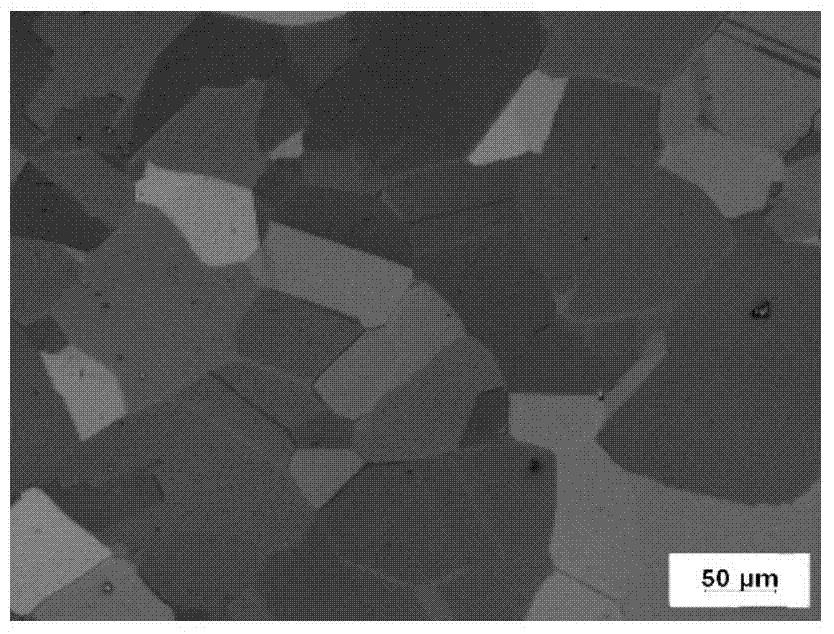

[0040] The metallographic structure of the resulting finished blank is shown in image 3 , the grain size is about 60 μm.

Embodiment 3

[0042] For the preparation of the 4N5 NiPt alloy with higher purity, the 4N5 NiPt ingot with a Ni:Pt mass ratio of 70:30 is heated and forged at 1250°C to form a billet of the desired shape. Broken as-cast structure.

[0043] The billet is rolled at room temperature using a two-roll rolling mill, and the rolling method is cross rolling. The deformation of each pass is maintained at 10%-25%, and the total deformation reaches 70%.

[0044] The billet after rolling is subjected to vacuum heat treatment, and the heat treatment temperature is 1000°C.

[0045] The metallographic structure of the resulting finished blank is shown in Figure 4 , the grain size is about 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com