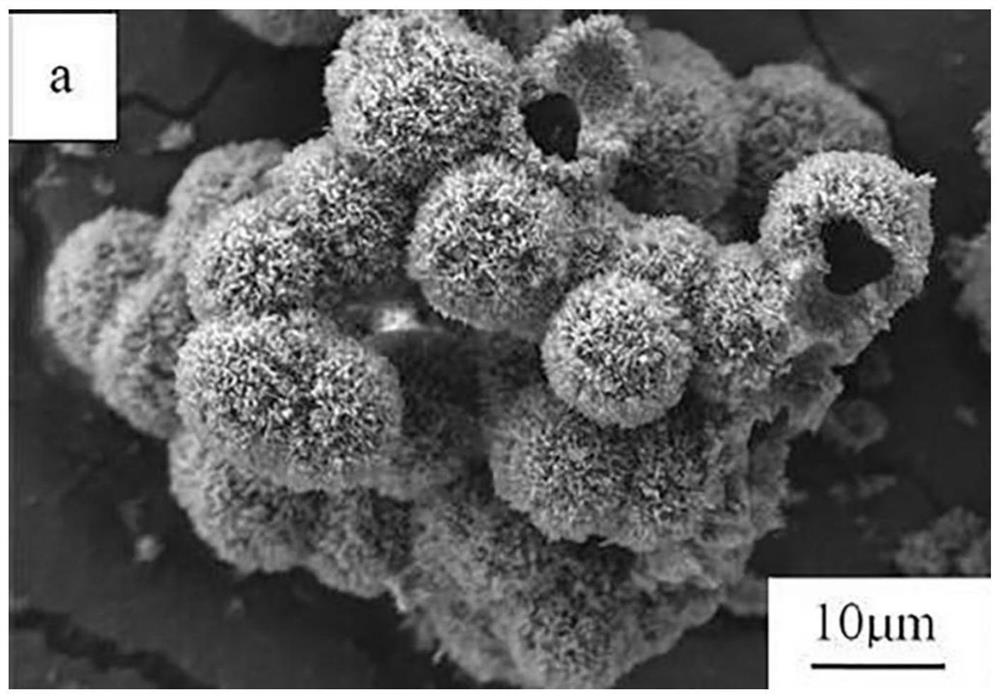

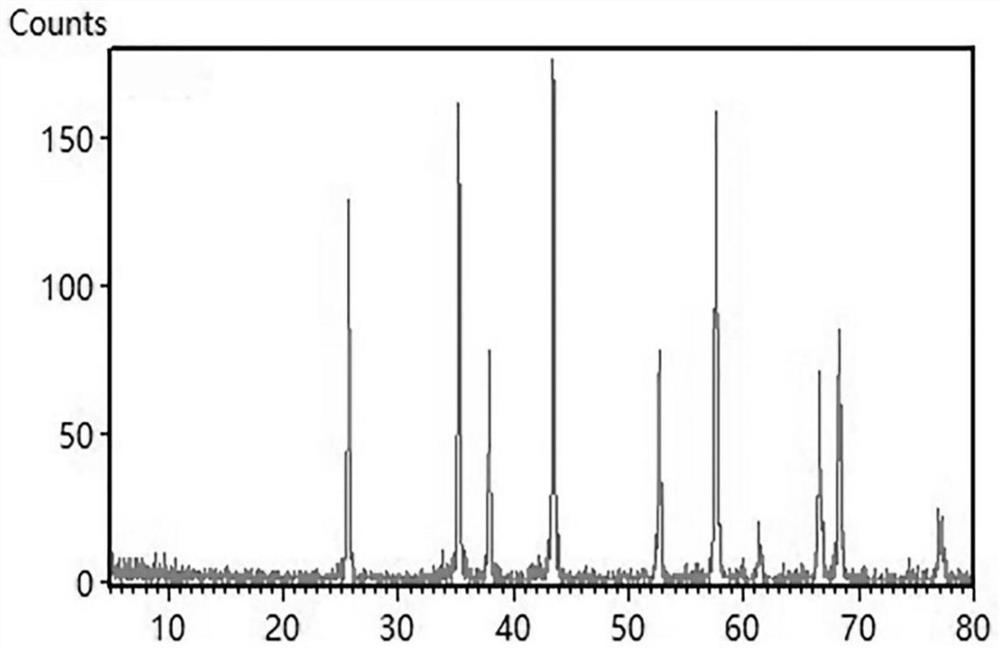

Method for preparing self-assembled hollow alumina microspheres by taking sesbania gum as template

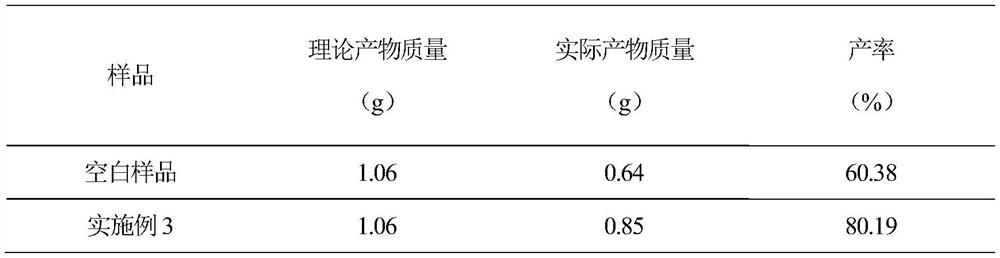

A hollow alumina and self-assembly technology, applied in the field of materials, can solve the problems of difficulty in realizing alumina preparation, difficulty in large-scale promotion, limitation of alumina growth specificity, etc., so as to reduce the loss of target products, increase the precipitation width, and increase production. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Add 5.5g of aluminum sulfate octadecahydrate, 6.0g of dicyandiamide and 7.5g of methylpyrrolidone into 70ml of deionized water in sequence, and ultrasonically disperse at 80°C for 25min to obtain a clear solution A;

[0033] Step 2: Gradually add 40ml of safflower gum solution with a concentration of 1.2mol / L dropwise to solution A, then add dropwise an ammonia solution with a concentration of 1.0mol / L until the pH value is 8.5, and finally at a temperature of 160°C with 500r / L The stirring rate of min was heated and magnetically stirred for 25 min to obtain solution B;

[0034] Step 3: Move solution B to a rotary micro-polymerization reactor, and set the following system to react in two stages for 8 hours: the pressure of the first stage is 40Pa, the temperature is 100°C, the rotation speed is 40r / min, and the micro-polymerization reaction time is 2h; the pressure of the second stage is 30Pa, the temperature is 180°C, the rotation speed is 100r / min, the micropo...

Embodiment 2

[0038] Step 1: Add 7.5g of aluminum sulfate octadecahydrate, 5.0g of dicyandiamide and 7.0g of methylpyrrolidone into 60ml of deionized water in sequence, and ultrasonically disperse at 70°C for 15 minutes to obtain a clear solution A;

[0039] Step 2: Gradually add 20ml of 2.4mol / L squash gum solution dropwise to solution A, then dropwise add ammonia solution with a concentration of 1.5mol / L until the pH value is 8.2, and finally at 170°C at 400r / L The stirring rate of min was heated and magnetically stirred for 15 min to obtain solution B;

[0040] Step 3: Move solution B to a rotary micro-polymerization reactor, and set the following system to react for 5 hours in two stages: the pressure of the first stage is 30Pa, the temperature is 80°C, the rotation speed is 100r / min, and the micro-polymerization reaction time is 1h; the pressure of the second stage is 40Pa, the temperature is 200°C, the rotation speed is 80r / min, and the micro-polymerization reaction time is 5h. After ...

Embodiment 3

[0046] Step 1: Add 6.5g of aluminum sulfate octadecahydrate, 7.0g of dicyandiamide and 6.2g of methylpyrrolidone into 80ml of deionized water in sequence, and ultrasonically disperse at 60°C for 22min to obtain a clear solution A;

[0047] Step 2: Gradually add 30ml of 2.0mol / L squash gum solution dropwise to solution A, then dropwise add ammonia solution with a concentration of 0.6mol / L until the pH value is 9.2, and finally at 180°C at 450r / L The stirring rate of min was heated and magnetically stirred for 20 min to obtain solution B;

[0048] Step 3: Move solution B to a rotary micro-polymerization reactor, and set the following system to react for 7 hours in two stages: the pressure of the first stage is 20Pa, the temperature is 60°C, the rotation rate is 70r / min, and the micro-polymerization reaction time is 1.5h; the pressure of the second stage is 50Pa, the temperature is 160°C, the rotation speed is 120r / min, the micro-polymerization reaction time is 4h, and the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com