Patents

Literature

248 results about "Sesbania gum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind general multi-purpose foam fire-extinguishing agent

InactiveCN101125243ASimple production processReduce water consumptionFire extinguisherSalt freeAlkyl polyglycoside

The invention relates to an A popular type multifunctional foam fire extinguishing agent, which mainly consists of a protecting colloid consisting of microlite chitin, sesbania gum and hydroxyethyl cellulose; vesicant consisting of polyoxyethylene fatty alcohol sodium sulfate, alkyl polysaccharide glycoside, salt free imidazoline and hydrocarbon surface active agent; burn resisting film forming agent consisting of silicone surface active agent, fluorocarbon surface active agent and fluorocarbon silicone surface active agent; flame retardant comprising one or a plurality of condensed phosphate, borax and boric acid; addition agent consisting of short chain alcohol and ether and metal salt; osmotic agent which is high efficient osmotic agent BS or rapid osmotic agent T; and water margin. Being applicable for the prior various foam fire extinguishing devices, the fire extinguishing agent not only can put out the polar and non-polar A, B fires, but also can effectively put out the polar and non-polar mixture fires with any ratio with little fire extinguishing agent and water. The invention has the advantages of simple processing technique, no special facility, low cost and no environmental pollution in production and usage.

Owner:只茂海

Anti-vein precoated sand and preparation method thereof

InactiveCN103567357AAnti-sticking sand strengthStrong anti-veining abilityFoundry mouldsFoundry coresSesbania gumPhenol

The invention discloses anti-vein precoated sand and a preparation method thereof. The anti-vein precoated sand is prepared from the following raw materials in parts by weight: 80-90 parts of quartz sand, 15-25 parts of menaccanite, 10-15 parts of spodumene, 2-3 parts of boric acid, 2-3 parts of thermoplastic phenolic resin, 0.5-1 part of thermosetting phenol resin, 5-10 parts of cement clinker, 4-7 parts of sulphite liquor, 3-5 parts of corn flour, 2-3 parts of sesbania gum, 1-2 parts of ammonium benzoate, 0.5-0.8 part of gamma-aminopropyl triethoxy silicane, 3-6 parts of dioctyl phthalate, 7-11 parts of urotropine, 2-4 parts of calcium stearate and 3-5 parts of composite powder. The anti-vein precoated sand has strong anti-sand burning and anti-vein capacities, also has the characteristics of high strength, good liquidity, low gas evolution, good heat resistance, good gas permeability and the like, can obviously reduce or eliminate defects of vein, sand burning, pores and the like, effectively improves quality of the inner surface and the outer surface of a casting and is applicable to production of a gray iron bulb iron steel casting.

Owner:TONGLING JINGWEI FLUID SCI & TECH

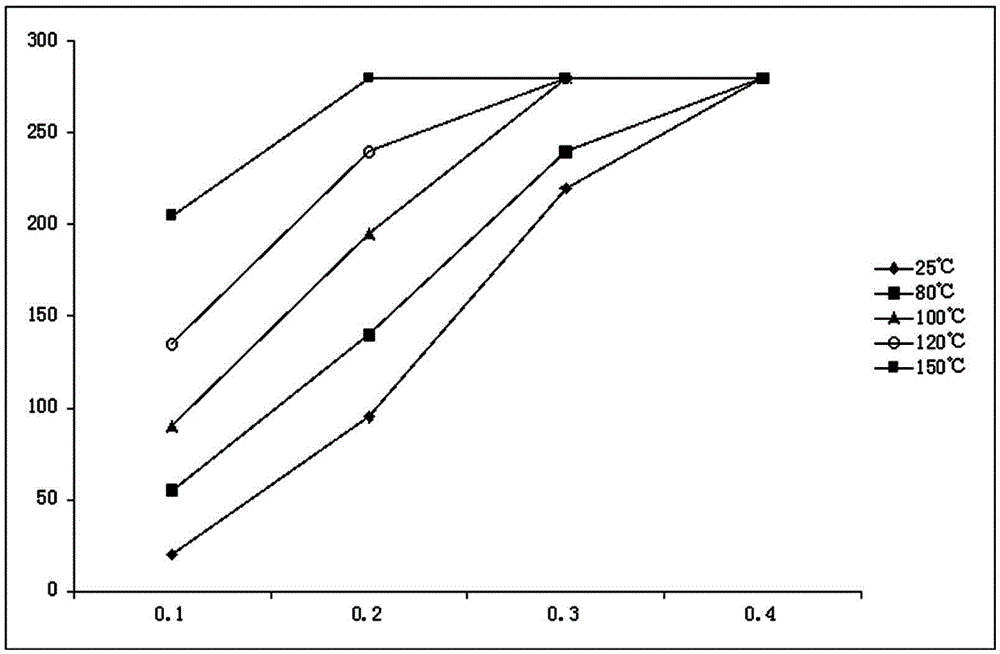

Seawater-based fracturing fluid for fracturing sea high-temperature oil-gas reservoir

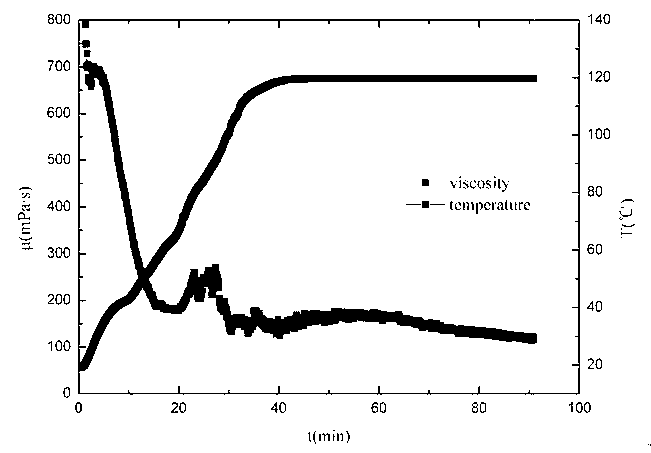

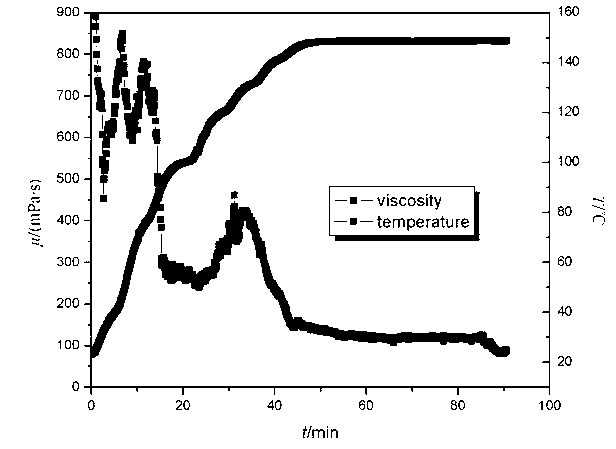

ActiveCN103215024AFulfil requirementsControllable delay timeDrilling compositionCross-linkFracturing fluid

The invention discloses a seawater-based fracturing fluid for fracturing a sea high-temperature oil-gas reservoir and relates to the technical field of cross-linked gel fracturing fluid. The seawater-based fracturing fluid comprises a base solution, a cross-linking agent and a thickening agent, wherein the base solution comprises the components (in percentage by weight) in terms of the weight of the prepared seawater-based fracturing fluid total solution as follows: 0.3%-0.8% of thickening agent, 0.1%-0.3% of pH regulating agent, 0.1%-0.5% of discharge aiding agent and the balance being seawater; relative to the mass fraction of the base solution, the cross-linking agent is 0.4%-0.6%; and the thickening agent refers to guar gum, carboxy-methyl hydroxypropyl guar gum, hydroxypropyl guar gum, fenugreek gum or sesbania gum. The seawater-based fracturing fluid is adopted, so that the dissolving speed of the thickening agent is quick, and therefore, direct mixing and continuous constructing can be realized, and therefore, the seawater-based fracturing fluid is in particular suitable for the fracturing construction of the sea high-temperature oil-gas reservoir. Meanwhile, the fracturing fluid can be continuously sheared for 90 minutes under the conditions of 150 DEG C and 170s<-1>, so that the viscosity is kept to be 70mPa.s or more.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Rancidity removed walnut kernel containing balsam pear and preparation method thereof

InactiveCN104824731AImprove film-forming propertiesHas moisture resistanceNatural extract food ingredientsFood ingredient as coating agentPEARWater Chestnuts

The invention discloses a rancidity removed walnut kernel containing balsam pear. The walnut kernel is prepared from the following raw materials by weight: 40-50 parts of walnut, 18-22 parts of balsam pear, 10-13 parts of banana, 12-14 parts of dark plum powder, 12-13 parts of hawthorn, 3-4 parts of green bean cake, 8-9 parts of coconut milk, 1.5-2 parts of Chinese angelica, 1.8-2 parts of wild chrysanthemum, 0.5-1 part of water chestnut stems, emulsifier, sesbania gum and zein. The method uses prolamin to carry out the coating treatment on walnuts, so as to isolate outside moisture and oxygen, inhibit oxidative rancidity process of walnuts and prolong the shelf life of walnut kernel; the added traditional Chinese medicines such as Chinese angelica and wild chrysanthemum enhance the health care effects of walnut kernel, such as clearing heat, calming the liver, enriching blood and invigorating the circulation of blood.

Owner:HEFEI FULAIDUO FOOD

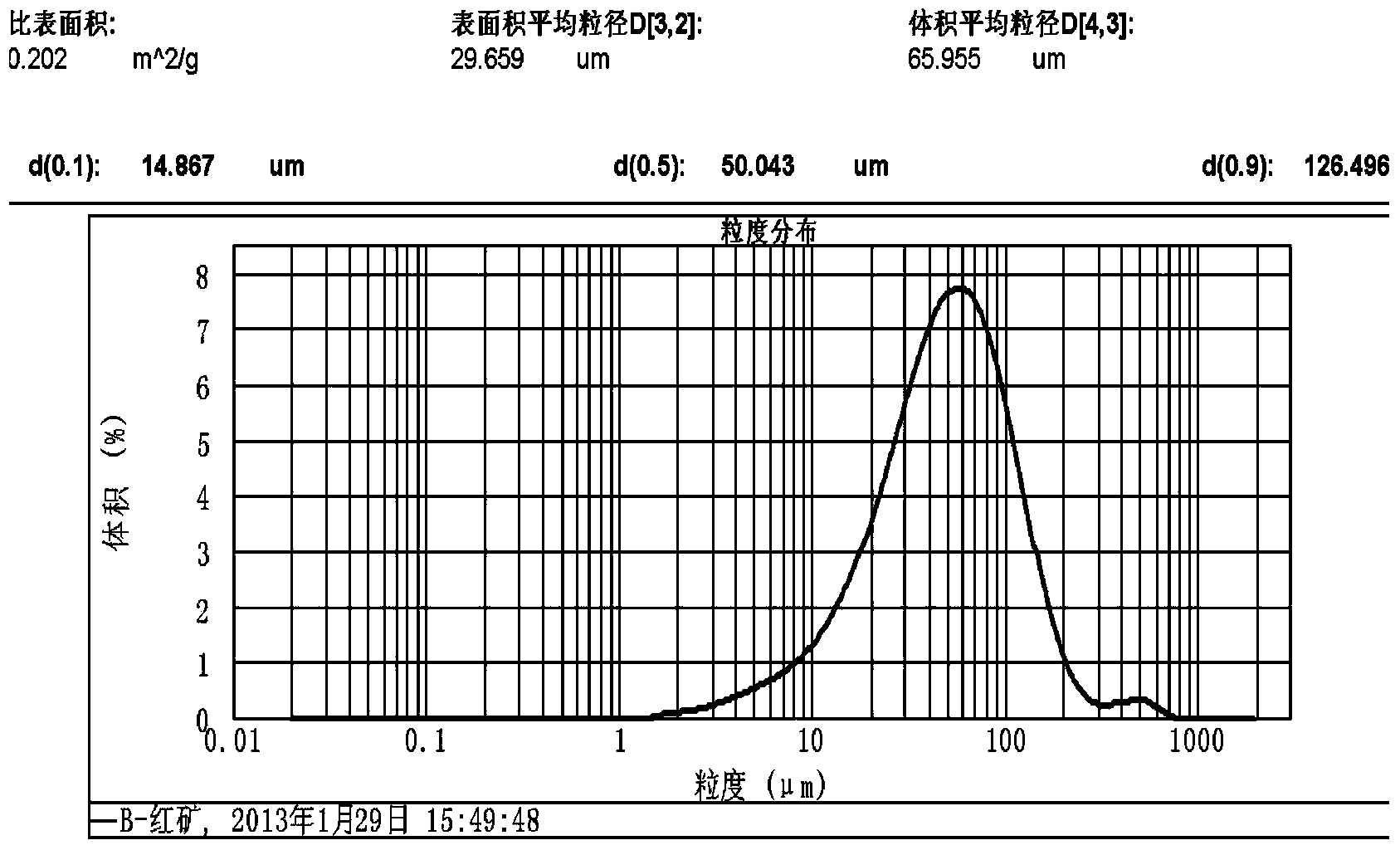

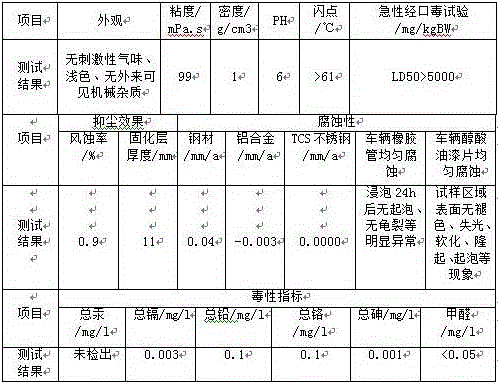

Dust suppressant for suppressing mineral powder and dust exposed on ground and preparation method thereof

InactiveCN109575882ADoes not affect growthHigh viscosityOther chemical processesInstabilitySesbania gum

The invention relates to a dust suppressant for suppressing mineral powder and dust exposed on the ground and a preparation method thereof. The dust suppressant comprises dust suppressing powder and water according to a mass ratio of 1:(30-150), the dust suppressing powder comprises, by weight, 5-45 parts of gelatinizing agent, 15-50 parts of auxiliary material and food-grade preservative accounting for 2-18% of total mass of the dust suppressing powder, the gelatinizing agent comprises one or multiple of sesbania gum, carboxymethylcellulose, polyacrylamide, latex powder, maltodextrin, guar gum and xanthan gum, and the auxiliary material comprises tapioca gelatinized starch, sodium humate, glucose, humic acid, attapulgite and diatomite. Through reasonable matching with modified starch, high bonding force with the mineral powder and good wind-erosion-resistant dust suppressing effect, a prepared dust suppressant solution is low in viscosity, little in power needed for spraying, high instability, less prone to layering and low in using cost, and production raw materials of the dust suppressant itself are easy to get and low in cost.

Owner:北京首创大气环境科技股份有限公司

Production method for preparing high-purity oligosaccharides by hemicellulose enzymolysis

The invention provides a method for preparing high-purity oligosaccharides by the enzymolysis of hemicellulose containing mannosan, and a product which is a high-effect beta-mannase BM-II produced by fermenting bacillus subtilis TQBm with the preservation No. of CCTCC No: M 211147. Konjac glucomannan, guar gum, sophora bean gum, sesbania gum and other hemicelluloses containing the mannosan are hydrolyzed into relatively small molecule materials, and then are desalted, decolored and deodorized through centrifugal separation, flocculation clarification and ion exchange techniques, large molecule materials in sugar solution are separated by the combination of an ultrafiltration technique and a molecular sieve chromatography technique, and finally the high-purity oligosaccharides is prepared through concentration and drying. The method for preparing the high-purity oligosaccharides disclosed by the invention has the advantages of simple operation, good separation effect, low cost and no chemical pollution, and industrialized production can be realized. The oligosaccharides product disclosed by the invention can obviously proliferate bifidobacteria in the human intestinal tract and otherbeneficial bacteria and obviously reduce enterobacter and other harmful bacteria, has the functions of blood sugar and blood fat reduction and immunoregulation, and is a novel raw material and assistant for gastrointestinal health, blood sugar and fat reducing, immunoregulation and disease resisting and preventing medicines.

Owner:深圳绿天琪生物医药有限公司

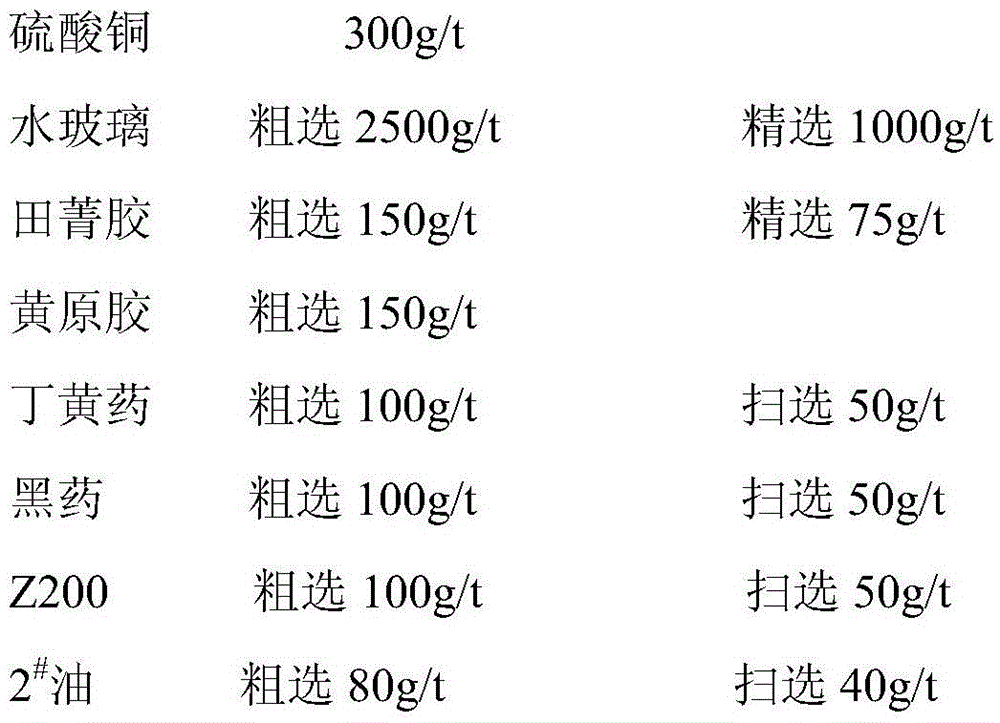

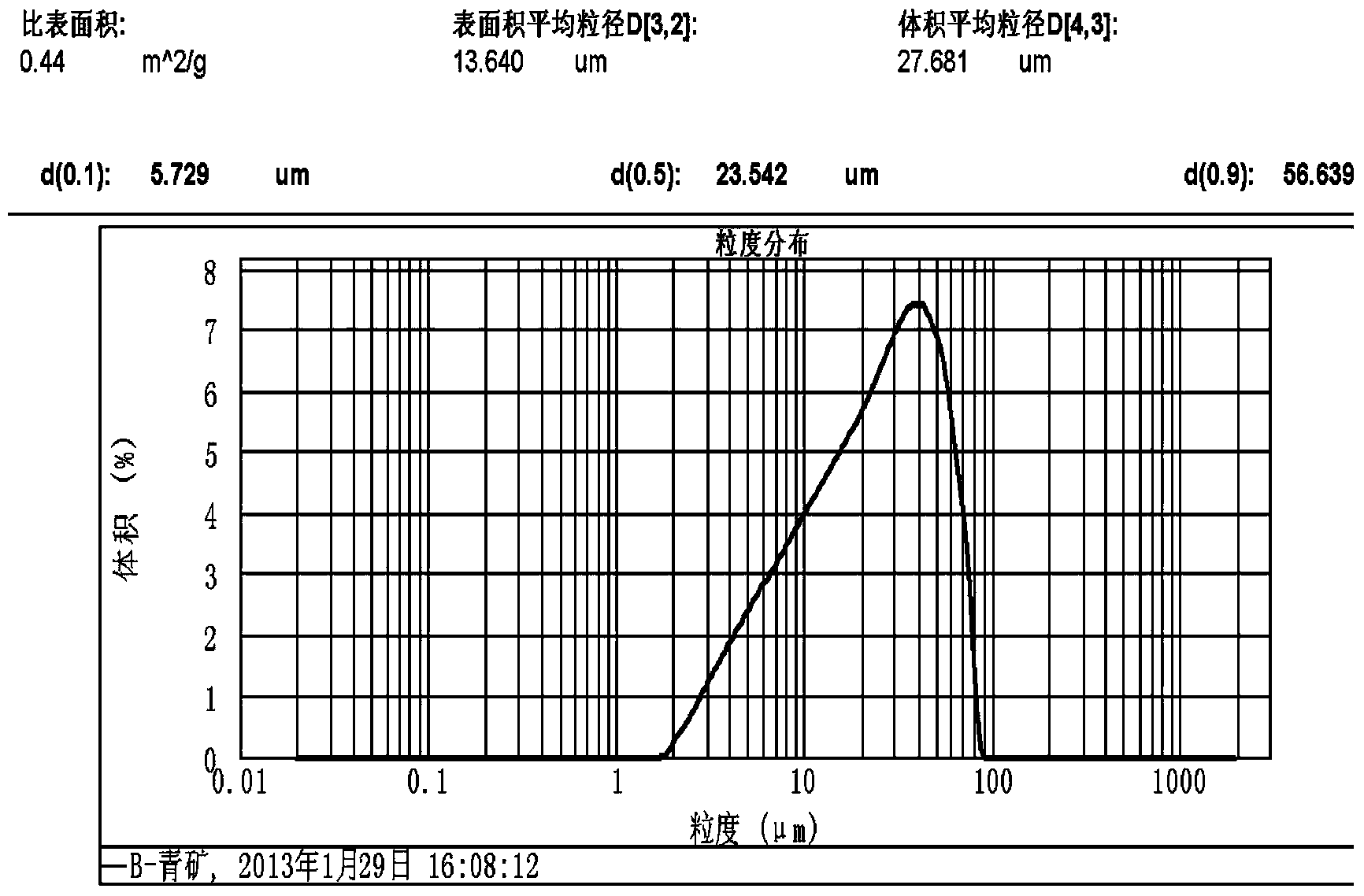

Floatation separation method for copper pyrites and iron pyrites

The invention discloses a floatation separation method for copper pyrites and iron pyrites. According to the method, copper sulfate serves as an activating agent of the copper pyrites, sodium silicate, sodium hexametaphosphate and the like serve as an inhibitor of a gangue mineral and a pulp dispersing agent, sesbania gum serves as an inhibitor of the iron pyrites, Z200 and the like serve as a collecting agent of the copper pyrites, 2# oil serves as a foaming agent, the floatation separation is carried out, and flotation of the iron pyrites can be effectively restrained. Under the neutrality condition, floatation separation of the copper pyrites and the iron pyrites can be effectively achieved, and under the condition that the copper content of fed ore is 0.5%-0.9% and the sulfur content is 3%-11%, the copper concentrate with the copper content of 18%-21% can be obtained after flotation separation, and the recycling rate can reach 77%-85%.

Owner:CENT SOUTH UNIV

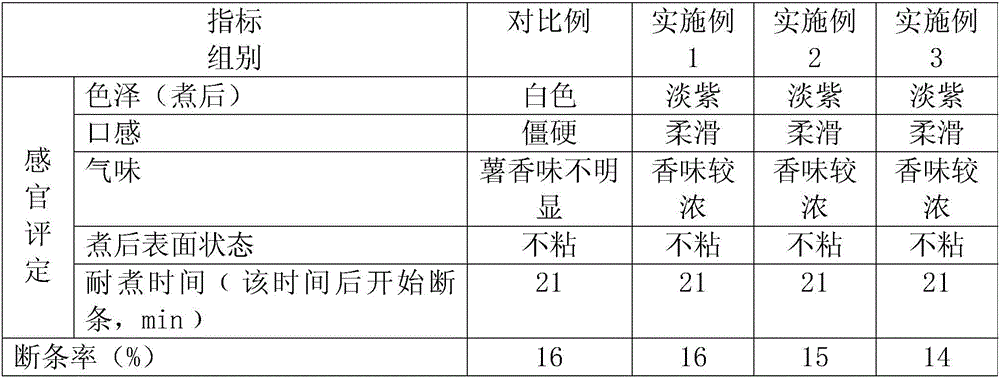

Full potato flour vermicelli with increased anthocyanin content and making method thereof

The invention provides full potato flour vermicelli with the increased anthocyanin content and a making method thereof, and belongs to the field of food processing. The vermicelli is made from full potato flour, celery, black fungi, sucrose, 80-mesh early indica rice, blueberry powder, tamarind gum, kelp dietary fiber, sesbania gum, buckwheat rutin, garlic powder, calcium chloride, ferrous sulfate, ground cloves powder, cinnamon bark and flour. The anthocyanin content of the full potato flour vermicelli can reach 82.44-83.70 mg / 100 g, and therefore the vermicelli has an obvious health care effect on the aspects of improving sleep and eyesight, promoting blood circulation, resisting aging and the like. The vermicelli is pale purple, rich in nutrition, good in flexibility, low in breakage rate, smooth in mouthfeel, strong in fragrance, long in freshness keeping period and easy to be popular with mass customers.

Owner:定西薯宝农科清真食品有限公司

Qi benefiting and blood nourishing fragrant and hot walnut kernel and preparation method thereof

InactiveCN104886662AImprove film-forming propertiesFruityMulti-step food processesFood dryingAdditive ingredientGlycerol

The present invention discloses a qi benefiting and blood nourishing fragrant and hot walnut kernel which is made of following raw materials in parts by weight: walnut kernels 80-90 parts, watermelon seed kernels 10-20 parts, fish roes 20-30 parts, corn pollen 7-8 parts, oolong tea 8-10 parts, papaya 8-10 parts, capsicum frutescens 4-5 parts, kadsura longipedunculata 2-2.4 parts, elaeagnus pungens 0.7-1.5 parts, Chinese wolfberry fruits 0.7-2 parts, glycerol, sesbania gum, zein, and an appropriate amount of 3%-4% sodium carbonate aqueous solution. The qi benefiting and blood nourishing fragrant and hot walnut kernel utilizes zein to conduct film coating treatment on walnut kernels, which can completely cut off walnut kernels from the outside moisture and oxygen, inhibit oxidative and rancid process of walnut kernels, and extend the shelf life of walnut kernels; and the added kadsura longipedunculata, elaeagnus pungens and other traditional Chinese medicines increase the health-care efficacies of walnut kernels in clearing liver and improving eyesight, supplementing blood and beautifying features, and calming mind and benefiting qi.

Owner:石台县横渡镇香口二郎家庭农场

Building glue

InactiveCN104164201AEnergy saving and environmental protectionHigh bonding strengthNon-macromolecular adhesive additivesStarch adhesivesSodium BentonitePotato starch

Disclosed building glue is prepared from the following raw materials in parts by weight: 15-30 parts of sesbania gum, 7-14 parts of sodium tripolyphosphate, 20-30 parts of triethanolamine, 4-8 parts of sodium-base bentonite, 10-13 parts of talcum powder, 15-25 parts of acetone, 6-9 parts of sodium bisulfite, 4-8 parts of hydroxyethyl cellulose, 4-10 parts of sodium polyacrylate aqueous solution with the concentration of 0.2%, 6-10 parts of urea, 7-12 parts of sodium hydroxide, and 6-11 parts of potato starch. The provided building glue is energy-saving, environment-friendly, non-toxic, high in bonding strength, free of powder falling phenomenon, easy for batch scraping, and excellent in water retention property.

Owner:QINGDAO JISHUNLONG TRADING

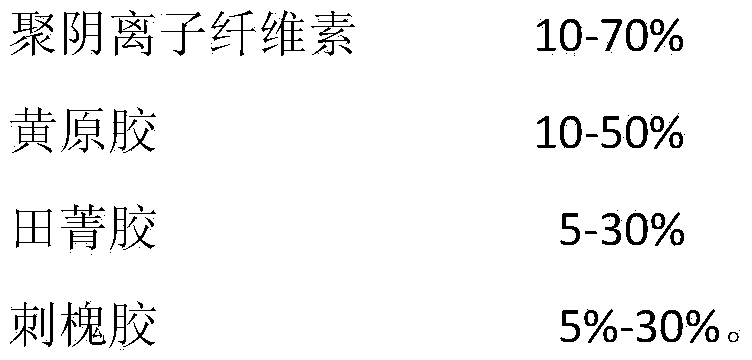

Iron ore powder pellet adhesive and application thereof

The invention discloses an iron ore powder pellet adhesive and an application thereof. Chemical components of the iron ore powder pellet adhesive comprise polyanionic celluloses, xanthan gum, sesbania gum and locust glue. An application of the iron ore powder pellet adhesive comprises the following steps: during preparing pellets, firstly preparing a mixture which comprises the iron ore powder pellet adhesive, sodium carbonate and bentonite, and then adding 0.9-1.1% of mixture to iron concentrate powder. After the components are mixed, the components can react with each other by using the synergistic effect of high-viscosity water-soluble macromolecules, so that the viscosity and the consistency are improved, the overall binding power is increased, and the overall using amount of the adhesive in the iron ore powder is reduced. The good pelleting index can be obtained under the condition that the adhesive only accounts for 0.009%-0.011% of the iron ore powder.

Owner:UNIV OF SCI & TECH LIAONING

Foamed plastic binder for lost foam casting of valve

InactiveCN105290312AImprove adhesionReduce manufacturing costFoundry mouldsFoundry coresManufacturing technologyNano al2o3

The invention discloses a foamed plastic binder for lost foam casting of a valve, and relates to the technical field of valve manufacturing. The foamed plastic binder is made from, by weight, 70-80 parts of polymerized rosin, 15-20 parts of bismaleimide, 13-18 parts of modified starch, 11-15 parts of calcined kaolin, 10-13 parts of sodium polyacrylate, 10-13 parts of maltodextrin, 8-12 parts of gypsum powder, 6-10 parts of nanometer aluminium oxide, 6-10 parts of palm wax, 5-8 parts of sesbania gum, 3-6 parts of dibutyltin dilaurate, 2-4 parts of sodium citrate, 40-50 parts of n-butyl alcohol and 60-70 parts of water. The foamed plastic binder has the characteristics that the production cost is low, the binding effect is good, the use quantity is low and the gas-forming amount is low; besides, gasification is fast, no residue is generated, and the foamed plastic binder is suitable for binding foamed plastic for lost foam casting of the valve.

Owner:HEXIAN KEJIA VALVE CASTING

Grey paper clay material for fabricating relief paintings and method for preparing paper clay material

The invention relates to a paper clay material for fabricating a relief stereo-painting. A grey paper clay material for fabricating a relief painting provided by the invention is prepared from paper pulp, polyvinyl alcohol, borax, white dextrin, Arabic gum, sesbania gum, bamboo charcoal powder, calcium propionate, potassium sorbate, talcum powder, gypsum powder, glycerol, sorbierite and water. The grey paper clay material is good in plasticity and excellent in tackiness and adhesion, thus being high in fixing capability; and after being air-dried and solidified, the material may not be crazed, and is resistant to insolation and acids-bases, anti-freezing, resistant to aging, and corrosion resistant antibacterial, as well as stable in chemical properties and long in service life.

Owner:浙江银太郎动漫文化股份有限公司

Cation modified sesbania gum surface sizing agent and preparation method thereof

InactiveCN103103878AImprove stabilityStrong interference abilityWater-repelling agents additionCross-linkFiber

The invention relates to a cation modified sesbania gum surface sizing agent and a preparation method thereof. The preparation method of the cation modified sesbania gum surface sizing agent comprises the following steps of: adding 5-20 parts of sesbania gum, 2-16 parts of polyoxyethylene, 0.2-20 parts of polyethylene glycol and 4-16 parts of cationic monomer to 800kg-900kg of aqueous solution; adding acid to the solution to regulate the pH to 3-4; regulating the temperature to 80 DEG C to 90 DEG C and reacting for 1 hour to 3 hours; adding 2-14 parts of cross-linking agent, 0.1-10 parts of initiator and 1-10 parts of stearin gum to the solution prepared in the step 1; adding the acid to regulate the pH of the solution to 3-4; regulating the temperature to 80 DEG C to 90 DEG C and reacting for 1 hour to 3 hours; and 100 parts of adding aluminum sulfate aqueous solution with concentration of 40%-80%, and stirring and discharging to obtain the cation modified sesbania gum surface sizing agent. The modified sesbania gum surface sizing agent has the beneficial effects that the sizing agent prepared by carrying out soluble emulsion cationization to vegetable gelatin and synthetic macromolecule compound and carrying out cross-linking grafting copolymerization has the function of reacting with the fiber to form a covalent bond; moreover, the curing time during the sizing process can be shortened, and the water resistance and strength of the paper are obviously improved.

Owner:李端

Dust depressor for railway coal transport and use method of dust depressor

InactiveCN106675522AExtended service lifeStop evaporationOther chemical processesDust removalDispersityAdditive ingredient

The invention relates to a dust depressor for railway coal transport and a use method of the dust depressor. The dust depressor is prepared from components in parts by weight as follows: 15-25 parts of xanthan gum, 20-38 parts of carboxymethyl cellulose, 10-28 parts of modified starch and 25-40 parts of sesbania gum powder. The dust depressor is prepared from multiple pure natural vegetable gum through refinement and compounding, the problems about dispersity, permeability and dry strength are solved in combination with an instant dissolution technology of the use method, and the dust depressor has a good anti-evaporation characteristic and long service life and can be made into a water solution on the scene to facilitate transportation and spray operation as well as scene operation. Due to the synergistic function of ingredients, the dust depressor has multiple functions on adhesion, wetting and water retention. The preparation method is simple, convenient to operate, low in cost and environment-friendly, facilitates large-scale production, can prevent dust pollution and has an environment protection function.

Owner:河南省九金科技有限公司

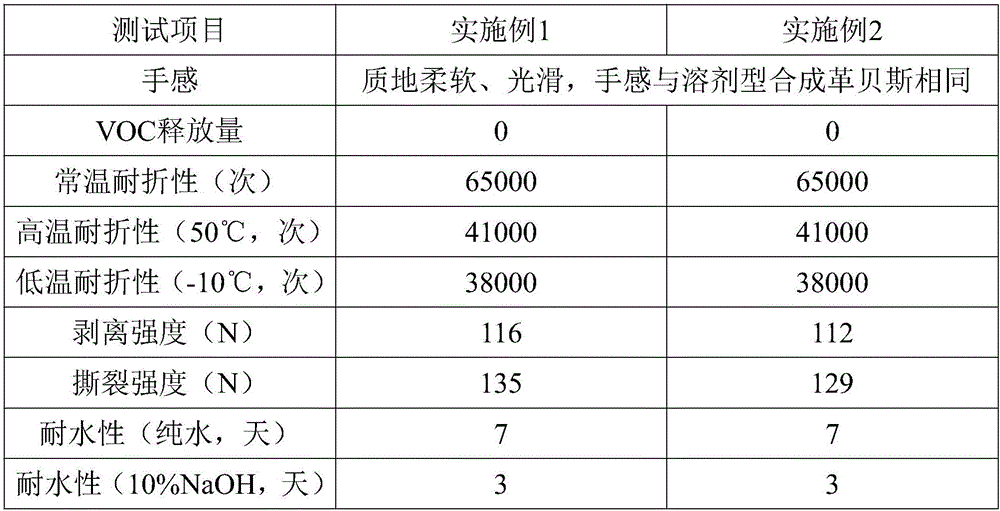

Waterborne polyurethane slurry for producing synthetic leather bass through wet method

The invention discloses waterborne polyurethane slurry for producing a synthetic leather bass through a wet method. The waterborne polyurethane slurry relates to the technical field of synthetic leather processing, and is prepared from the following raw materials in parts by weight: 60 to 70 parts of waterborne polyurethane resin, 5 to 10 parts of waterborne acrylic resin, 5 to 10 parts of hydrogenated ester gum, 4 to 8 parts of polyvinyl alcohol resin, 4 to 8 parts of chlorinated polyethylene, 3 to 6 parts of terpene resin, 3 to 6 parts of microcrystalline cellulose, 2 to 4 parts of C5 petroleum resin, 2 to 4 parts of hydrogenated palm oil, 2 to 4 parts of activated clay, 1 to 2 parts of dipentaerythritol, 1 to 2 parts of sesbania gum, 0.5 to 1 part of tea seed powder, 0.5 to 1 part of molecular sieve raw powder, 0.5 to 1 part of nanometer titanium dioxide, and 200 to 250 parts of water. The waterborne polyurethane slurry provided by the invention adopts the water as a solvent, so that the problems of environmental pollution and harm to human health existed by using an organic solvent are avoided; the curing time of an intumescent coating is short, no harmful gas escapes during a curing process, and the prepared synthetic leather bass and a solvent type synthetic leather bass have close textures and operational performance.

Owner:南平慧薇网知识产权营运有限公司

Environmentally friendly diatom ooze latex paint and preparation method thereof

InactiveCN107083124AEfficient removalPurify indoor airAntifouling/underwater paintsPaints with biocidesEpoxyHazardous substance

The invention discloses environmentally friendly diatom ooze latex paint and a preparation method thereof. The environmentally friendly diatom ooze latex paint is prepared from 60-63 parts of acrylate emulsion, 45-50 parts of epoxy resin, 40-43 parts of diatom ooze, 35-36 parts of glutinous rice glue, 30-32 parts of heat insulation filler, 29-30 parts of negative-ion natural mineral substance powder, 26-28 parts of bamboo vinegar liquid, 23-25 parts of essential oil component, 18-21 parts of antimicrobial powder, 15-16 parts of sesbania gum, 10-15 parts of additive and 65-68 parts of water. Free formaldehyde, benzene, ammonia and hazardous substances in the air and peculiar smell can be effectively removed, indoor air is purified, and the environmentally friendly diatom ooze latex paint is environmentally friendly and safe.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Walnut kernel with polygonatum odoratum and jasmine and preparation method thereof

The invention discloses a walnut kernel with polygonatum odoratum and jasmine. The walnut kernel with polygonatum odoratum and jasmine is prepared from the following raw materials in parts by weight: 70-75 parts of walnut kernel, 9-15 parts of fish eggs, 18-23 parts of rice slurry, 6-8 parts of rice vinegar, 2-2.2 parts of Chinese prickly ash, 5-8 parts of jasmine, 2-3 parts of beewax, 0.8-1.1 part of polygonatum odoratum, 1.8-2.3 parts of common fenugreek seeds, 2-2.4 parts of semen cassia, a proper quantity of emulgators, a proper amount of sesbania gum, a proper amount of zein and a proper amount of 3-4% sodium carbonate solution. The alcohol soluble protein is used for coating the walnut kernel; the outside water and oxygen are isolated; the oxidative rancidity process of the walnut kernel is inhibited; the shelf life of the pecan kernel is prolonged; by virtue of the traditional Chinese herbal medicinal ingredients such as polygonatum odoratum and common fenugreek seeds added into the walnut kernel, the healthcare functions of nourishing yin to moisten dryness, moistening lung, invigorating yang and relieving fatigue of the walnut kernel are added.

Owner:石台县横渡镇香口二郎家庭农场

High-strength iron-ore slag-containing powder thermal insulation mortar and preparation method thereof

High-strength iron-ore slag-containing powder thermal insulation mortar is characterized by comprising the following raw materials in parts by weight: 300 to 340 parts of cement, 50 to 55 parts of cement road slag powder, 20 to 24 parts of iron-ore slag powder, 8 to 10 parts of flaky graphite, 14 to 18 parts of sodium bentonite powder, 5 to 8 parts of sodium carboxymethyl cellulose, 20 to 25 parts of meerschaum powder, 50 to 56 parts of kaolinite powder, 10 to 15 parts of gypsum powder, 4 to 6 parts of hydroxypropyl sesbania gum powder, 5 to 8 parts of xanthan gum, 1 to 2 parts of acrylamide, 3 to 4 parts of borax, 4 to 6 parts of modified nano-carbon powder, and 600 to 650 parts of water. The thermal insulation mortar adopting iron-ore slag powder is high in unit weight, low in heat conductivity, anti-crack, ageing resistant, high in cohesive force, good in workability and construction property, convenient to use, waterproof, impervious, high in compressive strength, convenient to store and transport, and pollution-free.

Owner:BENGBU TIANWANG FISHING NEED SUPPLIES

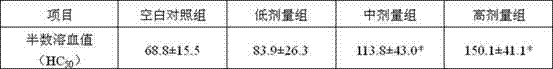

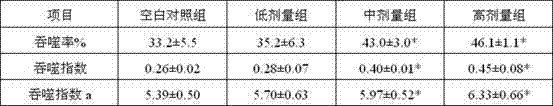

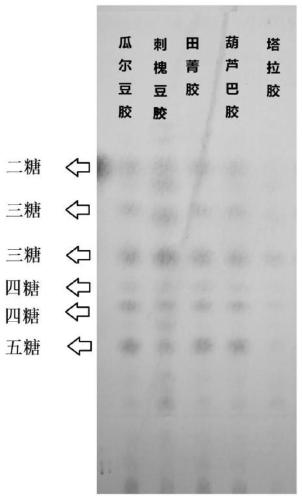

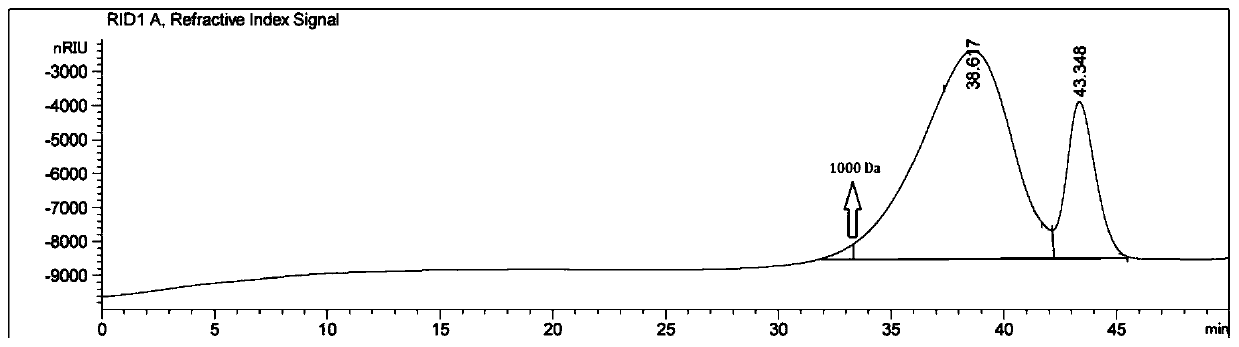

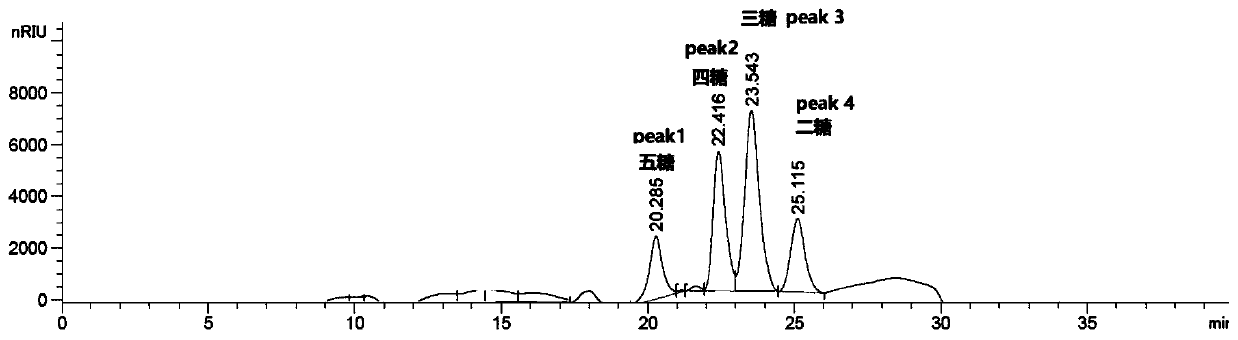

Preparation method of galacto-mannan-oligosaccharides and application of galacto-mannan-oligosaccharides

ActiveCN109811022ARapid Fermentation MetabolismLower pHAccessory food factorsFermentationA-trisaccharideUltrafiltration

The invention discloses a preparation method of galacto-mannan-oligosaccharides and application of the galacto-mannan-oligosaccharides. The preparation method comprises the following steps: (1) performing segmented composite enzymatic hydrolysis on galacto-mannan-oligosaccharides such as guar gum, sesbania gum, locust bean gum, fenugreek gum and Tara gum, wherein the enzyme is a complex enzyme ofacid mannase and cellulase; and (2) by segmented ultrafiltration classification, obtaining degraded galacto-mannan-oligosaccharides which are a mixture of a disaccharide, a trisaccharide, a tetrasccharide and a pentosaccharide. The preparation process is simple and easy, and is environmentally friendly. The conversion rate of the galacto-mannan-oligosaccharides is high, and the galacto-mannan-oligosaccharides are easy to separate. The prepared galacto-mannan-oligosaccharides can be used as prebiotics to be applied to food and animal feed, the proliferation of a butyric acid-production probiotic is promoted, and the intestinal environment is improved.

Owner:NANJING YIXIAN BIOTECHNOLOGY CO LTD +2

Dust suppressant for suppressing mineral powder and bare ground dust and preparation method thereof

InactiveCN109652016ADoes not affect growthHigh viscosityOther chemical processesSesbania gumGuar gum

The invention relates to a dust suppressant for suppressing mineral powder and bare ground dust and a preparation method thereof. The dust suppressant comprises dust suppression powder and water witha mass ratio of 1:(30-150). The dust suppression powder includes 5-45 parts by weight of gelling agents, 5-55 parts by weight of an auxiliary material and a food-grade preservative which accounts for2 to 18 in a thousand of the total mass of the dust suppression powder. The gelling agents include one or more of sesbania gum, carboxymethyl cellulose, polyacrylamide, latex powder, maltodextrin, guar gum and xanthan gum. The auxiliary material is corn pre-gelatinized starch. Through the reasonable collocation of modified starch, the dust depressant has strong adhesion with the mineral powder andgood wind erosion resistance and dust suppression effect. The prepared dust suppressant solution has the advantages of low viscosity, small power required for spraying, good stability, difficult delamination and low use cost. The production raw materials of the dust suppressant is easily available and low in cost.

Owner:北京首创大气环境科技股份有限公司

Cleaning addition agent for cleaning beef bloodstain before making of beef broth

InactiveCN107439913AGuaranteed food safetyImprove the safety of useFood ingredientsVitamin CSesbania gum

The invention discloses a cleaning addition agent for cleaning beef bloodstain before making of beef broth, and relates to the technical field of food processing. The cleaning addition agent is prepared by mixing the following raw materials in parts by weight: 10-20 parts of hydroxypropyl starch-polyglutamic acid-mannitol, 5-10 parts of microcrystalline cellulose-glycine, 0.5-3 parts of a poloxamer 188, 0.5-3 parts of sodium alginate, 0.05-0.5 part of sesbania gum and 0.05-0.5 part of vitamin C powder. The cleaning addition agent can effectively eliminate beef bloodstain, the elimination rate is 99% or above, and based on the situations that the cleaning time is obviously shortened and the consumption of water for cleaning is reduced, the cleaning effect is guaranteed. The cleaning addition agent is non-toxic and harmless, in the rinsing process through the clean water, the cleaning addition agent can be rapidly removed, and the remaining rate of the cleaning addition agent on the beef is lower than 0.01%, so that the eating safety of the beef is guaranteed.

Owner:安徽芈八子食品科技有限公司

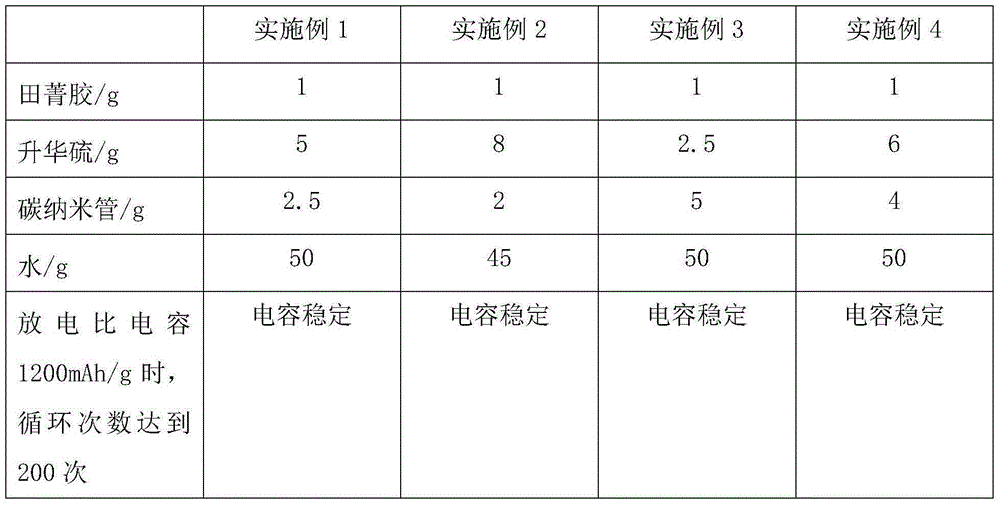

Modified sulfur positive electrode nanometer paste of lithium sulfur battery, preparation method of modified sulfur positive electrode nanometer paste, and preparation method for modified sulfur positive electrode plate of lithium sulfur battery

The invention discloses a modified sulfur positive electrode nanometer paste of a lithium sulfur battery. The modified sulfur positive electrode nanometer paste comprises the following constituents based on weight: 1 part of sesbania gum, 45-52 parts of water, 2.5-8 parts of elemental sulfur and 2-5 parts of carbon nanotube. In the modified sulfur positive electrode nanometer paste, the safe and green sesbania gum is taken as a binding agent for a positive electrode material of a lithium sulfur secondary battery, thus, the electrochemical performance of the electrode material is improved, moreover, no pollution is generated to an environment, and no harm is brought to a human body. Through tests, the cycle index reaches over 200 times when the lithium sulfur battery prepared from the positive electrode material is at high discharging specific capacitance (1,200mAh / g), and the capacity still can be maintained stability.

Owner:QINGDAO NENGXUN NEW ENERGY TECH CO LTD +1

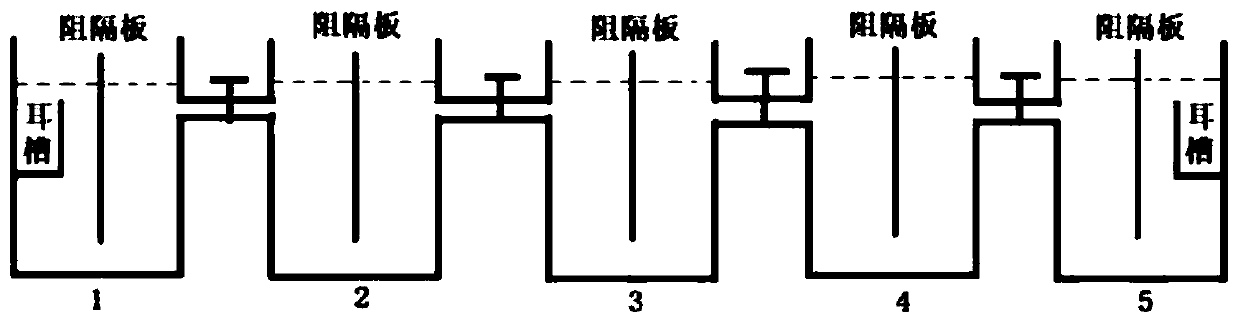

Biomimetic preparation method of strontium carbonate crystal

InactiveCN108675335AUse low concentrationCompact structureStrontium carbonatesNanotechnologyStrontium carbonateStrontium chloride hexahydrate

The invention discloses a biomimetic preparation method of a strontium carbonate crystal, wherein a coronary strontium carbonate nano crystal is prepared by a biomimetic method in a specific communication device by adopting strontium chloride hexahydrate and ammonium bicarbonate as reactants and sesbania gum as a biological regulation agent. According to the target product coronary strontium carbonate nano crystal, the corolla diameter is 3,000-6,000nm; the corolla is composed of nano rods with diameter being 50-80nm; the corolla structure is tight, with purity being greater than or equal to 99% and yield being 97-99%. The method disclosed by the invention has the characteristics of mild conditions, low energy consumption, large corolla diameter, tight corolla structure, high purity, highyield, low preparation cost, etc.

Owner:NANCHANG HANGKONG UNIVERSITY

High-temperature-resistant gel plugging agent

ActiveCN105331340AImprove the blocking effectImprove salt toleranceDrilling compositionSalt resistancePolymer science

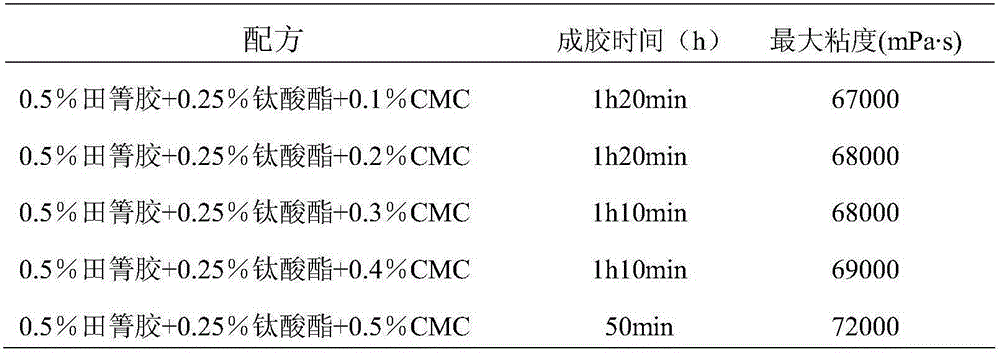

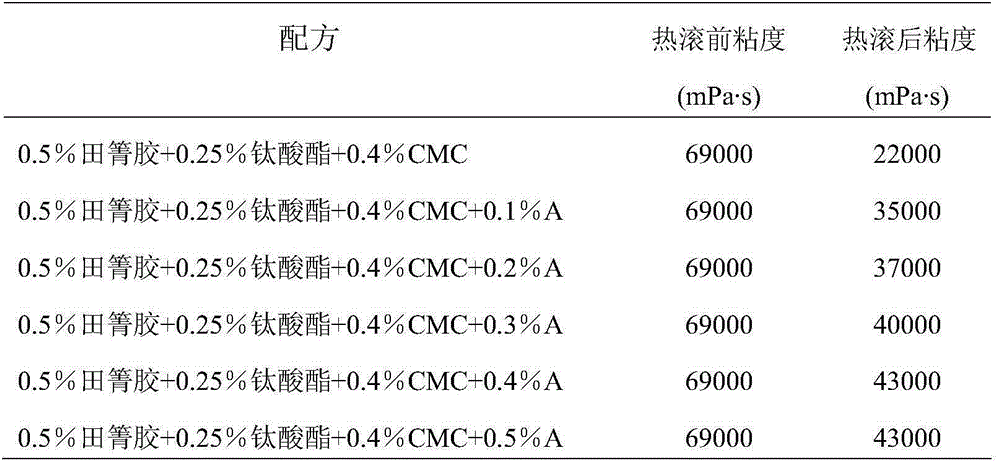

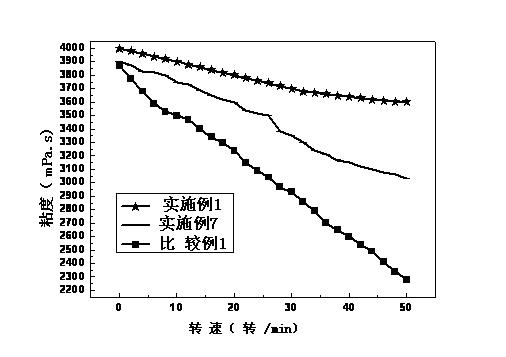

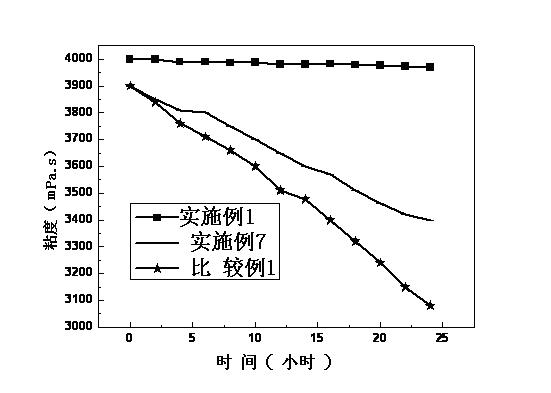

The invention relates to a high-temperature-resistant gel plugging agent. The high-temperature-resistant gel plugging agent is characterized by being prepared from sesbania gum, titanate, carboxymethylcellulose, polyacrylamide, solid-phase particles and distilled water in parts by weight. The high-temperature-resistant gel plugging agent can resist the high temperature of 120 DEG C and has the good salt resistance. The plugging agent is not limited by the size and the shape of a leakage path and can enter the leakage path through compressional deformation, the utilization rate of the plugging agent is increased, and the waterproof performance is good. Besides, common gel plugging agents are limited for high-temperature stratums and stratums with the higher mineralization degree, and the temperature resistance and the salt resistance of the newly developed gel plugging agent are tried to be improved.

Owner:DAQING BEIHUA CHEM PLANT

Lithium ion battery and electrode material, electrode paste and electrodes of lithium ion battery

ActiveCN102082273AImprove uniformityHigh strengthSecondary cellsNon-aqueous electrolyte accumulator electrodesSesbania gumLithium-ion battery

The invention discloses an electrode material of a lithium ion battery, comprises an electrode active material and a binder, wherein the binder comprises sesbania gum phosphate, carboxymethyl sesbania gum, ethoxyl-sesbania gum or oxidation sesbania gum. The invention also discloses an electrode paste of the lithium ion battery, comprising the electrode material of the lithium ion battery and a solvent, wherein the electrode material of the lithium ion battery is the electrode material of the lithium ion battery. The invention also discloses electrodes of the lithium ion battery, which are prepared by coating the electrode paste of the lithium ion battery on the polar electrics of the electrode, and drying and rolling. The invention discloses the lithium ion battery, comprising a battery shell, an electrode assembly and electrolyte, wherein the electrode assembly and the electrolyte are sealed in the battery shell; the electrode assembly comprises a positive pole, a negative pole and a membrane between the positive pole and the negative pole; and the positive pole and / or the negative pole are the electrodes of the lithium ion battery. According to the invention, the capacity, the rate discharge performance and the cycle performance of the battery are improved.

Owner:SHANGHAI PYLON TECH CO LTD

Sealant for interior decoration

InactiveCN104231972AEnsure that the living environment is environmentally friendlyHealth hazardNon-macromolecular adhesive additivesOther chemical processesSesbania gumPolyphenol

The invention discloses a sealant for interior decoration. The sealant comprises the following constituents in parts by weight: 10 to 18 parts of plant starch, 5 to 11 parts of casein-soybean glue, 6 to 13 parts of konjac glucomannan, 8 to 15 parts of jellyfish collagen, 5 to 10 parts of persimmon leaf polyphenol extractive, 3 to 7 parts of sesbania gum, 6 to 13 parts of coffee senna extractive, and 1 to 3 parts of a dispersant. By adopting the mode, the sealant does not volatilize harmful organics, can guarantee that the living environment of people is protected, and cannot bring any harm to health of people.

Owner:WUXI HITXINCHENG POLYMER TECH

Film-forming auxiliary agent prepared by utilizing organosilicon polymer and used for construction metal formwork release agent

InactiveCN106520281AImprove film formationShorten curing film forming timeLubricant compositionPolyvinyl alcoholLanolin

The invention discloses a film-forming auxiliary agent prepared by utilizing an organosilicon polymer and used for a construction metal formwork release agent, and relates to the technical field of release agents. The film-forming auxiliary agent is prepared from the following raw materials in parts by weight: 15 to 20 parts of the organosilicon polymer, 6 to 11 parts of hydrogenated rosin glycerin ester, 5 to 9 parts of chlorinated polyethylene, 4 to 8 parts of a silicone emulsion, 4 to 8 parts of polyvinyl butyral, 3 to 6 parts of turpentine oil, 3 to 6 parts of sesbania gum, 3 to 6 parts of pregelatinized starch, 2 to 4 parts of rice bran wax, 2 to 4 parts of tea seed powder, 1 to 2 parts of sulfated castor oil, 1 to 2 parts of lanolin, 0.5 to 1 part of disodium hydrogen phosphate and 25 to 35 parts of isopropanol. The film-forming auxiliary agent provided by the invention can significantly improve the film-forming properties of a release agent, can effectively shorten the curing and film-forming time of the release agent, can reinforce the adhesion force of a formed film layer, avoids the occurrence of phenomena of air pores and pulverization of the film layer in the process of use, thereby facilitating to improving release effect.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

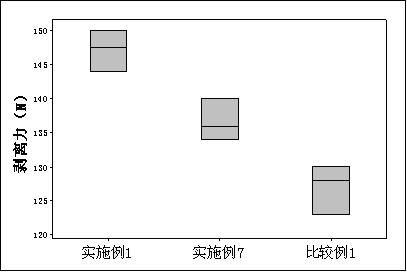

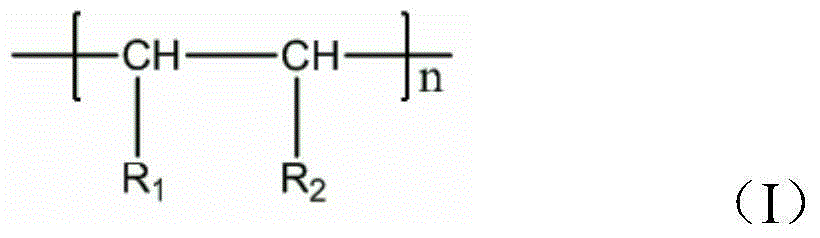

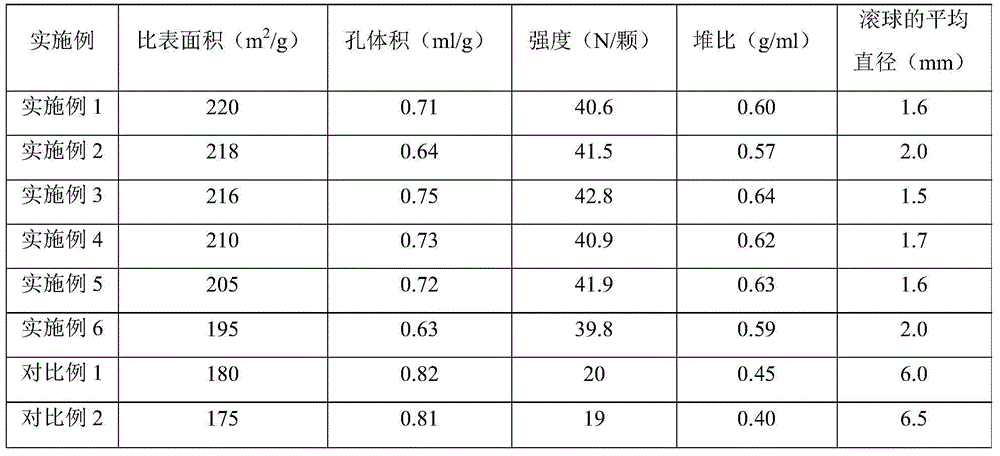

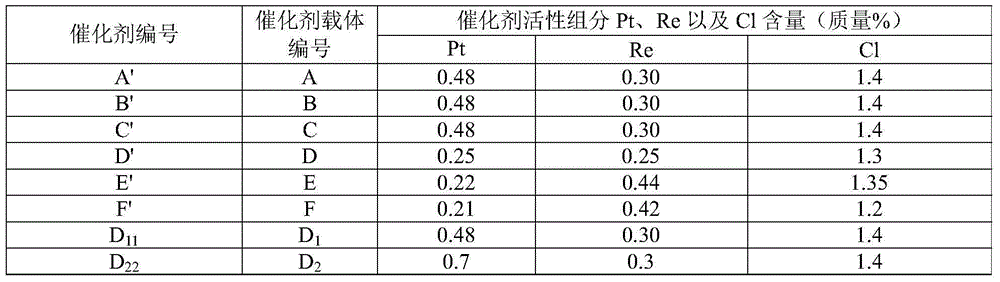

Alumina carrier and ball-rolling molding method and application thereof

ActiveCN105618156ASimple processHigh strengthCatalyst carriersCatalytic crackingCellulosePtru catalyst

The invention discloses an alumina carrier and ball-rolling molding method and an application thereof. The method comprises the following steps: 1) an alcohol polymer and sesbania gum are contacted in an aqueous solvent to obtain a spray glue, wherein a number-average molecular weight of the alcohol polymer is 1500-2000; an acid source and methyl cellulose are contacted in the aqueous solvent to obtain a kneading glue; 2) an alumina source and the kneading glue are homogenized to obtain the homogenized powder; 3) the partially homogenized powder is subjected to first ball-rolling molding to prepare a female ball, the residual homogenized powder is added for second ball-rolling molding to mold the female ball and grow up the female ball. The method has the advantages of simple process, no pollution, no massive industrial dust generation, strong operation controllability, and strong repeatability; a prepared catalyst or a carrier has the advantages of high intensity, flexible ratio regulation and control, good wear resistance, ideal wearing index, concentrated and uniform particle size, and smooth surface; and the method is suitable for producing small microspheres with sizes of 0.5 millimeters, 1.0 millimeter, 1.5 millimeters and 2.0 millimeters.

Owner:BEIJING ENERGY ENG TECH

Primary precipitator for waste water treatment of livestock breeding

InactiveCN106396054AReduce the difficulty of follow-up processingReduce processing costsOther chemical processesWater/sewage treatment by flocculation/precipitationCelluloseDry bean

The invention discloses a primary precipitator for waste water treatment of livestock breeding, and relates to the technical field of breeding waste water treatment. The primary precipitator is prepared from, by weight, 25-30 parts of wheat straw dry powder, 10-15 parts of lignocellulose, 4-8 parts of pregelatinized starch, 4-8 parts of acrylic acid macroreticular resin, 3-6 parts of dry bean dregs, 3-6 parts of ceramic micro powder, 2-4 parts of polyoxyethylene, 2-4 parts of sesbania gum, 2-4 parts of water-soluble chitosan, 1-2 parts of polyving akohol resin, 1-2 parts of poly dimethyl diallyl ammonium chloride, and 0.5-1 part of asbestos wool. Through the absorption and flocculation, the precipitator can effectively precipitate fine grains in the waste water, ammonia nitrogen, and organic phosphorus matters, and fully play the primary treatment effect, greatly lighten the subsequent treatment difficulty of waste water, and reduce the waste water treatment cost.

Owner:MAANSHAN JINNONG ANIMAL HUSBANDRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com