Iron ore powder pellet adhesive and application thereof

A technology of binder and powder pellets, which is applied in the field of mineral processing, can solve problems such as the difficulty of large-scale industrial supply of chrysanthemum root, low cohesive force, and reduced output, and achieve good ball-making indicators, increased cohesive force, and reduced dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

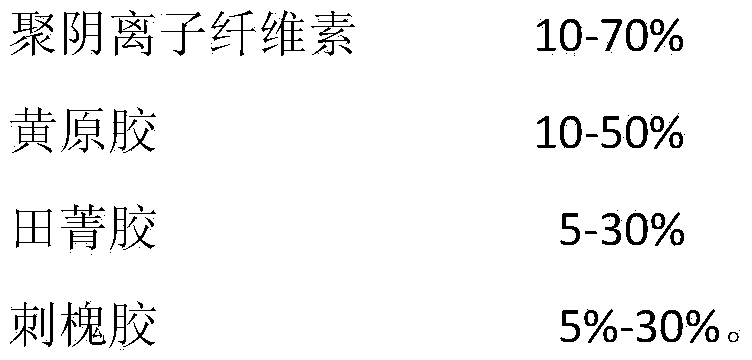

[0018] When preparing pellets, first prepare a mixture, the chemical composition and weight percentage of the mixture are: iron ore powder pellet binder 0.9-1.1%; sodium carbonate 3.5%; bentonite 95.5%, and then add iron ore powder For a mixture of 0.8-1.2% by weight, the composition of the binder and the wet bulb index of the pellets are shown in Table 1:

[0019] Table 1 Iron ore powder pellet binder composition and pellet wet bulb index

[0020]

[0021] Note: In Table 1, PAC is polyanionic cellulose, yellow is xanthan gum, field is squash gum, and thorn is locust gum.

[0022] The wet balls produced above were dried and roasted at high temperature. During the furnace temperature process, the temperature was controlled at 900°C for 20 minutes, the temperature was controlled at 1250°C for 20 minutes, and the temperature was controlled at 800°C for 20 minutes.

[0023] Table 2 The metallurgical index of pelletizing

[0024] Into a ball

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com