Waterborne polyurethane slurry for producing synthetic leather bass through wet method

A technology of polyurethane slurry and water-based polyurethane, which is applied in the field of synthetic leather processing, can solve problems such as poor water solubility, and achieve the effects of short curing time, expanding the scope of use, and similar texture and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 5 parts of chlorinated polyethylene, 2 parts of C5 petroleum resin and 1 part of dipentaerythritol to 5 parts of hydrogenated rosin glycerides, heat to 120-125 ° C and mix for 30 minutes, then cool down naturally, until the temperature drops to After 30-35°C, heat again to 120-125°C and mix for 15 minutes to obtain material I;

[0024] (2) Add 3 parts of terpene resin, 2 parts of hydrogenated palm oil and 1 part of squash gum to 4 parts of polyvinyl alcohol resin, heat to 115-120 ° C and mix for 30 minutes, then add 0.5 parts of molecular sieve powder and 0.5 Part nanometer titanium dioxide, continue heat preservation and mix 10min, obtain material II;

[0025] (3) Add 4 parts of microcrystalline cellulose, 3 parts of activated clay and 0.5 part of tea seed powder to 200 parts of water, heat to reflux state and mix for 10 minutes, then add material I and material II, continue to reflux and mix for 15 minutes, then add 65 parts of water-based polyurethane resin ...

Embodiment 2

[0030] (1) Add 4 parts of chlorinated polyethylene, 2 parts of C5 petroleum resin and 1 part of dipentaerythritol to 7 parts of hydrogenated rosin glycerides, heat to 120-125 °C and mix for 30 minutes, then cool down naturally until the temperature drops to After 30-35°C, heat again to 120-125°C and mix for 15 minutes to obtain material I;

[0031] (2) Add 3 parts of terpene resin, 2 parts of hydrogenated palm oil and 1 part of squash gum to 5 parts of polyvinyl alcohol resin, heat to 115-120 ° C and mix for 30 minutes, then add 0.5 parts of molecular sieve powder and 1 Part nanometer titanium dioxide, continue heat preservation and mix 10min, obtain material II;

[0032](3) Add 5 parts of microcrystalline cellulose, 2 parts of activated clay and 1 part of tea seed powder to 200 parts of water, heat to reflux state and mix for 10 minutes, then add material I and material II, continue to reflux and mix for 15 minutes, then add 70 parts of water-based polyurethane resin and 8 p...

Embodiment 3

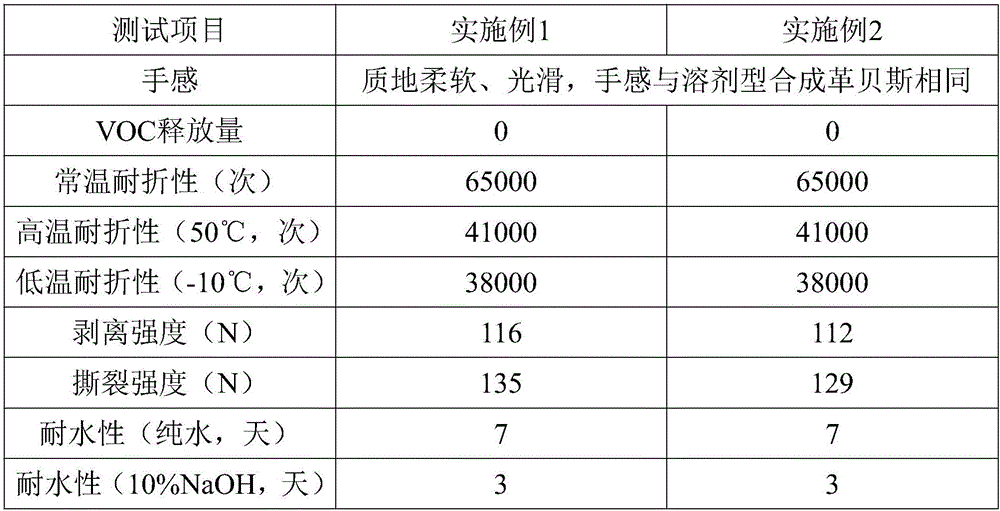

[0037] The water-based polyurethane slurry prepared in Example 1 and Example 2 was used to prepare a synthetic leather base by wet method, and the performance test of the prepared synthetic leather base was performed, and the results are shown in Table 1.

[0038] The performance test result of the made synthetic leather bass in table 1

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com