High-temperature-resistant gel plugging agent

A technology of high temperature-resistant gel and loss-stopping agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of low pumping efficiency, limitation, dilution and flushing away, etc., and achieves good plugging effect. , improve the utilization rate, the effect of good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0033] The plugging agent is prepared from Tianqing glue, titanate, carboxymethyl cellulose, polyacrylamide, peanut shells and distilled water in parts by weight, Tianqing glue: titanate: carboxymethyl cellulose: polypropylene Amide: peanut shell: distilled water = 0.3:0.1:0.2:0.2:3:90.

Embodiment 3

[0035] The plugging agent is prepared from Tianqing glue, titanate, carboxymethyl cellulose, polyacrylamide, walnut shell and distilled water in parts by weight, Tianqing glue: titanate: carboxymethyl cellulose: polypropylene Amide: walnut shell: distilled water = 0.8:0.4:0.6:0.6:8:96.

Embodiment 4

[0037] The plugging agent is prepared from Tianqing gum, titanate, carboxymethyl cellulose, polyacrylamide, peanut shells, walnut shells and distilled water in parts by weight, Tianqing gum: titanate: carboxymethyl cellulose : Polyacrylamide: Peanut shell: Walnut shell: Distilled water = 0.3: 0.4: 0.6: 0.2: 1: 2: 90.

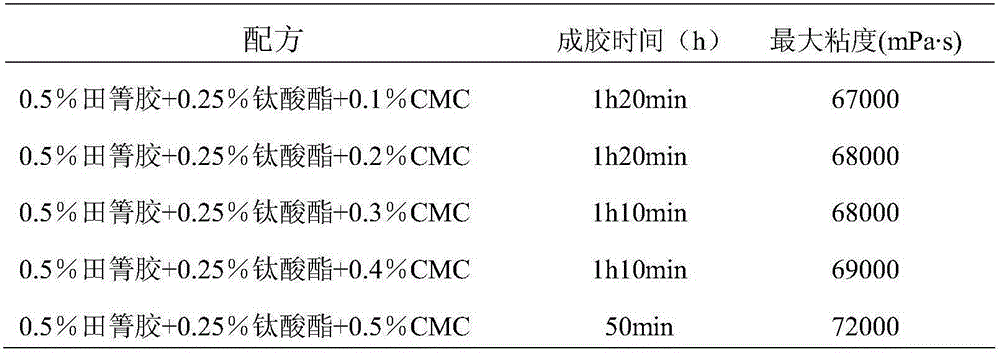

[0038] Table 1 The gelation time and viscosity of the polymer of Tianqing gum and titanate with different amounts of CMC at 25°C

[0039]

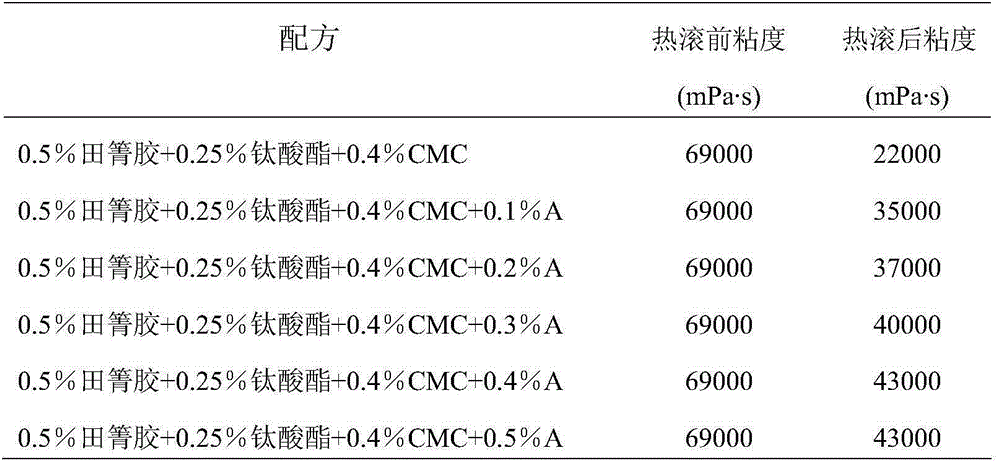

[0040] Table 2 Comparison of the viscosity of the gel after hot rolling at 120°C for 16 hours and before hot rolling

[0041]

[0042] Table 3 The gelation time and viscosity of the gel system at different pH values

[0043]

[0044] Table 4 Gel forming time of gel system at 40°C, 60°C, 80°C, 100°C, 120°C, 140°C

[0045]

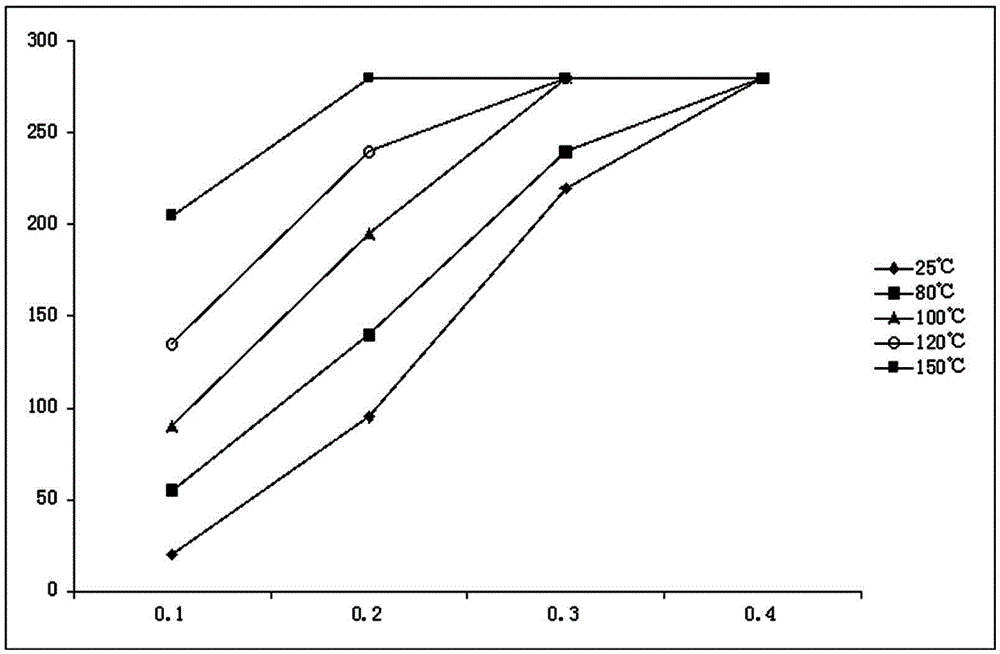

[0046] Table 5 Leakage of the gel system at 0.1MPa, 0.2MPa, 0.3MPa, 0.4MPa pressure at 25°C

[0047]

[0048] Table 6: Leakage of the gel system at 0.1MPa, 0.2MPa, 0.3MPa, 0.4MPa pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com