Biomimetic preparation method of strontium carbonate crystal

The technology of strontium carbonate and crystal is applied in the field of preparing corolla nano strontium carbonate crystals by a bionic method, which can solve the problems of loose corolla structure, small corolla diameter and high preparation cost, and achieve the effects of tight corolla structure, low preparation cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

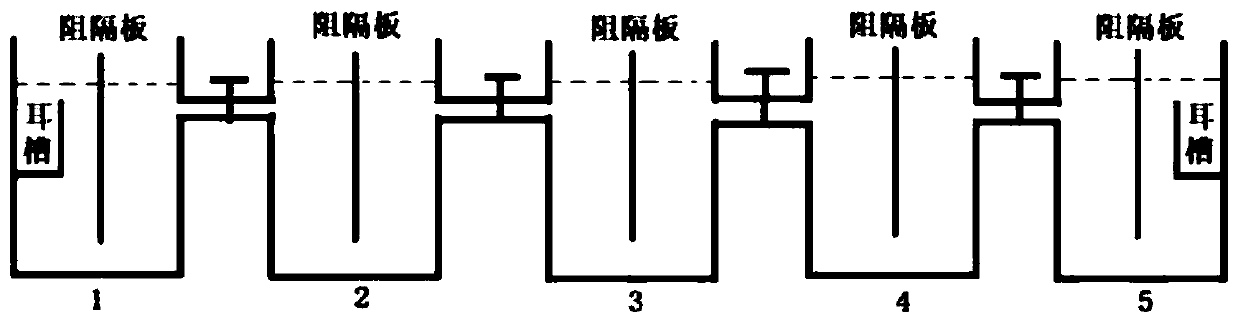

[0014] The preparation device is a communication device composed of 5 reactors with an effective reaction volume of 200L, which are named Reactor No. 1, Reactor No. 2, Reactor No. 3, Reactor No. 4 and Reactor No. 5 in order of connection. Each reactor has a communication port, and the vertical distance between the upper edge of the communication port and the upper edge of the reactor is 15cm. The reactors are connected by connecting pipes, which can be disassembled; switches are installed on the connecting pipes. A barrier plate is installed in the middle of each reactor to control and change the direction of movement of reactant molecules. The upper edge of the group partition is 5 cm higher than the upper edge of the communication port; a space of 10 cm is left between the lower edge of the group partition and the bottom of the reactor to ensure that the solutions in the five reactions are connected. An ear groove is respectively installed on the opposite side of the connec...

Embodiment 2

[0017] The preparation device is a communication device composed of 5 reactors with an effective reaction volume of 200L, which are named Reactor No. 1, Reactor No. 2, Reactor No. 3, Reactor No. 4 and Reactor No. 5 in order of connection. Each reactor has a communication port, and the vertical distance between the upper edge of the communication port and the upper edge of the reactor is 15cm. The reactors are connected by connecting pipes, which can be disassembled; switches are installed on the connecting pipes. A barrier plate is installed in the middle of each reactor to control and change the direction of movement of reactant molecules. The upper edge of the group partition is 5 cm higher than the upper edge of the communication port; a space of 10 cm is left between the lower edge of the group partition and the bottom of the reactor to ensure that the solutions in the five reactions are connected. An ear groove is respectively installed on the opposite side of the connec...

Embodiment 3

[0020] The preparation device is a communication device composed of 5 reactors with an effective reaction volume of 200L, which are named Reactor No. 1, Reactor No. 2, Reactor No. 3, Reactor No. 4 and Reactor No. 5 in order of connection. Each reactor has a communication port, and the vertical distance between the upper edge of the communication port and the upper edge of the reactor is 15cm. The reactors are connected by connecting pipes, which can be disassembled; switches are installed on the connecting pipes. A barrier plate is installed in the middle of each reactor to control and change the direction of movement of reactant molecules. The upper edge of the group partition is 5 cm higher than the upper edge of the communication port; a space of 10 cm is left between the lower edge of the group partition and the bottom of the reactor to ensure that the solutions in the five reactions are connected. An ear groove is respectively installed on the opposite side of the connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com