Dust depressor for railway coal transport and use method of dust depressor

A dust suppressant and coal technology, applied in dust prevention, earth square drilling, safety devices, etc., can solve the problem of clogging the pipe nozzles of spraying equipment, failure to prevent wind erosion and dust suppression, thin crust of dust suppressant, etc. problems, to achieve the effect of preventing dust pollution, protecting the environment, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

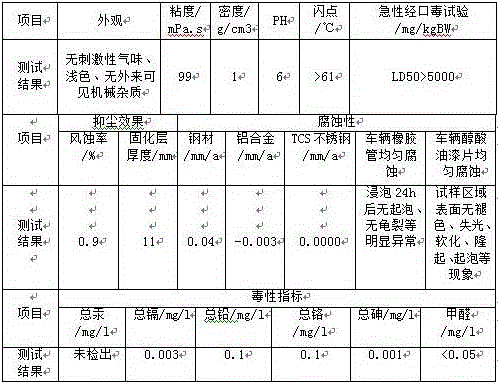

Image

Examples

Embodiment 1

[0029] The dust suppressant for railway coal transportation is composed of the following components by weight: 15 parts of xanthan gum, 20 parts of carboxymethyl cellulose, 10 parts of modified starch and 25 parts of squash gum powder.

[0030] Its preparation method comprises the following steps:

[0031] (1) Put the above-mentioned various raw materials into the ribbon mixer according to the weight part and heat up while stirring. Stop heating when the temperature rises to 75°C, and then cool down after stirring at constant temperature for 3 hours. The finished dust agent, the ribbon mixer model is 424-215, purchased from Sino-US joint venture Nantong Ross Mixing Equipment Co., Ltd.;

[0032] (2) Pack the finished dust suppressant obtained in the step, 25Kg per bag.

[0033] Its method of use includes the following steps:

[0034] (1) Evenly sieve the obtained dust suppressant finished product into a water-powder mixer filled with 1Kg of water according to the dosage of 10...

Embodiment 2

[0037] The dust suppressant for railway coal transportation is composed of the following components in parts by weight: 20 parts of xanthan gum, 30 parts of carboxymethyl cellulose, 20 parts of modified starch and 30 parts of squash gum powder.

[0038] Its preparation method comprises the following steps:

[0039] (1) Put the above-mentioned various raw materials into the ribbon mixer according to the weight part and heat up while stirring. Stop heating when the temperature rises to 75°C, and then cool down after stirring at constant temperature for 3 hours. Finished dust agent, the model of the ribbon mixer is 424-215;

[0040] (2) Pack the finished dust suppressant obtained in the step, 25Kg per bag.

[0041] Its method of use includes the following steps:

[0042] (1) Evenly sieve the obtained finished dust suppressant into a water-powder mixer filled with 1.5Kg of water according to the amount of 15g per square meter to prepare a dust suppressant solution. The model of ...

Embodiment 3

[0052] The dust suppressant for railway coal transportation is composed of the following components by weight: 25 parts of xanthan gum, 38 parts of carboxymethyl cellulose, 28 parts of modified starch and 40 parts of squash gum powder.

[0053] Its preparation method comprises the following steps:

[0054] (1) Put the above-mentioned various raw materials into the ribbon mixer according to the weight part and heat up while stirring. Stop heating when the temperature rises to 75°C, and then cool down after stirring at constant temperature for 4 hours. Finished dust agent, the model of the ribbon mixer is 424-215;

[0055] (2) Pack the finished dust suppressant obtained in the step, 25Kg per bag.

[0056] Its method of use includes the following steps:

[0057] (1) Evenly sieve the obtained finished dust suppressant into a water-powder mixer filled with 3.5Kg of water according to the amount of 20g per square meter to prepare a dust suppressant solution. The model of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com