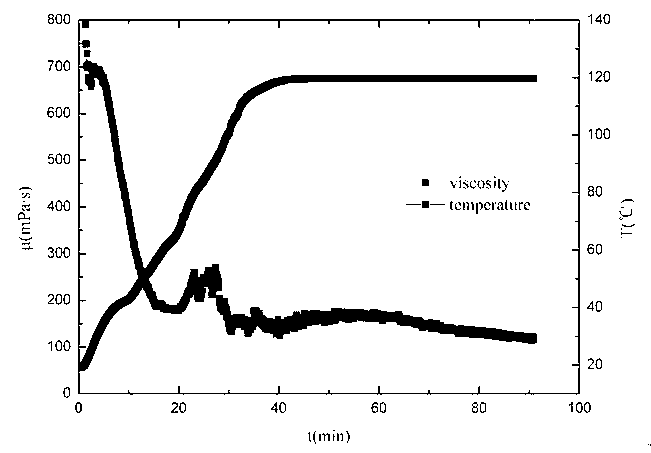

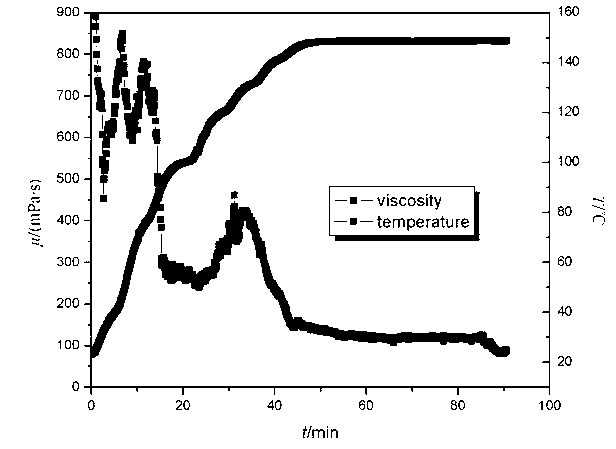

Seawater-based fracturing fluid for fracturing sea high-temperature oil-gas reservoir

A technology for oil and gas reservoirs and seawater, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor high temperature resistance, and the inability to directly mix fracturing fluid for continuous construction, and achieve good gel breaking performance, enhanced Sand-carrying performance and effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] As a preferred embodiment of the present invention, the present invention includes:

[0038] Base fluid: based on the mass of the prepared seawater-based fracturing fluid solution, of which: thickener accounts for 0.3%, pH regulator accounts for 0.1%, drainage aid accounts for 0.1%, and the balance is seawater;

[0039] Cross-linking agent: based on the mass fraction of the cross-linking agent relative to the base liquid, the cross-linking agent accounts for 0.4;

[0040] The thickener refers to: guar gum, carboxymethyl hydroxypropyl guar gum, hydroxypropyl guar gum, coumarin or kale gum.

[0041] According to the above formula, using the conventional mixing method using seawater as a solvent in this field, add the thickener to the seawater, stir for 5 minutes, then add the pH regulator, drainage aid, and then add the cross-linking agent to form a fracturing fluid .

Embodiment 2

[0043] As another preferred embodiment of the present invention, the present invention includes:

[0044] Base fluid: based on the mass of the prepared seawater-based fracturing fluid solution, of which: thickener accounts for 0.8%, pH regulator accounts for 0.3%, drainage aid accounts for 0.5%, and the balance is seawater;

[0045] Cross-linking agent: based on the mass fraction of the cross-linking agent relative to the base liquid, the cross-linking agent accounts for 0.6%;

[0046] All the other are with embodiment 1.

Embodiment 3

[0048] As the best implementation mode of the present invention, the present invention includes:

[0049] Base fluid: based on the mass of the prepared seawater-based fracturing fluid solution, including: 0.5% thickener, 1% oxygen scavenger, 0.4% temperature-resistant enhancer, 0.2% pH regulator, 0.2% bactericide, 0.3% clay stabilizer, 0.3% drainage aid, 0.3% foaming agent (or demulsifier), and the rest of seawater;

[0050] The thickener refers to: guar gum, carboxymethyl hydroxypropyl guar gum, hydroxypropyl guar gum, coumarin or kale gum.

[0051] Cross-linking agent: based on the mass fraction of the cross-linking agent relative to the base liquid, the cross-linking agent accounts for 0.4-0.6%;

[0052] Gel breaker: Based on the mass fraction of the gel breaker relative to the base fluid, the gel breaker accounts for 0.04-0.06%.

[0053] The temperature-resistant enhancer is hydrazine, thiourea, sulfite, etc., which can improve the flexibility of the molecular chain of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com