Alumina carrier and ball-rolling molding method and application thereof

A technology of alumina carrier and molding method, which is applied in the direction of catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc. Large diameter and other problems, to achieve the effect of smooth and smooth surface, strong operation controllability, and concentrated particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] According to another preferred embodiment of the present invention, the method may also include: before step (3), the homogenized powder described in step (2) is ultra-fine to obtain a particle size of Powder below 0.074mm.

[0032] According to the present invention, the ultrafine refers to pulverizing powder or granules to a particle size of less than 0.074mm. There is no special limitation on the ultrafine device, as long as the powder or granule can be pulverized to a particle size of less than 0.074mm. For example, what adopted in the embodiment of the present invention is the high-speed pulverizer of Tester 24000r / min.

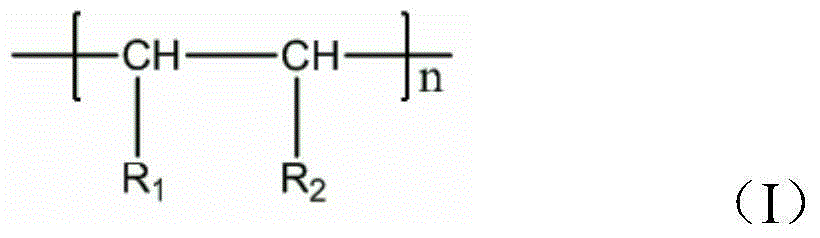

[0033] According to the present invention, the spray glue is obtained by contacting the alcohol polymer to the squash gum with a weight ratio of preferably 1-3:1 in an aqueous solvent. Wherein, the solid content of the squash gum in the aqueous solvent is preferably 2-8% by weight.

[0034] According to the present invention, in order to make t...

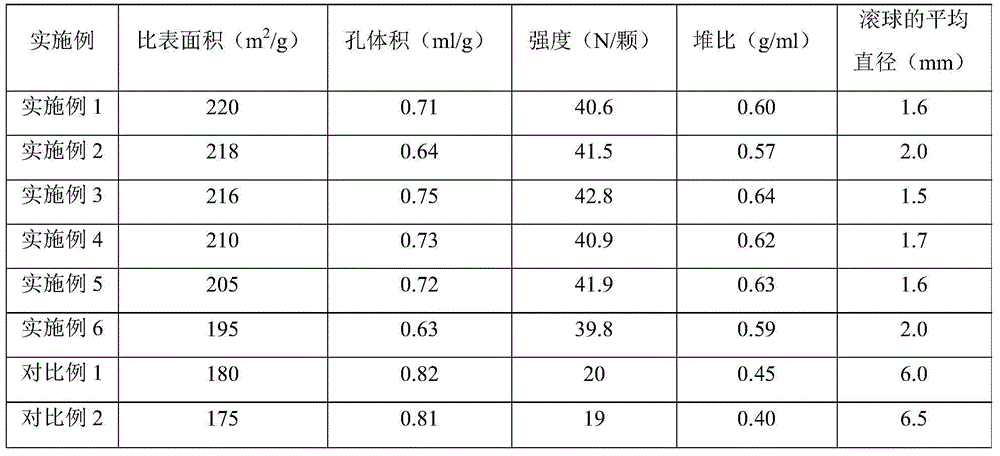

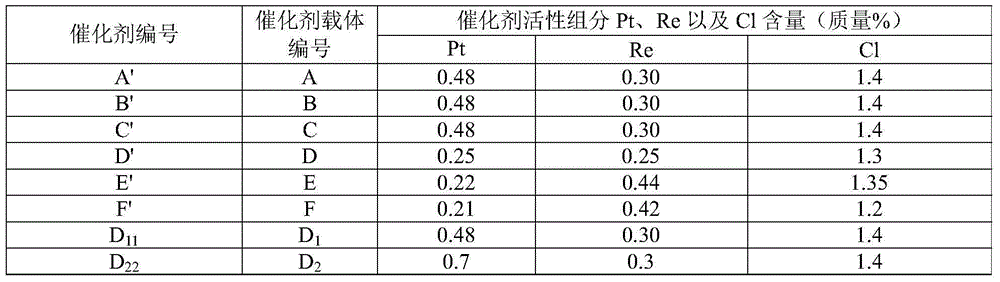

Embodiment 1

[0063] 40g polyvinyl alcohol (the number-average molecular weight is 2000) and 20g kale powder are pulverized on a pulverizer to obtain a powder below 0.074mm, and the powder is dropped into 1000ml of ionized water, and the powder is mixed at a temperature of 60°C. The material was stirred into a colloid, and left to stand for 12 hours to obtain a spray glue.

[0064] 40g citric acid, 30g acetic acid (concentration is 100%) and 20g nitric acid (concentration is 100%) are mixed, obtain the mixed acid of 90g; 10g methylcellulose is dropped into the deionized water of 1000ml, stir 3 hours at 25 ℃, After standing still for 12 hours, 260 g was added to the aforementioned mixed acid to obtain a kneaded gel.

[0065] Put 1000g of SB aluminum hydroxide into the kneader at a speed of 25r / min, pour 350g of kneading glue into the kneader twice, and knead for 0.5 hours to obtain a homogenized powder, and put the homogenized powder into Pulverize in the pulverizer, and then screen out the...

Embodiment 2

[0067] Rolling ball molding was carried out according to the method of Example 1 to obtain a spherical alumina carrier B. The properties of the carrier are shown in Table 1. The difference is: SB aluminum hydroxide is replaced by macroporous aluminum hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com