Preparation method and application of carbon-phosphorus-boron ternary co-doped copper/nickel-based catalyst

A nickel-based catalyst and co-doping technology, applied in the direction of catalyst activation/preparation, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as difficult to have a large improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

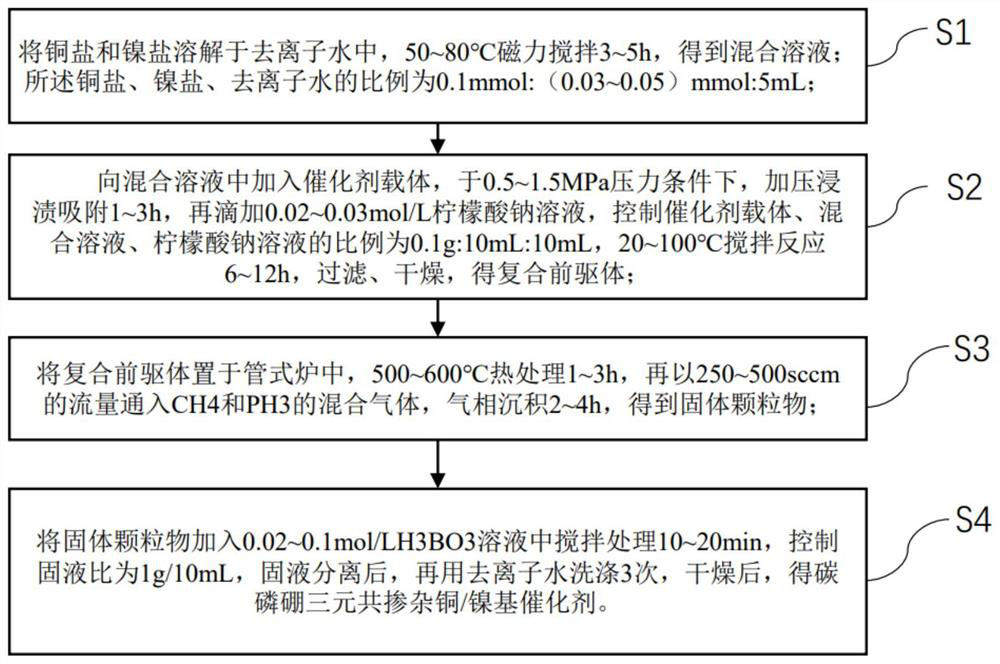

[0022] The present invention provides a method of preparing an embodiment of a carbohydrate terpolyces a copper / nickel-based catalyst, and is further applied to catalytic hydrogenation reactions, the hydrogenation reaction specifically: CO 2 Hydrogenation synthesis CH 3 OH, HCHO hydrogenation synthesis CH 3 OH, CH 3 CHO hydrogenation synthesis CH 3 CH 2 OH, including the following steps:

[0023] S1: The copper salt and nickel salt were dissolved in deionized water, and the magnetism of 50 to 80 ° C was stirred for 3 to 5 hours to obtain a mixed solution; the ratio of the copper salt, nickel salt, and deionized water was 0.1 mmol: (0.03 ~ 0.05) Mmol: 5ml; the copper salt is sodium tetracetate with ethylenediamine; the nickel salt is one or more of nickel nickel nitrate, nickel sulfate, nickel chloride;

[0024] S2: Add a catalyst vector to a mixed solution, the catalyst carrier, ZSM-5 molecular sieve, which is 100 ~ 400 nm of 0.5 ~ 1.5 MPa, pressure impregnation adsorption 1 to ...

Embodiment 1

[0028] Method for preparing carbonophosphate ternate co-doped copper / nickel based catalyst, including the following steps:

[0029] S1: 1 mmol ethylenediamine tetraceralate and 0.3 mmol nickel nickel were dissolved in 50 ml of deionized water, and 50 ° C magnetic force was stirred for 3 h, resulting in a mixed solution;

[0030] S2: 0.5 g of a zsm-5 molecular sieve of 0.5 g of a particle diameter of 100 nm, under 0.5 MPa pressure conditions, pressurized impregnation adsorption for 1 h, and then add 50 ml of 0.02 mol / L citrate solution, stirred at 20 ° C Reaction 6h, filtration, drying, composite precursor;

[0031] S3: Place the composite precursor in the tube furnace, heat treatment at 500 ° C for 3 h, and then pass through the flow rate of 250 SCCM. 4 PH 3 Mixant, CH 4 , PH 3The volume ratio is 1: 0.5, and the gas phase deposits 2 h to obtain a solid particulate matter;

[0032] S4: Add 0.5 g of solid particles to 0.02 mol / lh 3 BO 3 The mixture was stirred in the solution ...

Embodiment 2

[0034] Method for preparing carbonophosphate ternate co-doped copper / nickel based catalyst, including the following steps:

[0035] S1: 1 mmol ethylenediamine tetracetate and 0.4 mol of nickel sulfate were dissolved in 50 ml of deionized water, and the magnetic force was stirred at 65 ° C for 4 h to give a mixed solution;

[0036] S2: An ZSM-5 molecular sieve of 0.5 g of a particle size of 250 nm was added to 50 ml of mixed solution. Under 1.0 MPa pressure conditions, pressurized impregnation adsorption 2H, and 50 ml of 0.025 mol / L citrate solution, 60 ° C agitation Reaction 10H, filtration, drying, composite precursor;

[0037] S3: Place the composite precursor in the tubular furnace, heat treatment at 550 ° C for 2 h, and then pass the flow rate of 400 sccm 4 PH 3 Mixant, CH 4 , PH 3 The volume ratio is 1: 0.6, the gas phase deposits 3 h, resulting in solid particulate matter;

[0038] S4: Add 0.5 g of solid particles to 0.06 mol / lh 3 BO 3 The mixture was stirred in the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com