Method for doping and transferring graphene

A transfer method and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of easy volatility, increased square resistance of graphene, weak interaction between small molecule dopants and graphene, etc., to simplify the production process, The effect of eliminating the doping step and improving the doping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

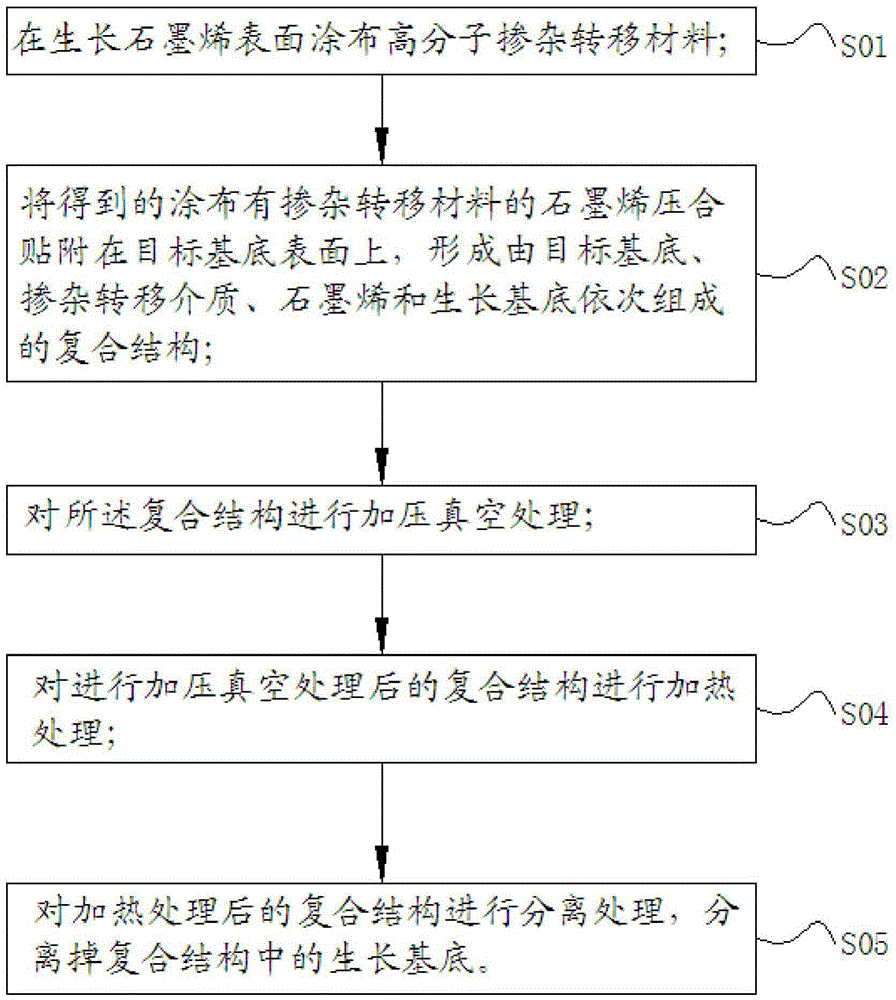

[0026] This embodiment includes the following steps:

[0027] Step 1, dissolving polyacrylonitrile (PAN) in dimethylformamide, and coating it on the surface of growing graphene 3 by roll coating;

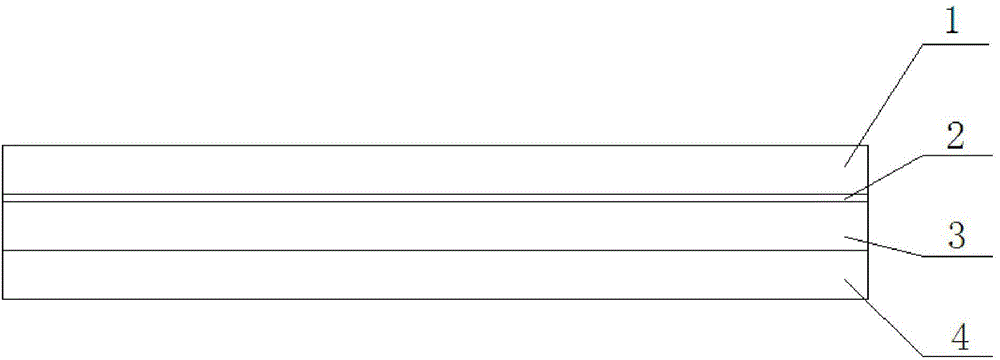

[0028] Step 2, pressing the graphene coated with polyacrylonitrile and the PET substrate to form a composite structure of PET / PAN / graphene / growth substrate;

[0029] Step 3, performing pressurized vacuum treatment on the composite structure, the pressure is 0.5MPa, the vacuum pressure is 0.1Pa, and the time for pressurized vacuum treatment is 5hr;

[0030] Step 4, heat-treating the composite structure after the pressurized vacuum treatment, the temperature of the heat treatment is 50° C., and the heat treatment time is 400 minutes;

[0031] Step 5, separating the heat-treated composite structure to separate the growth substrate 4 in the composite structure.

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] Step 1, ethanol dissolves nitrocellulose, and coats the surface of growing graphene 3;

[0035] Step 2, press and attach the obtained graphene 3 coated with nitrocellulose 2 on the surface of the target substrate PET1 to form a composite structure of PET / nitrocellulose / graphene / growth substrate;

[0036] Step 3, performing pressurized vacuum treatment on the composite structure, the pressure is 15MPa, the vacuum pressure is 200Pa, and the time for pressurized vacuum treatment is 0.5hr;

[0037] Step 4, heat-treating the composite structure after the pressurized vacuum treatment, the temperature of the heat treatment is 50° C., and the heat treatment time is 400 minutes;

[0038] Step 5, separating the heat-treated composite structure to separate the growth substrate 4 in the composite structure.

Embodiment 3

[0040] This embodiment includes the following steps:

[0041] Step 1, dissolving ethyl cyanoacrylate and methyl methacrylate copolymer in ethyl acetate, coating on the surface of growing graphene 3;

[0042] Step 2, the obtained graphene 3 coated with ethyl cyanoacrylate and methyl methacrylate copolymer 2 is pressed and attached on the surface of the target substrate PET1 to form PET / ethyl cyanoacrylate copolymer / graphite Composite structure of composite structure of ene / growth substrate;

[0043] Step 3, performing pressurized vacuum treatment on the composite structure, the pressure is 0.5MPa, the vacuum pressure is 200Pa, and the time for pressurized vacuum treatment is 3hr;

[0044] Step 4, heat-treating the composite structure after the pressurized vacuum treatment, the temperature of the heat treatment is 50° C., and the heat treatment time is 400 minutes;

[0045] Step 5, separating the heat-treated composite structure to separate the growth substrate 4 in the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com